Datasensor BWS-T2 Series User manual

DATASENSO

R

BWS-T2 SERIES

Multiray safety barrier, level 2,

1 … 2 pairs of photocells

INSTRUCTION MANUAL

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from

defects.

DATASENSOR S.p.A. will repair or replace, free of charge,

any product found to be defective during the warranty period

of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving

from the improper application of DATASENSOR products.

CONDIZIONI DI GARANZIA

DATASENSOR S.p.A. garantisce i suoi prodotti esenti da

difetti.

DATASENSOR S.p.A. riparerà o sostituirà, gratuitamente,

ogni prodotto che riterrà difettoso durante il periodo di

garanzia di 36 mesi dalla data di fabbricazione.

La garanzia non copre danneggiamenti o responsabilità

dovute ad un uso non corretto del prodotto.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

DATASENSOR S.p.A. reserves the right to make modifications and improvements without prior notification.

DATASENSOR S.p.A. si riserva il diritto di apportare modifiche e/o miglioramenti senza preavviso.

826190024 Rev.E

D

DE

EC

CL

LA

AR

RA

AT

TI

IO

ON

N

O

OF

F

C

CO

ON

NF

FO

OR

RM

MI

IT

TY

Y

We

DATASENSOR S.p.A.

Via Lavino, 265

40050 Monte San Pietro

Bologna - Italy

declare under our sole responsibility that the product(s)

BWS-T2 SAFETY CONTROLLER (TYPE 2)

to which this declaration relates in conformity with the following

standard(s) or other normative document(s)

CEI EN 55022, JUNE 1997:

LIMITS AND METHODS OF MEASUREMENTS OF RADIO DISTURBANCE OF INFORMATION

TECHNOLOGY EQUIPMENT

CEI EN 61000-4-2, SEPTEMBER 1996:

ELECTROMAGNETIC COMPATIBILITY (EMC). PART 4: TESTING AND MEASUREMENT

TECHNIQUES. SECTION 2: ELECTROSTATIC DISCHARGE IMMUNITY TEST

CEI EN 61000-4-3, NOVEMBER 1997:

ELECTROMAGNETIC COMPATIBILITY (EMC). PART 4: TESTING AND MEASUREMENT

TECHNIQUES. SECTION 3: RADIATED, RADIO-FREQUENCY, ELECTROMAGNETIC FIELD

IMMUNITY TEST

CEI EN 61000-4-4, SEPTEMBER 1996:

ELECTROMAGNETIC COMPATIBILITY (EMC). PART 4: TESTING AND MEASUREMENT

TECHNIQUES. SECTION 4: ELECTRICAL FAST TRANSIENT/BURST IMMUNITY TEST

CEI EN 61000-4-5, JUNE 1997:

ELECTROMAGNETIC COMPATIBILITY (EMC). PART 4: TESTING AND MEASUREMENT

TECHNIQUES. SECTION 5: SURGE IMMUNITY TEST

CEI EN 61000-4-6, NOVEMBER 1997:

ELECTROMAGNETIC COMPATIBILITY (EMC). PART 4: TESTING AND MEASUREMENT

TECHNIQUES. SECTION 6: IMMUNITY TO CONDUCTED DISTURBANCES, INDUCED BY

RADIO-FREQUENCY FIELDS

CEI IEC 61496-2, NOVEMBER 1997:

SAFETY OF MACHINERY - ELECTRO-SENSITIVE PROTECTIVE EQUIPMENT - PART 2:

PARTICULAR REQUIREMENTS FOR EQUIPMENT USING ACTIVE OPTO-ELECTRONIC

PROTECTIVE DEVICES (AOPDS)

Following the provision of the Directive(s):

89/336 CEE AND SUCCESSIVE AMENDMENTS

Monte San Pietro, 02/01/2001

Gianni Stradiotti

Quality Assurance Manager

UNI EN ISO 14001

BWS-T2 Series Instructions manual

INDEX

1. INTRODUCTION ............................................................................... 2

1.1. OPERATING DESCRIPTION ........................................................................... 5

2. INSTALLATION................................................................................. 9

2.1 MOUNTING THE BWS-T2............................................................................... 9

2.2 START SWITCH............................................................................................... 9

2.3 SENSORS.......................................................................................................10

2.4 SAFETY DISTANCE........................................................................................11

2.4.1. PROTECTION OF DANGER ZONES WITH BWS-T2

FOR PROTECTION OF FINGERS AND HANDS ................................11

2.4.2. PROTECTION OF ACCESS WITH BWS-T2 - 1-

OR MORE BEAMS FOR ARM AND BODY PROTECTION .................12

2.5 UNWANTED BEAM REFLECTIONS ...............................................................12

2.6 PHOTOELECTRIC SENSOR INSTALLATION ................................................14

2.7 ALIGNMENT OF THE SENSORS....................................................................15

3. ELECTRICAL CONNECTIONS ...................................................... 16

4. TECHNICAL DATA ......................................................................... 21

BWS-T2 Series Instructions manual

1

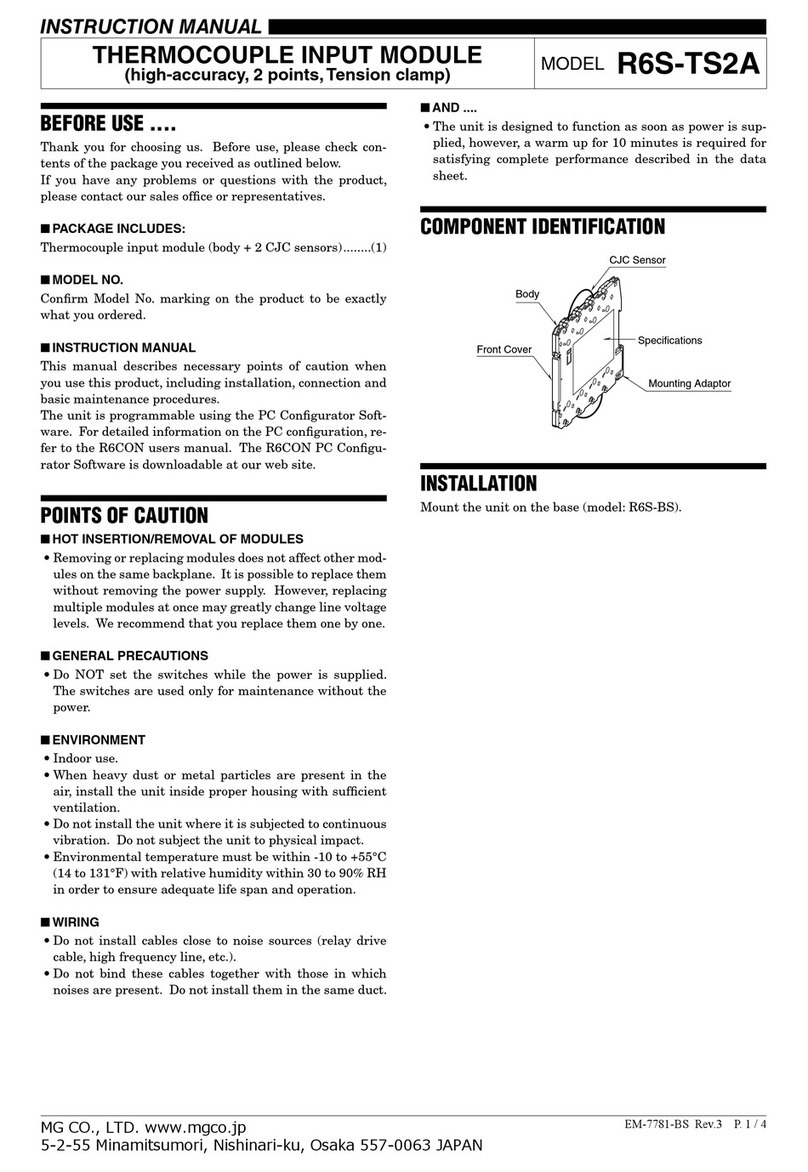

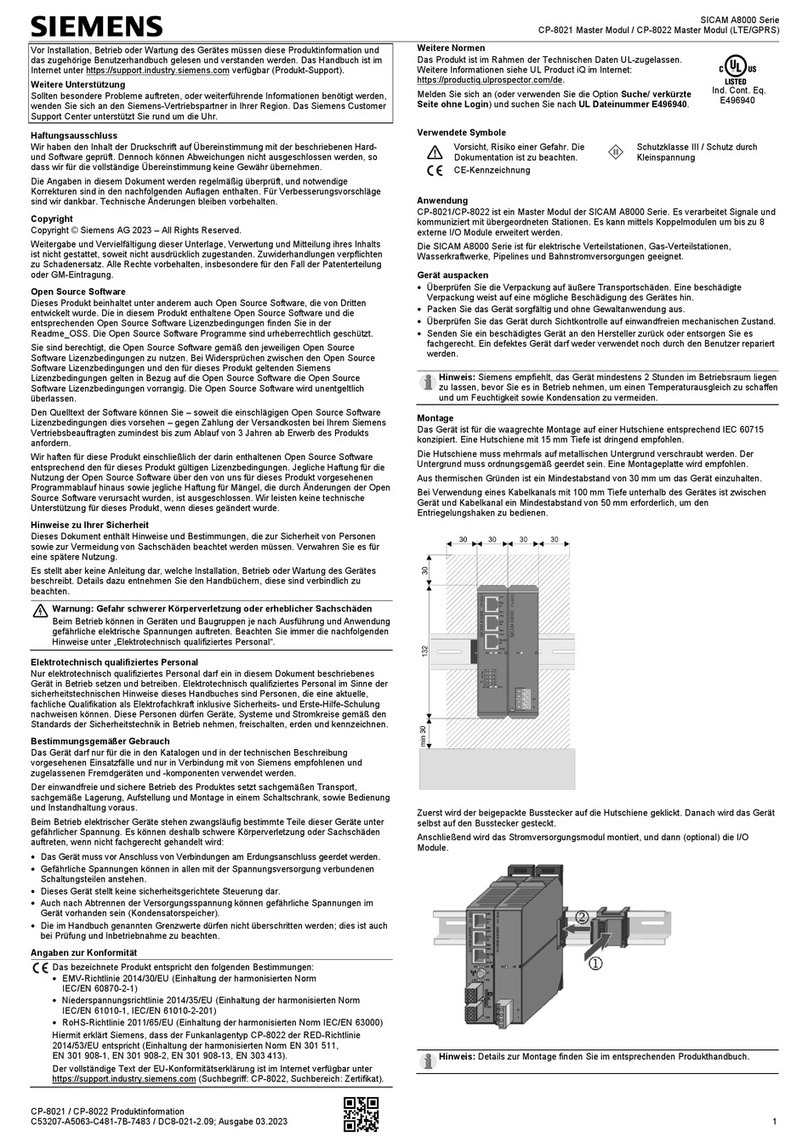

GENERAL VIEW

Figure A

BWS-T2 Series Instructions manual

2

1. INTRODUCTION

The BWS-T2 is an essential part of a photoelectric installation whose

purpose is to maintain a safe environment in potentially dangerous

areas where electrical machinery or equipment is in operation. It

performs this task by not allowing such machinery to start up unless the

dangerous area is clear of any persons or objects.

The product is designed to satisfy the following specifications (German

normatives):

The BWS-T2 can be used in the below listed insustrial sectors.

We inform that eventually other normatives and rules of local bodies for

safety at work have to be respected.

• Cold treatment of metals

prEN692 Mechanic presses

prEN693 Hydraulic presses

• Machinery for plastics and rubber

prEN201 Injection presses - moulding maschinery

prEN289 Shape- and moulding presses

prEN1114 Rail- and extrouding presses

prEN1417 Equipment for mixing with 2 cylinders

prEN422 Blow- shaping machinery

• Machinery for packaging

prEN415-2 Machinery for packaging of rigid prechaped goods

prEN415-3 Machinery for packaging, filling and enclosure

prEN415-4 Equipment for palleting and unpalleting

prEN415-5 Machinery for wraping

prEN415-6 Group packing machinery

prEN415-7 Machinery for arrangements

BWS-T2 Series Instructions manual

3

• Machinery for wood treatment

prEN691 General requirements

prEN859 Planing and straightening machinery with manual transport

prEN860 Single sided machinery for planing

prEN861 Machinery for combined planing and straightening

prEN1807 Band- saws

prEN848 Table milling machinery

prEN940 Combined Machinery

prEN1218 Double profile maschinery

• Paper- and printing machinery

prEN1010 Printing machinery

prEN1034 Machinery for paper production

• Machinery for tanning

prEN972 Alternative machinery with movable rolls

prEN1035 Machinery with movable slats

prEN931 Machinery for scratching, grinding, polishing, folding and

nailing

• Ohter machinery

prEN11553 Safety of Laser machinery for treating materials

EN775 Safety of handling automation

prEN1525 Driverless transport systems and their systems

Further normatives to be applied:

EN 292 Part 1: November 1991

Safety of machinery- Basic concepts, general principles for design:

Part 1: Basic terminology , methodology

EN 292 Part 2: November 1991

Safety of machinery - Basic concepts, general principles for design:

Part 2: Technical principles and specifications

EN 294: Juni 1992

Safety of machinery - Safety distances to prevent danger zones being

reached

by the upper limbs

BWS-T2 Series Instructions manual

4

EN 811: Oktober 1992

Safety of machinery - Safety distances to prevent danger zones being

reached

by the lower limbs

EN 999: Januar 1995

Safety of machinery - The positioning of protective equipment in respect

of approach of parts of the human body

EN 954 Part 1: März 1997

Safety of machinery; Safety related parts of control systems

- General principles for design

EN 60204 Part 1 Safety of machinery, electrical equipment of

machines - General requirements

Draft prEN 1050: Aprl 1996

Safety of machinery; risk assesment

FINAL DRAFT IEC 61496-1/Ed. 1.0: Safety of machinery - electro -

sensitive equipment,

Part 1: General requirements and tests.

Documents 44/206/FDIS and 44/206A/FDIS: 1997-03-28

FINAL DRAFT IEC 61496-2/Ed. 1.0: Safety of machinery - electro -

sensitive equipment,

Part 2: Particular requirements for equipment using active

opto-electronic protective devices.

Documents 44/208/FDIS and 44/206A/FDIS: 1997-0530

The BWS-T2 can be used in conjunction with our line of photoelectric

sensors as shown in the Technical Specifications.

The BWS-T2 has been designed so that one (1) or two (2) Emitter-Receiver

pairs can be connected to it.

The operating voltage is: 24VDC ±10%.

The status of the system is indicated by 3 visible LEDs:

•FREE green

•ALARM red

•TEST yellow

BWS-T2 Series Instructions manual

5

The BWS-T2 is rated as a type 2 ESPD (Electro Sensitive Protective

Device) according to the EUROPEAN STANDARD.

A type 2 ESPD is a device which relies on the correct response to external

tests to maintain its safety integrity. The device may not detect failures in

system integrity between tests.

1.1 OPERATING DESCRIPTION

The BWS-T2 features the following functions:

START INTERLOCK:

A start interlock is a means for preventing automatic starting after the

BWS-T2 is switched on.

INITIAL TEST:

A test which is performed via the start switch, after the BWS-T2 has

been powered, in order to test the complete safety related control

system before the first operation is initiated.

RESTART INTERLOCK:

A means for preventing automatic re-starting of a machine after the

optical beam(s) was (were) interrupted.

CYCLE TEST:

A test which can be performed at any time while the BWS-T2 is in the

active operating mode in order to test the complete safety related control

system.

BWS-T2 Series Instructions manual

6

The flow chart on the following page can be used to describe the

operation of the BWS-T2:

BWS-T2 OPERATION

Start

Activated

?

Failure Blocked state

Interrupt

Light-Beam

Test

Power on

Output-Contact

Open

?

Output-Contact

Closed

?

?

Yes

Yes

Yes

Failure

?

Blocked state

YesNo

No

No

No

No

Output-Contact

Open

Yes

Initial Test

Cycle Test

Q

QQ

Q

R

RR

R

S

SS

S

T

TT

T

U

UU

U

V

VV

V

Output-Contact

Open

Figure 1

BWS-T2 Series Instructions manual

7

QUpon application of power, the red ALARM LED lights up and the

START INTERLOCK function will prevent the operation of the output

contacts.

RThe active operation mode can be initiated only with a N.O. (normally

open) start switch. After closing the start switch, the INITIAL TEST

function will be activated automatically. The red ALARM LED goes off

and the yellow TEST LED lights up.

SAfter the start switch is released, and only if no fault is detected, both

N.O. output contacts will switch to the active operation mode.

In this case the yellow TEST LED goes off and the green FREE LED

lights up.

TThereafter, any interruption of the optical beam(s) will cause the

RESTART INTERLOCK to prevent automatic re-activation and force

the operator to re-initiate with the start switch.

UIf a fault is detected, after the start switch is released, the yellow TEST

LED goes off and the red ALARM LED lights up; the output contacts

remain open (preventing machine start up).

VDuring the active operating mode, the CYCLE TEST can be performed

by means of 2 N.C. contacts: Test 1 and Test 2 (see figure 2).

This procedure is normally used to detect the status of the BWS-T2

periodically.

By opening the Test 1 contact, the CYCLE TEST is started; the output

contacts are OPEN for the duration of the test and will CLOSE after

the test is completed only if the BWS-T2 has detected no fault.

The test is completed when the Test 2 contact is opened and then

closed.

The CYCLE TEST is such that any short-circuit, open, or component

malfunction will be instantly recognized.

The LED indicators for the CYCLE TEST have the same function as in

the INITIAL TEST.

BWS-T2 Series Instructions manual

8

There are two ways to connect the Test 1 and Test 2 contacts:

a) CYCLE TEST procedure using 2 N.C. contacts.

1 2 3 4

TEST1 TEST2

Figure 2

When the Test 1 contact opens, the test procedure begins.

When the Test 2 contact opens and closes again, the test procedure ends.

This type of connection allows to detect short-circuits at the test cables.

b) CYCLE TEST procedure using 1 N.C. contact.

1 2 3 4

TEST

Figure 3

When the Test contact opens, the test procedure begins; when it closes,

the test procedure ends.

BWS-T2 Series Instructions manual

9

2. INSTALLATION

2.1 MOUNTING THE BWS-T2

The BWS-T2 must be mounted in an enclosure with at least an IP54

rating. The dimensions of the BWS-T2 are given in the following

diagram for mounting purposes:

100

8 6

110

2035.519.5

75

85

6

60

4.5

mm

Figure 4

2.2 START SWITCH

The external start switch, which allows the enabling of the active

operating mode, must be installed in such a way that an unobstructed

view of the danger area is provided.

IT MUST NOT BE POSSIBLE TO ACTIVATE THE START SWITCH

FROM INSIDE THE DANGER AREA !

By-passing the start switch in order to eliminate the START

INTERLOCK and the RESTART INTERLOCK functions is not allowed.

Therefore the start switch must be closed and then opened again to

begin the INITIAL TEST.

BWS-T2 Series Instructions manual

10

2.3 SENSORS

The photoelectric sensors must be mounted in front of the danger area

(as per EN 999) so as to protect the entire danger area.

The sensors must be installed in the vicinity of the operating

equipment in such a way as to allow ENTRY or OPERATION of the

machine ONLY THROUGH the safety barrier. The possibility of

reaching the danger area from below, above or from around the safety

barrier must be prevented. It must not be possible to move or alter the

installation in any way.

In addition, it must not be possible to be inside of the danger area

behind the safety barrier. This must be detected by the safety barrier.

The electrical connection from the BWS-T2 box to the sensors is done

via shielded cables. The possible lengths are listed in the sensor

datasheets. If using sensors with connectors, be sure that your cable is

shielded.

2.4 SAFETY DISTANCE (SD)

The photoelectric sensors must be mounted at a "safety distance" (S)

in front of the machine or danger area. It must be assured that the

dangerous movement is stopped before a person is able to touch the

dangerous moving parts.

This safety distance (S) depends upon the reaction time of the BWS-

T2, the speed of the person or object penetrating the "guarded" area

(approx. value: v=1.6m/s) and the lagtime of the machine. See figure

5.

BWS-T2 Series Instructions manual

11

H

S

BWS Danger zone

H

H1

n-1

n

Figure 5

S = V * T+C C=8(d-14mm)

S: Minimum distance - safety distance

V: Approaching speed

T: Delay time of the complete system

C: Supposed length of a part of a body with ∅< resolution of fotocell

array, that exceeds the protecting area without a guaranteed

detection.

d: Detection capabillity (see table characteristics of photocells) -

Fingerresolution: ∅≤14mm; handresolution: ∅≤40mm;

armresolution: ∅≤70mm.

H: Vertical position of the protecting area above the floor

2.4.1. Protection of danger zones with BWS-T2 for protection of fingers

and hands

Condition: 14mm<d40mm; C0

For 100mm<S500mm is valid:

S=2000*T+C

For S500mm is valid:

S=1600*T+C

Must not be applied if also children have to be protected!

BWS-T2 Series Instructions manual

12

2.4.2. Protection of access with BWS-T2 - 1- or more beams for arm

and body protection

Condition: 40mm<d70mm; C0

S=1600*T+850mm

Mounting hight of the emitter(s) and reiceiver(s):

1 Pair E/R: 750mm

2 Pairs E/R: 400mm, 900mm

3 Pairs E/R: 300mm, 700mm, 1100mm

4 Pairs E/R: 300mm, 600mm, 900mm, 1200mm

Criterion: No limbs passing below the lowest beam

No limbs passing below the highest beam

No limbs passing between 2 beams

No passage between 2 beams

Highest beam 900mm, lowest beam 300mm

2.5 UNWANTED BEAM REFLECTIONS

Specular reflections from shiny surfaces in proximity or within the

beam envelope (cone) can reflect light, thus affecting the ability to

detect an intrusion into the guarded area.

The minimum distances shown in figures 7a and 7b must be respected

to satisfy the arrangement shown in figure 6b (figure 6a is not correct).

BWS-T2 Series Instructions manual

13

x

8

D

8

INCORRECT

INSTALLATION

Figure 6a

88

x

D

CORRECT

INSTALLATION

Figure 6b

12 5634 7 8

D

30

X

10

20

cm

m

reflecting surface

X

D

S5 or S10

D

X

0.5

1.0

10 20 30 40 50

0.6

0.7

0.8

0.9

m

m

reflecting surface

D

X

S30

Figure 7a Figure 7b

BWS-T2 Series Instructions manual

14

2.6 PHOTOELECTRIC SENSOR INSTALLATION

When mounting the sensors (emitter(E)/receiver(R) pairs) to the BWS-

T2, care must be taken to position these components in such a way as

not to interfere with each other. (including with the help of a mirror, see

figure 8b and 8c). The layouts in figures 8a-8d are bad examples NOT

to follow because they are unreliable.

E

E

R

R

Figure 8a

ERR

E

Figure 8d

E

E

R

R

mirror

Figure 8b

ER

ER

mirror

Figure 8c

BWS-T2 Series Instructions manual

15

Figures 9a-9b show the proper disposition of these elements.

E

E

E

E

RR

RR

Figure 9a

E

E

R

R

Figure 9b

2.7 ALIGNMENT OF THE SENSOR(S)

To align the sensor(s), you have to bridge the start switch from

terminal 19 to terminal 20. Using the Receiver output LED of the

photoelectric sensor(s) you can align the light barrier.

If the sensors are correctly positioned, the yellow TEST LED lights up.

If beam 1 or 2 is interrupted, the ALARM LED at the BWS-T2 lights up

and the TEST LED turns off.

When the alignment is completed, disconnect the bridge between

Terminal 19 and Terminal 20.

BWS-T2 Series Instructions manual

16

3. ELECTRICAL CONNECTIONS

The BWS-T2 controller provides for the following connections:

Signal Terminal

Output 1 14; 29

Output 2 15; 30

Start 19; 20

Test 1 1;2

Test 2 3;4

Emitter 1 5;6;7;8

Receiver 1 21;22;23;24

Emitter 2 25;26;27;28

Receiver 2 9;10;11;12

Input +24 VDC 16

GND 18

Earth GND 17

See the individual diagrams (figures 10 - 13) for wiring details.

One (1) or two (2) emitter-receiver pair(s) can be connected to the BWS-T2.

If using only one Emitter-Receiver pair, the cables of the Emitter must be

connected to the EMITTER 1 terminals and the cables of the Receiver must

be connected to the RECEIVER 2 terminals.

The EMITTER 2 and RECEIVER 1 terminals remain free.

CAUTION

Supply only the photocells from this device!

Always use shielded cables to wire the emitter and

receiver pairs.

BWS-T2 Series Instructions manual

17

START

User tool User tool

EL. CONTROL CABINET

VOLTAGE

SUPPLY

24 V + 10 %

-

EMITTER RECEIVER

max. 220 VAC

S

H

I

E

L

D

FUSE

TEST1 TEST2

L1

N

+

-

302928272617 18 19 20 21 23 24 252216

1234 567 891011 1312 1514

O

T

1

U

O

T

2

U

SB-BW S-T2

- +

+ -

Figure 10 - One Emitter/Receiver pair

Table of contents