6 7

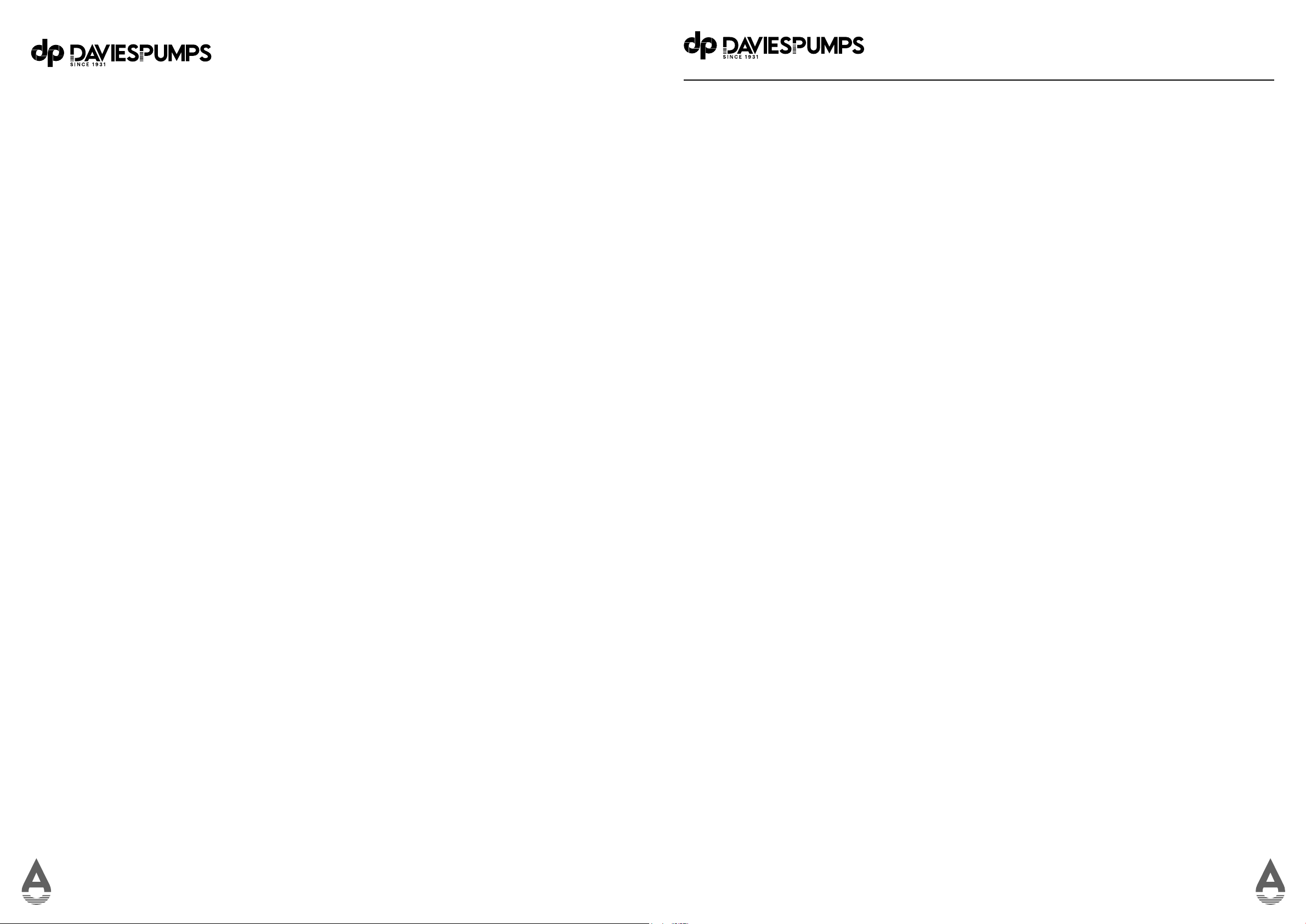

Overview

The HPX system combines a high-quality self-priming pump, advanced pump control with dual-stage

sediment iltration and ultraviolet water treatment to provide clean, safe pressurised water for your

home. The housing is designed and manufactured in NZ to meet our harshest conditions yet blend

into the landscape and protect your equipment.

Cartridge pre-iltration removes sediment that could reduce ultraviolet (UV) eectiveness and water

clarity.

The incorporated Greenway® UV Advance Series™ ultraviolet technology system is a natural

puriication process that’s completely eco-friendly, chemical-free and kills 99.9% of bacteria,

including E. Coli, Giardia, and Cryptosporidium. This process is critical for untreated water supplies

such as rain tanks, bores or other back up water supplies.

Note: water quality will adversely aect the performance of your UV disinfection system, and the

following levels should be utilised as a guideline for pre-treatment requirements of the inluent water

supply before UV treatment:

• Iron Total iron count must be less than 0.3 ppm (0.3 mg/L)

• Turbidity Count must be less than 1 NTU

• Tannins Count must be less than 0.1 ppm (0.1 mg/L)

• Manganese Count must be less than 0.05 ppm (0.05mg/L)

• Hardness Count must be less than 120 ppm (7 grains per gallon)

• %UVT (transmittance) Must be greater than 75%

The HPX system cartridges and lamp need regularly replacing to maintain optimum performance.

This is a simple procedure when following instructions. For replacements, contact your nearest

Davies Pumps Filtration stockist.

Your new HPX system incorporates a failure warning feature that warns you of a lamp failure by a LED

warning light and an audible alarm. The alarm sounds when the lamp is due to be changed to ensure

eective treatment is maintained. A green LED indicates that the system is operating correctly.

Your HPX will arrive thoroughly tested from the factory and require minimal

installation to save you time and money.

MODEL NUMBER HP150 HP160 HP165 HP166

Pump Model: DJS 100M MPRS 0310M MPRS 0515M MPRS 0515T

Pump Type Self Priming pump Self Priming Multi-Stage

Pump Sound Medium Quiet

Rated Power: 1Hp 1Hp 1.5Hp

Maximum Current Consumption 4.5A 4.4A 6.5A

Pump Flow Rate 30 LPM @ 30M 60 LPM @ 30M 105 LPM @ 30M

Pressure Controller: HG 3.1 HG 8 VFD

Power Supply: 230V 1 Ph

Energy Saving Tank NA YES

Water Temperature Range 0600C (Protect from freezing)

Connection 1” BSP (25mm)

Warranty 3 Years (extension via registration)

First Line Defense

Dual cartridge ilters for maximum

life and iltration 10” and 20” options

available.

Optimum Control

Pressure gauge on ilter outlet and pump controller

to show if the ilters are blocked and allow for timely

replacement.

Durability

Weatherproof housing made of powder-coated

galvanised steel is designed to survive the harshest

New Zealand conditions. Choice of powder coat colors

available.

Stainless Steel options available.

Dimensions: 1000mm x 1000mm x400mm

Silent Night

Optional sound deadening panels for silent operation.

Plumb & Run

Simple plumbing connection with 25mm inlet/

outlet ports on either left or right.

*Option to have uniltered water take o for

irrigation. **Option for 32mm ports

Heat Control

Ventilation on both sides and around the roof to keep ambient

temperatures cool even in the toughest conditions.

Pump Control

HydroGenie HG3.1 or HG8 VFD pump control options for system

protection and provide optimum user experience.

*HG8 only on large model.

Second Line Defense

High volume 10S UV treatment and quality

ballast with 365-day timer and audible alarm

Functionality

Storage for replacement ilter

cartridges and ilter spanner..

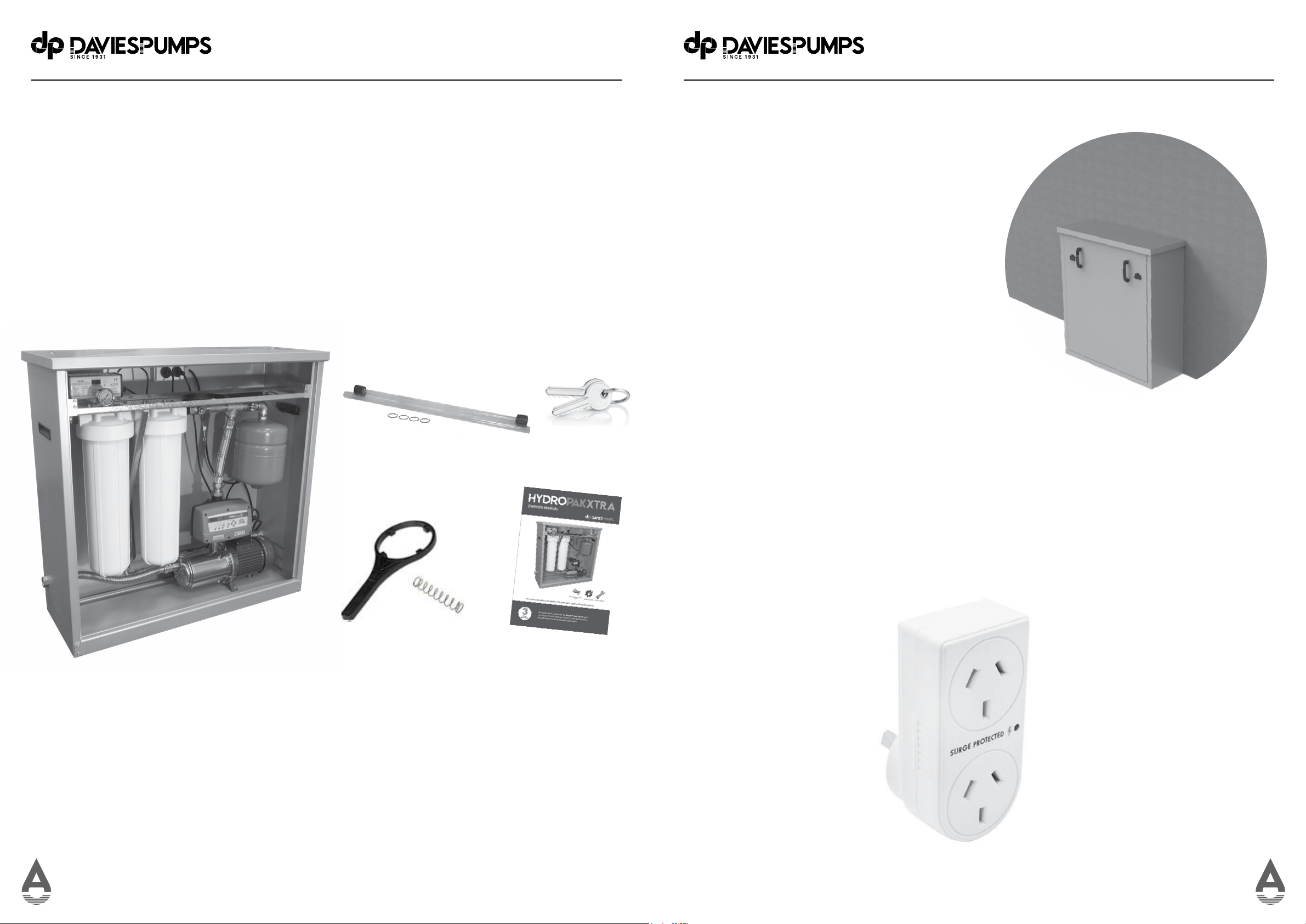

Power Supply

230V 10A single Ph power supply required.

Increased Eiciency

Using a Flexpansion pressure tank increases

eiciency and pump life by reducing cycle time and

also prevent shocks on system from water hammer or

thermal expansion.

Easy As

Convenient lifting handles to make delivery and installation

easy. Removable door and lid for easy servicing of ilters,

UV and pump.

Tamper Proof

Lockable door to prevent theft or tampering

but allowing easy access for maintenance

High Flow

High quality self-priming multistage MPRS pump

models to meet any conditions.

Options:

DJS100M with 30LPM @ 3.0bar duty

MPRS0310 with 60LPM @ 3.0bar duty

MPRS0515 with 105LPM @ 3.0bar duty

*Filter condition will aect performance.

OverviewOverview