Datron 1062 How to use

rrControl #-106637 Control Date -05/1 5,^2000

Mfg -DATRON

Model/'Series -1062, 1061A, 1061

Document T}pe -Calibration &Servicing Handbook

Note -Digital Multimeter

s

0

0

.13

0

Q

a

li

CALIBRATON

AND

SERVICING

HANDBOOK

10B1A10B1

^INS'C RUM

Idigital multimeter

CALIBRATION AND SERVICING

HANDBOOK

for

THE DATRON AUTOCAL 1062, 1061Aand 1061

DIGITAL MULTIMETERS

(The calibration and servicing information in this Handbook applies equaily to the

Autocal instruments 1061, 1061 Aand 1062.

For operating procedures refer to the User's Handbook.

850045 Issue

For any assistance contact your nearest Datron Sales and Service center.

Addresses can be found at the back of this handbook.

Due to our policy of continuously updating our products, this handbook may contain minor differences in specification, components and

circuit design to the instrument actually supplied. Amendment sheets precisely matched to your instrument serial number are available

on request.

:1984 Datron Instruments

I

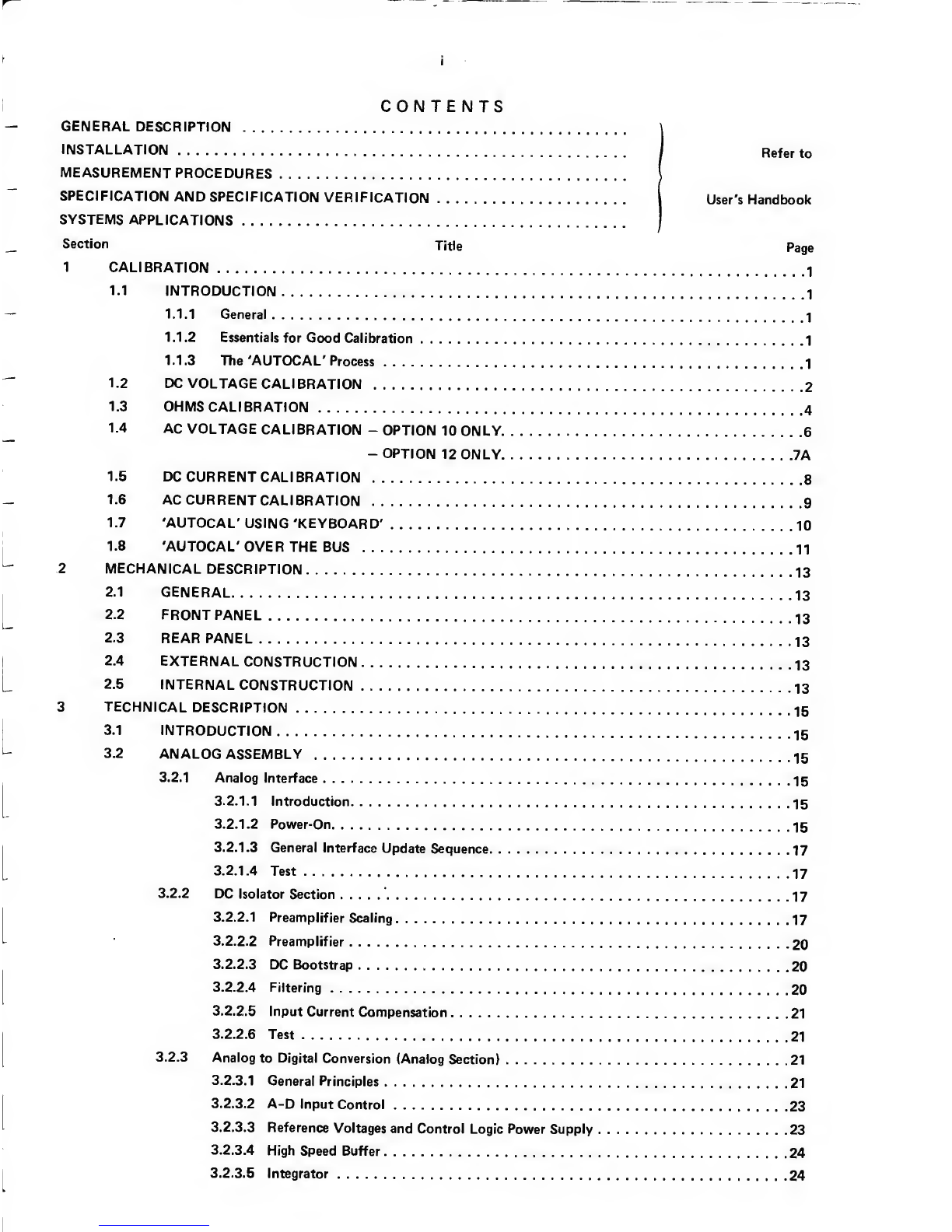

CONTENTS

GENERAL DESCRIPTION \

INSTALLATION 1Refer to

MEASUREMENT PROCEDURES (

SPECIFICATION AND SPECIFICATION VERIFICATION 1User's Handbook

SYSTEMS APPLICATIONS )

Section Title Page

1CALIBRATION

1.1 INTRODUCTION

1.1.1 General

1.1.2 Essentials for Good Calibration 1

1.1.3 The 'AUTOCAL' Process 1

1.2 DC VOLTAGE CALIBRATION 2

1.3 OHMS CALIBRATION 4

1.4 AC VOLTAGE CALIBRATION -OPTION 10 ONLY 6

-OPTION 12 ONLY 7A

1.5 DC CURRENT CALIBRATION 8

1.6 AC CURRENT CALIBRATION 9

1.7 'AUTOCAL' USING 'KEYBOARD' 10

1.8 'AUTOCAL' OVER THE BUS 11

2MECHANICAL DESCRIPTION 13

2.1 GENERAL 13

2.2 FRONT PANEL 13

2.3 REAR PANEL 13

2.4 EXTERNAL CONSTRUCTION 13

2.5 INTERNAL CONSTRUCTION 13

3TECHNICAL DESCRIPTION 15

3.1 INTRODUCTION 15

3.2 ANALOG ASSEMBLY 15

3.2.1 Analog Interface 15

3.2.1. 1Introduction 15

3.2. 1.2 Power-On 15

3.2.1. 3General Interface Update Sequence 17

3.2.1.4Test 17

3.2.2 DC Isolator Section '17

3.2.2.1 Preamplifier Scaling 17

3.2.2.2 Preamplifier 20

3.2.2.3 DC Bootstrap 20

3.2.2.4 Filtering 20

3.2.2.5 Input Current Compensation 21

3.2.2.B Test 21

3.2.3 Analog to Digital Conversion (Analog Section) 21

3.2.3.1 General Principles 21

3.2.3.2 A-D Input Control 23

3.2.3.3Reference Voltages and Control Logic Power Supply 23

3.2.3.4 High Speed Buffer 24

3.2.3.5 Integrator 24

ii

Section Title Page

3.2.3.6 1st Null Detector 25

3. 2.3.7 2nd Null Detector 25

3. 2. 3.8Reset Period 25

3.3 OPTION 10 AC ASSEMBLY 27

3.3.1 General Principles 27

3.3.2 Preamplifier and Scaling 27

3.3.3 RMS Converter 28

3.3.4 High Frequency Compensation 29

3.3.5 Frequency Detection 29

3.3.6 Test 29

A3.3 OPTION 12 AC ASSEMBLY A27

A3.3.1 General Principles A27

A3.3.2Preamplifier and Scaling A27

A3.3.3RMS Converter A28

A3.3.4 High Frequency Compensation A29

A3.3. 5Frequency Detection A29

A3.3.6 Test A29

3.4 OHMS ASSEMBLY 30

3.4.1 Low Drift Voltage Follower 30

3.4.2 Constant Current Source 30

3.4.3 Test 31

3.5 CURRENT ASSEMBLY 31

3.5.1 Current Measurements 32

3.5.2 Test 32

3.6 REAR INPUT/RATIO INPUT 32

3.6.1 General 32

3.6.2 Front Panel/Rear Panel Input 32

3.6.3 Ratio 32

3.6.4 Test 33

3.7 ANALOG OUTPUT 33

3.7.1 General 33

3.7.2 Description 33

3.8 DIGITAL ASSEMBLY 33

3.8.1 Processor and Memory 33

3.8. 1.1 Software Overview 34

3.8.1 .2 The Two-Phase Clock 35

3.8.1.3 RAM/ROM Circuit 36

3.8.2 CMOS Address Decode and Input/Output Circuits 36

3.8.3 Analog to Digital Conversion (Digital Section) 39

3.8.3.1 General Principle 39

3.8.3.2 Preset Procedure 39

3. 8.3.3A-D Measurement Sequence 41

3. 8. 3.4Master Clock and Line Locking 41

II

Section Title Page

3.9 FRONT PCB ASSEMBLY 42

3.9.1 Analog Input Signals 42

3.9.2 Display Signals 42

3.9.3 Keyboard Data Encode 42

3.9.4 Keyboard LED Data Decode 43

3.10 DISPLAY DRIVER ASSEMBLY 45

3.10.1 Write Mode 45

3.10.2 Read Mode 45

3.11 IEEE DIGITAL INTERFACE 46

3.11.1 ROM Circuit 46

3.11.2 Interface Circuit 46

3.12 BCD DIGITAL INTERFACE

3.12.1 RAM/ROM Circuit

3.12.2 Interface Circuit

3.13 REAR (POWER SUPPLY) PCB ASSEMBLY 48

3.13.1 General

3.13.2 180V Supply 48

3.13.3 5V Supply 48

3.13.4 ±15V Supply 48

3.14 SELF TEST SEQUENCE 48

4INTERNAL ADJUSTMENT PROCEDURES 51

4.1 ALTERATION OF LINE VOLTAGE AND FREQUENCY 51

4.1.1 Changing Line Voltage 51

4.1.2 Changing Line Frequency 51

4.2 BATTERY REPLACEMENT 51

4.3 POST-REPAIR PROCEDURES 51

4.3.1 Basic DC Instrument 52

4.3.2 Ohms Assembly 5^

4.3.3 AC Assembly (Option 10) 54

4.3.4 AC Assembly (Option 12) 55

APPENDIX 1ANALOG DATA LINE 'F.E.T.' PATTERNS 57

IV

Section Title Page

5COMPONENT LISTS, BOARD LAYOUTS AND CIRCUIT DIAGRAMS

Interconnection Diagram 430291

Front PCB Assembly 400294/430294

Rear PCB Assembly 400295/430295

Centre PCB Assembly 400296/430296

Left Hand PCB Assembly 400297/430297

Right Hand PCB Assembly 400298/430298

Current Assembly 400304/430304

Ratio/Rear Input 400307/430307

Analog Output 400308/430308

Analog Assembly 400328/430328

Digital Assembly 400329/430329

Display Driver Assembly 400330/430330

Ohms Assembly 400331/430331

BCD Interface Assembly 400332/430332

Rear Input 400386/430386

AC Assembly (Option 10) 400402/430402

IEEE Interface Assembly 400427/430427

AC Assembly (Option 12) 400552/430552

IEEE 488 Option kit 440082/83/84

ILLUSTRATIONS AND TABLES

Figure Title Page

1.1 Zero Resistance Source Connections 4

2.1 Exploded View of Instrument 14

3.1 Printed Circuit Boards Block Diagram 15

3.2 Power-On Options Fitted Test 16

3.3 Analog Interface Sequence; Power-Up 16

3.4 Analog Interface Data Line Timing Diagram (Power-Up) 16

3.5 Analog Interface Sequence: Ohms Select 17

3.6 General Form of Analog Interface Update Timing Diagram 18

3.7 Simplified Diagram of DC Isolator 18

3.8 Simplified Diagram of Isolator Switching 19

3.9 Preamplifier Gain Circuits 20

3.10 Simplified DC Isolator Filtering Circuit 21

3.11 Simplified Diagram of Bias Current Compensation 21

3.12 Simplified Diagram of Analog Section of A-D Converter 22

3.13 Timing Diagram For Analog Section of A-D Converter 22

3.14 Multiplexer Control Line Signals 23

3.15 Positive Reference Circuitry 23

3.16 High Speed Buffer Circuitry 24

3.17 Integrator Circuit 24

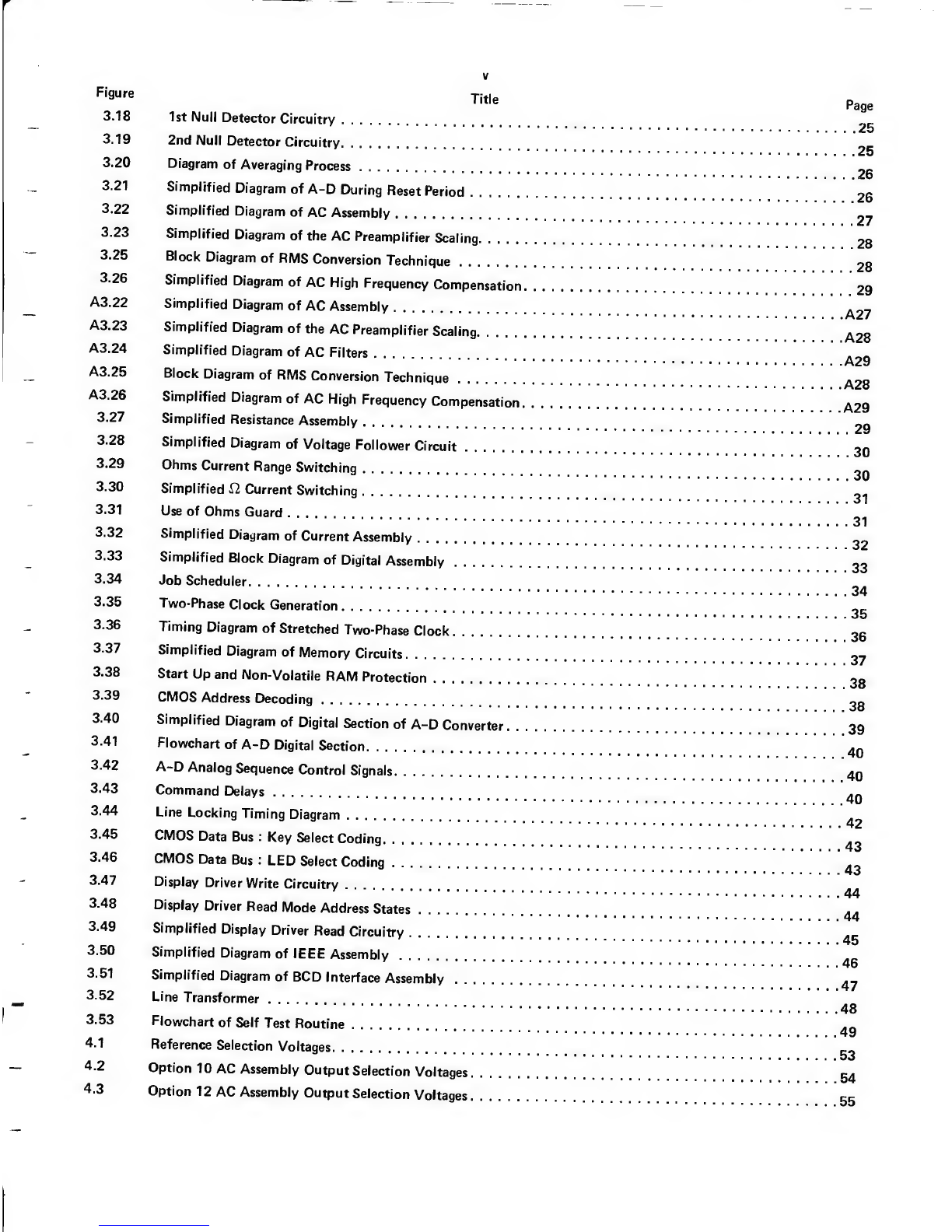

V

Figure

3.18

Title

1st Null Detector Circuitry ...

Page

3.19 2nd Null Detector Circuitry. ...

3.20 Diagram of Averaging Process ..Oft

3.21 Simplified Diagram of A-D During Reset Period Oft

3.22 Simplified Diagram of AC Assembly .0*7

3.23 Simplified Diagram of the AC Preamplifier Scaling OR

3.25 Block Diagram of RMS Conversion Technioue . . OR

3.26 Simplified Diagram of AC High Frequency Compensation oq

A3.22 Simplified Diagram of AC Assembly A0"7

A3. 23 Simplified Diagram of the AC Preamplifier Scaling AOQ

A3. 24 Simplified Diagram of AC Filters ...

A3.25 Block Diagram of RMS Conversion Technioue AOQ

A3.26

3.27

Simplified Diagram of AC High Frequency Compensation

Simplified Resistance Assembly ..OQ

3.28 Simplified Diagram of Voltage Follower Circuit .. . on

3.29 Ohms Current Range Switching ...on

3.30 Simplified 12 Current Switching ..01

3.31 Use of Ohms Guard ....

3.32 Simplified Diagram of Current Assembly oo

3.33 Simplified Block Diagram of Digital Assembly oo

3.34 Job Scheduler

3.35 Two-Phase Clock Generation ....

3.36 Timing Diagram of Stretched Two-Phase Clock Oft

3.37 Simplified Diagram of Memory Circuits oo

3.38 Start Up and Non-Volatile RAM Protection OR

3.39 CMOS Address Decoding . . .OR

3.40 Simplified Diagram of Digital Section of A-D Converter ."iq

3.41 Flowchart of A-D Digital Section. .An

3.42 A-D Analog Sequence Control Signals. ., , 40

3.43 Command Delays .... An

3.44 Line Locking Timing Diagram ,

3.45 CMOS Data Bus *K©v Salect Codinc| A*y

3.46 CMOS Data Bus :LED Select Coding .

3.47 Display Driver Write Circuitry ..

3.48 Display Driver Read Mode Address States .AA

3.49 Simplified Display Driver Read Circuitry AC

3.50 Simplified Diagram of IEEE Assembly

3.51 Simplified Diagram of BCD Interface Assembly ...>IO

3.52 Line Transformer

3.53 Flowchart of Self Test Routine ^Q

4.1 Reference Selection Voltages. ...

4.2 Option 10 AC Assembly Output Selection Voltages ..ft/1

4.3 Option 12 AC Assembly Output Selection Voltages

1

SECTION 1

CALIBRATION

1.1 INTRODUCTION

1.1.1 General

The purpose of calibration is to take account of any

long-term drifts in the components of the instrument and

to restore the accuracy, traceable to aknown standard.

The period between calibrations depends upon the

accuracy performance required from the instrument and for

guidance, guaranteed accuracies for 24 hours, 90 days and

1year are quoted.

The calibration procedures presented in the following

pages should cater for most calibration situations. If, how-

ever, aspecial problem arises, please contact our Customer

Service Section.

1.1.2

The Essentials for Good Calibration

Temperature -So that the instrument can meet its

specification over the quoted temperature range, the temp-

erature environment should be stabilised at 230C ±1oc.

In addition, temperature gradients around the instrument

should be considered, therefore calibrate the instrument in

its normal operating position and allow plenty of room for

ventilation.

Warm up -It is essential that the instrument has

fully temperature stabilised if the best results from cali-

bration are to be achieved. Therefore, at least a2hour

warm-up period is recommended during which time the

line supply or the covers should not be removed even for a

short period. In addition, if the covers have been removed,

make certain that they are correctly fitted and that the leaf

contacts to the Earth and Guard Shields are in good shape.

Calibration Source -To perform auseful calibration

the accuracy of the source should always be at least four

times that of the instrument being calibrated. In most

cases, examples of likely sources are given for each cali-

bration function.

With some calibration sources, the output may take

several seconds to settle to afinal value, therefore unless

ashorter settling time is assured, aperiod of 10 seconds is

'ecommended before each calibration operation.

Guarding -It is preferable to arrange for the DVM

to be calibrated with 'Local Guard' selected. Furthermore

to arrange for the 'Lo' terminal of the DVM to remain at

'earth' throughout and let the calibration source float.

If a'Remote Guard' connection is necessary then examples

are shown in the Operating Manual.

1.1.3

The 'AUTOCAL' Process

1.1.3.1 General

The Datron 'AUTOCAL' process means that complete

calibration of AC, DC, Ohms and Current on every range

can be carried out from the instruments own front panel.

In the process, an internal non-volatile memory stores

calibration constants for each function and range as deter-

mined when the instrument takes aseries of 16 readings of

the applied calibration source. Internally, each of the

readings is deviated by one sixteenth of adigit and when

an average is taken, the instrument is able to resolve to

better than one least significant digit displayed.

Access to the non-volatile memory is gained using

akey inserted into the rear panel. When calibration is

complete, the key is removed, therefore preventing acci-

dental or unauthorised use of the calibration routine.

1.1.3.2Procedure Outline

-Select the 'FUNCTION' and 'RANGE' to be cali-

brated and cancel any 'MODE' or 'COMPUTE' buttons.

Insert the key into the 'CALIBRATE ENABLE'

keyswitch on the rear panel and turn to the 'CAL' position.

(The 'cal' legend will be displayed on the front panel.)

If the instrument is fitted with Option 50 IEEE Bus,

set the rear panel address switch to 31 i.e. all 1's.

-Connect the calibration source to the input terminals

and operate the keys shown in the tables in the following

pages. When a'CALIBRATE' button is operated, its assoc-

iated L.E.D. indicator will light and extinguish when the

calibration operation is executed.

-When all calibration is complete turn the keyswitch

to 'RUN' and remove the key.

1.1.

3.3

The Five 'AUTOCAL' Keys

'Zero' -This takes account of offsets in the instrument

and in the calibration source.

'Gain' -This sets ascaling factor for each range and

function.

Ib -This nulls the input bias current of the DC

voltage measurement circuits to around lOpA. Therefore

it only has asignificant effect on the low DC voltage ranges

and high resistance Ohms ranges. It can be operated as

often as required and independently of other calibration

operations. It will be seen that successive operations of 'Ib'

approach the final nulled value of current iteratively.

2

'AcHf' -This flattens the response of the A.C. ampli-

fier used for AC voltage measurement. It should only be

used when afull calibration i.e. 'Zero', 'Gain' and 'AcHf'

is carried out. As with 'lb' the calibration action is iterative

and requires several operations of the key to complete.

'Lin' -This is an important calibration operation as

it optimises the basic linearity of the internal measurement

circuitry used for all ranges and functions. It must be used

before any DC voltage or Ohms calibration is carried out.

1. 1.3.4 'AUTOCAL' using 'KEYBOARD'

This is an extension of the 'AUTOCAL' process

which is useful when using acalibration source set to a

nominal value but with known errors. This means for

example that calibration directly to astandard cell is

possible. Afull explanation of the procedure is covered

in section 1.7.

1. 1.3.5 'AUTOCAL' over the Bus

Each of the five calibration operations can be control-

led using Option 50, the IEEE bus. This means that the

instrument can be entirely calibrated remotely or under

program control. As mentioned in the 'Procedure Outline'

for amanual calibration, the rear panel address switch

should be set to 31, i.e. all 1's. When abus calibration is

required the address switch must be set to the address

number assigned to the DVM in the system. More details

of calibration with the bus are included in section 1.8.

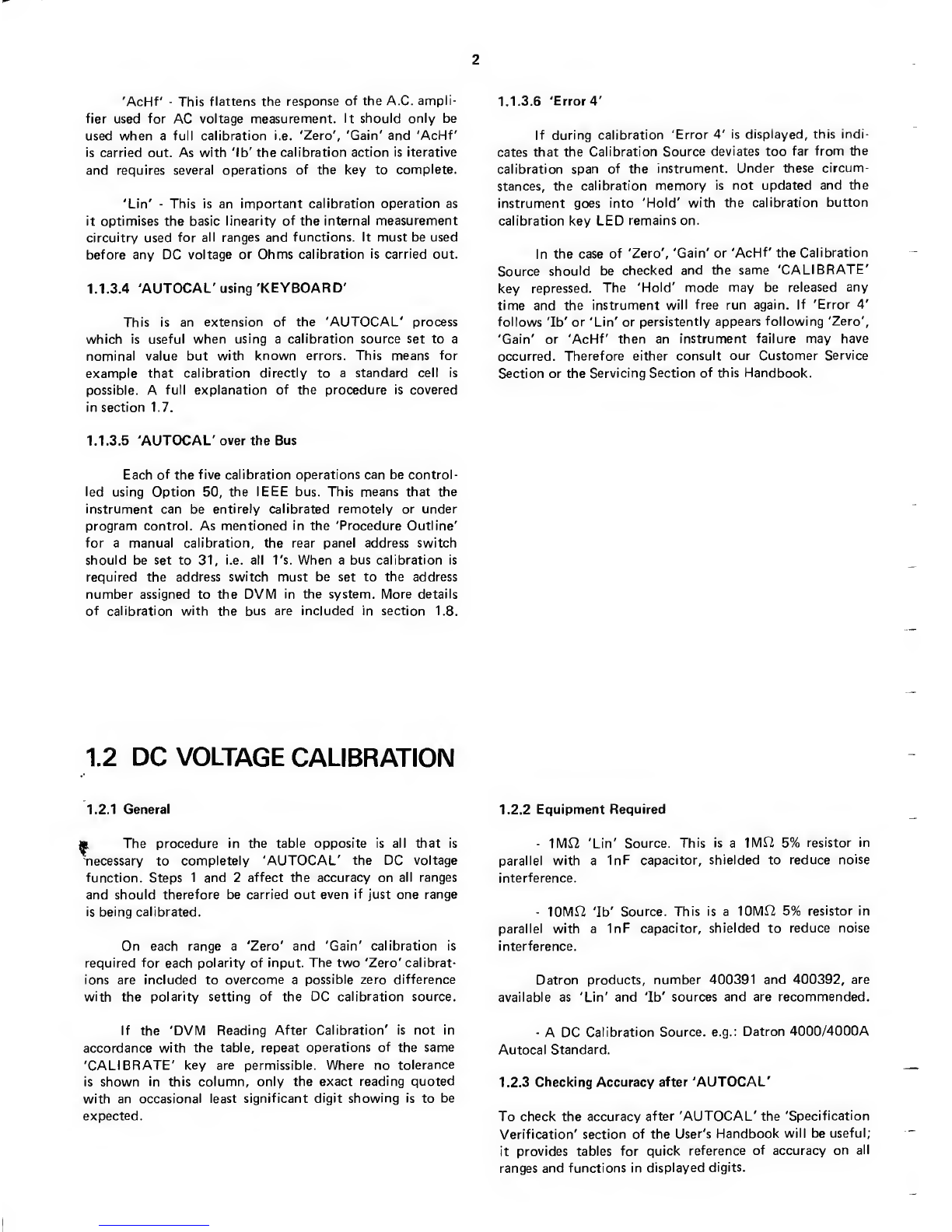

1.2 DC VOLTAGE CALIBRATION

1.2.1

General

^The procedure in the table opposite is all that is

'necessary to completely 'AUTOCAL' the DC voltage

function. Steps 1and 2affect the accuracy on all ranges

and should therefore be carried out even if just one range

is being calibrated.

On each range a'Zero' and 'Gain' calibration is

required for each polarity of input. The two 'Zero' calibrat-

ions are included to overcome apossible zero difference

with the polarity setting of the DC calibration source.

If the 'DVM Reading After Calibration' is not in

accordance with the table, repeat operations of the same

'CALIBRATE' key are permissible. Where no tolerance

is shown in this column, only the exact reading quoted

with an occasional least significant digit showing is to be

expected.

1.

1.3.6

'Error 4'

If during calibration 'Error 4' is displayed, this indi-

cates that the Calibration Source deviates too far from the

calibration span of the instrument. Under these circum-

stances, the calibration memory is not updated and the

instrument goes into 'Hold' with the calibration button

calibration key LED remains on.

In the case of 'Zero', 'Gain' or 'AcHf' the Calibration

Source should be checked and the same 'CALIBRATE'

key repressed. The 'Hold' mode may be released any

time and the instrument will free run again. If 'Error 4'

follows 'Ib' or 'Lin' or persistently appears following 'Zero',

'Gain' or 'AcHf' then an instrument failure may have

occurred. Therefore either consult our Customer Service

Section or the Servicing Section of this Handbook.

1.2.2 Equipment Required

-1M12 'Lin' Source. This is aIMfi 5% resistor in

parallel with aInF capacitor, shielded to reduce noise

interference.

-10MJ2 'Ib' Source. This is alOMfi 5% resistor in

parallel with aInF capacitor, shielded to reduce noise

interference.

Datron products, number 400391 and 400392, are

available as 'Lin' and 'Ib' sources and are recommended.

-ADC Calibration Source, e.g.: Datron 4000/4000A

Autocal Standard.

1.2.3 Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the 'Specification

Verification' section of the User's Handbook will be useful;

it provides tables for quick reference of accuracy on all

ranges and functions in displayed digits.

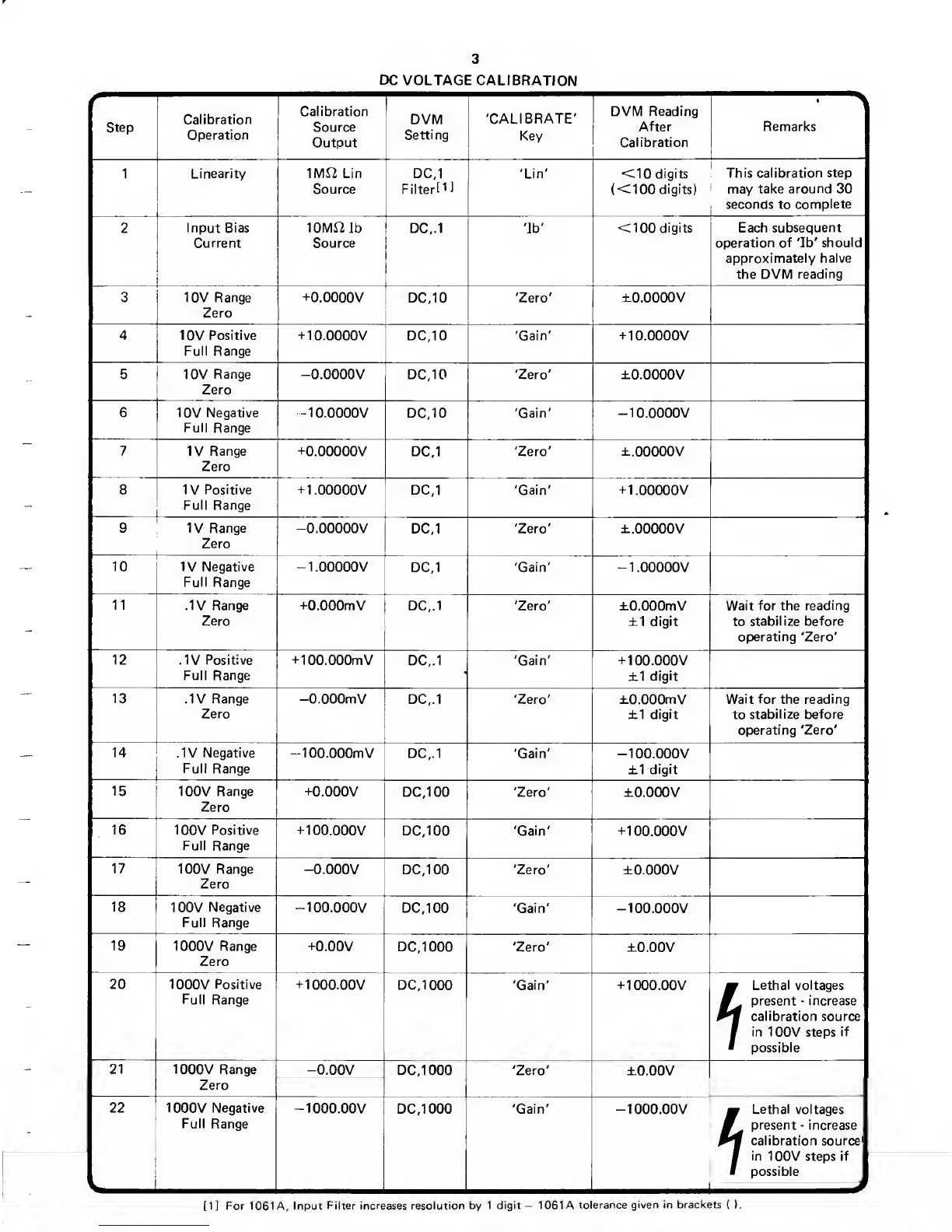

3

DC VOLTAGE CALIBRATION

-Step Calibration

Operation

Calibration

Source

Output

DVM

Setting

'CALIBRATE'

Key

DVM Reading

After

Calibration

Remarks

—1Linearity 1M12 Lin

Source DC,1

FilterMI

'Lin' <10 digits

(<100 digits)

This calibration step

may take around 30

seconds to complete

2Input Bias

Current 10Mi2 Ib

Source DC,.1 'Ib' <100 digits Each subsequent

operation of 'Ib' should

approximately halve

the DVM reading

310V Range

Zero +0.0000V DC, 10 'Zero' tO.OOOOV

410V Positive

Full Range +10.0000V DC,10 'Gain' +10.0000V

510V Range

Zero -O.OOOOV DC,10 'Zero' ±0.0000V

610V Negative

Full Range -10.0000V DC,10 'Gain' -10.0000V

7IV Range

Zero +0.00000V DC,1 'Zero' ±.00000

V

8IV Positive

Full Range +1.00000V DC,1 'Gain' +1.00000V

gIV Range

Zero -O.OOOOOV DC,1 'Zero' ±.00000

V

10 IV Negative

Full Range -1.00000V DC,1 'Gain' -1.00000V

-

11 IV Range

Zero +0.000mV DC,.1 'Zero' ±0.000mV

±1 digit

Wait for the reading

to stabilize before

operating 'Zero'

12 •IV Positive

Full Range +100.000mVDC,.1 'Gain' +100.000V

±1 digit

13 IV Range

Zero -O.OOOmV DC,.1 'Zero' ±0.000mV

±1 digit

Wait for the reading

to stabilize before

operating 'Zero'

—14 ,1V Negative

Full Range -1 00.000mVDC,.1 'Gain' -100.000V

±1 digit

15 100V Range

Zero +O.OOOV DC,100 'Zero' iO.OOOV

16 100V Positive

Full Range +100.000V DC,100 'Gain' +100.000V

—17 100V Range

Zero -o.ooov DC,100 'Zero' ±0.000V

18 100V Negative

Full Range -100.000V DC, 100 'Gain' -100.000V

—19 1000V Range

Zero +0.00V DC,1000 'Zero' ±0.00V

-

20 1000V Positive

Full Range +1000.00V DC,1000 'Gain' +1000.00V mLethal voltages

mpresent -increase

calibration source

fin 100V steps if

possible

—21 1000V Range

Zero -0,00V DC, 1000 'Zero' ±o.oov

-

22 1000V Negative

Full Range -1000.00V DC,1000 'Gain' -1000.00V mLethal voltages

Mpresent -increase

calibration source'

fin 100V steps if

fpossible

[1] For 1061 A, Input Filter increases resolution by 1digit —1061 Atolerance given in brackets ().

4

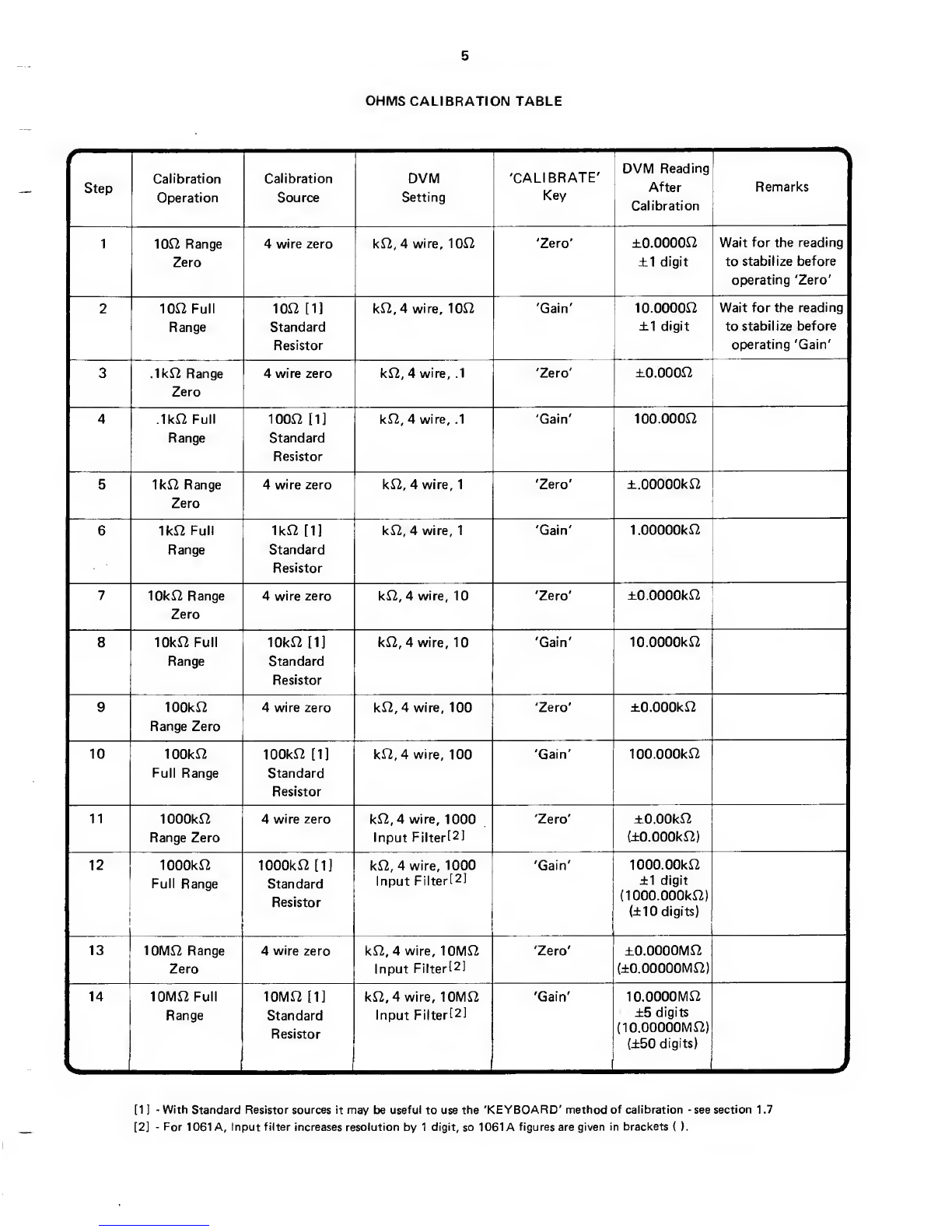

1.3 OHMS CALIBRATION

1.3.1

General

The procedure in the table opposite is all that is

necessary to completely 'AUTOCAL' the Ohms function.

If just the Ohms or just one range of the Ohms is to be

calibrated, then steps 1and 2in the DC Voltage Calibration

table should be carried out first. Then on each Ohms range

just a'Zero' and 'Gain' calibration is required.

If the 'DVM Reading After Calibration' is not in

accordance with the table, repeat operations of the same

'CALIBRATE' key is permissible to improve the reading.

Where no tolerance is shown in this column, only the exact

reading quoted with an occasional least significant digit

showing is to be expected.

1.3.2 'Zero' Resistance Source

For accurate 'Zero' calibration on Ohms it is

ESSENTIAL that acorrectly connected zero source is used.

Two arrangements are necessary as shown in Fig. 1.1;

it can be seen that '4 wire J2' selection is recommended on

all ranges.

1.3.3 Equipment Required

Aset of resistance standards from lOfil to lOMO in

decades; it is essential that 10J2 to lOOkfi standards are

4terminal devices, e.g. Datron 4000/4000A Autocal

Standard with Option 20.

1.3.4 Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the 'Speci-

fication Verification' section of the Operating Handbook

will be useful. It provides tables for quick reference of

accuracy on all ranges and functions in displayed digits.

5

OHMS CALIBRATION TABLE

r

Step Calibration

Operation

Calibration

Source

DVM

Setting

'CALIBRATE'

Key

DVM Reading

After

Calibration

’

Remarks

110J2 Range

Zero

4wire zero kl2, 4wire, 1012 'Zero' ±0.000012

±1 digit

Wait for the reading

to stabilize before

operating 'Zero'

210S2 Full

Range

10O [1]

Standard

Resistor

kl2, 4wire, 1012 'Gain' 10.000012

±1 digit

Wait for the reading

to stabilize before

operating 'Gain'

3,1kJ2 Range

Zero

4wire zero kl2, 4wire, .1 'Zero' ±0.00012

4.1kl2 Full

Range

10012 [1]

Standard

Resistor

kl2, 4wire, .1 'Gain' 100.00012

51kJ2 Range

Zero

4wire zero kl2, 4wire, 1'Zero' ±.00000kl2

61kJ2 Full

Range

1kl2 [1]

Standard

Resistor

kl2, 4wire, 1'Gain' 1.00000kl2

7lOkfi Range

Zero

4wire zero kl2, 4wire, 10 'Zero' ±0.0000kl2

8lOkfi Full

Range

10kl2 [1]

Standard

Resistor

kl2, 4wire, 10 'Gain' 10.0000kl2

9100kJ2

Range Zero

4wire zero kl2, 4wire, 100 'Zero' ±0.000kl2

10 100kS2

Full Range

100kl2 [1]

Standard

Resistor

kl2, 4wire, 100 'Gain' 100.000kl2

11 1000kS2

Range Zero

4wire zero kl2,4 wire, 1000

Input Filter[2]

'Zero' ±0.00kl2

(±0.000kl2)

12 1000k^2

Full Range

1000kl2 [1]

Standard

Resistor

kl2, 4wire, 1000

Input Filter[2l

'Gain' 1000.00kl2

±1 digit

(1000.000kl2)

(±10 digits)

13 10MJ2 Range

Zero

4wire zero kl2, 4wire, 10M12

Input Filter(2]

'Zero' ±0.0000M12

(±O.OOOOOM12)

14 10MJ7 Full

Range

10M12 [1]

Standard

Resistor

kl2, 4wire, 10M12

Input Filter[2]

'Gain' 10.0000M12

±5 digits

(10.00000M12)

(±50 digits)

[1 ]-With Standard Resistor sources it may be useful to use the 'KEYBOARD' method of calibration -see section 1.7

[2] -For 1061 A, Input filter increases resolution by 1digit, so 1061 Afigures are given in brackets ().

6

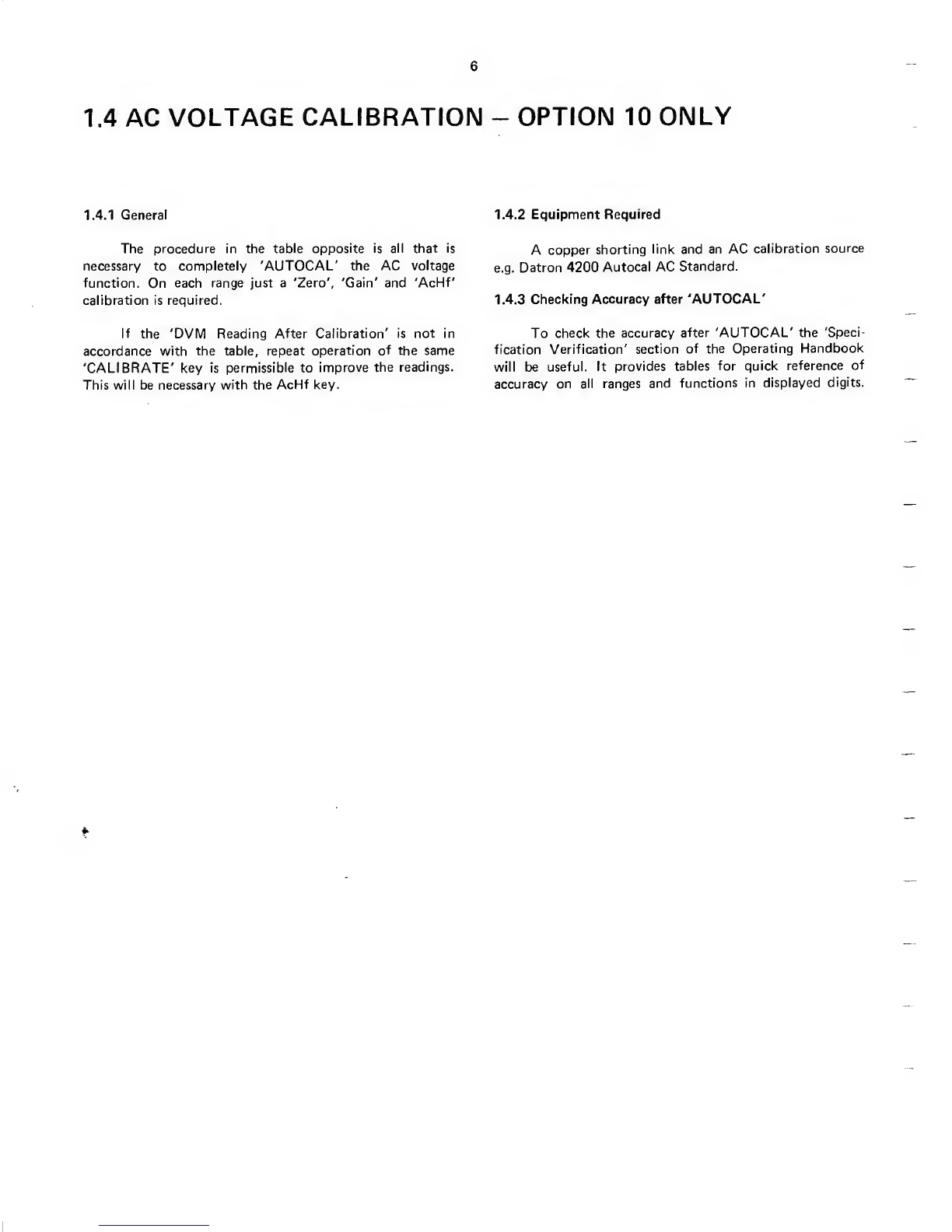

1.4 AC VOLTAGE CALIBRATION -OPTION 10 ONLY

1.4.1

General

The procedure in the table opposite is all that is

necessary to completely 'AUTOCAL' the AC voltage

function. On each range just a'Zero', 'Gain' and 'AcHf'

calibration is required.

If the 'DVM Reading After Calibration' is not in

accordance with the table, repeat operation of the same

'CALIBRATE' key is permissible to improve the readings.

This will be necessary with the AcHf key.

1.4.2 Equipment Required

Acopper shorting link and an AC calibration source

e.g. Datron 4200 Autocal AC Standard.

1.4.3 Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the 'Speci-

fication Verification' section of the Operating Handbook

will be useful. It provides tables for quick reference of

accuracy on all ranges and functions in displayed digits.

7

Calibration

Operation

DC coupled

AC Zero

Calibration

Source

Output

Copper

Shorting link

DVM

Setting

AC,DC,.1

'CALIBRATE'

Key

'Zero'

1000V Full

Range HF 1000V rms

20kHz AC,1000

Input filter

'AcHf'

DVM Reading

After

Calibration

O.OOOmV

±3 digits

2.IV Range

Zero

Copper

Shorting link

AC,.1 Check only <100 digits

3IV Range

Zero

Copper

Shorting link

AC,1 'Zero' .OOOOOV

±1 digit

410V Range

Zero

Copper

Shorting link

AC,10 'Zero' O.OOOOV

±1 digit

5100V Range

Zero

Copper

Shorting link

AC,100 'Zero' O.OOOV

±1 digit

61000V Range

Zero

Copper

Shorting link

AC,1000 'Zero' O.OOV

±1 digit

710V Full

Range LF 10V rms

500 Hz AC,10

Input Filter

'Gain' 10.0000V

±1 digit

810V Full

Range HF 10V rms

30 kHz AC, 10

Input filter

'AcHf' 10.0000V

±5 digits

9IV Full

Range LF IV rms

500Hz AC,1

Input filter

'Gain' 1.00000V

±1 digit

10 IV Full

Range HF IV rms

30 kHz AC,1

Input filter

'AcHf' 1.00000V

±5 digits

11 .IV Full

Range LF .IV rms

500 Hz AC,.1

Input filter

'Gain' 100.000mV

±2 digits

12 .IV Full

Range HF .IV rms

30 kHz AC,.1

Input filter

'AcHf' 10O.OOOmV

±5 digits

13 100V Full

Range LF

10OV rms

500 Hz AC, 100

Input filter

'Gain' 100.000V

±1 digit

14 100V Full

Range HF 100V rms

30 kHz AC,100

Input filter

'AcHf 100.000V

±5 digits

15 1000V Full

Range LF 1000V rms

500 Hz AC, 1000

Input filter

'Gain' 1000.00V

±1 digit

1000.00V

±5 digits

Remarks

Set 'Local Guard'. Do

not set 'Input filter'.

Wait for reading to

stabilize before

operating 'Zero'

Select 'Input filter'

for remaining steps

Lethal voltage

present. -increase

calibration source

in 10OV steps if

possible

Lethal voltage

present -increase

calibration source

in 100V steps if

possible. DO

NOT EXCEED

25 kHz

7A

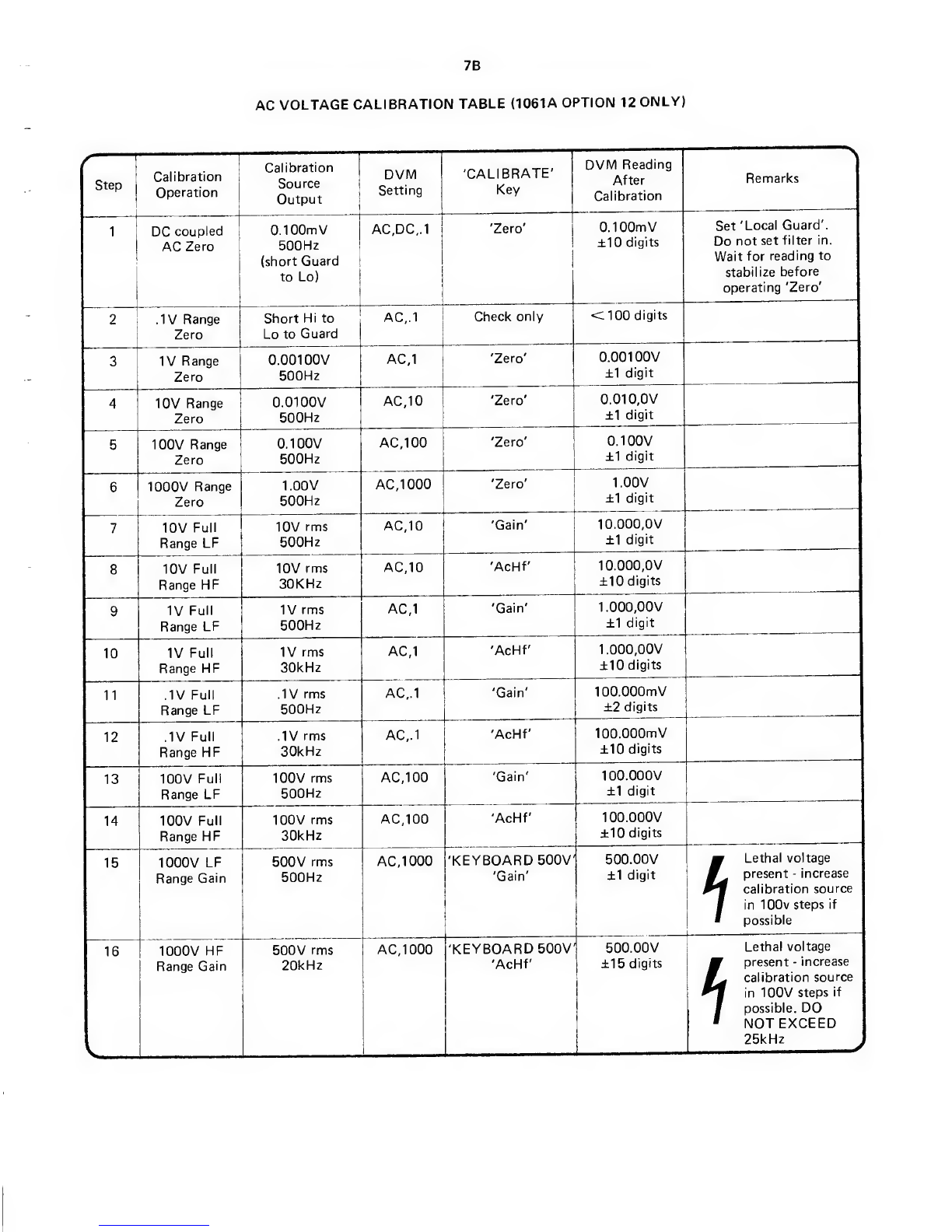

1.4 AC VOLTAGE CALIBRATION -1061 AOPTION 12 ONLY

1

.4.4

General

The procedure in the table opposite is all that is

necessary to completely 'AUTOCAL' the AC voltage

function. On each range just a'Zero', 'Gain' and 'AcHf'

calibration is required.

If the 'DVM Reading After Calibration' is not in

accordance with the table, repeat operation of the same

'CALIBRATE' key is permissible to improve the readings.

This will be necessary with the AcHf key.

Note; To reduce the effect of noise at low input levels, AC

zero calibration is carried out at 0.1% Range; and for

lOOmV Range zero (steps 1&2of the table). Guard is

connected to Lo using acopper shorting link.

1.4.5 Equipment Required

Acopper shorting link and an AC calibration source

e.g. Datron 4200 Autocal AC Standard.

1.4.6 Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the 'Specif-

ication Verification' section of the User's Handbook can

be employed. It describes the use of 'Spec' mode to verify

the accuracy of the instrument, also providing areport

sheet 'master copy' for compilation of permanent records.

7B

AC VOLTAGE CALIBRATION TABLE (1061A OPTION 12 ONLY)

Calibration

Operation

DC coupled

AC Zero

.IV Range

Zero

IV Range

Zero

10V Range

Zero

100V Range

Zero

1000V Range

Zero

10V Full

Range LF

10V Full

Range HF

IV Full

Range LF

IV Full

Range HF

.IV Full

Range LF

.IV Full

Range HF

100V Full

Range LF

100V Full

Range HF

1000V LF

Range Gain

I1000V HF

jRange Gain

Calibration

Source

Output

O.IOOmV

500Hz

(short Guard

to Lo)

Short Hi to

Lo to Guard

0.00100V

500Hz

0.0100V

500Hz

0.100V

500Hz

1.00V

500Hz

10V rms

500Hz

10V rms

30KHZ

IV rms

500Hz

IV rms

30kHz

.IV rms

500Hz

.IV rms

30kHz

100V rms

500Hz

100V rms

30kHz

500V rms

500Hz

500V rms

20kHz

DVM

Setting

AC,DC,.1

AC, 10

AC, 100

AC, 1000

AC, 10

AC, 10

AC,100

AC, 100

'CALIBRATE'

Key

'Zero'

Check only

'Zero'

'Zero'

'Gain'

'AcHf'

'Gain'

'AcHf'

'Gain'

'Gain'

'AcHf'

AC,1000 'KEYBOARD 500V'

'Gain'

DVM Reading

After

Calibration

O.IOOmV

±10 digits

<C100 digits

0.00100V

±1 digit

0.010,0V

±1 digit

0.100V

±1 digit

1.00V

±1 digit

10.000,0V

±1 digit

10.000.

0V

±10 digits

1

.000.

00V

±1 digit

1.000,00V

±10 digits

100.000mV

±2 digits

100.000mV

±10 digits

100.000V

±1 digit

100.000V

±10 digits

500.00V

±1 digit

AC.1000 'KEYBOARD 500V' 500.00V

'AcHf' ±15 digits

Remarks

Set 'Local Guard'.

Do not set filter in.

Wait for reading to

stabilize before

operating 'Zero'

Lethal voltage

present -increase

calibration source

in lOOv steps if

possible

Lethal voltage

present increase

calibration source

in 100V steps if

possible. DO

NOT EXCEED

25kHz

1.5 DC CURRENT CALIBRATION

(No DC Current facility if Option 12 is fitted)

8

1.5.1

General

The procedure in the table below shows all that is

necessary to completely 'AUTOCAL' the DC Current

function. If just the DC Current or just one range of DC

Current is to be calibrated, then step 11 to 14 of the DC

Voltage Calibration table should be carried out first.

Then on each DC Current range just a'Zero' and 'Gain'

calibration is required.

If the 'DVM Reading After Calibration' is not in

accordance with the table then repeat operation of the

same 'CALIBRATE' key is permissible to improve the

reading. Where no tolerance is shown in this column, only

the exact reading quoted with an occasional least significant

digit showing is to be expected.

1.5.2

Equipment Required

ADC Current calibration source, e.g. Datron 4000/

4000A Autocal Standard with Option 20.

1.5.3

Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the 'Speci-

fication Verification' section of the Operating Handbook

will be useful. It provides tables for quick reference of

accuracy on all ranges and functions in displayed digits.

DC CURRENT CALIBRATION TABLE

Step Calibration

Operation

Calibration

Source

Output

DVM

Setting

'CALIBRATE'

Key

DVM Reading

After

Calibration

Remarks

1.1mA Range

Zero

O.OOOjuA DC,I,.1 'Zero' ±0.000)iA

±1 digit

Do not select

'Input filter'

2.1mA Full

Range

-MOO.OOOmA DC,I,.1 'Gain' -MOO.OOOmA

±2 digits

31mA Range

Zero

O.OOOOOmA DC,I,1 'Zero' ±.00000mA

±1 digit

41mA Full

Range

-M.OOOOOmA DC,I,1 'Gain' H.00000mA

±2 digits

510mA Range

Zero

O.OOOOmA DC,1,10 'Zero' ±0.(K)00mA

±1 digit

610mA Full

Range -MO.OOOOmA DC,1,10 'Gain' -H O.OOOOmA

7100mA Range

Zero O.OOOmA Dc;,ioo 'Zero' ±0.000mA

8100mA Full

Range

-I- 100.000mA DCJ[,100 'Gain' -1-1 00.000mA

91000mA

Range Zero 0.00mA DC,1, 1000 'Zero' iO.OOmA

1

10 1000mA

Full Range

-n 000.00mA DC,I,1000 'Gain' +1000.00mA

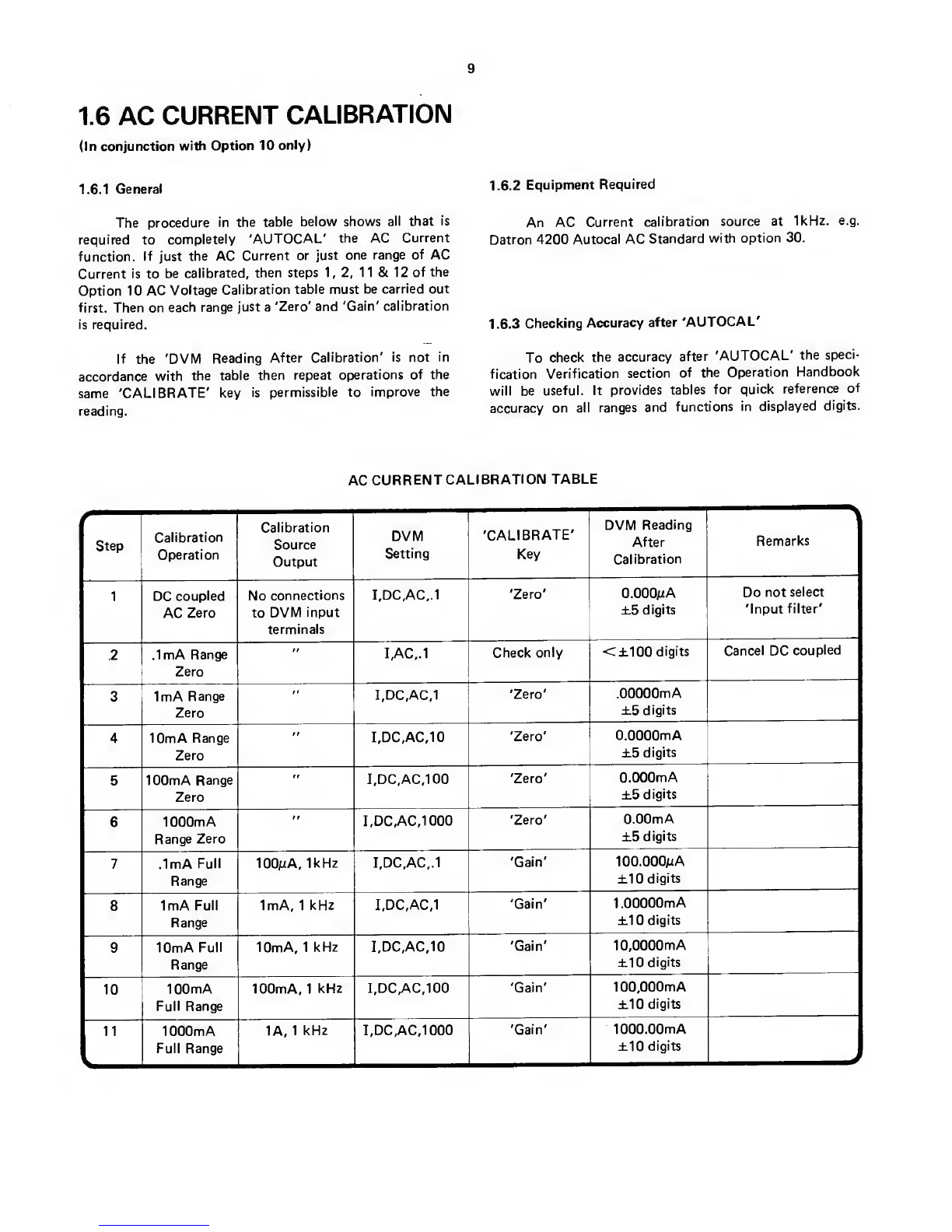

1.6 AC CURRENT CALIBRATION

(In conjunction with Option 10 only)

9

1.6.1

General

The procedure in the table below shows all that is

required to completely 'AUTOCAL' the AC Current

function. If just the AC Current or just one range of AC

Current is to be calibrated, then steps 1, 2, 11 &12 of the

Option 10 AC Voltage Calibration table must be carried out

first. Then on each range just a 'Zero' and 'Gain' calibration

is required.

If the 'DVM Reading After Calibration' is not in

accordance with the table then repeat operations of the

same 'CALIBRATE' key is permissible to improve the

reading.

1.6.2

Equipment Required

An AC Current calibration source at 1kHz. e.g.

Datron 4200 Autocal AC Standard with option 30.

1.6.3

Checking Accuracy after 'AUTOCAL'

To check the accuracy after 'AUTOCAL' the speci-

fication Verification section of the Operation Handbook

will be useful. It provides tables for quick reference of

accuracy on all ranges and functions in displayed digits.

AC CURRENT CALIBRATION TABLE

Calibration

Operation

Calibration

Source

Output

DVM

Setting

'CALIBRATE'

Key

DVM Reading

After

Calibration

Remarks

DC coupled

AC Zero No connections

to DVM input

terminals

I,DC,AC,.1 'Zero' O.OOOmA

±5 digits

Do not select

'Input filter'

Hi .1mA Range

Zero

nI,AC,.1 Check only <±100 digits Cancel DC coupled

H1mA Range

Zero

ft I,DC,AC,1 'Zero' .00000mA

±5 digits

10mA Range

Zero

ft I,DC,AC,10 'Zero' 0.0000mA

±5 digits

5100mA Range

Zero

ft I,DC,AC,100 'Zero' O.OOOmA

±5 digits

61000mA

Range Zero

ft I,DC,AC,1000 'Zero' 0.00mA

±5 digits

7.1mA Full

Range

IOOmA, 1kHz I,DC,AC,.1 'Gain' 100.000/uA

±10 digits

81mA Full

Range 1mA, 1kHz I,DC,AC,1 'Gain' 1.00000mA

±10 digits

910mA Full

Range

10mA, 1kHz I,DC,AC,10 'Gain' 10,0000mA

±10 digits

10 100mA

Full Range

100mA, 1kHz I,DC,AC,100 'Gain' 100,000mA

±10 digits

11 1000mA

Full Range

1A, 1kHz I,DC,AC,1000 'Gain' 1000.00mA

±10 digits

10

1.7 CALIBRATION USING KEYBOARD'

1.7.1

General

The 'KEYBOARD' method of calibration is useful

when acalibration source although set to anominal value

has known errors. In this situation the known value of the

calibration source can be entered into the DVM before the

'AUTOCAL' process is executed. The process is functional

during any calibration with asource of magnitude between

20% and 200% of the range selected, but it should be noted

that for equal magnitude source errors, calibrating at the

lower percentage end of range produces ahigher percentage

calibration error. The 'KEYBOARD' method operates for

both the 'Gain' and 'AcHf' calibration operations. An

example using 'KEYBOARD' to calibrate directly against

aStandard Cell is shown in the table below.

1.7.2 'KEYBOARD' with Negative Inputs

If the 'KEYBOARD' method is used on DC Voltage

calibration with Negative polarity sources, it is important

NOT to enter anegative sign with the keyed-in source

value. The instrument itself can determine the polarity of

the source and update the appropriate calibration memory

location.

1.7.3 'KEYBOARD' Calibration Example

The example shown in the table below uses 'KEY-

BOARD' to calibrate the 1000V AC LF Range Gain at

500V (step 15 of the AC Voltage Calibration table for

Option 12).

11

1.8 'AUTOCAL' OVER THE BUS

All the calibration procedures covered in this manual

can be carried out remotely using Option 50, the IEEE Bus.

Effectively, the five calibration keys are replaced

by five Bus instructions and these are used instead of the

'CALIBRATE' keys listed in the Calibration tables on

previous pages.

An example of calibration with the Bus is given in

the table below. Acomplete program listing for the same

calibration operation assuming an HP9825 controller is as

follows:

-

0; dim DS[15]

1: clr728

2: wrt 728,"F3R3Q1W1="

3: O-^'S

4: wrt 728,"G0="

define 15 character string

variable

send 'device clear' to DVM

(interface 7, address 28)

program to DC IV, SRQ

Mode 1, Enable Cal.

program zero cal. trigger

5: oni 7,"srq"

6: eir 7,128

7: if bit ("01XXXXXX' ,S)

=0;jmp —1

8: dsp "Apply IV &

CONTINUE"

9: 0-^S;stp

10: wrt 728,"G1="

11: oni 7,"srq”

12: eir 7,128

13: if bit ("01XXXXXX' ,S)

=0:jmp —1

14; wrt 728,"T0W0="

15: Id 728

16: stp

17: "srq":rds(728)->S

18: red 728, DS

19: iret

*7717

jump to SRQ service routine

on interrupt

enable SRQ interrupts from

interface 7

check status byte S

obtained by service routine

prompt operator to apply

calibration source on com-

pleting zero cal

program gain cal. trigger

program to Internal Trigger,

Disable Cal. on completion

of gain cal.

program DVM to local state

SRQ service routine to read

status byte

CALIBRATION EXAMPLE USING THE BUS

Step Calibration

Operation

Calibration

Source DVM

Setting

Bus

Controller

Instruction

DVM Reading

After

Calibration

Remarks

1Set DVM to

known state

In Remote

State

'Device Clear' Program DVM to

predetermined state

A0C0DXE0F3M0N0

O0P0Q0R6S0T5

2Set DVM to

DCV, IV

Range, and

prepare for

calibration

-(-O.OOOOOV Calibration

key to 'CAL'

'F3R3Q1W1=' Program DVM to

Function:DC V(F3)

Range:1V (R3)

SRQ Mode 1(Q1)

Enable Cal. (W1)

3IV Range

Zero

-^O.OOOOOV In Remote

State

'G0=' ±.ooooov Program 'Zero' cal.,

SRQ indicates when

calibration operation

completed

4IV Positive

Full Range

-1- 1.00000V In Remote

State

'G1=' -(-1.00000V Program 'Gain' cal.,

SRQ indicates when

calibration operation

completed

5Set DVM to

Internal

Trigger,

Disable Cal.

In Remote

State

'T0W0=' Program DVM to

Internal Trigger (T0),

Disable Cal. (W0)

6In Local State,

Calibration key

to 'RUN'

'Local' DVM in normal mode,

free-running

This manual suits for next models

2

Table of contents

Other Datron Multimeter manuals