Dato CSST13020 User manual

SCREW AIR

COMPRESSOR

CSST13020

Instruction

Manual

Release August 2018

1

TABLE OF CONTENTS

1. Safety Information…………………...………………………………………………4

1.1 Safety Alert Symbols………………………………………………………………4

1.2 Safety Precautions………………………………………………...………………...5

1.3 Pressure……………………………………..……………………………………….5

1.4 Fire and Explosion…………………………..……………………………………...6

1.5 Moving Parts………………………………………………..………………………6

1.6 Hot Surfaces…………………………….………………………….……………….6

1.7 Proper Compressed Air Applications.................................................6

1.8 Electrical Shock……………………………………………….…………………….7

2. General Information……………………………………………………………………8

2.1 Introduction…………………………………………………………………………8

2.2 The Compression Cycle…………………………………………………………….9

2.3 Compressor Lubrication and Cooling System…………………………..……...10

2.4 Compressor Discharge System…………………………………….……………..10

2.5 Air-end, Inlet Valve and Filtration System…………………………………….11

2.6 Control Panel Layout...…………………………………………………………..12

2.7 Technical Data…………………………………………………………….. 14

3. Fluid Information……………………………………………………………………..15

3.1 Fluid Guide………………………………………………………………….……..15

3.2 Fluid Change and Recommendations……………………………………....……15

4. Installation……………………………………………………………………………..16

4.1 Compressor Mounting, Support and Location…………………………………16

4.2 Ventilation and Cooling……………………………………….…………………16

4.3 Piping Connection………………………………………………………..............18

4.4 Fluid Level Inspection………………………………………….…………………19

4.5 Electrical………………………………………..…………………………………19

4.6 Motor Rotation Inspection…………………………………………...…………...20

4.7 Fan Rotation Inspection …………………………………………….……………21

5. Operation…………………………………………………………………….………...22

5.1 Routine Operation…………………………………………….…………………..22

5.2 Operating Procedures (Electrical Control Panel)………………………………24

5.3 Display Unit Status and Operations……………………………………………24

5.4 Customer Parameter and Functions………………………………….…………27

2

TABLE OF CONTENTS

5.5 Manufacturer Parameters……………………………………………………….31

5.6 Control Principle………………………………………………….…………...39

5.7 Network Control…………………………………………………………………41

5.8 Temperature Control of Fan………………………………………….………….41

5.9 Failure Shutdown and Emergency Shutdown…………………………………..41

5.10 Early-Warning and Prompts………………………………………..…………...41

5.11 Control Protection……………………………………………………….............42

5.12 Common Failure Solving………………………………………...…………..44

5.13 Electrical Control Diagram ……………………………………………...……46

6. Servicing………………………………………………………………………………..47

6.1 Fluid Change………………………………………………………………..……..47

6.2 Air Filter……………………………………………………………………….…..47

6.3 Fluid Filter………………………………………………………………………....48

6.4 Air/Oil Separator………………………………………………………………….48

6.5 Maintenance Schedule…………………………………………………………….49

7. Troubleshooting Guide.………………………………………………………………50

8. Standard Terms and Conditions ……………………………………………….…..53

3

Safety Information

Thank you for choosing our Compressor. Please read this instruction manual carefully

before using the compressor. This manual must be kept in the safe place for future

reference. Our Compressor’s authorized distributors provide maintenance service for CS

series rotary screw compressors. A certified technician is required to ensure compressors

maintenance is safely handled. By following the instructions in this manual, the user will

minimize possibility of an accident throughout the useful life of this equipment.

1.1 SAFETY ALERT SYMBOLS

Key hazards are used throughout this manual. The level of hazards seriousness is

symbolized as follows:

This symbol identifies immediate

hazards which will result in severe

personal injury, death or substantial

properly damage.

This symbol identifies hazards or

unsafe practices which could

result in personal injury, death or

substantial property damage.

This symbol identifies immediate

electrical hazards which will result

in severe personal injury, death or

substantial properly damage.

This symbol identifies hazards or

unsafe practices which could

result in personal injury or

substantial property damage.

This symbol identifies immediate

hot surface hazards which will

result in severe personal injury.

NOTICE

Identifies important installation,

operation or maintenance

information which is not hazard

related.

4

Safety Information

1.2 SAFETY PRECAUTIONS

This manual describes the safety precautions, structure and functions of all systems and

components, as well as the operation and maintenance methods for the GC series rotary

screw air compressors. The owner and operator shall read the manual carefully. Only after

thorough understanding should the machine be operated for the first time. This manual

gives you a general description of the, mechanical and electrical systems and maintenance.

However, if you have any questions about operating and maintenance of the compressor;

please contact your authorized distributor or our service department personnel.

Do not modify the compressor and/or controls in any way except with written factory

approval. While not specifically applicable to all types of compressors with all types of

prime movers, most of the precautionary statements contained herein are applicable to most

compressors and the concepts behind these statements are generally applicable to all

compressors.

Failure to follow any of these precautions may results in severe personal injury,

death, property damage and/or compressor damage

1.3 PRESSURE

A properly sized pressure relief valve must be installed in the discharge piping ahead

(upstream) of any shutoff valve (block valve), heat exchanger, orifice or any potential

blockage point. Failure to install a pressure relief valve could result in the rupturing or

explosion of some system component. Relieve all pressure internally to the compressor

prior to servicing. Do not depend on check valves to hold system pressure. Do not change

the pressure setting of the pressure relief valve, restrict the function of the pressure relief

valve, or replace the pressure relief valve with a plug. Over pressurization of system or

compressor components can occur, resulting in death, severe personal injury or property

damage. Do not operate the compressor at pressures in excess of its rating. Never use

plastic pipe, rubber hose, or soldered joints in any part of the compressed air system.

Failure to ensure system compatibility with compressor piping is dangerous.

5

Safety Information

1.4 FIRE AND EXPLOSION

Clean up any spills of lubricant or combustible liquid immediately. Keep sparks and flame

away from the compressor. Do not permit smoking during servicing, such as checking or

adding fluid. Wipe down spills immediately using industrial cleaner as required. Do not use

flammable material for cleaning purposes. Do not operate the compressor in a hazardous

environment unless the compressor has been specially designed for that environment. Wear

personal protective equipment including safety goggles and clothing during servicing the

compressor. Never use a flammable or toxic solvent for cleaning the air filter or any parts.

1.5 MOVING PARTS

Keep hands, arms and cloths away from the coupling and fans of the compressor. Do not

remove any guards or cabinet panels or attempt to service any compressor part while the

compressor is operating.

1.6 HOT SURFACES

Do not touch any hot surface and parts during the compressor’s operation. Keep all body

parts away from air/oil receiver tank, steel tubing, air end and after-cooler. Wear personal

protective equipment including gloves while servicing the compressor.

1.7 PROPER COMPRESSED AIR APPLICATIONS

Air from this compressor will cause severe injury or death if used for breathing or food

processing. Air used for those processes must meet OSHA and applicable industry

regulations. This compressor is designed for use in the compression of normal atmospheric

air only. No other gases, vapors or fumes should be exposed to the compressor intake, nor

processed through the compressor. Keep personnel away from the compressed air discharge.

Use compressed air for cleaning purpose, only with effective chip guarding and personal

protective equipment which meet OSHA standard and/or any federal, state, local codes,

standard and regulation.

6

Safety Information

1.8 ELECTRICAL SHOCK

Never start the compressor unless it is safe to do so. Do not attempt to operate the

compressor with a known unsafe condition. Tag the compressor and render it inoperative

by disconnecting and locking out all power at the source or otherwise disabling its prime

mover so others who may not know of the unsafe condition cannot attempt to operate it

until the condition is corrected. Install, use and operate the compressor only in full

compliance with all pertinent OSHA regulations and/or any applicable Federal, State, and

Local codes, standards and regulations. Never assume it is safe to work on the compressor

because it is not operating. Many installations have automatic start/stop controls and the

compressor may start at any time.

NOTICE

- Follow all maintenance procedures and check all safety devices on schedule.

- Use the correct compressor fluid at all time

- Do not rely on the discharge check valve to isolate the compressed air service line

- Keep panels closed at all times and stay away from hot surfaces to prevent hazards

NOTICE

These instructions, precautions and descriptions cover GC series air compressors.

As a service to our customers, we often modify or construct packages to the

customer’s specifications. This manual may not be appropriate in those cases.

Every effort has been taken to ensure complete and correct instructions have been included

in this manual. However, possible product updates and changes may have occurred since

printing this manual. Compressor reserves the right to change specifications without

incurring any obligation for equipment previously or subsequently sold.

7

General Information

2.1 INTRODUCTION

The GC series offer models with power ranging from 7.5 kw to 132 kw. The compressor is

a single stage, positive displacement, fluid-flooded rotary screw. A complete unit of

following:

⚫Screw air compressor

⚫Dryer(optional)

⚫Filters(optional)

⚫Air tank(optional)

All components are assembled on a structural steel base with enclosure. The control panel

is located in the front of the enclosure door panel. Acoustical enclosure is one of the

standard features for all compressors.

NOTICE!

Dismantling the compressor’s enclosure may void its warranty.

General Information

8

2.2 THE COMPRESSION CYCLE

The compressor housing contains of two rotors; Male and

Female rotors. The male rotor has five lobes and female rotor

has six flutes. They are constantly and precisely meshed, and

housed in the cylinder with two parallel adjoining bores. All

parts are machined to exacting tolerances. The rotors provide

positive-displacement internal compression smoothly and

without surging. As the rotors rotate, air is drawn into the

cylinder through the inlet port. A volume of air is filled and

trapped as the rotor lobes pass the inlet port in the cylinders.

Compression occurs as the male rotor rolls into the female

flute, progressively reducing the space thereby raising the

pressure. Compression continues until the lobe and flute pass

the discharge port. The compressed air is then discharged into the air/oil separator tank.

There are five complete compression cycles for each complete rotation of the male rotor.

When the compressor is operating, a partial vacuum is produced at the compressor inlet.

Fluid is injected into the compressor unit and mixed with the air. The fluid has three basic

functions:

•As a coolant, it controls the rise in air temperature normally associated with the heat

of compression.

•It seals the leakage paths between the rotors and stator and also between the rotors

themselves.

•It acts as a lubricating film between the rotors allowing one rotor to directly drive

the other, which is an idler.

After air/fluid mixture is discharged from compressor to the reservoir, fluid is separated

from the air in the separator tank. Compressed air then flows through the after-cooler for

moisture removal while the lubricant is being cooled by the fluid-cooler for re-injectio

General Information

9

2.3 COMPRESSOR LUBRICATION AND COOLING SYSTEM

The lubrication and cooling system consists of a reservoir, centrifugal fan, fan motor,

aluminum finned fluid-cooler and after-cooler, thermal valve & fluid filter. High pressure

forces the lubricant through a series of direction changes in the reservoir where it is

separated from the air. The fluid is then delivered to the thermal valve and fluid-cooler.

Cooled fluid will be filtered before being re-injected back into the compressor.

Ambient air is being forced through the cooler fins by the centrifugal fan, which cools the

fluid and compressed air in the cooler tubes. The after-cooler helps separate the water

content in the discharge air, and through the automatic condensate drain, the water will be

drained. This avoids water contamination problems downstream (in service lines). Cooler

fins must be kept clean at all times.

Fluid from reservoir circulates to the thermal valve. The thermal valve is fully closed when

the fluid temperature is below 70°C (158°F). Fluid (below 158°F) will bypass the thermal

valve and inject directly to the airend. As the discharge temperature rises above 80°C

(176°F), due to heat of compression, the thermal valve begins to open and fluid will be

circulated to the cooler.

2.4 COMPRESSOR DISCHARGE SYSTEM

Air/fluid mixture has been forced into reservoir after compression. The reservoir has two

basic functions:

•It acts as a primary fluid separator.

•It serves as the compressor fluid sump.

The compressed air/fluid mixture enters the reservoir and is directed against the internal

baffle. Turbulent flow occurs and velocity is significantly reduced, thus causing large

droplets of fluid to form and fall to the bottom of reservoir. Fluid collected in the reservoir

will then be returned to the compressor due to the pressure differential.

The sight glass enables the operator to visually monitor the reservoir fluid level. Fluid is

added to the reservoir by removing the fluid filling cap after all system pressure is relieved.

The fluid level should remain at the top red lines on the sightglass. Fluid refill is required

once its level drops below the lower red line.

General Information

10

The minimum pressure check valve assures the reservoir maintains a minimum pressure

between 58 psig and 72 psig (4Bar and 5Bar) during unloading conditions. This pressure is

necessary for air/fluid separation and fluid circulation.

2.5 AIREND, INLETVALVE AND FILTRATION SYSTEM

The compressor inlet system consists of a Kerry air filter, Kerry inlet valve. & SKKairend.

The Kerry inlet valve controls the air intake volume. It is also acts as the check valve to

prevent the reverse pressure and rotation when compressor is shutting down.

General Information

SKKair end

Kerry inlet valve

Casing for Kerry air filter

11

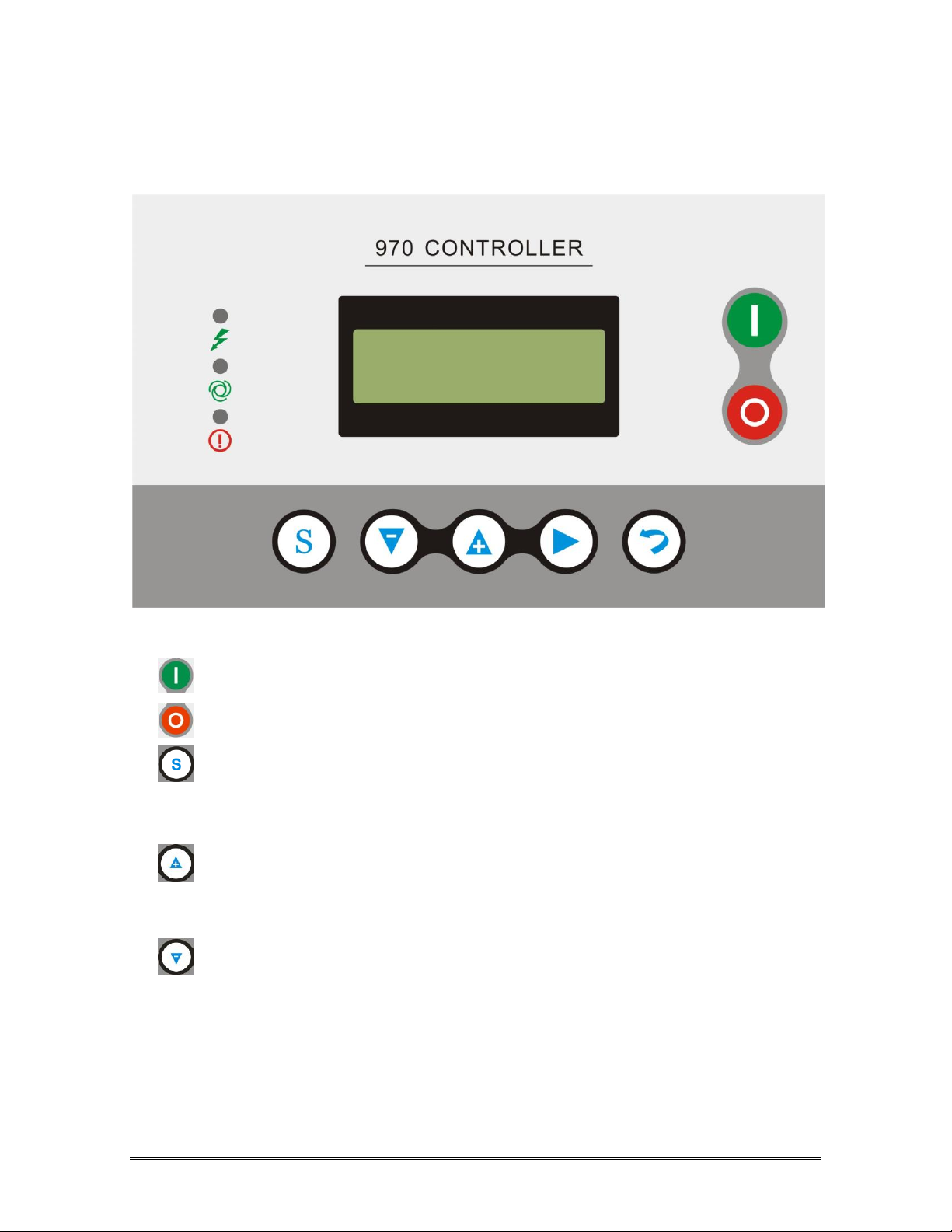

2.6 CONTROLLER PANEL LAYOUT

Standard GC compressor is equipped with microprocessor control panel.

Figure 1.1.1

——Start Button: Press this button to start the compressor.

——Stop button:Press this button to stop the compressor.

——Set Button/ Loading / unloading Button: After modification, press this to

confirm and save modified data;When the compressor is running ,press

this button to load or unload under a certain pressure.

——Move up button/increase button: Data at current position is increased by

pressing this button when data are modified; Menu is moved upwards when

menu is selected.

——Move down button / Descending button: Data at current position is

descended by pressing this button when data are modified; menu is moved

downwards when menu is selected.

General Information

12

——Shift button /Enter button: This button services as shift button when data

are modified and services as enter button when menu is selected.

——Back button / Reset button: This button services as back button when operate

menu to come back parent menu; resetting is carried out by pressing this button for

a little long time when failure shutdowns

Always check power supply before you service the unit. The power

indication light could be in faulty status.

General Information

13

2.7 TECHNICAL DATA

The specification of the models are as follow

Model

Pressure

Capacity

Main Motor

Exhaust connection

Weight

Dimensions

bar

m3/min

KW

kg

mm

GC7.5-8

0.8

1.2

7.5

G3/4

470

800×620×800

GC7.5-8G

0.8

1.2

7.5

G3/4

200

1020×820×1150

GC11-8

0.8

1.7

11

G1

370

1020×820×1150

GC11-10

1.0

1.5

11

G1

370

1020×820×1150

GC11-13

1.3

1.2

11

G1

370

1020×820×1150

GC15-8

0.8

2.4

15

G1

380

1020×820×1150

GC15-10

1.0

2.2

15

G1

380

1020×820×1150

GC15-13

1.3

1.7

15

G1

380

1020×820×1150

GC18-8

0.8

3.0

18

G1 1/2

500

1080×880×1235

GC18-10

1.0

2.7

18

G1 1/2

500

1080×880×1235

GC18-13

1.3

2.3

18

G1 1/2

500

1080×880×1235

GC22-8G

0.8

3.6

22

G1 1/2

560

1410×850×1235

GC22-8

0.8

3.6

22

G1 1/2

540

1410×850×1235

GC22-10

1.0

3.2

22

G1 1/2

540

1410×850×1235

GC22-13

1.3

2.7

22

G1 1/2

540

1410×850×1235

GC30-8

0.8

5.0

30

G1 1/2

650

1120×930×1290

GC30-10

1.0

4.4

30

G1 1/2

650

1120×930×1290

GC30-13

1.3

3.6

30

G1 1/2

650

1120×930×1290

GC37-8G

0.8

6.0

37

G1 1/2

740

1530×900×1435

GC37-8

0.8

6.0

37

G1 1/2

730

1530×1030×1435

GC37-10

1.0

5.5

37

G1 1/2

730

1530×1030×1435

GC37-13

1.3

4.6

37

G1 1/2

730

1530×1030×1435

GC45-8

0.8

7.1

45

G1 1/2

820

1240×1030×1595

GC45-10

1.0

6.5

45

G1 1/2

820

1240×1030×1595

GC45-13

1.3

5.6

45

G1 1/2

820

1240×1030×1595

GC55-8

0.8

9.5

55

G1 1/2

1200

1540×1200×1470

GC55-10

1.0

8.5

55

G1 1/2

1200

1540×1200×1470

GC55-13

1.3

7.4

55

G1 1/2

1470

1540×1200×1470

GC45-8GH

0.8

7.1

45

G1 1/2

970

1700×1050×1255

GC55-8GH

0.8

10.0

55

G1 1/2

1180

1790×1050×1255

GC75-8GH

0.8

13

75

G2

1470

2000×1200×1500

GC90-8GH

0.8

16

90

G2

1520

2000×1200×1500

GC110-8GH

0.8

20

110

G2

2210

2410×1300×1670

GC132-8GH

0.8

22

132

G2

2370

2410×1300×1670

14

Fluid Information

3.1 FLUID GUIDE

GC compressors are filled & tested with Kerry lubricant. Refer Figure 3-1 for filler port,

sightglass, quarter-turn valve location on the reservoir. The compressor is filled with the

manufacturer’s recommended quantity of Kerry fluid. Inspection of the reservoir fluid level

during installation or operation is recommended.

Figure 3-1: Fluid Fill Locatio

Do not use different fluid. Using different fluid will void compressor’s warranty.

3.2 FLUID CHANGE RECOMMENDATIONS

LUBRICANT

FLUID CHANGE

FLUID FILTER

CHANGE

SEPARATOR

CHANGE

Kerry 4000

Or equivalence*

Every 4,000 hours

Every 2,000 hours

Every 3,000 hours

15

Installation

4.1 COMPRESSOR MOUNTING, SUPPORT AND LOCATION

Compressor should be located on a flat surface in a clean, well-lit and well ventilated area.

The location must have sufficient access for maintenance equipment and lifting vehicle.

Four feet (4’) of clearance around the compressor is recommended for daily inspection and

easy access to all compressor components. The area must have sufficient lighting for

technicians to safely operate the compressor as well as perform maintenance work. The

location should be free from standing water.

The compressor’s base must be securely bolted to the floor with lag bolts. Rubber pad with

5 - 15mm thickness or pliable material should be placed under the bottom of the base if

floor surface is uneven or irregular. A stationary compressor will prevent accidents such as

broken piping or electrical connections. Do not over tighten the lag bolts because this may

cause the frame to twist or bind which could results in possible breakage of fluid coolers,

piping and the reservoir.

NOTICE!

Brand new compressor has “Orange Color” shipping bracket installed under

airend assembly. Please remove the bracket after the unit is installed.

Removal or paint over of safety labels will be a safety hazard. This could result in

personal injury or property damage. Warning signs and labels should be conspicuous

and on a bright legible surface. Do not remove any warning, caution or instructional

material attached with unit.

4.2 VENTILATION AND COOLING

Ambient temperature should not exceed 40°C (104°F). High ambient temperatures

may result in high air temperature shutdown.

16

Installation

NOTICE!

Do not install and operate compressor if the ambient temperature is below

5°C (41°F). Pre-heat option must be installed with the unit for lower ambient

temperatures.

The compressor air inlet must be located in the opposite direction to other compressors or

heat generating equipment. The object is to avoid hot air being drawn into the system. Do

not block the exhaust air from cooler or fan. Hot exhaust air must be vented outside through

a duct to prevent high ambient room temperature. The compressor room must be properly

ventilated to avoid compressor high temperature shutdown.

Maintain clean & fresh air, dust free, metal particle free and chemical vapor

free in the compressor’s room. Housing the compressor within a poorly

ventilated enclosure will cause higher operating temperature.

Under no circumstances should a compressor be installed in an area exposed to

toxic, volatile or corrosive atmosphere, nor should toxic, volatile or corrosive

agents be stored near the compressor.

All models are intended for indoor installation; however, it is possible, with certain

modifications, to accommodate some outdoor locations. Models with standard enclosure

are water-resistant but not water tight. Shelter is needed to protect the unit from rain, snow

and freezing temperatures. An optional weather hood or air grille could be installed to

protect compressor against blowing rain and snow as well as cabinet heater additions if

ambient temperature will be below 5°C (41 F).

17

Installation

4.3 PIPING CONNECTION

Before installation, review the complete air systems layout, which includes compressor(s),

receiver tank, dryer(s), line filter(s), pipe size, water drain and isolator valves. Never join

pipes or fittings by soldering. Never use PVC pipe or non-genuine rubber hose in the air

system. Use flexible connections to prevent pipe load from being transmitted to the

compressor. Never use a different pipe size other than the manufacturer specification for

the compressor unit.

A service line shut off valve must be installed after the compressor air outlet connection

with a pressure relief valve installed to release compressed air to the atmosphere. For a

single compressor and air receiver tank, manual shut off valves are typically being installed.

A union connector must be installed after the ball valve (quarter turn, shut off valve) at the

compressed air outlet. This will allow unit isolation for maintenance.

Release system pressure by opening manual pressure relief valve prior to

servicing. Failure to relieve system pressure could result in death or serious

injury and property damage.

The compressor after-cooler comes with an automatic condensate drain. The drain line

should be installed to remove the condensate during compressor operation.

A receiver tank should be installed if compressed air demands fluctuate. Service line piping

is recommended to be sized to match the compressor’s discharge connector. All piping &

fittings should be rated to withstand greater pressure than the discharge pressure. Isolation

valves & drain valves are installed to isolate the compressor when service is required.

These valves should have water drip legs with the drain direction facing downward to the

floor. Piping should all line up properly with an adequate loop radius or bend radius given

for easy installation and to prevent bending stress, flow restriction and damage due to

thermal expansion. Piping support brackets must be mounted independent of the

compressor and motor. This will avoid damage caused by vibration.

18

Installation

Pressure relief valves are sized to protect the system. Never change the pressure setting or

tamper with the valve. Only the valve manufacturer and their authorized representatives are

allowed to make such changes.

Pressure relief valves are used to protect system integrity in accordance with

safety standards. Failure to provide properly sized valves will result in death or

serious injury.

Pressure relief valves are installed prior to any potential blockage point such as shutoff

valves, heat exchangers and discharge silencers. Ideally, the valve should be threaded

directly into the pressure point it is sensing, not connected with tubing or pipe. Always

direct discharge from relief valves to a safe area away from personnel.

4.4 FLUID LEVEL INSPECTION

Inspect the fluid level when the compressor is in shut down mode. Fluid level is indicated

on the reservoir sight glass (see figure 3-1). The maximum fluid level is at the top red-mark.

Add fluid until the top red-mark is reached.

4.5 ELECTRICAL

Before installation, the electrical supply should be checked for adequate wire size and

capacity. User must comply with national & local electrical codes. The codes specify the

surrounding clearance requirement for the electrical panel. Wiring work should be

undertaken only by a qualified electrician in compliance with OSHA, national or local

electrical code. GC compressor provides wiring diagrams for user reference. Refer to the

electrical control schematic in the parts manual for wiring diagrams. Genuine fused

disconnect switch or circuit breaker should be purchased from the manufacturer. Any

unreasonable voltage imbalance (5%) between phases must be eliminated and low voltage

problems must be corrected to prevent excessive current draw. Air compressors must be

grounded in accordance with applicable codes, regulations and requirement.

Installation

Table of contents

Popular Air Compressor manuals by other brands

Elektra Beckum

Elektra Beckum Basic 270 Handleiding

Johnson Controls

Johnson Controls SAB 355 Engineering manual

EINHELL

EINHELL 40.206.55 Original operating instructions

Scheppach

Scheppach HC55 Translation from the original instruction manual

Solid State Logic

Solid State Logic THE BUS+ quick start guide

Becker

Becker KDT 3.100 operating instructions

General Air Products

General Air Products L20033 Installation, operation and maintenance manual

Airpress

Airpress HLO 215/25 operating instructions

Sealey

Sealey Professional AB900 instructions

VITO

VITO PRO-POWER VIBCPCSFL20 instruction manual

Vixen Horns

Vixen Horns VXC8301B installation guide

Atlas Copco

Atlas Copco GA5 user manual