Datakom DKG-175 User manual

DKG-175 User Manual V-1 (24.07.2017)

DKG-175 AUTOMATIC

TRANSFER SWITCH

(WITHOUT DC SUPPLY)

Datakom DKG-175 is a DIN Rail mounted ATS

controller not requiring DC supply. Thanks to this

feature, it is not required to carry the DC supply from

the battery to the transfer panels, providing ease of

installation.

The unit monitors 3-phase mains voltages, sends

remote start command to the generating set and

performs changeover of both generator and mains

contactors.

The front panel leds provide information about mains

and generator power availability as well as contactor

positions. Moreover, mains phase voltages and

frequency can be seen on front panel.

Mains voltage and frequency high and low limits,

mains waiting timer, mains fail timer, generator start

delay, cooldown timer and mains contactor timer are

front panel programmable. Generator contactor timer

is adjustable between 1 and 40 seconds through front

panel knob.

DIN Rail mounted

No DC supply required

Mains phase order check

Adjustable MCB and GCB delays

Programmable mains frequency and voltage high

and low limits

Programmable delay timers

10A/250VAC MCB and GCB outputs

10A/28VDC remote start output

Isolated mains and genset inputs

Test mode

FEATURES

DESCRIPTION

DKG-175 User Manual V-1 (24.07.2017)

- 2 -

Electrical equipment should be installed only by qualified specialist. No responsibility is

assured by the manufacturer or any of its subsidiaries for any consequences resulting from

the non-compliance to these instructions.

Check the unit for cracks and damages due to transportation. Do not install damaged

equipment.

Do not open the unit. There are no serviceable parts inside.

Fuses must be connected to the power supply and phase voltage inputs, in close proximity of

the unit.

Fuses must be of fast type with a maximum rating of 6A.

Disconnect all power before working on equipment.

When the unit is connected to the network do not touch terminals.

Any electrical parameter applied to the device must be in the range specified in the user

manual. Although the unit is designed with a wide safety margin, over-range parameters may

reduce lifetime, alter operational precision or even damage the unit.

Do not try to clean the device with solvent or the like. Only clean with a dump cloth.

Verify correct terminal connections before applying power.

SAFETY NOTICE

Failure to follow below instructions

will result in death or serious injury

DKG-175 User Manual V-1 (24.07.2017)

- 3 -

Section

1. INSTALLATION INSTRUCTIONS

1.1. Front Panel

1.2. Electrical Connections

2. LED INDICATORS

3. PUSHBUTTON FUNCTIONS

4. OPERATION OF THE UNIT

4.1. Test Mode

5. PROGRAMMING

6. DECLARATION OF CONFORMITY

7. TECHNICAL SPECIFICATIONS

8. CONNECTION DIAGRAM

TABLE OF CONTENTS

DKG-175 User Manual V-1 (24.07.2017)

- 4 -

Before installation:

Read the user manual carefully, determine the correct connection diagram.

Be sure that the temperature of the environment will not exceed the maximum operating temperature

in any case.

Below conditions may damage the device:

Incorrect connections.

Incorrect power supply voltage.

Voltage at measuring terminals beyond specified range.

Current at measuring terminals beyond specified range.

Overload or short circuit at relay outputs

Below conditions may cause abnormal operation:

Power supply voltage below minimum acceptable level.

Power supply frequency out of specified limits

1. INSTALLATION INSTRUCTIONS

DKG-175 User Manual V-1 (24.07.2017)

- 5 -

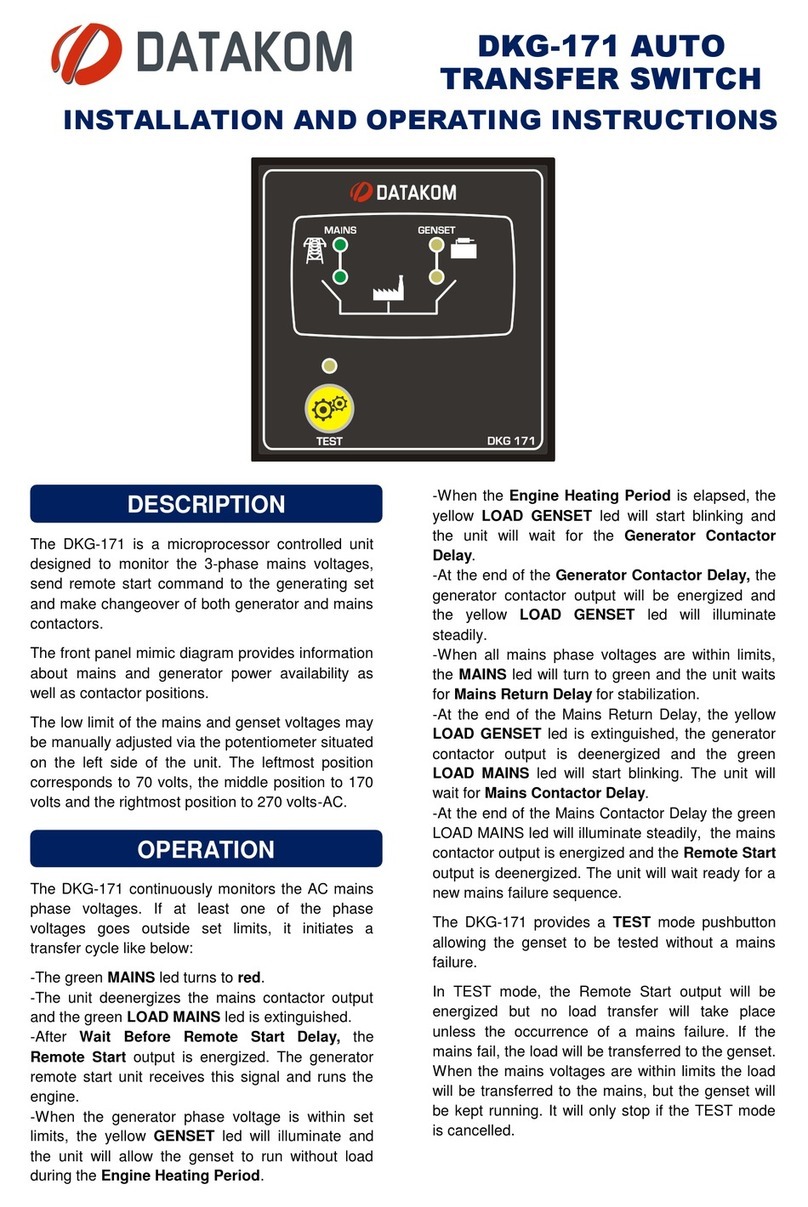

1.1 Front Panel

DKG-175 User Manual V-1 (24.07.2017)

- 6 -

Although the unit is protected against electromagnetic disturbance, excessive disturbance can affect the

operation, measurement precision and data communication quality.

ALWAYS remove plug connectors when inserting wires with a screwdriver.

Fuses must be connected to the power supply and phase voltage inputs, in close

proximity of the unit.

Fuses must be of fast type with a maximum rating of 6A.

Use cables of appropriate temperature range.

Use adequate cable section, at least 0.75mm2 (AWG18).

Follow national rules for electrical installation.

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switch mode power supplies and the like.

1.2 Electrical Connections

DKG-175 User Manual V-1 (24.07.2017)

- 7 -

Indicator

Colour

Description

G

Yellow

Generator voltage is within limits.

GC

Yellow

Generator contactor is energised.

RST

Green

Mains voltage and frequency is inside within limits.

Shows that mains waiting timer is counting if it is

blinking.

MC

Green

Mains contactor is energised.

ALARM

Red

Mains voltage or frequencyis outside the

programmed limits. Phase order is wrong if ALARM

led is blinking.

Operation Mode:

Displays name of the measured value.

Programming Mode:

Click menu button to display current value of the parameter. Click menu button to return

back programming menu after parameter is changed.

Operation Mode:

Navigate to next parameter.

Lamp test mode enable, when held pressed for 2 seconds.

Programming Mode:

Increase related value.

Operation Mode:

Navigate to previous parameter.

Test mode enable, when held pressed for 2 seconds.

Programming Mode:

Decrease related value.

3. PUSHBUTTON FUNCTIONS

2. LED INDICATORS

DKG-175 User Manual V-1 (24.07.2017)

- 8 -

If 3-phases of mains voltage and frequency are withing limits and phase order is correct:

-MC, RST leds turn on.

-MCB terminal is supplied with voltage R.

-REMOTE START relay will be energised. (Normally closed and normally open contacts will switch

position.)

If any phase voltage or frequency goes outside of the limits:

-ALARM led turns on, RST led turns off.

-After the expiration of mains fail timer MCB terminal is open, MC led turns off.

-REMOTE START relay de-energises after engine start delay timer. (Contacts switch back to normal

positions) Generator must run.

When genset voltage is over the limit:

-G led turns on.

-GC led turns on after generator contactor timer. GCB terminal is supplied with voltage G.

When mains voltages and frequency are inside the limits:

-RST led turns on.

-ALARM led turns off.

-After the expiration of mains waiting timer, GCB terminal is open.

-After the expiration of mains contactor timer, MC led turns on, MCB terminal is supplied with voltage R.

-After expiration of Cooldown timer (Cooldown timer starts counting when GCB terminal is open)

REMOTE START relay energises. (Normally closed and normally open contacts will switch position.)

Test mode will be active if button is held pressed for 2 seconds on operation mode. ALARM led

blinks, remote start relay will be deactive and generator is expected to start. Test mode will be disabled

at the end of test mode timer.Test mode will also be disabled by holding pressed the button for 2

seconds before expiration of test mode timer.

4.1 Test Mode

4. OPERATION OF THE UNIT

DKG-175 User Manual V-1 (24.07.2017)

- 9 -

DKG-175 has programmable parameters to provide flexibility to the user. Press and hold and

buttons for 5 seconds to enable programming mode. Click and buttons to navigate between

parameters when device displays program number. Click button to display value of the program

parameter. Value of the program parameter can be increased or decreased with and buttons.

Once program parameter is changed, click button again to display program number. Press and hold

and buttons for 5 seconds to exit programming mode.

PROGRAM

DESCRIPTION

P1

Mains voltage low limit

3-phase of the mains voltages must be higher than program parameter P1 to energise

mains contactor.

P2

Mains voltage high limit

3-phase of the mains voltages must be lower than program parameter P2 to energise

mains contactor.

P3

Mains frequency low limit

Mains frequency must be higher than program parameter P3 to energise mains

contactor.

P4

Mains frequency high limit

Mains frequency must be lower than program parameter P4 to energise mains

contactor.

P5

Cooldown timer

Remote start signal will be off after the delay adjusted with program parameter P5.

Cooldown timer will start counting when generator contactor is off.

P6

Generator start delay

Remote start signal will be on after the delay adjusted with program parameter P6.

Generator start delay timer starts counting when mains contactor is off.

P7

Mains contactor timer

Mains contactor will be on after the delay adjusted with program parameter P7. Mains

contactor timer starts counting when generator contactor is off.

P8

Mains waiting timer

Generator contactor will be off after the delay adjusted with program parameter P8.

Mains waiting timer starts counting when mains is available.

5. PROGRAMMING

DKG-175 User Manual V-1 (24.07.2017)

- 10 -

P9

Mains fail timer

Mains contactor will be off after the delay adjusted with program parameter P9. Mains

fail timer starts counting when mains is off.

P10

Phase order check

0: Mains phase order check disabled

1: Mains phase order check enabled

P11

Test mode timer

Test mode will be deactive at the end of timer adjusted with program parameter P10.

Remote start relay will be de-energises and generator is expected to start.

The unit conforms to the EU directives

-2006/95/EC (low voltage)

-2004/108/EC (electro-magnetic compatibility)

Norms of reference:

EN 61010 (safety requirements)

EN 61326 (EMC requirements)

The CE mark indicates that this product complies with the European requirements for safety,

health environmental and customer protection.

Alternator voltage: 170-300 V-AC (Phase-Neutral)

Mains voltage: 170-300 V-AC configurable (Phase-Neutral)

Mains frequency: 30 –70 Hz configurable

Generator contactor timer: 1 - 40 sec. configurable

Mains contactor timer: 0 - 999 sec configurable

Mains waiting timer: 0 - 999 sec configurable

Mains fail timer: 0 - 999 sec configurable

Cooldown timer: 0 - 999 sec configurable

Remote start delay: 0 - 999 sec configurable

Mains contactor output: 10A @ 250V-AC

Generator contactor output: 10A @ 250V-AC

Remote start output: 10A @ 250V-AC/28V-DC

Operating temperature: -30C to 70 C

Storage temperature: -30C to 80 C

Maximum humidity: 95% non-condensing.

Dimensions: 70x115x66mm (WxHxD)

Weight: 180g (approx.)

Installation: DIN Rail mounted.

Case material: High temperature, non-flammable ABS/PC

IP protection: IP20

6. DECLARATION OF CONFORMITY

7. TECHNICAL SPECIFICATIONS

DKG-175 User Manual V-1 (24.07.2017)

- 11 -

DATAKOM Electronics Ltd.

8. CONNECTION DIAGRAM

Table of contents

Other Datakom Switch manuals

Popular Switch manuals by other brands

Eneo

Eneo IAD-5SG1004MUC Quick installation guide

Cisco

Cisco Catalyst 3560-X-24P datasheet

Fortinet

Fortinet FortiGate 310B quick start guide

Dymec

Dymec DY-H8080XR user manual

DELTA M

DELTA M microtuf FS4200 Series Operation and maintenance manual

LEGRAND

LEGRAND Watt Stopper RS-100U installation instructions

PCI

PCI EH-505P user manual

Endress+Hauser

Endress+Hauser RTA421 operating instructions

Honeycomb Aeronautical

Honeycomb Aeronautical Alpha Flight Controls manual

NETGEAR

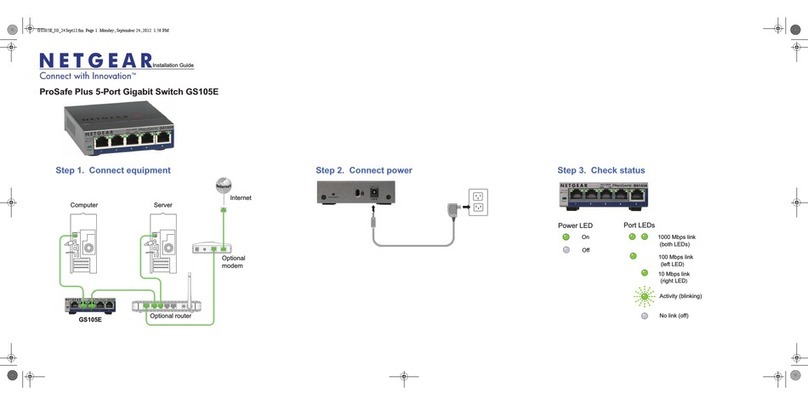

NETGEAR ProSafe Plus GS105E installation guide

TRENDnet

TRENDnet TK-423K - USB/PS/2 KVM Switch Specifications

Linear

Linear HDMI-SW-3X1 user manual