iii

CONTENTS

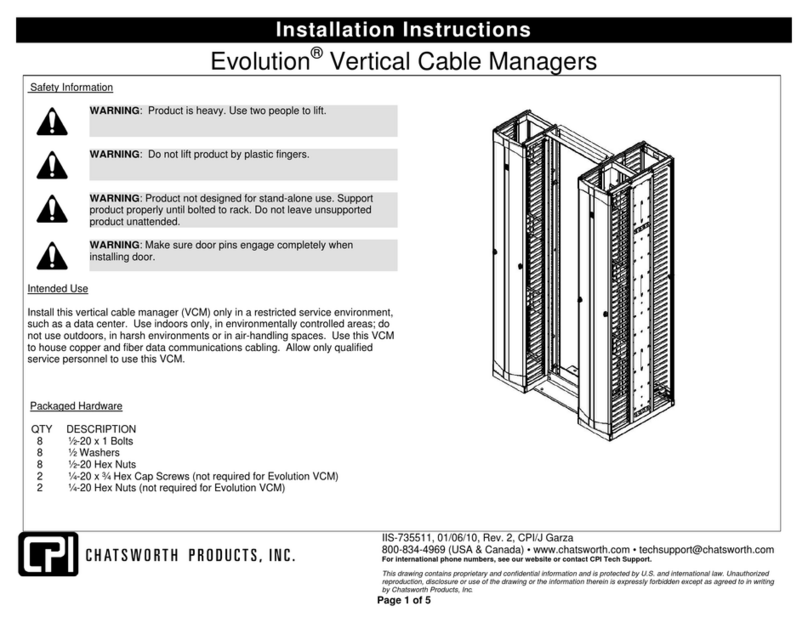

GUIDE TO INSTALLATION .........................................................................iv

GENERAL VIEW .......................................................................................... v

SAFETY PRECAUTIONS............................................................................. x

Power Supply................................................................................................ x

Safety Notes ................................................................................................. x

1 GENERAL FEATURES ................................................................................ 1

1.1 Description .................................................................................................... 1

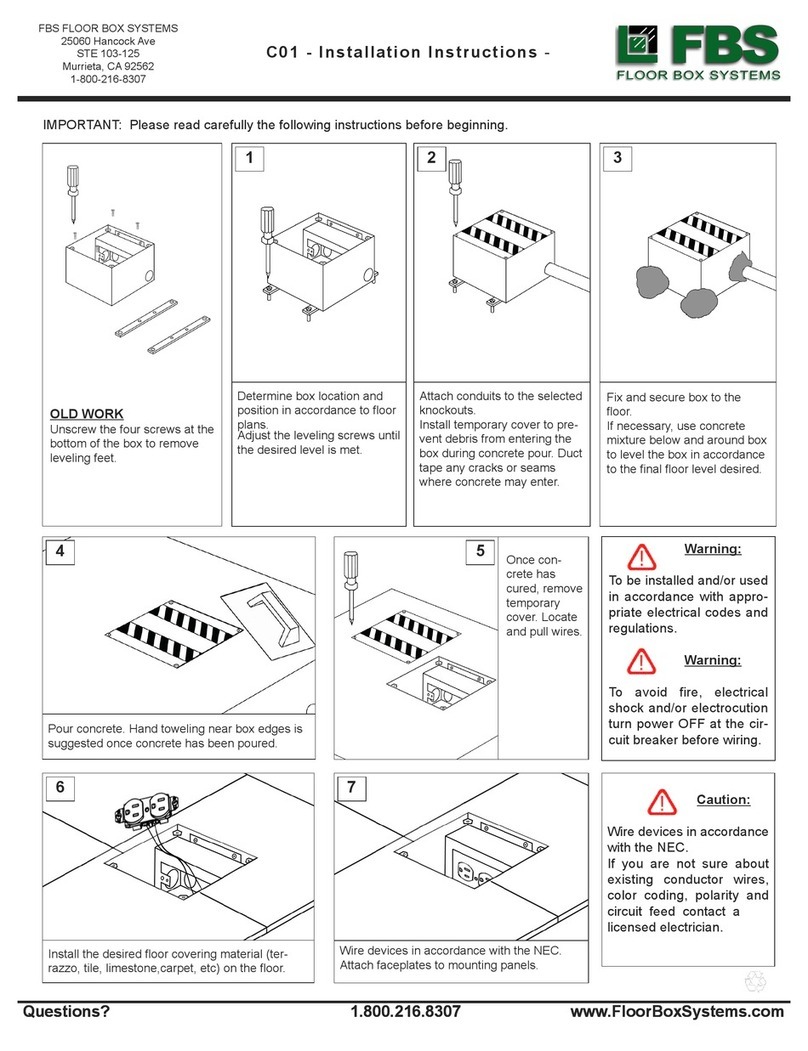

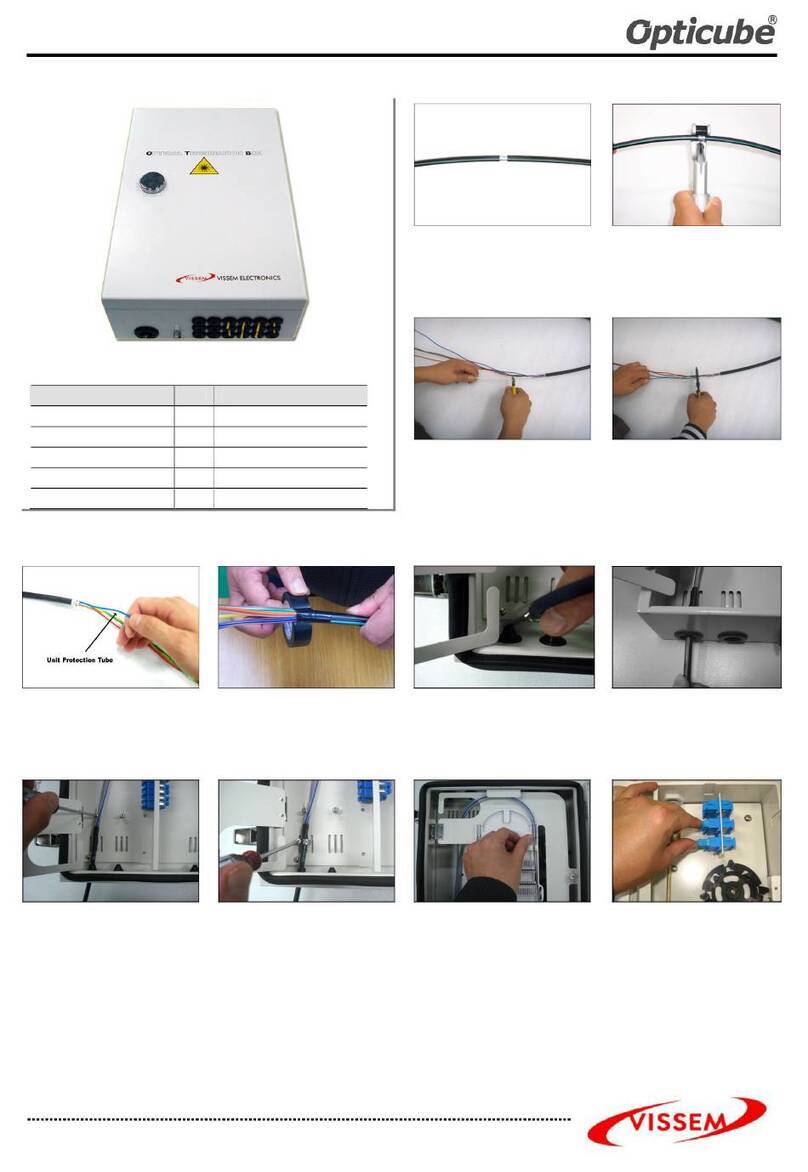

2 INSTALLATION............................................................................................ 2

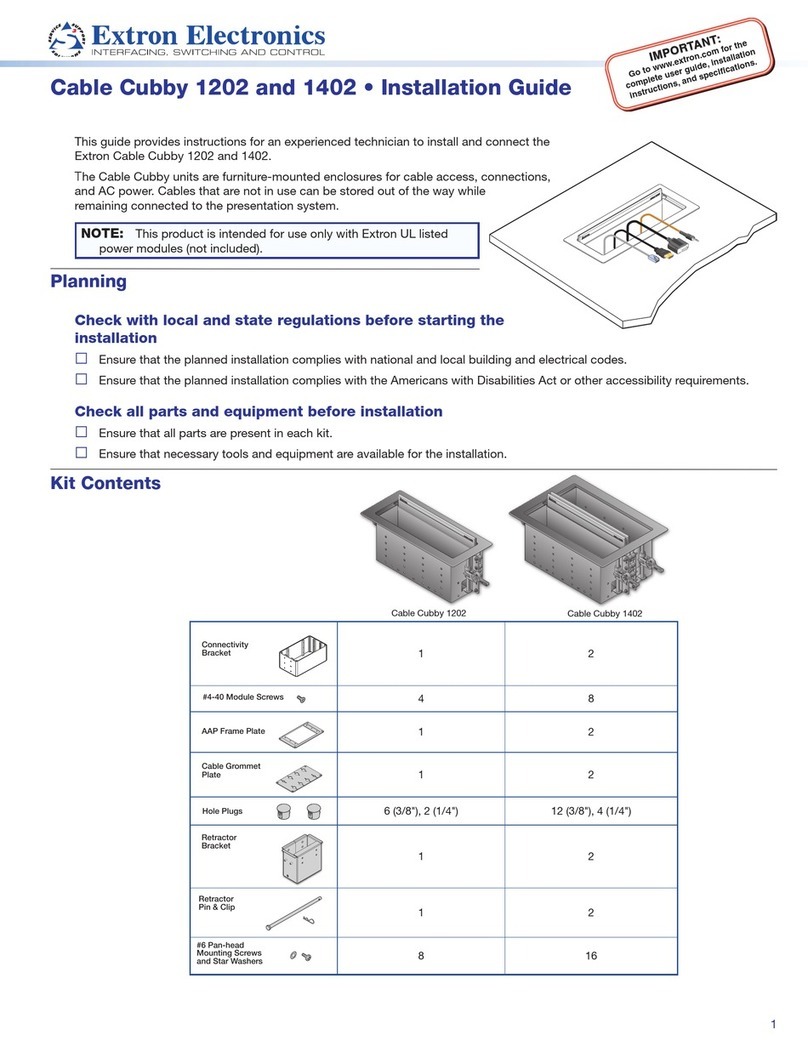

2.1 Package Contents......................................................................................... 2

2.2 Opening the Device ...................................................................................... 3

2.3 Applying the Adhesive Label......................................................................... 4

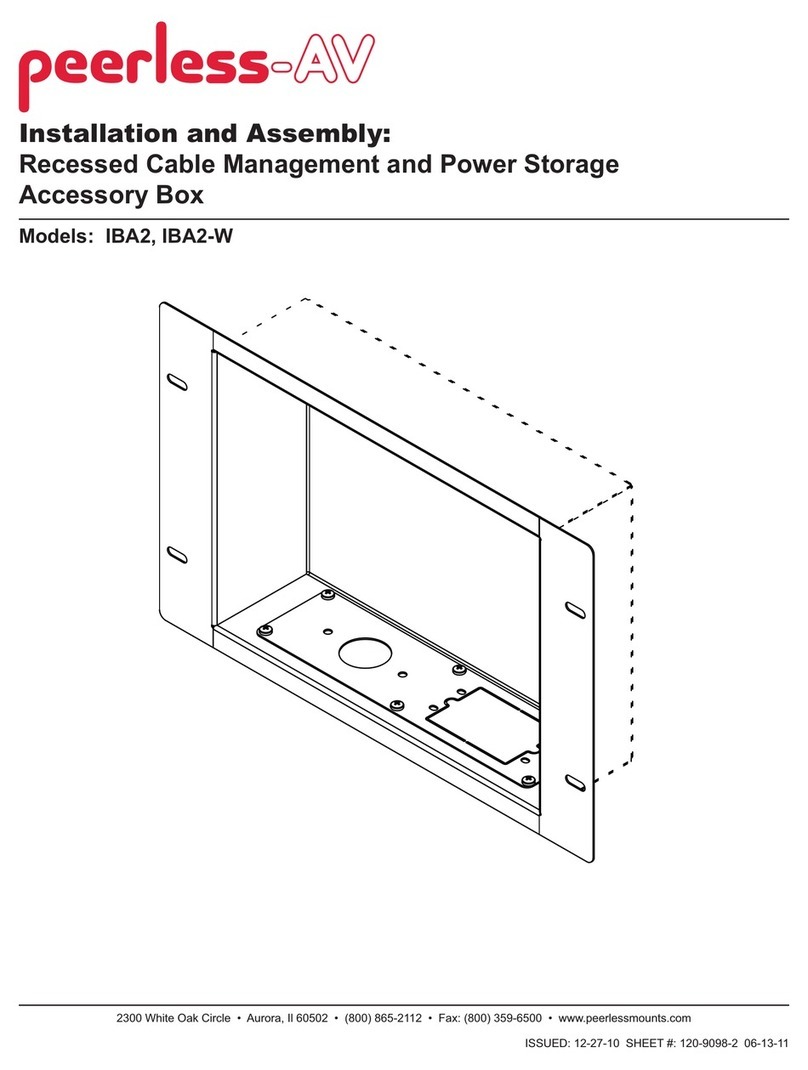

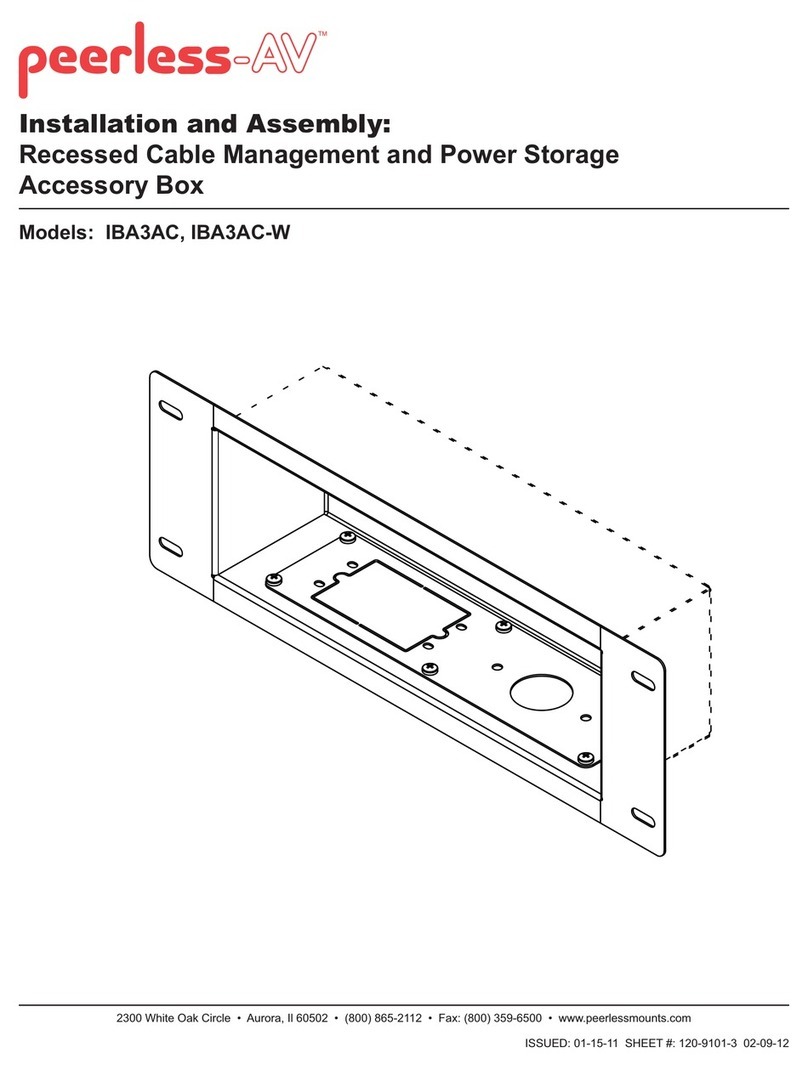

2.4 Mechanical Installation.................................................................................. 5

2.5 Electrical Connections and Setup ................................................................. 7

2.5.1 Power Supply................................................................................................ 8

2.5.2 System Wiring............................................................................................. 10

2.5.3 Chassis Grounding Jumper Settings........................................................... 12

2.5.4 Profibus Node Address Selection ............................................................... 12

2.5.5 Connection to a Profibus Network............................................................... 13

C-BOX 3X0 Configuration for Profibus DP Slave Node .............................. 14

2.5.6 OM4000 Jumper Settings ........................................................................... 14

2.6 Configuration Switch and 9-Pin Internal Connector ............................................ 15

2.7 Scanner Requirements ............................................................................... 17

2.8 Operating Modes ........................................................................................ 17

2.8.1 GET/TEST/SEND Functions ....................................................................... 18

2.8.2 LED Indicators ............................................................................................ 20

2.9 Profibus Connector (9-Pin Female External Connector) ............................. 22

3 TECHNICAL FEATURES ........................................................................... 23