Datron 4708 Instruction Manual

USER’S

HANDBOOK

4708

datron

INSTR LJN1 EN“TS

autocal multifunction

standard

USER’S

HANDBOOK

for

THE DATRON 4708

AUTOCAL

MULTIFUNCTION

STANDARD

150245 Issue 1(DECEMBER 1988)

lue to our policy of continuously updating our products, this handbook may contain minor differences in specification, components and circuit design

)the instrument actually supplied. Amendment sheets precisely matched to your serial number are available on request.

D1988 Datron Instruments

DANGER

HIGH VOLTAGE A

THIS INSTRUMENT IS CAPABLE

OF DELIVERING

ALETHAL ELECTRIC SHOCK !

when connected to ahigh voltage source

FRONT or REAR terminals

carry the Full Input Voltage

THIS CAN KILL !

Guard terminal is sensitive to

over-voltage

It can damage your

instrument

!

Unless you sure safe

DO NOT TOUCH

the 1+ i_ Hi ot Lo leads terminals

DANGER

1

CONTENTS

Page

SECTION 1THE DATRON 4708 AUTOCAL MULTIFUNCTION STANDARD 1-1

Introduction 1-1

Standard and Optional Facilities 1-2

SAFETY 1-3

Optional Facilities 1-3

Accessories 1-3

Additional Documentation 1-3

Principles of Operation 1-4

SECTION 2INSTALLATION 2-1

Unpacking and Inspection 2-

1

Preparation for Operation 2-

1

Bench Mounting 2-2

Rack Mounting 2-2

Connectors and Pin Designations 2-2

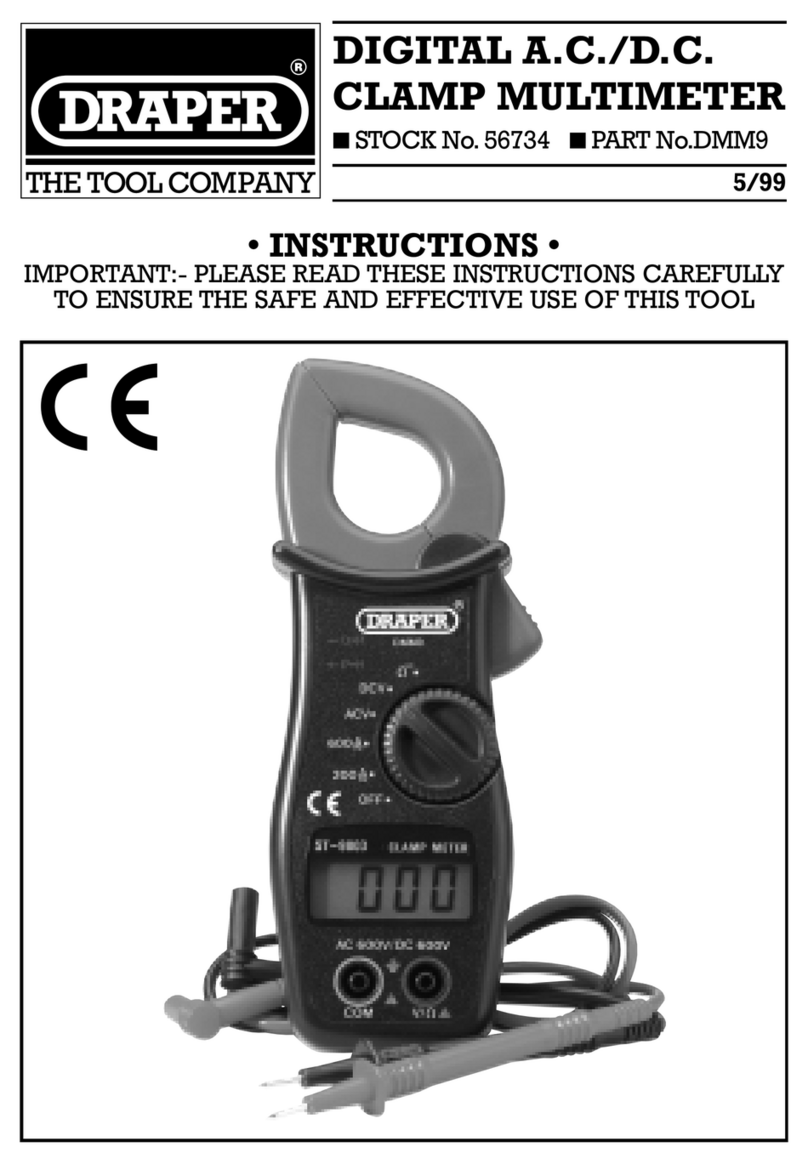

SECTION 3OPERATING CONTROLS 3-1

Front Panel 3-1

Front Panel Keys 3-1

Power Switch 3-1

OUTPUT Switching 3-2

FUNCTION Keys 3-3

OUTPUT RANGE Keys 3-3

OUTPUTDisplay and +Keys 3-4

Frequency 3-6

MODE Selection Keys 3-9

I+, I-, Hi, Lo, Guard and Ground Terminals 3-10

Rear Panel 3-11

SECTION 4USING THE DATRON 4708 4-1

Preliminaries 4-1

Limiting Characteristics 4-1

SAFETY 4-1

Interconnections 4-1

Typical Lead Connections 4-4

General Sequence of Operations 4-6

Display Messages 4-6

Operating Routines 4-7

DC Voltage Outputs 4-7

AC Voltage Outputs 4-7

DC Current 4-9

AC Current 4-9

Resistance 4-9

Additional Facilities 4-9

Frequency Store 4-9

Spot Frequency 4-10

‘Spec’ Mode 4-11

‘Error’ and ‘Offset’ Modes 4-12

Combining Offset and Error Modes 4-15

Test Key 4-16

Test Sequence 4-16

Warnings and Messages 4-19

11

SECTION 5SYSTEMS APPLICATION VIA THE IEEE 488 INTERFACE 5-1

Introduction 5-1

Interface Capability 5-1

Bus Addresses 5-2

Interconnections 5-2

Typical System 5-3

Using the 4708 in aSystem 5-3

Programming Instructions 5-4

Programming of Operational Functions 5-8

Programming of Bus Transmissions 5-10

Activation of Commands 5-13

Multiple Commands 5-13

Operational Sequence Guidelines 5-15

SECTION 6SPECIFICATIONS 6-1

General 6-1

DC Voltage 6-2

AC Voltage 6-4

Voltage/Frequency Constraints 6-6

Capacitive Loading Constraints 6-7

DC Current 6-8

AC Current 6-10

Resistance (Option 30) 6-12

SECTION 7SPECIFICATION VERIFICATION 7-1

Introduction 7-1

DC Voltage 7-2

DC Current 7-8

AC Voltage 7-12

AC Current 7-24

Resistance 7-26

Report Sheet RSI 7-30

APPENDICES TO SECTION 7:

1. Validity Tolerance Calculation 7-Al-l

2. Uncertainty and Traceability 7-A2-1

3. General Procedural Information 7-A3-1

4. Alternative Procedure for AC Millivolt Ranges 7-A4-1

5. Alternative Procedure for AC Current Verification 7-A5-1

SECTION 8ROUTINE AUTOCALIBRATION 8-1

The 4708 Autocal Feature 8-

1

DC Calibration 8-2

Autocal Availability 8-2

Zero Calibration 8-3

Equipment Required for DC Calibration 8-3

Interconnections 8-3

DC Calibration Sequence 8-3

4708 DC Voltage Calibration 8-4

4708 DC Current Calibration 8-7

4708 Resistance Calibration 8-8

AC Calibration 8-10

AC Calibration Sequence 8-11

4708 AC Voltage Calibration (IV -lOOOV) 8-13

4708 AC Millivolts (LF) Calibration (ImV -100mV) 8-14

4708 AC Millivolts (HF) Calibration (ImV -l(X)mV) 8-15

4708 AC Current Calibraticm (1mA -lA) 8-18

APPENDIX TO SECTION 8:

4708 AC Current Calibration (lOOjiA -lA) 8-Al-l

DATRON SALES REPRESENTATIVES WORLDWIDE Inside Rear

Cover

Note to Readers

This handbook has been designed for you to get the best use from your 4708. The sections are put together in a sequence flowing

logically from one subject to another, so that understanding increases as the text is read naturally from front to rear. Here is an

alternative (explanatory !) version of the Section Titles:

Section 1:Introduction and abrief account of the Internal design.

Section 2: Physical connections and mounting —getting It Installed.

Section 3; Abrief scan of the available controls —where they are and what they do.

Section 4: The correct procedures for making the 4708 perform foe you.

Section 5: How your 4708 can operate within an IEEE 488 system —the device dependent codes you will

need to use.

Section 6: Specifications —what accuracy you can expect to get from your Instrument.

Section 7: Verification that your 4708 matches the high specification It had when It left the factory.

Section 8: How to restore your 4708 to Its original specification after It has suffered the ravages of time and

temperature.

We are confident that your 4708 will give you many years of accurate and reliable service, and hope that you will use this hand-

book to obtain maximum benefit from its many facilities.

IV

SECTION 1

THE DATRON 4708

AUTOCAL MULTIFUNCTION STANDARD

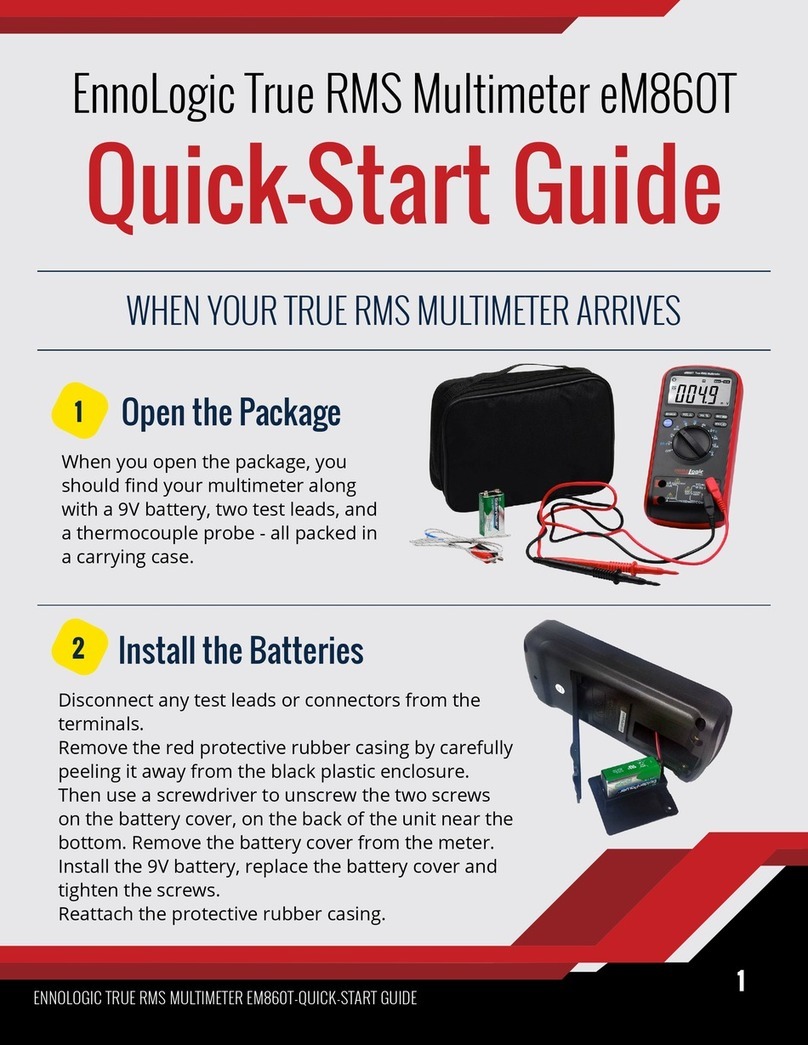

General View of Datron 4708 Autocal Multifunction Standard

Introduction

The Datron 4708 Autocal Multifunction Standard is ahigh-precision calibrator which features exceptionally high stability and full

systems capability. It is characterized by awide-range coverage of DC Voltage, AC Voltage, DC Current, AC Current and Resistance

functions in asingle unit.

The basic instrument consists of amainframe to which the various output options may be added.

Option 10 (factory-fitted) provides aDC Voltage function.

Option 20 (factory-fitted) provides an AC Voltage function.

Option 30 (factory-fitted) adds calibration sources of DC Current, AC Current and Resistance.

The 4708 incorporates areference module which maintains ahigh accuracy specification over the ambient temperature range of 23"^C

±lO^C. Ahigh level of stability is achieved by use of super-selected reference components and ultra-stable gain-defining resistors.

The ‘Autocal’ feature ensures that its 24-hour specifications are usable; not merely figures of merit.

The4708 uses amicroprocessor for control management, simplifying its use in complex manual operations, such as calibration of high-

quality digital multimeters. The IEEE 488 interface provides acomprehensive remote programming capability, allowing programmed

calibration of the 4708 itself.

1-1

standard and Optional Facilities

DC Voltage Ranges

By fitting Option 10, the instrument provides DC Voltage

calibration facilities in eight decade ranges from ±100|iV to

±1000V. 100% overrange is incorporated, except on the

±1000V range (see page 3-3), when the output is limited to

llOOV.

AC Voltage Ranges

By fitting Option 20, the instrument provides AC Voltage

calibration facilities in seven decade ranges from ImV to

1000V. 100% overrange is incorporated, except on the 1000

V

range (see page 3-3), when the output is limited to 1lOOV.

Resolution and Accuracy

The maximum resolution is 7.5 digits with afacility for display-

ing the specified accuracy of any output voltage. The 4708

specifications are shown in Section 6.

Resolution and Accuracy

The maximum resolution is 6.5 digits with afacility for display-

ing the specified accuracy of any output voltage. The 4708

specifications are shown in Section 6.

DC Current Ranges

By fitting Option 30, in conjunction with Option 10, the instru-

ment can be used to calibrate DC Current in five decade ranges

from lOOpA to 1A. The Datron Model 4600 may be used to

extend DC Currents to 11A.

Resolution and Accuracy

The maximum resolution is 6.5 digits with afacility for display-

ing the specified accuracy of output current. The 4708 speci-

fications are shown in Section 6.

AC Current Ranges

By fitting Option 30, in conjunction with Option 20, the

instrument can be used to calibrate AC Current in five decade

ranges from 100|iA to 1A. The Datron Model4600 may be used

to extend AC Currents to 11A.

Resolution and Accuracy

The maximum resolution is 6.5 digits with afacility for display-

ing the specified accuracy of output current. The 4708 speci-

fications are shown in Section 6.

Resistance Resolution and Accuracy

By fitting Option 30, in conjunction with Option 10, the instru- The maximum resolution is 7.5 digits with afacility for display-

ment can be used to calibrate resistance in eight decade ranges ing the specified accuracy of any output resistance. The 4708

from 10 ohm to lOOM ohm. specifications are shown in Section 6.

Frequency

The output frequency of the 4708 extends from lOHz to IMHz

in five overlapping decade ranges, at aresolution of 1% of

nominal Frequency Range. Any five frequency values within

the range of the instrument can be stored in volatile memory.

For higher accuracy, five ‘Spot Calibrated’ frequency values per

Output Range can be recalled from non-volatile memory stor-

age.

Autocal

All Datron AUTOCAL instruments are designed to make the

removal ofthe covers for calibration unnecessary, as full routine

calibration of all ranges and functions can be carried out from

the front panel or over the IEEE 488 bus.

Accidental or unauthorized use of the calibration routine is

prevented by akey operated switch on the instrumentrear panel.

The procedure for calibrating this instrument is contained in

Section 8.

Output Deviation

Auser may deviate the ouq)ut voltage from the output display

value by introducing again ‘Error’ within the general range

±10%. Additionally, for DC functions, the output may be

‘offset’ by up to ±2% of the range in use, or 200|iV, whichever

is greater.

Remote Sense

The specified output voltage may be sensed at the load, using 4-

wire connections. Remote or Local Sense is selectable from the

front panel.

Remote Guard

This facility allows the instrument’s internal guard shields to be

externally connected.

1-2

Self-test

On power-up, the internal calibration memory is automatically

checked. At any time when the output is off and not under

remote control, auser may conduct asequenced test of the

displays, keyboard, safety circuitry and Reset function.

Message Readout

Messages to the user are presented on the MODE display:

The two main groups are:

Fail

An internal fault condition has been detected.

Error

Auser has selected atask which is outside

the instrument’s capability.

Systems Use

The instrument can form part of asystem by means of the IEEE

488 standard digital interface. The method ofconnecting to the

system controller and the command codes are described in

Section 5.

Safety

For protection ofthe user, safety trip circuits are incorporated to

switch the OUTPUT OFF, in the event of instrument failures

which might generate dangerous output voltages.

UNDER NO CIRCUMSTANCES SHOULD

USERS TOUCH ANY OF THE OUTPUT, SENSE OR

GUARD TERMINALS UNLESS THEY ARE FIRST SATIS-

HED THAT NO DANGEROUS VOLTAGE IS PRESENT.

Optional Facilities

The available options for the 4708 are as follows:

Option 10: DCV function

Option 20: ACV function

Option 30: DC Current, AC Current and Resistance

functions

Option 42: Rear output terminals

(as afactory-fitted alternative to front

panel terminals).

NB: The rear output option is not

recommended for best performance in

calibrating high bandwidth, low level

instruments.

Option 90: Rack mounting kit.

Accessories:

The instrument is supplied with the following accessories:

Description Part Number

Power Cable 920012

Set of Calibration keys 700068

User’s Handbook 850245

Calibration and Servicing Handbook

(2 volumes) (Volume 1) 850246

(Volume 2) 850247

In addition the following accessories are available for

use with the 4708 instrument:

Description Part Number

RMK Rack Mounting kit (Option 90) 440094

Special Lead Kit 440070

Model 4600 Transconductance Amplifier

Slave Mode Lead Kit (4600) 440151

Analog Lead Kit (4600) 440154

Additional Documentation

The Calibration and Servicing Handbook contains information

required to adjust and service the 4708 instrument. It contains

detailed descriptions of the circuits, trouble shooting and cali-

bration procedures, parts lists, layout drawings and circuit dia-

grams.

1-3

Principles of Operation

Inputs/Outputs

Simplified Functionai Diagram. This shows the division and flow of functions within the 4708

Inputs

The 6802 microprocessor controls the output in response to

three main inputs:

i) Front panel keys

ii) IEEE 488 bus messages in ‘Remote’

operation

iii) Corrections placed in non-volatile memory

during ‘Autocalibration’.These modify

the values which control the output.

After processing, the computing system changes the output of

the instrument to respond to the input instructions.

Reference Voltages

A20V DC ‘Master’ Voltage Reference establishes the funda-

mental accuracy of the instrument. From this 20V, aprecision

electronic divider derives an adjustable ‘Working’ reference

voltage between OV and 20V, whose value depends on digital

inputs from front panel keys and calibration memory.

Precision Electronic Divider

In the out-guard section the selected output value, including

calibration corrections, is set into adigital comparator as a25-

bit number. This is counted out by acrystal controlled binary

counter, resulting in a125Hz square wave whose mark :period

ratio accurately represents the output value selection. When

transferred into guard, it chops the MasterReference voltage. A

7-pole active low-pass filter integrates the choppedreference, to

generate the ripple-free DC Working Reference Voltage.

DC Voltage Output

The working reference for DC Voltage Output is astable DC

voltage, accurately variable at high resolution between 0and

+20V.

1-4

DC Voltage Ranging

Low Voltage Ranges (100|iV- lOVFR). The basic range ofthe

4708 is ±10V Full Range (±19.999999V Full Scale), derived

directly from the working reference. The IV and 100mVranges

are achieved by attenuation:

The lOOmV range attenuator is also used for 10mV, ImV and

100|iV ranges, and the digital input to the f)recision divider is

scaled to provide the correct working reference values.

Range Working reference values

lOmV —2V -+2V

ImV —200mV +200mV

lOOpV _20mV-4 +20mV

High Voltage Ranges (100V and 1000V)

The lOOV range is adirect amplification of the working refer-

ence. The lOOOV range employs step-up AC transformation.

Output Switching.

In addition to switching between functions, the output switching

circuits isolate terminals on OUTPUT OFF. Remote/Local

Sense and Guard switching is incorporated.

AC Voltage Output

The working reference for AC Voltage Output is astable DC

voltage, accurately variable at high resolution between +0.1V

and +2V DC.

AC Reference Generator

The higher accuracy of AC/AC comparison (over AC/DC) is

exploited by converting the DC Working Reference into a

stepped waveform whose characteristics match those of asine-

wave. The amplitude of this ‘Quasi-sinewave’ is precisely

controlled by the DC Working Reference value.

Sinewave Source

Frequency Synthesizer

From the frequency value set into the MODE/FREQUENCY

display, the processor controls the synthesizer using an encoded

9-bit command. The synthesizer translates the command into

apulse train at acrystal-derived frequency between 240kHz and

4MHz, to be divided down for use as phase-reference for the

Quadrature Oscillator.

N.B. If required, the Frequency Synthesizer, can

be locked to an externally supplied IMHz

or lOMHz frequency, input via J53 on the

rear panel.

Quadrature Oscillator

The oscillator’s output frequency is set close to any demand,

between lOHz and IMHz, by selecting the RC time constants of

its dual integrators; and then by correcting to the actual demand

by phase-comparison with the output from the synthesizer. The

output sinewave purity and constant amplitude are precisely

defined by asophisticated control loop, and the RMS value of

the sinewave is adjusted to be roughly proportional to the de-

manded output voltage or current. Timing data is output from

the source to synchronize the actions of the AC Reference Gen-

erator and AC/AC Comparator.

Voltage-Controlled Amplifier (VCA)

This has variable gain, amplifying the output from the Sinewave

Source and providing abuffered drive to the output circuits. Its

gain is determined by the measured difference between the RMS

values ofthe sensed calibrator output and the AC Reference; so

the VCA provides the correcting fine adjustment for the output

amplitude loop.

AC Voltage Ranging

1V Range

This is the basic AC voltage range of the 4708. As the AC

working reference is variable between 0.1 Vand 2V RMS, it is

compared in 1:1 ratio with the sensed output. The IV Buffer

output is thus passed directly to the output 1+ and I- terminals.

lOOmV, l0mV and lmV Ranges

The 1VBuffer output is reduced by precision attenuators before

being connected to the terminals, the level being sensed before

attenuation.

10V, 100V and 1000V Ranges

The IV Buffer output is amplified on each of these ranges. A

separate amplifier is provided for the lOV range, the output

sense signal being obtained at the terminals and attenuated

before comparison with the reference. Acommon power

amplifieris used for both 100Vand 1000Vranges. On the 100

V

Range the output is fed directly to the terminals, on the lOOOV

Range the output is stepped up by atransformer. On both

ranges, the sensed terminal voltage is reduced to the reference

level by precision attenuators.

Output Sensing

On the IV range and above, the output is sensed at the front panel

Hi and Lo terminals. With Remote Sense selected, these are

isolated from 1+ and I-, but in Local Sense Hi is internally

connected to I+, and Lo to I-. As described above, the lOV,

1(X)V and 1(XX)V ranges’ sense signal is attenuated before

comparison with the reference.

AC/AC Comparator

The comparator generates an error voltage proportional to the

difference between the RMS values ofthe AC reference and the

sensed output. It alternately samples anumber of cycles from

its ‘Ref and ‘Sense’ inputs, computes and integrates the

squares of their instantaneous values, and uses a‘Sample and

Hold’ technique to subtract one from the other, this being the

‘error’ voltage to control the VCA. The loop thus controls the

4708 output so that the RMS value of the comparator’s sense

input equates to that of its reference input.

1-5

DC Current

On changing functions to DC Current, the Working Reference

voltage is switched to drive avoltage-to-current converter, and

the OUTPUTdisplay legend is changed to |liA, mAor A. Over-

voltage protection is provided, and the Output lines are fused.

AC Current

An AC Current output is produced by the voltage-to-current

converter. The 100|iA and 1Aranges are driven directly from

the basic IV range, and the others from the 10Vrange. Range

selection is achieved by switching internal shunts. Output

protection against over-voltage is provided, and the output lines

are fused. The OUTPUT display legend is altered to |0.A, mA

or A.

Resistance

Remote Sense.

One of aset of eight precision resistors is internally 4-wire

connected to the I+, I-, Hi and Loterminals by operation ofeach

RANGEkey.Simultaneously the 4-wire calibrated value ofthe

resistor is displayed (OUTPUT display). Pressing the OUT-

PUT Zero key connects atrue 4-wire short to the terminals, and

the OUTPUT display indicates zero. This zero display value

cannot be recalibrated.

Local Sense (Remote Sense LED Unlit).

The connections to the resistor remain the same, but the display

value includes the resistance ofthe connections from the Hi and

Lo terminals to the resistor. The arrangement provides a

calibrated 2-wire facility with external connection to the Hi and

Lo terminals. The Zero key shorts the Hi and Lo terminals, in

this case the resistance between the terminals is displayed and

may be recalibrated. When Qis selected from any other

function, the 4708 is forced into Remote Sense, but this may be

deselected for 2-wire operation.

Autocalibration

By setting the CAL ENABLE security keyswitch on the rear

panel to ENABLE, the 4708 can be calibrated. (Refer to

Section 8). The output value is measured and the microproces-

sor is activated, to add any new corrections to factors already

retained in non-volatile memory. The updated correction fac-

tors are applied in the normal RUN mode.

Processor

A6802-series microprocessorcontrols the internal performance

of the instrument, employing 26k bytes of program memory.

2k bytes of memory are used for stack and work space, and 2k

bytes are made non-volatile by abattery-powered back-up

supply, storing calibration correction factors.

With the exception of the Power ON/OFF switch, each front

and rear panel control provides an input to the microprocessor

system, which translates the information to command the 4708

analog and calibration functions.

The processor also controls the display, the IEEE 488 Interface

Bus and the operation of the restart and error circuitry.

1-6

SECTION 2INSTALLATION

This section contains information and instructions for unpacking and installing the Datron 4708.

Unpacking and Inspection

Every care is taken in the choice of packing materials to ensure

that your equipment will reach you in perfect condition.

If the equipment has been subject to excessive mishandling in

transit, the fact will probably be visible as external damage to the

shipping carton. In the event ofdamage, the shipping container

and cushioning material should be kept for the carrier’s inspec-

tion.

Unpack the equipment and check for external damage to the

case, sockets, keys, etc. If damage is found, notify the carrier

and your sales representative immediately.

Standard accessories supplied with the instrument are as de-

scribed in Section 1.

Preparation for Operation

DANGER

THIS INSTRUMENT IS CAPABLE OF DELIV-

ERING ALETHAL ELECTRIC SHOCK. THE

I+, I-, Hi AND Lo TERMINALS ARE MARKED

WITH SYMBOL TO WARN USERS OF

THIS DANGER.

UNDER NO CIRCUMSTANCES SHOULD

USERS TOUCHANYOFTHE FRONTTERMI-

NALS UNLESS THEY ARE FIRST SATISFIED

THAT NO DANGEROUS VOLTAGE IS PRES-

ENT.

Power Input

The recess POWER INPUT plug, POWER FUSE and LINE

VOLTAGE SELECTOR are contained in an integral filtered

module at the center of the rear panel.

The protective window allows the fuse rating and line voltage

selection to be inspected with the powersocket connected. This

window slides to the left once the socket has been disconnected,

for access to the fuse and voltage selector printed circuit board.

Power Cable

The detachable supply cable, comprising two meters of 3-core

PVC sheath cable permanently moulded to afully-shrouded 3-

pin socket, fits in the POWER INPUT plug recess, and should

be pushed firmly home.

The supply lead should be connected to agrounded outlet

ensuring that the ground lead is connected. Connect Black lead

to Line, White lead to Neutral and Green lead to Ground.

(European: Brown lead to Line, Blue lead to Neutral, and

GreenA'ellow lead to Ground).

Line Voltage

The 4708 is operative within the line voltage ranges 100/1 15/

120/220/230/240V ±10%, 50 or 60Hz. To accommodate the

ranges, asmall PC selector board is housed beneath the

POWER FUSE,

Operating Voltage Selection

FIRST ensure the POWER CABLE is removed. Slide the

window to the left to reveal the fuse and PC selector board.

Draw the fuse-extractor to the left and remove the fuse.

Remove the PC selector board and rotate until the desired

voltage is on the left of the upper surface.

Reinsert the selector board firmly into the module slot.

The desired voltage is visible in the cutout below the fuse.

Return the fuse extractor to the normal position.

Insert the appropriate POWER FUSE (see below).

Slide the window to the right and insert the POWER CABLE.

Power Fuse

The fuse rating is:

3.15A for 220/240V line supply

6.25A for 100/120V line supply

Itis located behind the window in the POWERINPUT module

on the rear panel, and should be of the anti-surge or SLO BLO

type.

WARNING

MAKE SURE THAT ONLY FUSES WITH THE

REQUIRED RATED CURRENT AND OF THE

SPECIFIEDTYPE ARE USED FOR REPLACE-

MENT. THE USE OF MENDED FUSES AND

2-1

THE SHORT CIRCUITING OF FUSE-HOLD-

ERS SHALL BE AVOIDED, AND RENDERS

THE WARRANTY VOID.

Bench Mounting

The instrument is fitted with six plastic feet. It is intended to

stand flat on abench, positioned so that the cooling-air inlet and

exhaust apertures are not obstructed. It is recommended that at

least 30cm (12 inches) of free space is at the rear.

Rack Mounting

Option 90permits the instrument to be mounted in astandard 19

inch cabinet.

To fit Option 90

CAUTION

Note that the 4708 is designed to be supported at

front and rear. AT NO TIME should the 4708 be

supported only by the front brackets. On no

account should the upper and lower covers be

removed.

Remove the tworear spacers from the case sides by releasing six

screws. Fit the two rack-mounting slides to the rear of the case

sides and secure using six of the shorter screws in the option kit.

N.B. The slides may be reversed to give rearward

extension.

Fit the two rear rack-mounting ears to the rear of the cabinet,

with tongues facing forward. In shallow cabinets it may be

necessary to trim the tongue.

CAUTION

Assistance is required to fit the 4708 into the

cabinet.

Lift the 4708 into position in the cabinet, locate the tongues in

the slides, and carefully slide backwards until the front ears butt

up against the cabinet front. Secure the front ears to the cabinet.

Also clear ventilation for fan cooling to operate properly.

suitable RACK depths

1depth NOTES

1mm »n

<75 SHORTEN REAR RACK

MOUNTING EARS

25-29 FIT AS SHOWN BY DRAWING

29-3i; REVERSE RACK MOUNTING

SLIDES TO EXTEND PAST

REAR PANEL

7Off 4S0300 REARSPACERS

6or F611038 M4y 12mm SOCKET HO CSK SCREWS

©FIT AS INSTRUCTED

2OFF 450317 RACK MOUNTING EAR FRONT

2OFF 450313 RACK MOUNTING EAR REAR

2OFF 450314 RACK MOUNTING SLIDE

17 OFF 611062 M4xBmm SOCKET HD CSK SCREWS

Connectors and Pin Designations

IEEE 488 Input/Output Socket J27

The IEEE input/output is a24-way connector that is directly

compatible with the IEEE 488 interface and the lEC 625 Bus.

Pin Layout

2-2

Pin Designations

J27

Pin No Name Description

1DlOl Data Input Output Line 1

2DIO 2Data Input Output Line 2

3DIO 3Data Input Output Line 3

4DIO 4Data Input Output Line 4

5EOI End or Identify

6DAV Data Valid

7NRFD Not ready for Data

8NDAC Not Data Accepted

9IFC Interface Clear

10 SRQ Service Request

11 ATN Attention

12 SHIELD Screening on cable (connected to

4708 Safety Ground)

13 DIO 5Data Input Output Line 5

14 DIO 6Data Input Output Line 6

15 DIO 7Data Input Output Line 7

16 DIOS Data Input Output Line 8

17 REN Remote Enable

18 GND6 Gnd wire of twisted pair with DAV

19 GND7 Gnd wire oftwisted pair with NRFD

20 GND8 Gnd wire oftwistedpair withNDAC

21 GND9 Gnd wire of twisted pair with IFC

22 GND 10 Gnd wire of twisted pair with SRQ

23 GNDll Gnd wire of twisted pair with ATN

24 GND 4708 Logic Ground (Internally con-

nected to 4708 Safety Ground)

External Reset Socket

&4600 Digital Connector J54

Pin Layout

#0000

000000#

15 9

Pin Designation

Pin Name Function

1SHIELD Case Ground

0V_6 Digital Common

IWR_R Write Strobe (Rising Edge)

0V_6 Digital Common

0V_6 Digital Common

ICAL_RST_L Not used on 4600

IA_H_D_ LAddress/Data on AD0-AD4

8IRD_L Read Strobe (Active Low)

IDIGBUSON.H -I-5V (5k) when 4708 is on.

0V_6 Digital Common

lADO Bi-directional Address/Data

lADl Lines, controlled by

IAD2 Strobes and

14

15

IAD3

IAD4 _IA_H_D_L

Rear Output Terminals (Option 42)

The 4708 is fitted with either six front panel output terminals or

six rear output terminals. The Rear Output alternative is fitted

at the customer’s request only at manufacture.

The 4708 cannot be fitted with both front and rear output

terminals.

The functions ofthe six terminals are identical to those normally

fitted on the front panel, and the external leads are connected in

the same way. (See Section 4for details).

External Reference Frequency Input Socket

J53.

This BNC socket is located next to the cooling air intake filter.

It enables the frequency synthesizer to be locked to acustomer’s

own frequency standard provided that it meets the following

criteria:

Voltage: 500mVto 15V peak-to-peak

Frequency: IMHz ±1% or lOMHz ±1%

N.B. The socket has an input resistance of

approximately 50Q

External Reset Switch Wiring

This D-type socket located next to the optional rear output

connectors may be used to input an external reset to restore the

4708 to its power-up state (DCV, IV Range)

.

Socket J54

4600 Analog Connect or J56 Pin Layout

and Designations

2-3

DANGER

HIGH VOLTAGE A

THIS INSTRUMENT IS CAPABLE

OF DELIVERING

ALETHAL ELECTRIC SHOCK !

when connected to ahigh voltage source

FRONT or REAR terminals

carry the Full Input Voltage

THIS CAN KILL !

Guard terminal is sensitive to

over-voltage

It can damage your

Instrument

!

Unless you are SUro that it is SSfO to do so,

DO NOT TOUCH

the 1+ I- Hi or Lo leads and terminals

DANGER

SECTION 3OPERATING CONTROLS

This section summarizes the main operating features of the 4706. For detailed operating procedures refer to

Section 4.

Front Panel

j

MODE /FREQUENCY

DANGER

HIGH VOLTAG

1

Xr Guard

FREQUENCY RANGE

Store 100 Ik 10k 100k 1M

—FI F2 F3 F4 F5

+lim -lim 'd——%ppm

lanrinri

Guard Sartsa Spac Error Olfeat Tast

Ramota STO SET Spot^ CAL

MODE

OUTPUT

ri 111 II IrII IrI

LllJlJilJlJLhiJ

S888SS

dBddasdFull

Ranga

OUTPUT RANGE

lOOp 1m 10m 100m 110 100 1000

iii IPmii^

ion loon ikn lOkn lookn img io«4niooMn

FUNCTION

UoU un

TMSTR^JM* MTS-

47Q8AUTQCAL,

MUI^TIFUNCTION

^TWSIDARD

OUTPUT JJ

Power-up State Power Switch

The controls are outlined in blocks, left and right, associated

with the appropriate display. The right-hand blocks generally

deal with function and output definition, whereas the left-hand

blocks are concerned with frequency, mode and terminal con-

figurations.

Front Panel Keys

All user commands from front panel keys are executed through

main program firmware. AKey LED lit signifies that condi-

tions are valid for the selected operation, and not merely that the

key has made contact.

At any time, the instrument status is described by the combina-

tion of LED states, display values and display messages.

Generally, if an invalid condition is selected, an error message

will be displayed and abuzzer will sound, the command is

ignored and the 4708 remains in its previous state.

WARNING

THE POWERSWITCH SHOULD NOT BE SET

TO ON UNTIL THE LINE VOLTAGE AND

POWER FUSE RATING HAVE BEEN SE-

LECTED AS DETAILED IN SECTION 2(IN-

STALLATION)

Power switch isolates the instrument from the supply.

When switched to ON, the instrument powers

up, runs aself-test program and is configured into the following

state:

OUTPUT

FUNCTION

OUTPUT RANGE

OUTPUT DISPLAY

FREQUENCY RANGE

MODE/FREQUENCY

DISPLAY

MODE Guard

Sense

Key LEDs Lit

OFF

DC

1

.000,000,V

Not selected

Blank

Not selected

Local connection (unlit)

Local connection (unlit)

OUTPUT OFF, DC, 1

3-1

OUTPUT Switching

OUTPUT ON/OFF

The 4708 should normally be connected and set up with its

output off. This isolates the I+, I-, Hi and Lo terminals from

their internal circuitry regardless of RANGE, FUNCTION,

FREQUENCY or MODE selections. The OUTPUT OFF

LED is lit

Pressing the OUTPUT ON key connects the I+, I-, Hi and Lo

terminals to their energized internal circuits.

OUTPUT OFF Default

Certain instrument states are prohibited, and some transfers

between states are restricted by program firmware. For safety

reasons some of these transfers result in the output being

switched off. Refer to Section 4, Operating Routines.

OUTPUT ON -+

On DC Voltage or Current, the polarity at the Output terminals

is determined by the Key used to switch the output on, as

labelled. In addition, polarity may be reversed by using the t

keys to step the output across zero value. The ON LEDs

describe the polarity AT THE OUTPUT TERMINALS, not

on the OUTPUT display. (In ‘‘error” and “offset” modes these

two could be opposite).

In AC Voltage, AC Current and Resistance functions, the ON +

key will cause the selected outputs to appear at the output

terminals. The ON -key will cause the error buzzer to sound

and Error 8to appear in the MODE/FREQUENCY display.

OUTPUT OFF Trip -Fail 5Message

Under certain abnormal conditions which might compromise

safety, the 4708 output will trip off, accompanied by aFAIL 5

message on the MODE display. Control is removed from the

front panel keys.

If the FAIL 5message is present, there is noautomatic recovery

from the tripped state whether internal conditions have or have

not returned to normal.

Reset Key

The Reset Key has two functions:

1.It allows the user to reset the safety trip to test whether

conditions have returned to normal. If they have; the

FAIL message will disappear, the previous instrument

state will be restored but with OUTPUT OFF, and

front panel control will be returned to the user. If

conditions are still abnormal the FAIL state will per-

sist, and afurther attempt may be made after asuitable

interval. The Reset LED is inoperative except in

‘TEST’ mode.

2. It returns the instrument to power-up conditions in all

cases except the following:

•Self-test mode

•FAIL conditions

•In remote control mode (where it is

inoperative).

Other Messages

Afull list of 4708 messages appears in Section 4. The fault

conditions which generate Fail messages are analyzed in the

Calibration and Servicing Handbook.

3-2

FUNCTION Keys

When changing from one function to another the output is

automatically set to OFF. When changing from Q, to ACor DC,

the OUTPUT value is automatically set to zero. If the corre-

sponding OUTPUTRANGE or value is not available on the new

function, the 4708 displays Error 8and sounds its error buzzer.

Q. selection forces the 4708 into Remote Sense for 4-wire

operation.

Selected Specified

Function Output

DC

AC

Q.

DC Voltage co^

1.1or Error 9and

AC Voltage |,..

1buzzer if any

Resistance >

DC and IDC Current 1of the Options

AC and IAC Current ^are not fitted

OUTPUT RANGE Keys

Each OUTPUT RANGE key scales the output as selected by

the user, setting the legend and decimal point on the OUTPUT

display to match. Full range values for voltage and current are

marked above the keys. Nominal values of each precision

resistor for the Ofunction are marked below the keys.

Voltage and current ranges are selectable as follows, the actual

output value being selected by use ofthe OUTPUT display t

keys.

DC Voltage

AC Voltage

DC Current

AC Current

Resistance

lOOjiV to lOOOV

ImV to lOOOV RMS

100|iA to 1

A

lOOfxA to 1ARMS

lOO to lOOMO

If OUTPUT is ON when changing ranges, it remains on unless

the change is to lOOOV range, or ranging up to more than 75V

RMS in AC or llOV in DC on lOOV range. In these cases

OUTPUT defaults to OFF. Any range selection which would

exceed the internally defined voltage-frequency limit is auto-

matically inhibited. These limits are described on page 3-7.

Key

Selections

100^

10

Im

100

10m

Ik

100m

10k

1

100k

10

IM 100

lOM 1000

lOOM

DC Voltage 100|iA ImV lOmV lOOmV IV lOV lOOV lOOOV

AC Voltage *ImV lOmV lOOmV IV lOV lOOV lOOOV

DC Current lOO^iA 1mA 10mA 100mA lA lOA^^^ * *

AC Current 100|iA 1mA 10mA 100mA lA lOA^^^ **

Resistance lOQ lOOQ IkQ lOkQ lOOkQ iMn lOMn lOOMQ

Error 8[1] Error 8if 4600 not connected in slave mode configuration

OUTPUT Display and Keys

Output Resolution

OUTPUT

Ul_l l_l MM M

Full

Range

Zero

The Output and display are resolved as follows:

Range

o

o

oIm

100

10m

Ik

100m

10k

1

100k

10

IM 100

lOM 1000

lOOM

DCV 4.5 5.5 6.5 7.5 7.5 7.5 7.5 7.5

ACV -4.5 5.5 6.5 6.5 6.5 6.5 6.5

DCI 6.5 6.5 6.5 6.5 6.5 6.5 --

ACT 6.5 6.5 6.5 6.5 6.5 6.5 --

Q(2-wire) 4.5 5.5 6.5 7.5 7.5 7.5 7.5 7.5

Q(4-wire) 7.5 7.5 7.5 7.5 7.5 7.5 7.5 7.5

The OUTPUT display is supplemented by legends, which

always indicate the correct units for the Range and Function

selected

Output and Display Control

Each vertical pair of 14keys is assigned to the display digit

above it. Thus the value registered on the display may be set

within the range permitted by the function selected. Each

momentary press of the tkey adds 1to its digit: pressing the 4

key subtracts 1.If OUTPUT is ON, the Output terminal value

is also changed by the same increments as the display (subject

to the instrument interlocks).

On Q. ranges, only the overrange (leftmost pair oO 14keys are

operative. These duplicate the action of the Full Range/Zero

Keys.

The Resistance value displayed is the calibrated value of the

standard internal resistor selected (not the nominal value). This

may be updated during periodic calibration. The value dis-

played depends on the selection ofLocal (2-wire) or Remote (4-

wire) Sense, and should be recalibrated in the correct Sense

mode (See Section 8).

3-4

Table of contents

Other Datron Multimeter manuals