DayTronic 3000 series User manual

MODEL

3240A

FREQUENCY CONDITIONER

SB.5

INSTRUCTION MANUAL

3000

Instrument Series

Manuals 3140A + 3200

with option C,G & P

Copyright © 1996, Daytronic Corporation. All rights reserved.

No part of this document may be reprinted, reproduced, or used in any form or by

any electronic, mechanical, or other means, including photocopying and recording,

or in any information storage and retrieval system, without permission in writing

from Daytronic Corporation. All specifications are subject to change without notice.

MODEL

3140A

FREQUENCY CONDITIONER

INSTRUCTION MANUAL

Model 3140A Instruction Manual, v. SB.5

Pub. No. 3140AM.5, Issued 10/96

Part No. 91122

Daytronic Corporation

Dayton, OH • Tel (800) 668-4745

www.daytronic.com

DAYTRONIC CORPORATION

Model 3140A Frequency Conditioner

Instruction Manual

The Model 3140A Frequency Conditioner accepts any type of AC or pulse input

signal, irrespective of waveform. It produces a standard five-volt analog

output, with low-pass corner frequency of 2 or 10 Hz, depending on the input

frequency range selected. This output is precisely proportional to the fre-

quency of the source.

I. Specifications: Table 1

Input Type: Any AC signal, single-ended or differential, irrespective of

waveform.

Input Sensitivity: Continuously adjustable from 0.1 to 200 V via front-

panel control. Input Sensitivity decreases above 10 KHz by

0.01 V/kHz to 0.5 V at 50 kHz.

Input Threshold Level: Automatic triggering of squarer at 75 and 25

percent of the input amplitude.

Input Frequency Ranges: Full-scale frequency ranges are selected with

internal switches. Ranqe switches of 100, 1000, and 10000 and

Multiplier switches of xl, x2, and x5 provide nine frequency ranges

(see Table 2).

Analog Output: 0 to ±5 V, with 50% overrange, 5 mA max. Active low-

pass filtering provides for rolloff of 60 dB per decade above corner

frequency. Corner frequency is 2 Hz for input ranges of 100, 200, and

500 Hz; it is 10 Hz for all other ranges (1000 to 50000 Hz).

Output Ripple and Noise: Less than 0.1% of full scale from 20 to 100% of

the selected range.

Step-Function Response: Response time (to 99.9% of final value) is 1.8

seconds for 100-, 200-, and 500-Hz ranges, and 350 milliseconds for all

other ranges.

Accuracy: 0.05% of full scale.

Dimensions: 1.7 x 4.41 x 8.5 (HWD inches).

Operating Temperature Range: 0 to +130 degrees F.

Power Requirements: 105 to 135 W-AC, 50 to 400 Hz at 5 W max.

The Model 3140A is also available in two other forms. The Model 3240A

contains a Digital Indicator to display the analog output. The Model

3340A is identical to the 3240A, except that it also includes high-low

limit monitoring. See separate Model 3200/3300 and Model 3300 Instruction

Manuals.

II. Installation and Cabling

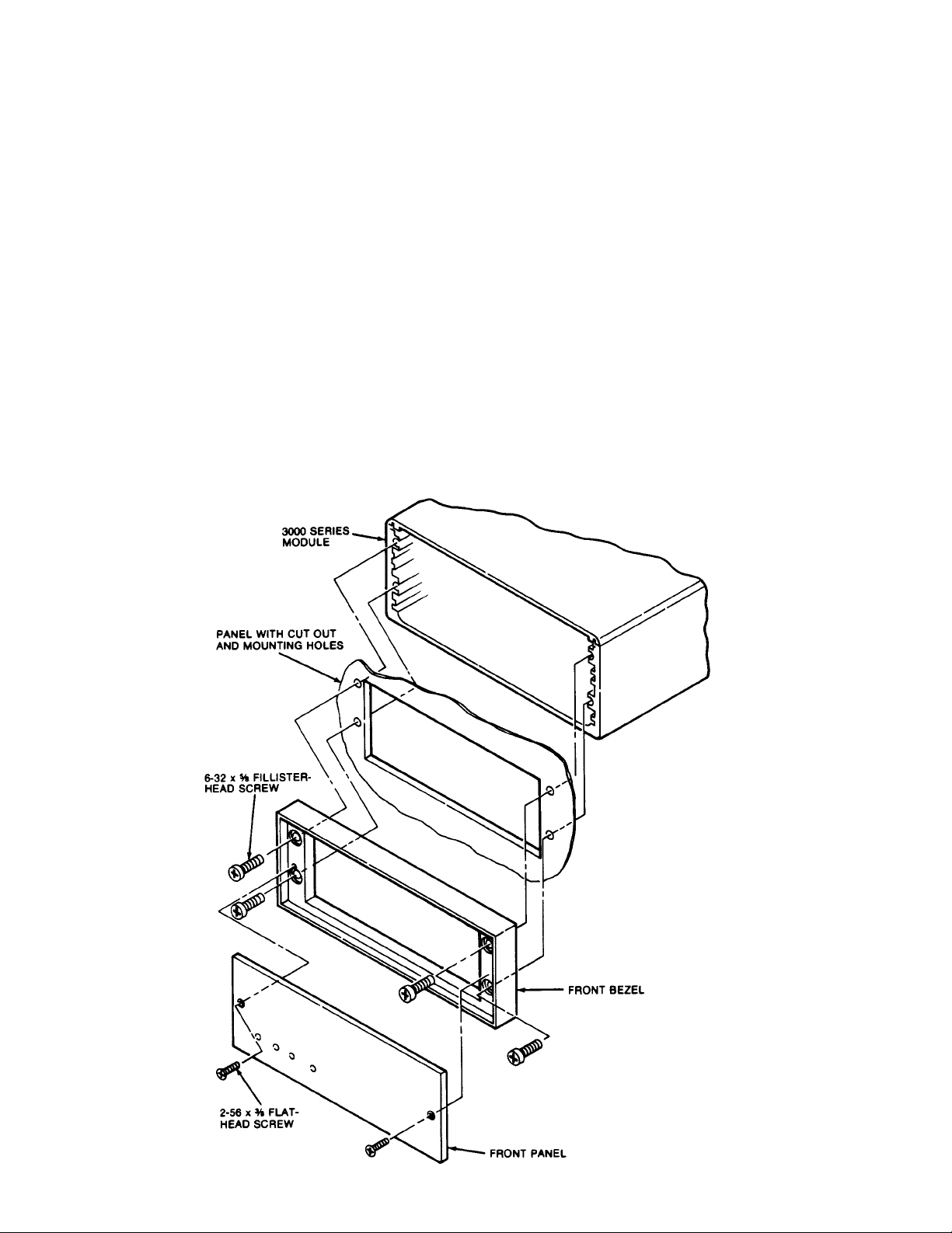

1. MOUNTING: 3000 Series instruments can be operated as bench-top, rack-

mounted, or panel-mounted units. See Fig. 1. Up to four 3000 Series in-

struments can be mounted in a standard 19-inch rack, using the 1-3/4"

high Model 3004 Adaptor. The following reassembly procedure lets you

quickly mount any 3000 Series unit in your own precut panel (see cutout

dimensions in Fig. 1C).

2

IMPORTANT: The unit is shipped with two spacer washers on the securing

screws of the rear-panel I/O Connector. When panel-mounting the unit, you

MUST REMOVE THESE WASHERS, so that the printed-circuit board may move for-

ward about 1/8" during Step f, below.

a. Remove the front

panel

(one small flat-head screw near each edge--

see Fig. 2).

Fig. 1 Instrument Mounting Dimensions

b. Remove the front bezel (four fillister-head screws fasten it to the

metal housing--see Fig. 2).

c. Make the panel cutout and drill the screw clearance holes shown in

Figs. 1C and 2. The front bezel can be used as a template to define

the rectangular cutout and to locate the clearance holes.

d. Hold the instrument behind the panel and use the four mounting screws

to reattach the front bezel to the metal housing, from the front of the

panel.

e.

Reinstall the front panel.

f. Tighten--BUT DON'T OVERTIGHTEN--the two securing screws of the rear-

panel I/O Connector. This will push forward the printed-circuit board

and all front-panel buttons and controls by about 1/8"--which is conse-

quently the maximum panel thickness allowed.

Fig. 2 Instrument

Panel Mounting

3

4

3.

AC POWER CONNECTION: Connect the supplied power cable to a 105-135 V-AC,

50-400 Hz source (for "F" versions, 210-260 V-AC; for "B" versions, there

is no external power connection). This is a three-conductor cord, plug-

ing into the AC power connector at the rear of the unit; the offset pin

connects to earth ground. To maintain the safety ground when operating

from a two-contact outlet, use a 3-prong-to-2-prong adapter and connect

the green pigtail on the adapter to earth ground.

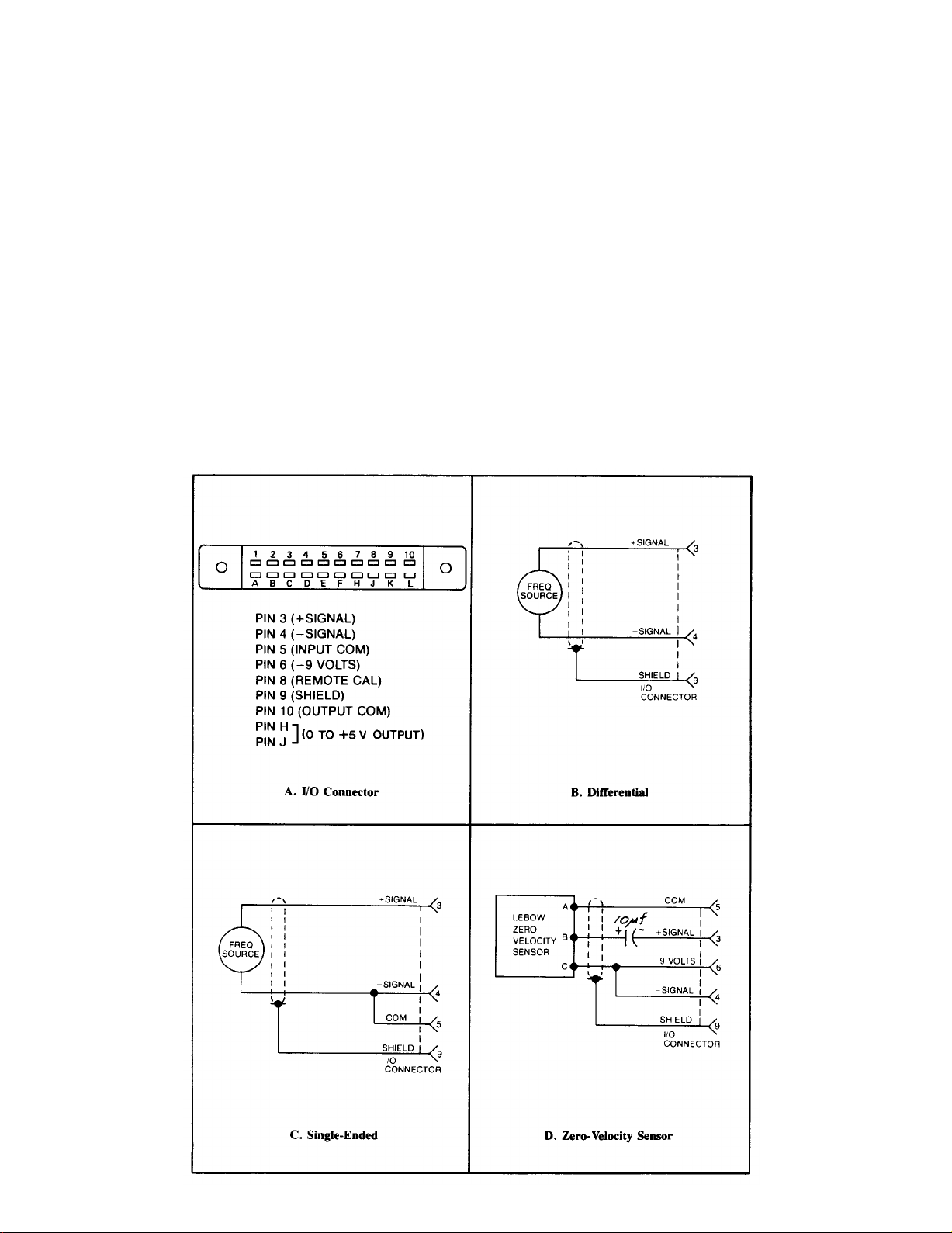

TRANSDUCER CABLING: The transducer is connected via the 3140A's rear-

panel I/O Connector. For pinout, see Fig. 3A, below. The frequency input

can be single-ended or differential, as shown in Fig. 3C and 3B, respecti-

vely. Shielded, twisted-pair cable is recommended. Fig. 3D gives the re-

quired cabling when the 3140A is used with Lebow Zero Velocity Sensors.

Fig. 3 I/O Wiring Data

2.

4.

5.

RANGE SELECTION: To access the internal bank of ten numbered range-

selection switches, remove the 3140A's front panel (two screws near each

edge--see Fig. 2). To select the desired full-scale frequency range,

place in the ON (i.e., downward) position the switches indicated in Table

2, below.

Table 2. Frequency Range Selection

REMOTE CALIBRATION CHECK: The 3140A can be placed in the REMOTE CAL mode

by connecting Pin 5 of the I/O Connector (Signal Common) to Pin 8. This

provides a means of periodically monitoring the instrument from a remote

location without pressing the front-panel CAL button. When the Remote Cal

input (Pin 8) is brought to a 0-volt (ground) level through the action of

an external switch, transistor driver, etc. (see Fig. 4), the effect is the

same as when the CAL button is pushed (see Section III, below).

Fig. 4 Remote Calibration

Connections

5

III. Calibration

1. Turn power ON by placing the rear-panel slide switch in the upward posi-

tion. With application of AC power, the front-panel red LED indicator

should light.

2. ZERO ADJUSTMENT: Establish a zero input to the 3140A by bringing the

transducer frequency to zero or by disconnecting the transducer from the

3140A I/O Connector. Then adjust the front-panel ZERO control (see Fig.

5, above) to produce an output of zero.

3. SPAN ADJUSTMENT: Press the front-panel CAL button. The input signal is

now replaced by a digitally divided, crystal-controlled frequency equal

to 80% of the full-scale value of the input ranqe selected in Step 4,

Section II, above. Now adjust the Coarse and Fine SPAN controls to

produce an output equal to 80% of the selected range. The 3140A is

4. TRIGGER LEVEL ADJUSTMENT: Turn the front-panel INPUT SENSITIVITY control

fully counterclockwise. Then, using the transducer as a frequency source,

apply the lowest-valued input signal for which a valid reading is requir-

ed. Then turn the INPUT SENSITIVITY control clockwise until a stable

output is observed.

FOR MODELS 3240A AND 3340A ONLY:

1A. POWER-UP and ZERO ADJUSTMENT: as in Steps 1 and 2, above.

2A. SCALE SELECTION: Determine the full-scale output of the transducer in

terms of the desired unit of measurement. For example, the full-scale

output for a flowmeter might be 5000 Hz, which corresponds (in units of

flow) to a measurement of, say, 728.2 cfm. Then select the full-scale

frequency ranqe, as explained in Step 4 of Section II. In our example,

this would be the 5000-Hz setting.

Now select the Digital Indicator scale that accommodates the full-scale

output of the transducer in the desired unit of measurement. In our ex-

ample, this scale would be ± 10000, with decimal point to the left of the

last zero, giving a full-scale reading of 1000.0, to accommodate a full-

scale measurement of 728.2 cfm. For the setting of scale and decimal-

point location, refer to the Model 3200/3300 Instruction Manual.

Fig. 5

Model

3140A

Front Panel

6

normally scaled for a full-scale output of +5 volts.

7

3A. SPAN ADJUSTMENT: Apply an input signal with a frequency equal to the

rated full-scale output of the transducer. Then adjust the Coarse and

Fine SPAN controls to produce a readout on the indicator of the value de-

termined in Step 2A, above--that is, of the full-scale transducer output

in terms of the desired unit of measurement (e.g., 728.2 cfm).

4A. TRIGGER LEVEL ADJUSTMENT: as in Step 4, above.

IV. Verification of Normal Operation

If the Model 3140A is suspected of faulty operation, you should do the fol-

lowing:

1.

2.

3.

If the unit is TOTALLY INOPERATIONAL (front-panel LED indicator does not

light), first check the primary power fuse (F1) located on the standup

board which forms the power-cord connection point. If this fuse is blown,

replace it with a 0.50-amp fuse ("F" version, 0.125-amp but not before

determining the cause of overload (inspect the input power connections for

any short-circuiting, etc.).

Push the front-panel CAL button, and observe the analog output. If it is

stable, noise-free, and adjustable via the Coarse and Fine SPAN controls,

then you can assume that all circuits--with the exception of the front-end

amplifier and trigger circuits--are functioning normally.

To check the front-end circuitry, replace the transducer and cable with a

transducer and cable known to be in good condition and operating reliably.

If the 3140A works properly with this different input source, then the

problem most likely lies in the original transducer/cable. However, if

the observed malfunction persists after this substitution, repairs to the

3140A are probably indicated.

MODEL

3200 / 3300

DIGITAL INDICATOR

SB.5

INSTRUCTION MANUAL

3000

Instrument Series

MODEL

3200 / 3300

DIGITAL INDICATOR

INSTRUCTION MANUAL

Model 3200/3300 Instruction Manual, v. SB.5

Pub. No. 3200/3300M.5, Issued 10/96

Part No. 91130

Daytronic Corporation

Dayton, OH • Tel (800) 668-4745

www.daytronic.com

Daytronic Corporation

TABLE OF CONTENTS

Section Page

1

Description ..................................................... 1

2

Installation ......................................................

4

3

Operation

....................................................... 7

4

Block Diagram Description .......................................

8

5

Verification of Normal Operation ..................................

15

LIST OF ILLUSTRATIONS

Figure

Page

1

3000 Series Instrument with Digital Indicator .......................

1

2

Full-Scale Displays for Three Ranges ..............................

6

3

Scale, Decimal Point, Dummy Zero Switches .......................

7

4

A/D Converter Timing Diagram ...................................

5Block Diagram Description

LIST OF TABLES

Table

Page

1

3000 Series Model Numbering ....................................

2

2

Specifications

.................................................... 4

PLEASE NOTE: Sections 6 and 7, Figures 6 and 7, and Table 3 have been

removed from this manual.

If you need information regarding specific 3200/3300 components and

circuitry, please contact the Daytronic Service Department at (937) 293-2566.

....................................... 13

10

Daytronic Corporation

INSTRUCTION MANUAL

3200/3300

SERIES DIGITAL INDICATOR

1. DESCRIPTION

The 3000

Instrument

Series

is a family of premium signal conditioning instru-

ments that includes models to

accomodate

virtually all types of transducers and

signal sources commonly encountered in electro-mechanical testing and control

operations. The 3000

Instruments

are available in three forms: Form 1 contains the

Signal Conditioner only; Form 2 is the Signal Conditioner with Digital Indicator;

Form 3 is the Signal Conditioner with Digital Indicator and Hi-Lo Limits. The

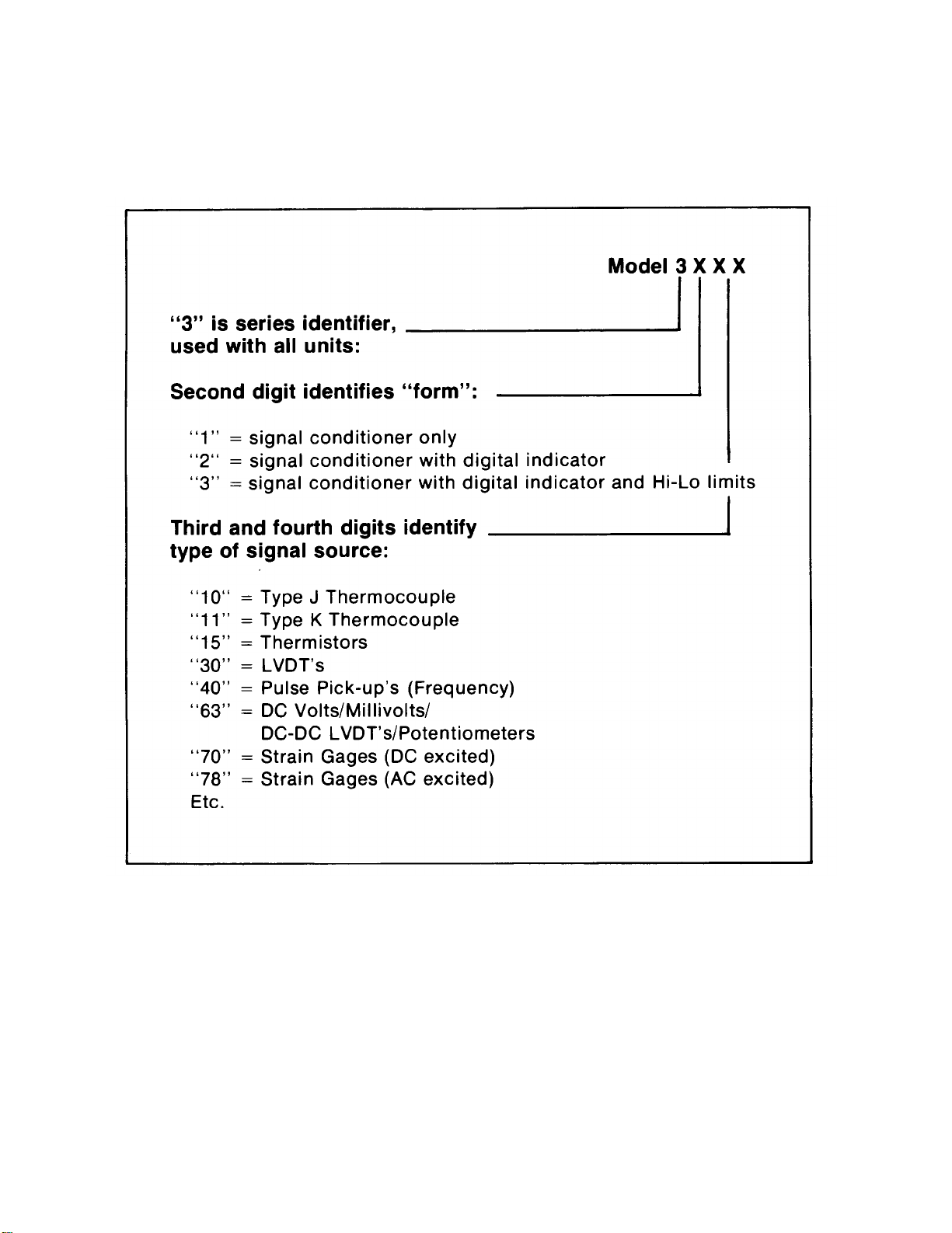

Model numbering system used with the 3000 Series identifies the form and the type

of signal source. This numbering system is further explained in Table 1. From Table

1, it can be seen that all models having a Digital Indicator are identified by a 32XX or

33XX number, with the last two digits identifying the type of signal source (ther-

mocouple, LVDT, etc).

Figure 1. 3000 Series Instrument with Digital Indicator 1

"3000"

Digital Indicator

Table 1. 3000 Series Model Numbering

The 3000 Series instruction manual system is designed to provide the user with

the following documentation: (1) a separate instruction manual for each type of

Signal Conditioner purchased; (2) an instruction manual covering only the Digital

Indicator section of a 3000 Series instrument, but applicable to any Form 2 or Form

3 instruments; and (3) an instruction manual covering only the Hi-Lo Limit section

2

Daytronic Corporation

of a

3000

Series instrument, but applicable to any Form 3 instrument. It is the

purpose of this manual to cover the Digital Indicator section of all Form 2 and Form

3 instruments.

The Digital Indicator section of any Form 2 or Form 3 instrument consists of a

printed-circuit board on which are mounted the required circuit components for

digitizing the analog output of the Signal Conditioner and the light-emitting-diode

(LED) display. This board is mounted above the circuit board which contains the

components for the Signal Conditioner. The digits which comprise the display are

mounted on a small board which is affixed to the digitizer board with a right-angle

printed-circuit board header. The Form 3 instruments contain an additional

printed-circuit board for the Hi-Lo Limit circuitry.

The LED display is comprised of six orange digits with polarity sign. The 0.4 inch

height of the digits, combined with the inherent brilliance of an LED type of display,

make the display easily discernible in normal room lighting. The display is viewed

through the red plastic front panel of the instrument to provide filtering of external

light and enhance the display brilliance. The front panel is opaque except for that

portion through which the display is viewed. A typical 3000 Instrument with Digital

Indicator is shown in Figure 1.

The Digital Indicator scaling is selected with rear-panel pushbutton switches.

Full-scale values of ±5000 counted by

1's,

±

10000 counted by

2's,

or

±20000

counted by

5's

can be selected. The most significant digit (MSD) of the display

contains the polarity sign and is either unlit or lights as a 1for displays of 10000 or

greater. The least significant digit (LSD) is a dummy zero which can be turned ON

or left unlit as desired. In addition, decimal-point position can be selected to give

display readings as follows:

1.XXXX,

lX.XXX,

1XX.XX,

1XXX.X,

or

1XXXX

(no decimal point). Decimal-point location and dummy zero selection are also

accomplished with rear-panel switches (miniature slide-switch bank). When the

20000 scale is selected, the display is digitally limited to read a maximum number of

19995 since the MSD is either unlit or reads a "1" for displays of 10000 or greater.

The 5000 and 10000 scales are analog limited to an overrange of approximately 5600

and 11200, respectively. An overrange condition on any range is indicated by a

flashing display. The sampling rate of the display is 3 samples per second. The

Digital Indicator specifications are summarized in Table 2.

3

"3000" Digital Indicator

Table 2. Specifications

Display: Orange LED’s, six digits with polarity sign, 0.4 inch height.

MDS

is either unlit or reads a 1 and contains the polarity sign. LSD is a

dummy zero which can be programmed to be lit or unlit (rear-panel

switch).

Scaling: Selectable at rear panel; full-scale values of ±5000 counted

by

1's,

±

10000 counted by

2's,

or

±20000

counted by

5's.

Decimal Point: Decimal-point location can be selected with rear-

panel switches as follows:

1.XXXX,

1X.XXX,

1XX.XX,

1XXX.X,

or

1XXXX

(no decimal point).

Sampling Rate: 3 samples per second.

Legends: Each instrument supplied with an appropriate assortment

of user-installable rub-on engineering unit legends.

2. INSTALLATION

The 3000 Series Instruments can be operated as bench-top instruments or they

can be rack- or panel-mounted. Dimensions for all three types of mounting and

corresponding mounting instructions are given in the accompanying Signal Con-

ditioner Instruction

Manual.

The following paragraphs provide the instructions for

legend installation, scale selection, decimal point/dummy zero selection, and ac

power connection.

Legend

Installation.

A sheet of dry-transfer lettering is supplied with each

instrument to provide the user with a means of affixing an engineering-unit legend to

the front panel. The sheet contains the common engineering units encountered in

making electro-mechanical measurements and additional alpha-numeric charac-

ters. Space is supplied on the front panel to affix the desired legend to the right of the

display. To affix the legend to the front panel, press the dry-transfer sheet firmly

4

Daytronic Corporation

against the panel with the desired legend or character situated in place. Rubbing the

legend or character with a ball-point pen will cause the legend to be transferred onto

the panel. The legend can be protected from scratches which may occur during

calibration/operation of the instrument by lightly spraying it with Krylon

#1306

Workable Fixative.

If it is desired to change a legend, remove the legend to be replaced by pressing

masking tape against the legend, then pulling off the gummed tape.

Scale Selection. Figure 2 shows the full-scale display for the three selectable

scales: ±5000 counted by 1's,±10000 counted by 2's, and ±20000 counted by 5's.

The figure also indicates the last active digit and the dummy zero which can be lit for

any scale selection. The first digit of the display contains the polarity sign and lights

as 1on the 10000 and 20000 scales for values equal to or greater than 10000. On the

20000 range, because the most significant digit is either unlit or a 1and the count is

by 5's,

the greatest number which can be displayed is 19995. Of course, this would be

displayed as 199950 if the dummy zero were lit.

Scale selection is accomplished with the two pushbutton switches located at the

rear panel. The panel is marked to indicate which switches are pushed IN or left

OUT for the corresponding scale selection. The switches have a push-push action

and are illustrated, with the scale selection coding, in Figure 3. With both switches

OUT, the ±5000 range is selected. With the left switch OUT and the right switch

IN, the

±

10000 range is selected. With the left switch IN and the right switch OUT,

the

±

20000 range is selected.

Decimal Point/Dummy Zero Selection. Decimal-point location and

dummy-

zero activation are selected with a rear-panel miniature slide switch bank. The

switch bank is marked on the rear panel as shown in Figure 3. The decimal-point

position can be fixed at any one of the display locations indicated on Figure 3. Place

any one of slide switches 1through 4 ON to light the decimal point at the desired

location. Place slide switch 5 ON if no decimal point is to be lit. To activate the

dummy zero (digit to the right of last active digit will continuously light as a zero),

place slide switch 6 ON.

AC Power Connection. To protect operating personnel, the 3000

Series

Instru-

ments are equipped with a three-conductor power cord. When the cord is plugged

into the appropriate receptacle, the instrument is grounded. The offset pin on the

5

"3000" Digital Indicator

Figure 2. Full-Scale Displays for Three Ranges

6

A. ±20000 Range

B. ±10000 Range

C. ±5000 Range

Daytronic Corporation

power cord is ground. To maintain the safety ground when operating the instrument

from a two-contact outlet, use a three-prong to two-prong adaptor and connect the

green pigtail on the adaptor to ground.

To prepare the instrument for operation, connect the power cable to a 105-135

volt ac, 50-400 Hz power source. The instrument can use up to 5watts of power.

3. OPERATION

The only operation required is turning ON/OFF ac power to the instrument. This

is accomplished with the rear-panel slide switch (see Figure 3). The display lights

immediately when ac power is ON.

NOTE

In all instances, a flashing display indicates that an overrange condition

has occurred, and it is likely that the Signal Conditioner amplifiers are

being overdriven. The 5000 and 10000 ranges are analog limited at

approximately 5600 and 11200, and while a number may be displayed, if

Figure 3.

Scale,

Decimal Point, Dummy Zero Switches 7

Other manuals for 3000 series

2

This manual suits for next models

3

Popular Industrial Electrical manuals by other brands

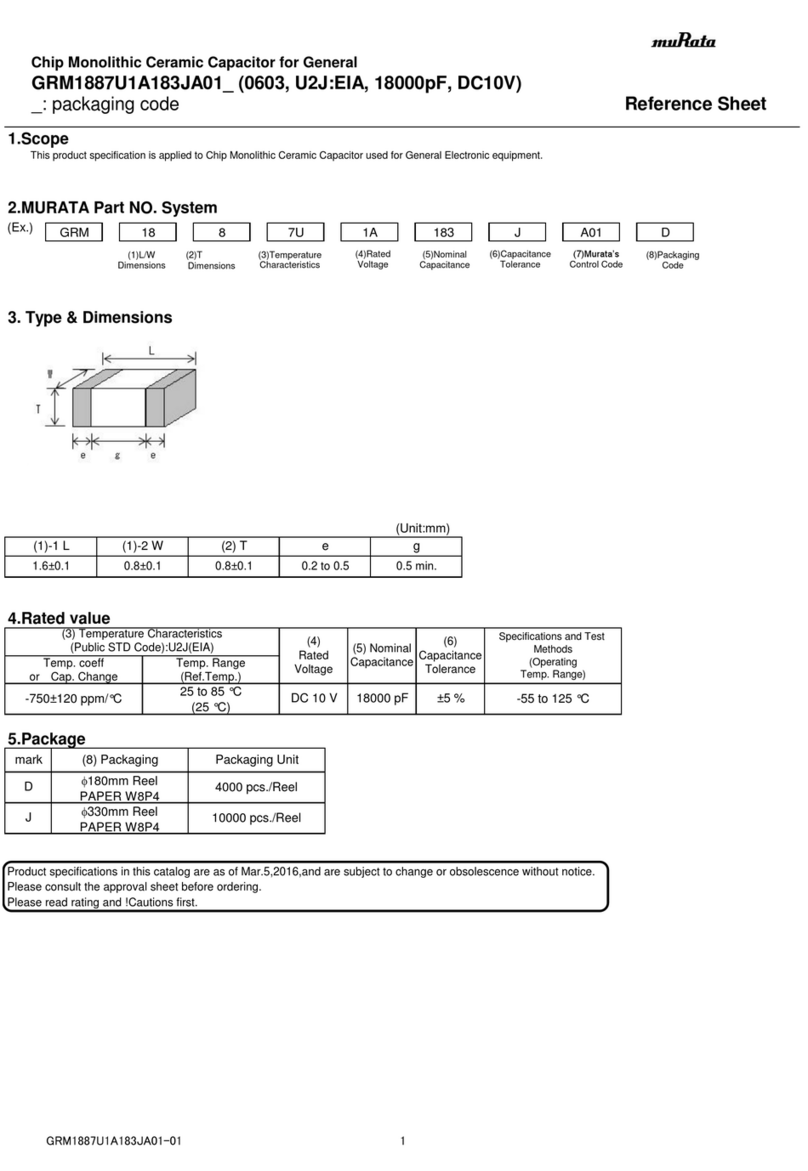

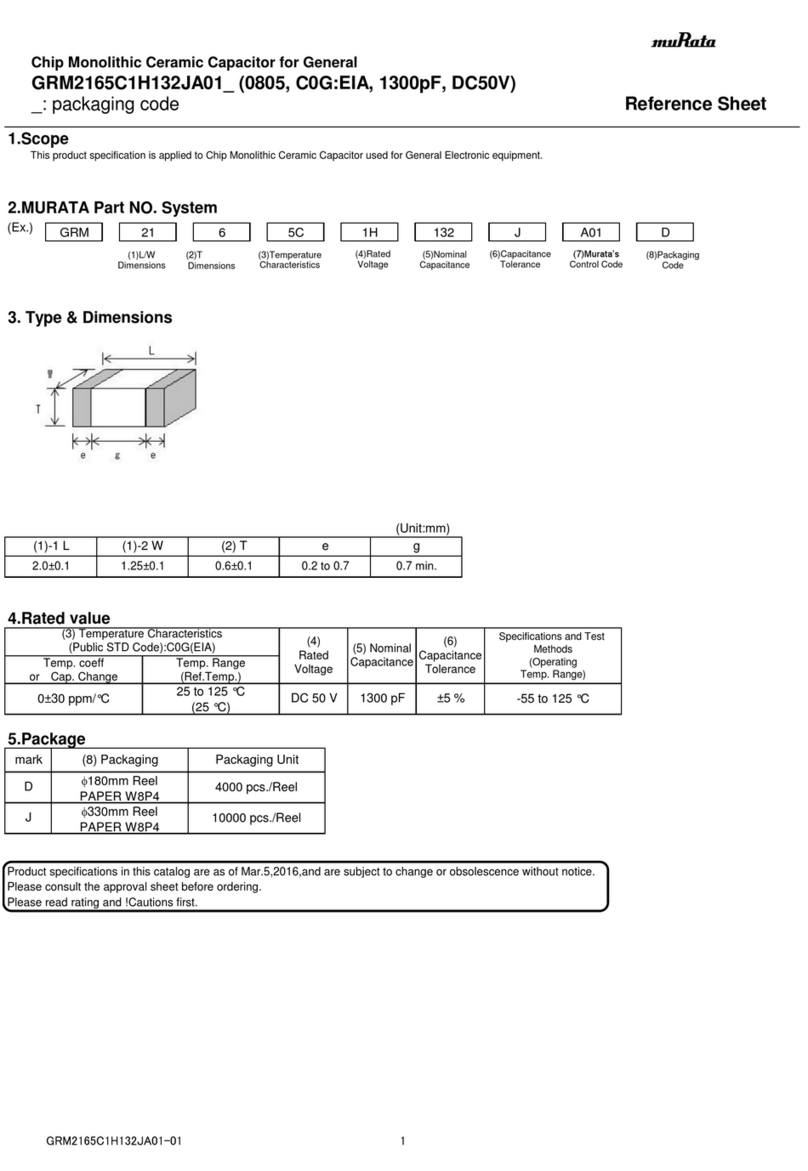

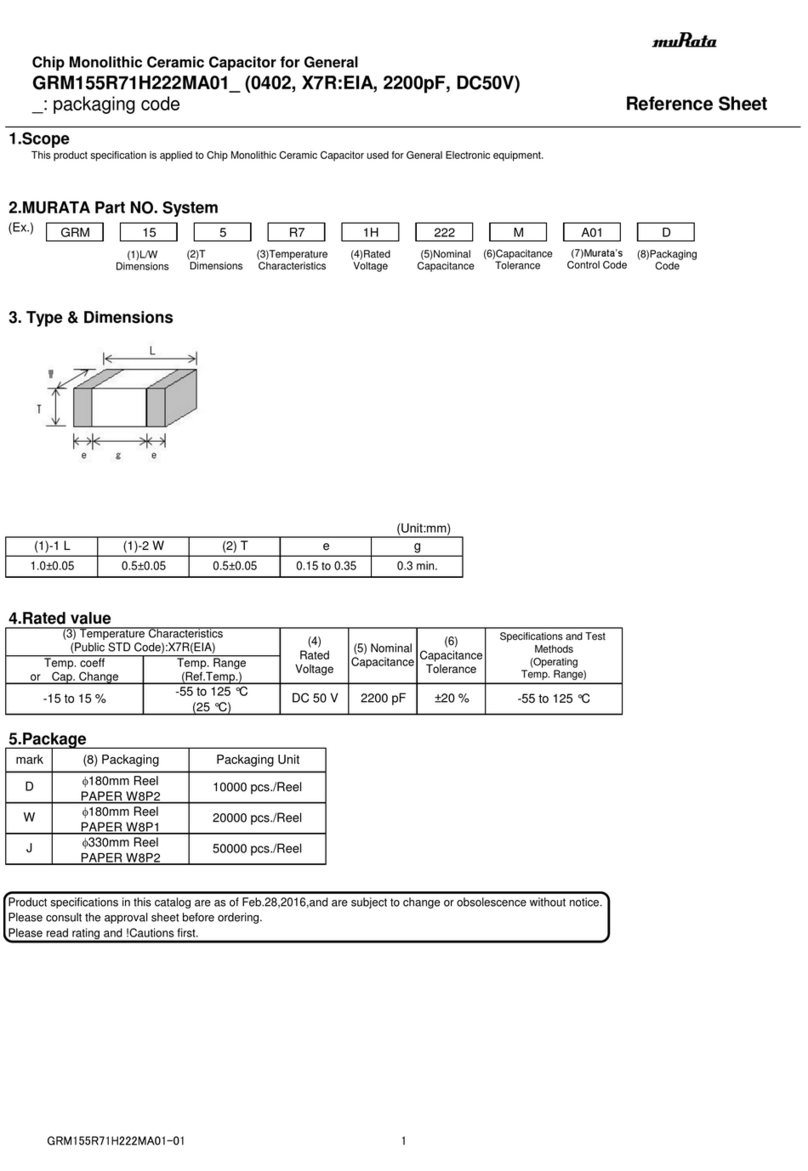

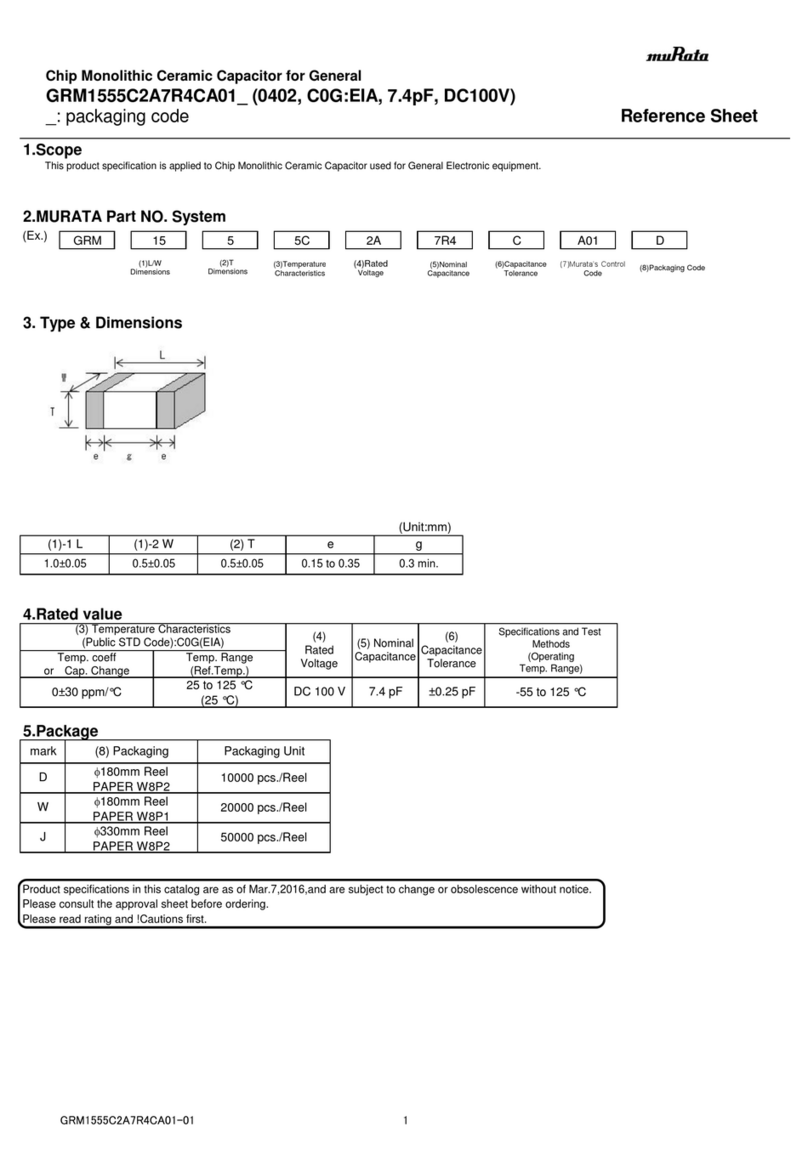

Murata

Murata GRM1555C2A7R4CA01 Series Reference sheet

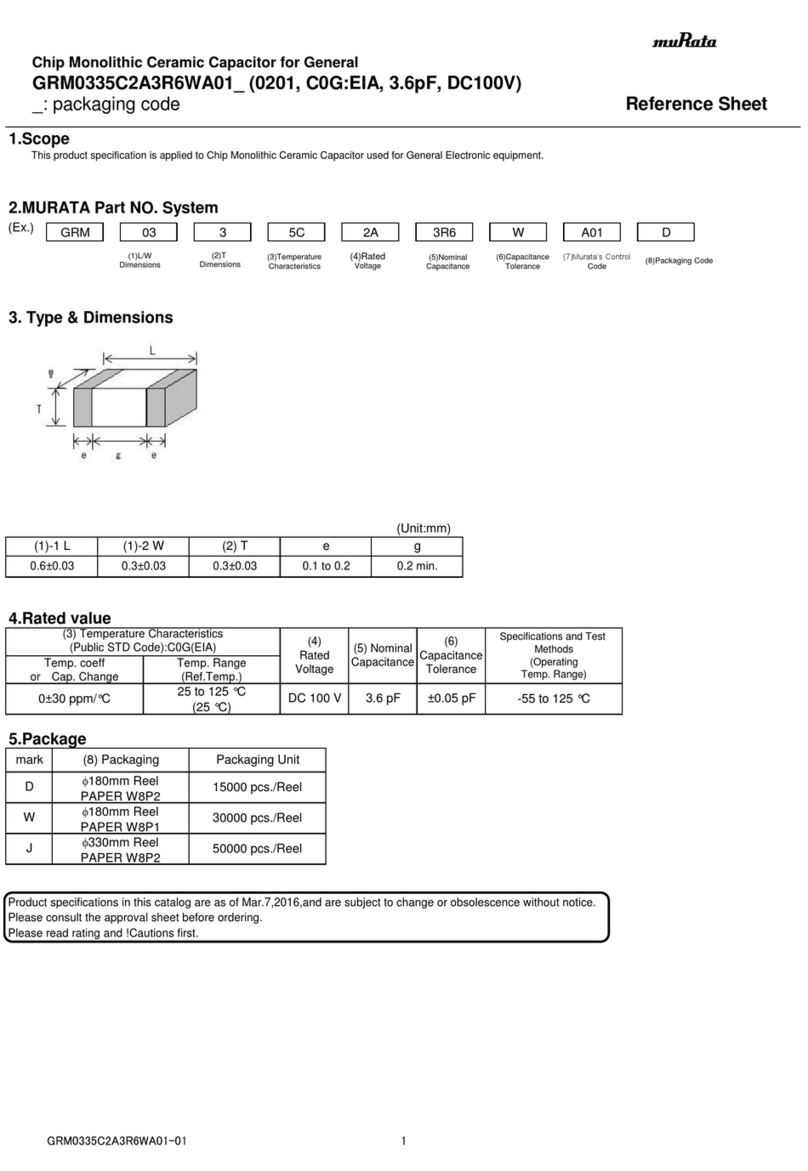

Murata

Murata GRM0335C2A3R6WA01 Series Reference sheet

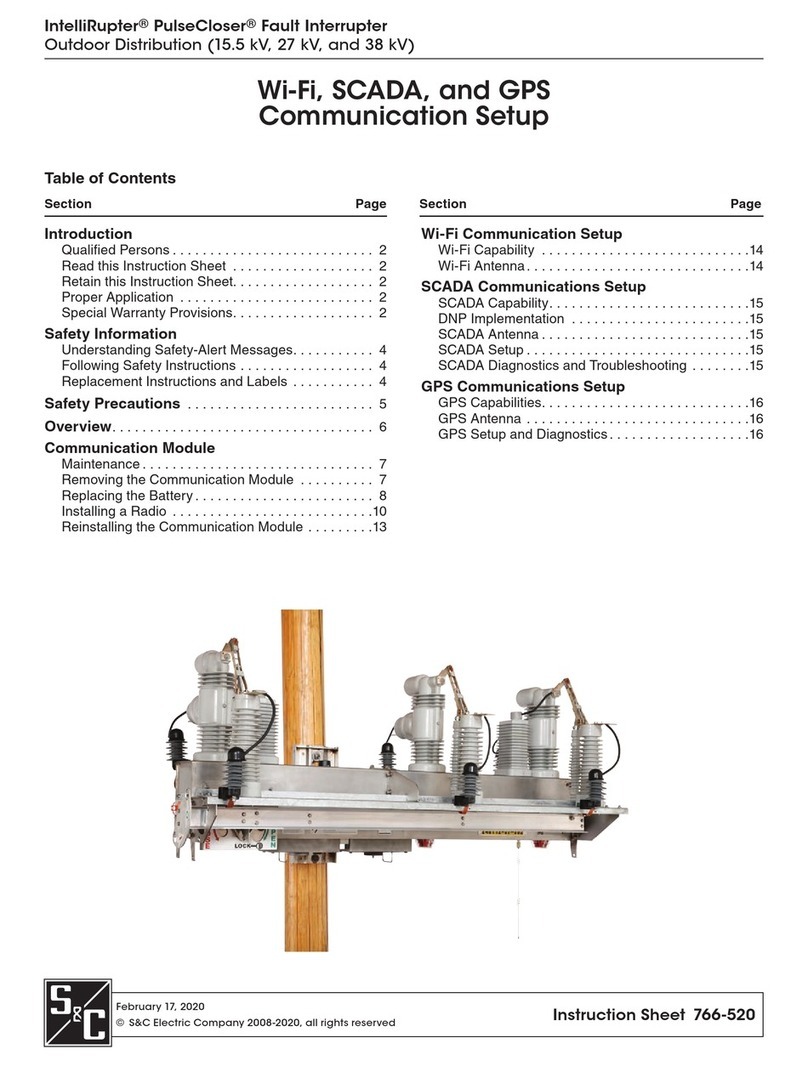

S&C

S&C IntelliRupter PulseCloser instruction sheet

Murata

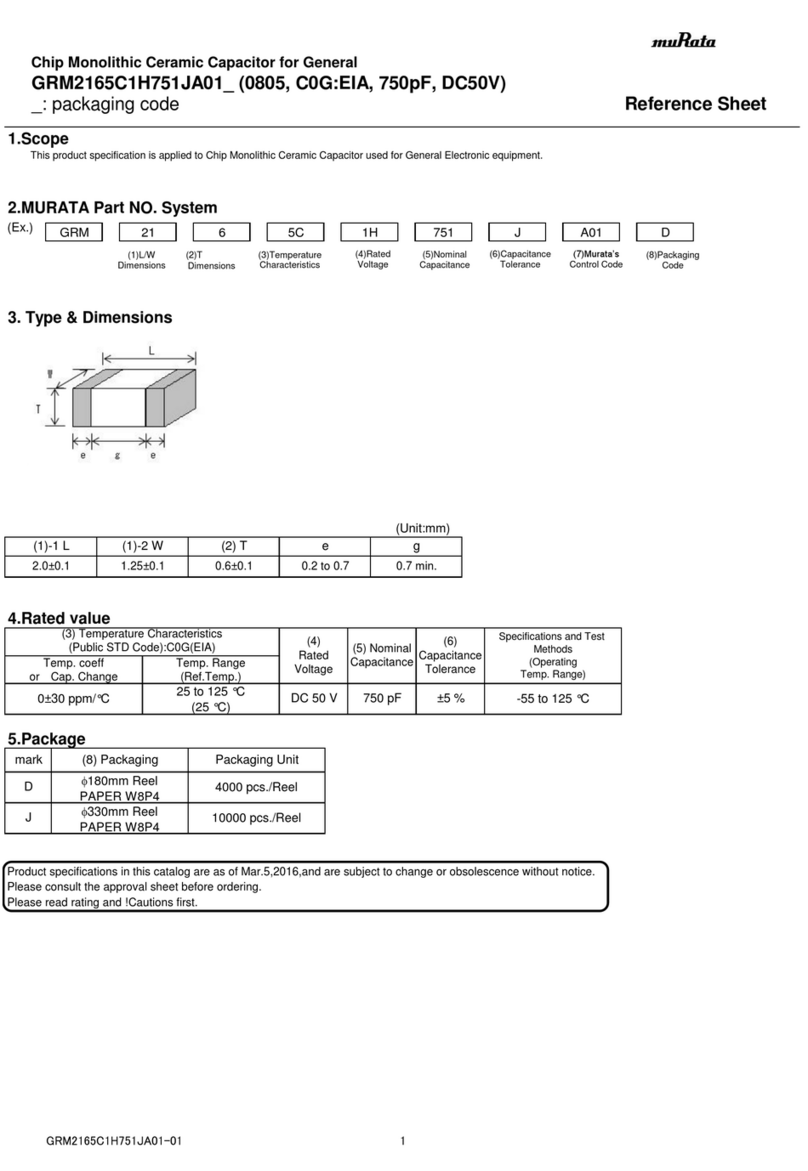

Murata GRM2165C1H751JA01 Series Reference sheet

Murata

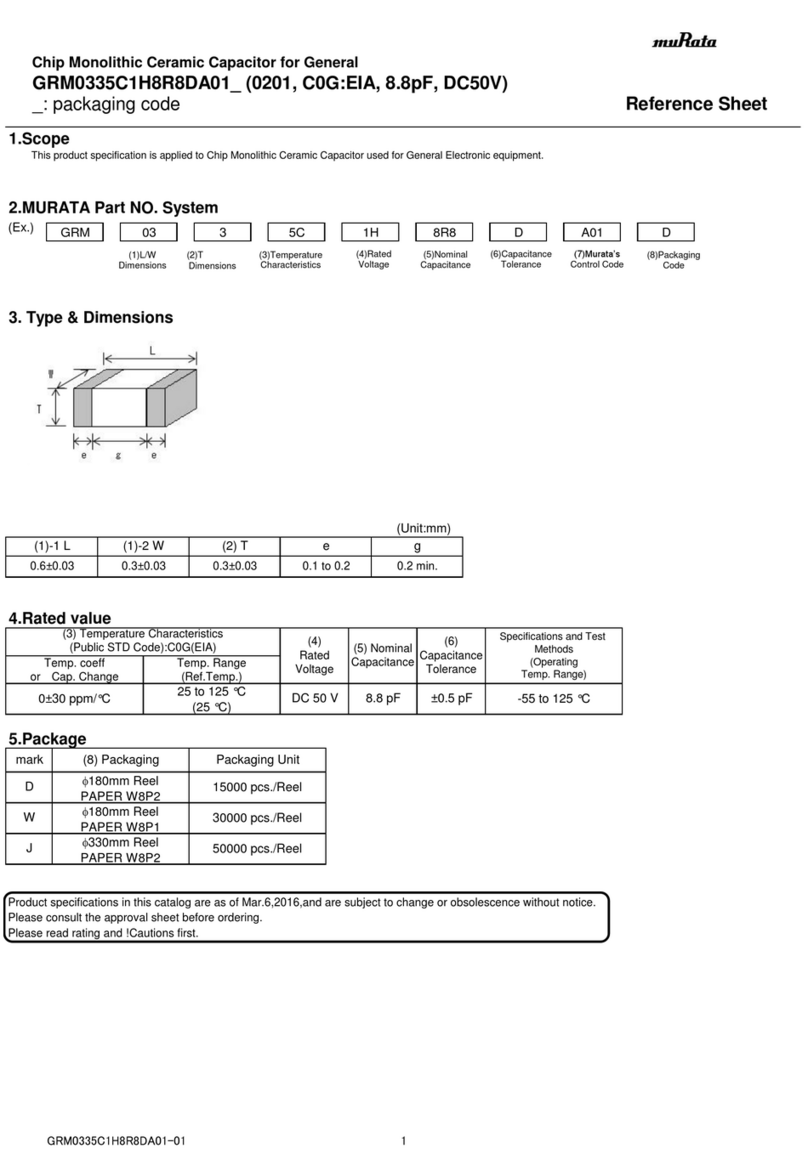

Murata GRM0335C1H8R8DA01 Series Reference sheet

Murata

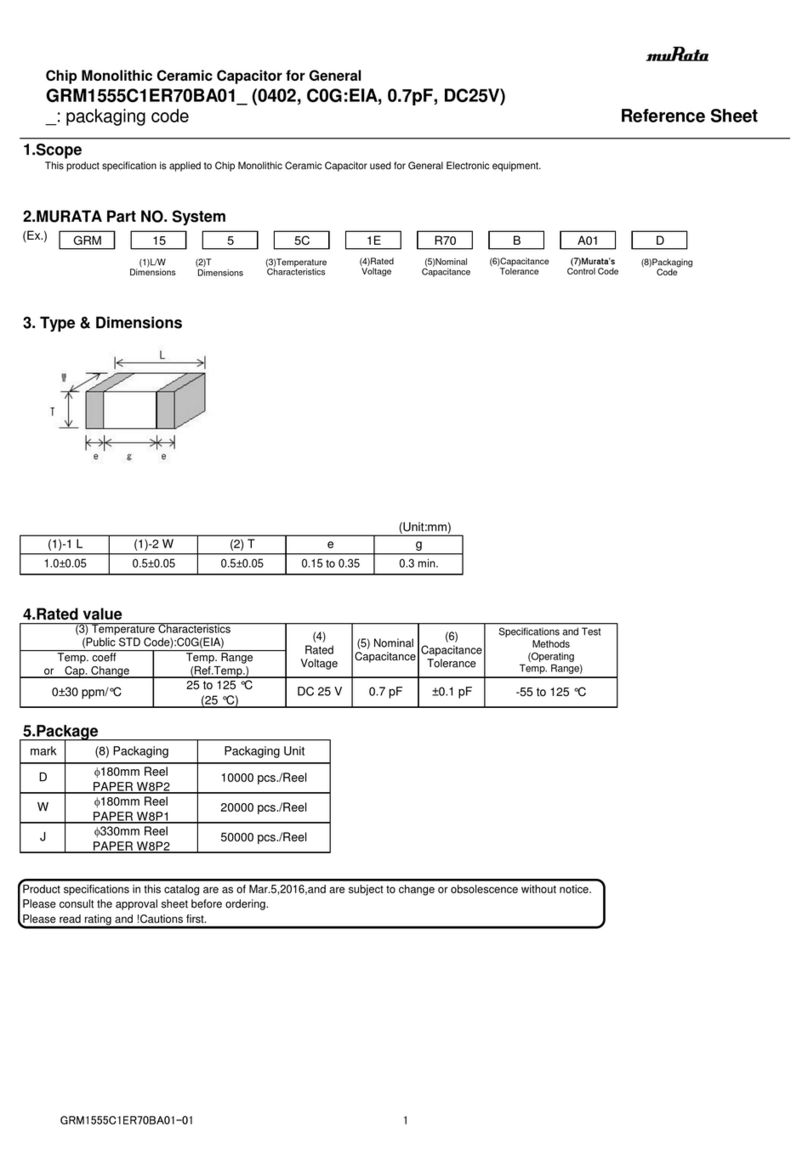

Murata GRM1555C1ER70BA01 Series Reference sheet

Rockwell Automation

Rockwell Automation Allen-Bradley CENTERLINE 1500 user manual

Murata

Murata GRM31CR61E475KA88 Series Reference sheet

ABB

ABB SACE Emax 2 manual

Circutor

Circutor OPTIM P&P Series instruction manual

Graphic Whizard

Graphic Whizard Finishmaster 100 Reference manual

Kathrein

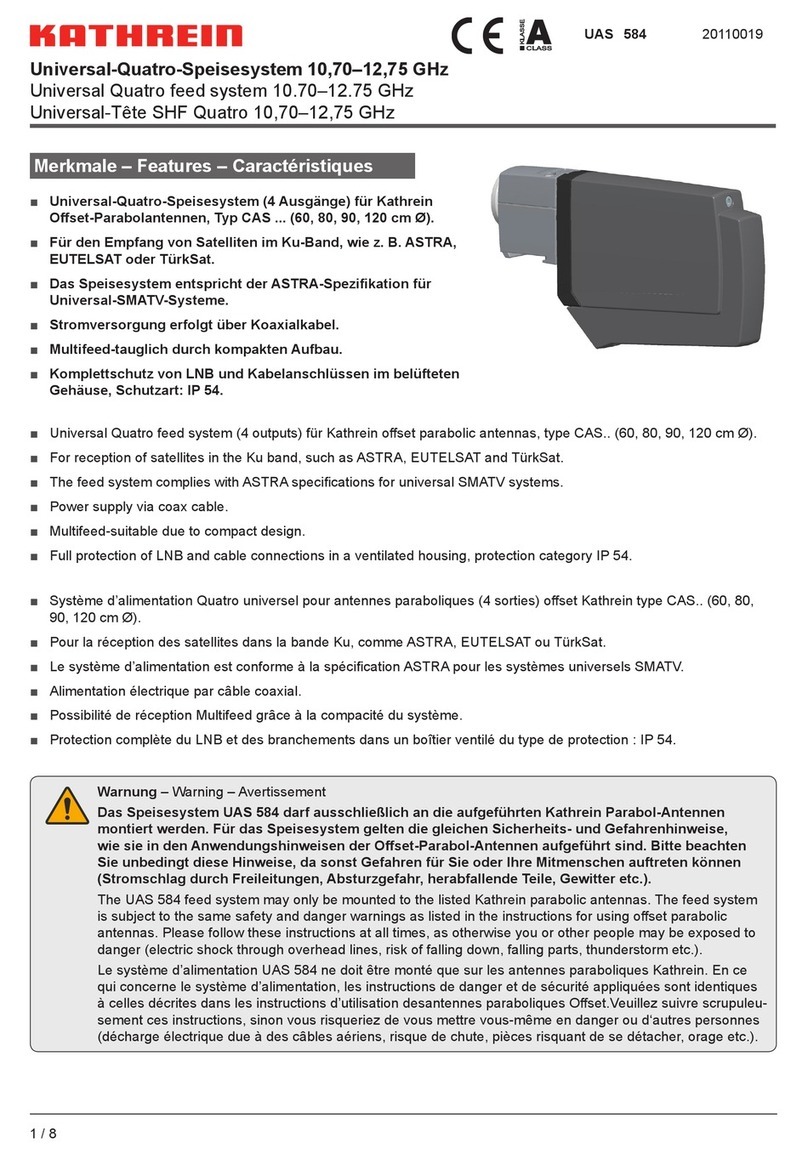

Kathrein 20110019 Mounting instructions