DayTronic 3000 series User manual

MODEL

3170

STRAIN GAGE CONDITIONER

SB.5.1

INSTRUCTION MANUAL

3000

Instrument Series

Copyright © 1996, Daytronic Corporation. All rights reserved.

No part of this document may be reprinted, reproduced, or used in any form or by

any electronic, mechanical, or other means, including photocopying and recording,

or in any information storage and retrieval system, without permission in writing

from Daytronic Corporation. All specifications are subject to change without notice.

Correction

to Model 3170 Instruction Manual, v. SB.5.1

The I/O Wiring Data in Fig. 4 of this manual does not give the correct shield pairing of

cable wires, which is shown in the revised diagrams below and on the following page:

1

A

2

B

3

4

C

9

A

D

B

C

+EXC

–EXC

+SENSE

–SENSE

+SIG

–SIG

CAL SENSE

.

.

.

A

Extra Wire, paired

with CAL SENSE,

unconnected at

Connector A

SHIELD

Bendix PT02E-10-6S

Burndy BT06AC-10-6S

Daytronic 400 Series

Transducer Connections

1

A

2

B

3

4

C

9

D

A

B

C

+EXC

–EXC

+SENSE

–SENSE

+SIG

–SIG

CAL SENSE

.

.

.

A

Extra Wire, paired

with CAL SENSE,

unconnected at

Connector A

SHIELD

Amphenol 97-3106A-

14S-6S, AN3057-6

Daytronic 500 Series

Transducer Connections

(cont’d)

Correction

to Model 3170 Instruction Manual, v. SB.5.1 (cont’d)

+SENSE

–EXC

–SENSE

+SIG –SIG

CAL

SENSE

1

A

2

B

3

C

4

9

.

.

.

A

SHIELD

+EXC

Daytronic 3X70 Instrument to Generalized Strain Gage Transducer

4-Wire Configuration for Cables

Shorter Than 20 Feet

+SENSE

–EXC

–SENSE

+SIG –SIG

CAL

SENSE

1

A

2

B

3

C

4

9

.

.

.

A

SHIELD

Extra Wire, paired with CAL SENSE,

unconnected at Connector A

+EXC

6-Wire Configuration for Cables

Shorter Than 20 Feet

+SENSE

–EXC

+SIG –SIG

CAL

SENSE

1

A

2

B

3

C

4

9

.

.

.

A

SHIELD

Extra Wire, paired with CAL SENSE,

unconnected at Connector A

–SENSE

+EXC

8-Wire Configuration for Cables

Longer Than 20 Feet

MODEL

3170

STRAIN GAGE CONDITIONER

INSTRUCTION MANUAL

Model 3170 Instruction Manual, v. SB.5.1

Pub. No. 3170M.5.1, Issued 03/01

Part No. 91132

Daytronic Corporation

Dayton, OH • Tel (800) 668-4745

www.daytronic.com

Daytronic Corporation

TABLE OF CONTENTS

Section Page

1

Description ................................................. 1

2

Installation and Cabling ......................................

3

3

Calibration .................................................. 8

4

Block Diagram Description ................................... 12

5

Verification of Normal Operation ..............................

14

LIST OF ILLUSTRATIONS

Figure

Page

1

Model 3170 Strain Gage Conditioner...........................

1

2

Instrument Mounting Dimensions ............................. 4

3

Instrument Panel Mounting .................................. 5

4

I/O Wiring Data ............................................

.

9

5

Front-Panel Description ...................................... 11

6

Block Diagram .............................................. 15

7

Star-Bridge Construction ..................................... 17

LIST OF TABLES

Table

Page

PLEASE NOTE: Sections 6 and 7, Figures 8 and 9, and Table 2 have been

removed from this manual.

If you need information regarding specific 3170 components and circuitry,

please contact the Daytronic Service Department at (937) 293-2566.

1Specifications ............................................... 2

Daytronic Corporation

INSTRUCTION MANUAL

MODEL 3170 STRAIN GAGE CONDITIONER

1. DESCRIPTION

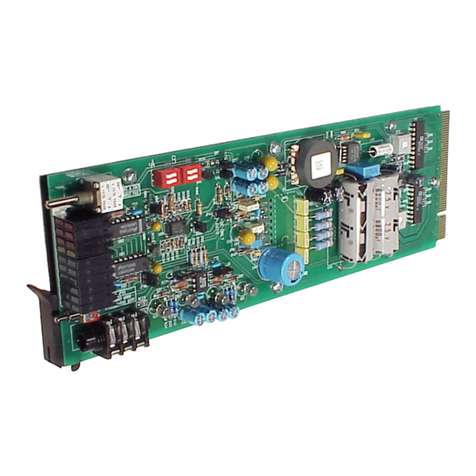

The Model 3170 conditioner-amplifier module for use with resistance strain

gage transducers. It supplies a regulated dc excitation voltage to the transducer

bridge, provides the necessary balancing and calibration controls, and amplifies the

resulting signal to a standard Five-Volt Data Signal Level which is the output analog

signal level of 3000 Series Modules. The

3170

has three separate analog outputs,

each having a different bandpass: (1) dc to 2

kHz,

(2) dc to 200 Hz, and (3) dc to 2

Hz. Active low-pass filters are used to achieve the 200 Hz and 2 Hz cutoff

frequen-

cies.

The filtered outputs provide for averaging or smoothing signals containing

noise or other unwanted dynamic components which are periodic in nature. Filter-

ing removes these dynamic components so that stable digital indication and precise,

jitter-free control action can be obtained. The Model 3170 is shown in Figure 1 and

the specifications are given in Table 1.

Figure 1. Model 3170 Strain Gage Conditioner

1

Model 3170

Table

1.

Specifications

Transducers: 4-arm bridges, 90

to

2000 ohms, nominally 1

to

8

mv/v,

full

scale (120 ohms or less requires use of 5-volt excitation).

Cables:

4-,

5-,

or 7-wire, depending on application; 1000

feet

maximum length.

Bridge Excitation: Regulated 5 volts or 10 volts dc, selected

with

I/O

connector wiring. Transducers

with

sensitivity from 4 to 8

mv/v

full

scale must use

5-volt

excitation.

Balance Adjustments:

10-turn

coarse and fine; will balance 1.5

mv/v

initial unbalance.

Span Adjustments:

10-turn

coarse and fine; 1to 8

mv/v,

full scale.

Analog Outputs: Three analog outputs available; 0 to ±5 volts with

50% overange,

5

milliamperes maximum.

Bandpass

is dc

to

2 kHz, dc

to 200 Hz, or dc to 2 Hz, depending on

output

used. Active low-pass

filters provide for rolloff of 60

dB

per decade above cutoff frequency.

Full-scale slew

time

is 1.4/f seconds, where f is

the

cutoff frequency.

Common Mode Rejection: Greater

than

80

dB.

Output Ripple and Noise: 0.15% of full scale (rms) maximum for

2-kHz and 100-Hz outputs; 0.02% of full scale (rms) on 2-Hz output.

Accuracy: 0.05% of full scale.

Dimensions: 1.7 x 4.41 x 8.5 (HWD inches).

Operating Temperature Range: 0 to + 130 degrees F.

Power Requirements: 105 to 135 volts ac, 50 to 400 Hz at 5 watts

maximum.

2

Daytronic Corporation

Remote sensing techniques are used to regulate the excitation voltage at the

transducer. Either a 10-volt or a

5-volt

excitation voltage can be selected by

appropriate wiring at the module

I/O

connector. The excitation voltage is protected

against overloads and accidental short circuits.

The 3170 uses a CMOS chopper-stabilized differential signal amplifier which

has over

100-megohms

input impedance per input line. This circuit guarantees

negligible drift with temperature variations or component aging.

Calibration of the 3

170

is accomplished by the conventional shunt technique,

using an internally installed calibration resistor. A front-panel CAL button or

Remote

Cal

terminals on the module I/O connector can be used to initiate the

calibration procedure.

The 3

170

Strain Gage Conditioner is also available in two additional forms. The

Model 3270 includes the addition of a digital indicator to view the analog output of

the conditioner. The Model 3370 includes a Limit section (in addition to a digital

indicator) which provides high, low, and ok indications and outputs. The digital

indicator and limit options are standard to all 3000 Modules and are covered in

separate instruction manuals.

2.

INSTALLATION AND CABLING

The following paragraphs provide the instructions for module installation and

cabling.

Module Mounting. The 3000 Series Modules can be operated as bench-top

instruments or they can be rack- or panel-mounted. Clearance dimensions for a

bench-mounted instrument are given in Figure 2. Panel cut-out dimensions for

panel mounting are also shown in Figure 2. Up to four 3000 Series instruments can

be mounted in a

19-inch

rack using the

1.75

-inch high Model 3004 Rack Adaptor.

Rack-mounting dimensions are also given in Figure 2. To panel mount an instru-

ment, proceed as follows. Refer to Figure 3.

Important: The unit is shipped with two spacer washers on the securing screws of the

rear-panel I/O Connector. When panel-mounting the unit, you MUST REMOVE

THESE WASHERS, so that the printed-circuit board may move forward about 1/8"

during Step (f).

(a)

Remove the front panel by removing the two 2-56 x

3/8

flat-head screws.

3

4

Model 3170

Figure 2. Instrument Mounting Dimensions

C. Panel Mounting

B. Rack Mounting

A. Bench Mounting

Daytronic Corporation

5

Figure 3. Instrument Panel Mounting

Model 3170

(b) Remove the front bezel by removing the four 6-32 x 5/8 fillister-head

screws.

(c) Make the panel cutout and drill the screw clearance holes indicated in

Figure 2. The front bezel can be used as a template to define the

rectangular cutout and locate the clearance holes.

(d) Hold the module enclosure behind the panel and reattach the front bezel

to the enclosure from the front of the panel with the four mounting

screws.

(e) Reinstall the front panel.

(f) Tighten the two securing screws of the rear-panel module I/O connector

to insure that the connector is seated and that the module printed-circuit

board is pushed fully forward so that the front-panel screwdriver ad-

justments and buttons are accessible. These screws give approximately

1/8-inch of adjustment; consequently, this is the maximum panel width

which should be used.

CAUTION

Do not overtighten the connector securing screws or resultant

damage may occur to the printed-circuit board.

AC Power Connection. To protect operating personnel, the 3000 Series Mod-

ules are equipped with a three-conductor power cord. When the cord is plugged into

the appropriate receptacle, the instrument is grounded. The offset pin on the power

cord is ground. To maintain the safety ground when operating the module from a

two-contact outlet, use a three-prong to two-prong adaptor and connect the green

pigtail on the adaptor to ground.

To prepare the module for operation, connect the power cable to a 105-135 volt

ac, 50-400 Hz power source. The instrument can use up to

5

watts of power.

Calibration Resistor. If a fixed resistor is shunted across one arm of a strain

gage bridge, it produces an unbalance equivalent to that of a particular value of

mechanical input. If this Equivalent Input value is accurately known, it can be used

as a reference point for shunt calibration of the system. Upon completion of

installation of the transducer and its associated cabling, the user can:

6

Daytronic Corporation

(1) Perform an overall

dead

weight calibration using a precisely known

value of mechanical input. The calibration can then be transferred to the

installed shunt calibration resistor for convenience in subsequent check-

ing.

(2) Replace the installed calibration resistor with one (or an equivalent

resistance value) supplied by the transducer manufacturer to achieve a

precisely known Equivalent Input, allowing the instrument sensitivity to

be adjusted correctly.

(3) Determine the

Equivalent

Input value for the installed calibration resis-

tor, knowing the transducer sensitivity, and adjust the instrument sen-

sitivity accordingly.

A precision 59-kilohm calibration resistor is installed in the 3170 at the factory.

The installed resistor can usually be used even though the transducer calibration

data mentions some other resistance value. In Section 3 of this manual, the tech-

niques described above are demonstrated. If, however, the installed value of

calibration resistor is not appropriate, the

59-kilohm

resistor should be replaced at

this time by one that is appropriate for the transducer and measurement range to be

used. The calibration resistor is mounted on terminals located at the front edge of

the strain gage conditioner printed-circuit board. It can be accessed by removing

the module front panel.

Transducer Cabling. Cabling to the transducer is accomplished via the

supplied module I/O connector. The I/O connector pin numbers and functions are

given in Figure 4. When Daytronic 400 or 500 Series Transducers are used,

factory-wired cables are available as shown in Figure 4. When user-fabricated

transducer cabling is used, it should take the form of either the 4-, 5-, or 7-wire cable

configuration shown in Figure 4.

The 4-wire configuration should be used when overall dead weight calibration

is the method used and the required cable length is less than 20 feet. The 5-wire

configuration should be used when the instrument is to be calibrated by achieving a

precisely known

Equivalent

Input value through the use of a shunt calibration

resistor (or resistance value) supplied by the transducer manufacturer and when the

required cable length is less than 20 feet. The 7-wire configuration should be used

with cable lengths longer than 20 feet since the excitation voltage is sensed and

regulated at the transducer and optimum shunt calibration can be achieved.

7

Model 3170

Transducer Excitation. Either

5-volt

or 10-volt bridge excitation can be

selected. In general,

5-volt

excitation is used with

120-ohm

transducers, and the

10-volt excitation is used with 350-ohm devices. However, for any transducer

which has a 4

mv/v

or higher sensitivity,

5-volt

excitation must be used to maintain

proper operation without saturating the conditioner amplifiers. Five-volt excitation

is selected by shorting pins D and E of the module I/O connector (see Figure 4).

Ten-volt excitation is achieved when pins D and E are not connected together.

Remote Calibration Check. The instrument can be remotely placed in the

calibration mode by shorting pins 5

(Signal

Common)and 8 (Remote

Cal)

of the

module I/O connector. Figure 4 indicates three methods of remotely entering the

calibration mode through the use of an external switch, transistor, or TTL source.

The

Remote

Cal

function provides a convenient method for periodically monitoring

calibration of the instrument.

Analog Outputs. Three different analog outputs are available at the module

I/O connector. Each output has a different passband: dc to 2 kHz, dc to 200 Hz, and

dc to 2 Hz. The 200 and 7 Hz cutoff frequencies are achieved with active low-pass

filters. As the cutoff frequency is lowered, a trade off is made between noise

elimination and increased time-to-answer or slew time. Each output has a

60-dB

rnlloff a decade from the cutoff frequency. The filter characteristics are given by the

following equations.

A

out

@ f

0

= 0.7 A

in

A

out

@ 10f

0

= 0.001 A

in

T = 1.4/f

0

where A

out

= output amplitude

A

in

= input amplitude

f

0

= selected cutoff frequency

T = time-to-answer in seconds (output of filter within 0.1%

of final value after step function is applied).

3. CALIBRATION

This section contains the instructions for calibrating the 3

170

Included is a

functional description of the module front panel (see Figure 5). To perform calibra-

tion, proceed as follows.

(a) Turn power ON by placing the rear-panel slide switch in the ON posi-

tion. The front-panel indicator should light to indicate the application of

8

Figure 4 I/O Wiring Data

See the CORRECTION to Fig. 4 in the front of this manual.

Figure 4 (cont'd)

See the CORRECTION to Fig. 4 in the front of this manual.

Daytronic Corporation

BALANCE Controls:The coarse

(R

c

)

and fine

(R

f

)

BALANCE controls are

used to set the module output to zero when the transducer is unloaded.

SPAN Controls: The coarse (c) and fine (f) SPAN controls are used to set

the output to the

Equivalent

Input

value when the CAL button is pressed.

CAL Pushbutton: The CAL pushbutton provides for enabling or entering

the calibration mode. The Cal resistor is shunted across the + Signal

and

+Sense terminals when the button is pressed, supplying an Equivalent

Input value to the module.

Figure

5.

Front-Panel Description

ac power. Allow

5

minutes of warm-up for stabilization of transducer

characteristics.

(b)

With the transducer unloaded, set the module output to zero using the

coarse

(R

c

)and fine (Rf) BALANCE controls. In some instances, an

integral digital indicator will be used to display the conditioner output

(Model 3270 or 3370). When only the conditioner is supplied

(3170),

an

external indicator must be used to monitor the conditioner output.

(c)

Load the transducer to a convenient up-scale value which is greater than

one half of full scale. Adjust the coarse (c) and fine (f) SPAN controls

until the output signal causes a reading equal to the

dead

weight value.

Remove the

dead

weight, then press the CAL button and note the

indicator reading obtained. This reading can now be used in future

calibrations since it is related to a value obtained thru

dead

weight

11

Model 3170

calibration. To calibrate the instrument in the future, simply press the

CAL button and adjust the SPAN controls to obtain the reading previ-

ously recorded after dead weight calibration.

(d) If dead weight calibration is not practical and the transducer manufac-

turer has supplied a calibration resistor (or resistor value), install the

recommended calibration resistor. Now press the CAL button and

adjust the SPAN controls until the module output is equal to the

Equiva-

lent Input value simulated by the installed calibration resistor.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the

Equivalent

Input value for the factory-installed

calibration resistor can be approximated as follows, assuming that the

mv/v

sensitivity rating of the transducer and the bridge resistance is

known.

X =

where X = Equivalent Input, % of full scale

R

b

= bridge resistance, ohms

K = transducer sensitivity, mv/v full scale

R

c

= calibration resistance, ohms (59 K installed)

25000 R

b

Sample Calculation: Assume that K = 3.000

mv/v

for a

5000-pound

load cell

(full scale) with a bridge resistance of 350 ohms.

25000 x 350

59000 x 3 = 49.44% of full scale = 2472 pounds

4. BLOCK DIAGRAM DESCRIPTION

The purpose of this section is to explain how the 3170 works by using a

simplified block diagram of the conditioner. This is not intended to be used as a

detailed theory of operation discussion for personnel untrained in electronic

technology, but as a simplified explanation of the detailed schematic diagram

provided with this manual.

Refer to Figure

6.

Primary power (115 volts ac,

50-400

Hz) is applied to the

module by means of the attached power cable. A rear-panel slide switch is used to

turn ON primary power. Overload protection is provided by a 0.25 ampere fuse

12

K R

c

X =

Daytronic Corporation

mounted on the conditioner printed-circuit board. When the slide switch is ON,

primary power is applied to the power transformer which provides the necessary

power-line isolation and the low ac voltages required to develop the regulated dc

voltages used in the module. The secondary of the power transformer has a

grounded center tap, and a diode bridge functions as two full-wave rectifiers to

produce

±

9 volts regulated dc. Two three-terminal regulators are used to develop

these regulated voltages. The reference terminal of each regulator is biased with one

or two diodes to make certain that a minimum regulated voltage of 9

volts

is

achieved. The proper diode biasing is accomplished at factory check out.

A dc reference voltage of

+2.5

volts dc is further developed from regulated +9

volts by the use of a third three-terminal regulator. This precision dc reference is

used to bias an amplifier/driver which works in conjunction with a series-pass

regulator to regulate the excitation voltage at the transducer bridge. The excitation

voltage is normally 10 volts dc, but a jumper can be installed at the module I/O

connector to select a

5-volt

excitation voltage. The excitation voltage is developed

from the minus unregulated side of the diode bridge to more equally balance the

current drain on the power transformer secondary. The series-pass regulator has

short-circuit protection in the event that the excitation voltage is accidentally

shorted at the transducer or module

I/O

connector.

Figure 6 shows the connections between the transducer bridge and the module

made via a 7-wire cable. Optimum accuracy is obtained with the 7-wire configura-

tion since the excitation voltage is regulated at the transducer bridge and a

Cal

Sense line is returned to the module for accurately setting the Equivalent Input

value when the Cal resistor is shunted across one leg of the transducer bridge. The

Calibration mode is entered (Cal resistor is shunted across the + Signal and +

Sense lines) when the front-panel CAL button is pressed or the Remote Cal input at

the module

I/O

connector is brought to a zero-volt level through the action of an

external switch, transistor driver, etc. Either of these actions fires a comparator

which, in turn. closes an analog switch in series with the Cal resistor.

The + and – Signal inputs from the transducer bridge are applied to a differen-

tial signal amplifier. Each leg of the signal amplifier inputs has approximately

100-megohms input impedance so that no loading is seen by the bridge. The signal

amplifier is chopper stablized to prevent drift which might result from temperature

or component aging. A two-phase clock signal synchronized with power line

frequency is used as the chopper signal. The differential signal amplifier also

provides excellent common-mode rejection.

13

Model 3170

The bridge balance circuit immediately follows the signal amplifier. The BA-

LANCE and SPAN controls act upon the output of the signal amplifier, not the

bridge, to achieve the proper impedance isolation.

Three analog outputs of the conditioned strain gage signal are available at the

module I/O connector. The three outputs provide three different passbands of dc to

2

kHz,

dc to 200 Hz, and dc to 2 Hz. Output selection is a trade off between

eliminating unwanted signals caused by vibration or increasing the time-to-answer

(slew rate) of the conditioner. The 200-Hz and 2-Hz cutoff frequencies are achieved

with the use of active low-pass filters. The

rolloff

of each output is 60

dB

within a

decade of the cutoff frequency.

5.

VERIFICATION OF NORMAL OPERATION

It is the purpose of this section to aid the user in determining, in the event of a

malfunction to which the Model 3170 is suspected of contributing, whether the

module is functioning normally or whether it is a source of the observed trouble. In

the event the module requires repair, a complete parts list, schematic diagram, and

component location drawing are included in this manual. The user may also contact

the factory Service Department or the local Daytronic Representative for assis-

tance.

If the module is suspected of faulty operation, observe the following steps.

(a)

If the module is totally inoperational (front panel power indicator does

not light), check the primary power fuse (Fl) located on the conditioner

printed-circuit board (see Figure 8). If the fuse is blown, replace it with a

0.50 ampere fuse. Before reapplying power, visually inspect the power

cord wiring and the printed-circuit board for any discrepancy which

could have caused the overload.

(b)

If the transducer has some preloading, the BALANCE controls may not

allow successful zeroing of the module output. This condition can be

remedied by connecting a resistor (50 K-200 K range, metal-film type)

from the + Signal terminal of the transducer to the + or – Excitation

terminals. The Excitation terminal to which the connection is made is

determined by the direction of the loading or off-zero reading.

(c)

The inability to balance correctly where the module output reads totally

off scale and the BALANCE controls have no authority can very likely

be the result of a damaged or defective transducer or cable. This

possibil-

14

Other manuals for 3000 series

2

This manual suits for next models

1

Table of contents

Other DayTronic Amplifier manuals

Popular Amplifier manuals by other brands

Gryphon

Gryphon XT owner's manual

Phontech Communication

Phontech Communication Argo A-1 Handbook

Audio Note

Audio Note SORO Phono SE Signature Owner's Information

Elliott Studio Arts

Elliott Studio Arts 66-001P owner's manual

Link electronics

Link electronics DigiFlex 1626 Specification sheet

Racal Instruments

Racal Instruments 5601 user manual