DC SD40 Manual

OPERATION

REMOVE ALL DEBRIS FROM THE GLASSES TO BE WASHED BEFORE PLACING THEM INTO THE BASKET.

CLOSE THE DOOR - PRESS THE CYCLE START SWITCH - THE CYCLE LAMP WILL COME ON.

AT THE END OF THE CYCLE THE WASH CYCLE LAMP WILL GO OUT .SHORT BURSTS OF THE COLD RINSE SWITCH WILL COOL THE GLASSES FOR SERVICE.

OPEN THE DOOR AND PULL OUT THE BASKET.ALLOW EXCESS WATER TO RUN OFF BEFORE REMOVING.

PREPARATION

CHECK THE DRAIN PLUG IS PUSHED FIRMLY IN PLACE AND FILTERS ARE PROPERLY SECURED.

CHECK THE DETERGENT CHEMICAL ( RED ) AND RINSE AID CHEMICAL ( CLEAR ) SUPPLY TUBES - WITH FOOT VALVES - ARE SUBMERGED IN SUFFICIENT PRODUCT.

CHECK THE DOOR IS CLOSED AND PRESS THE POWER SWITCH - THE GREEN POWER LAMP WILL COME ON.

ALLOW 30 MINUTES FOR THE MACHINE TO FILL WITH WATER AND REACH THE CORRECT WASHING TEMPERATURE.THE MACHINE READY LAMP WILL COME ON.

ROUTINE MAINTENANCE

AT THE END OF A SESSION TURN OFF THE POWER SWITCH. DO NOT REMOVE THE FILTER AT THIS STAGE.

REMOVE THE DRAIN PLUG - THE WASH TANK WILL EMPTY - (MACHINES FITTED WITH DRAIN PUMP WILL AUTOMATICALLY START TO PUMP THE WATER OUT).

COLLECT THE DEBRIS AND REMOVE FROM THE WASH TANK.

CLEAN AROUND THE WASH TANK - DOOR SURROUNDS AND HINGES WITH AN 'ADDIS'’ TYPE WASHING UP BRUSH AND CLEANING CLOTH.

DO NOT USE CHLORIDE OR BLEACH CONTAINING BASED CLEANING SOLUTIONS OR ABRASIVES WHEN CLEANING THE WASH TANK.

TAKE OUT THE MAIN FILTER - CLEAN THOROUGHLY AND REPLACE .

DO NOT ALLOW DEBRIS TO GO DOWN THROUGH THE FIXED FILTER AND OUTLET HOLE AS THIS MAY DAMAGE YOUR MACHINE.

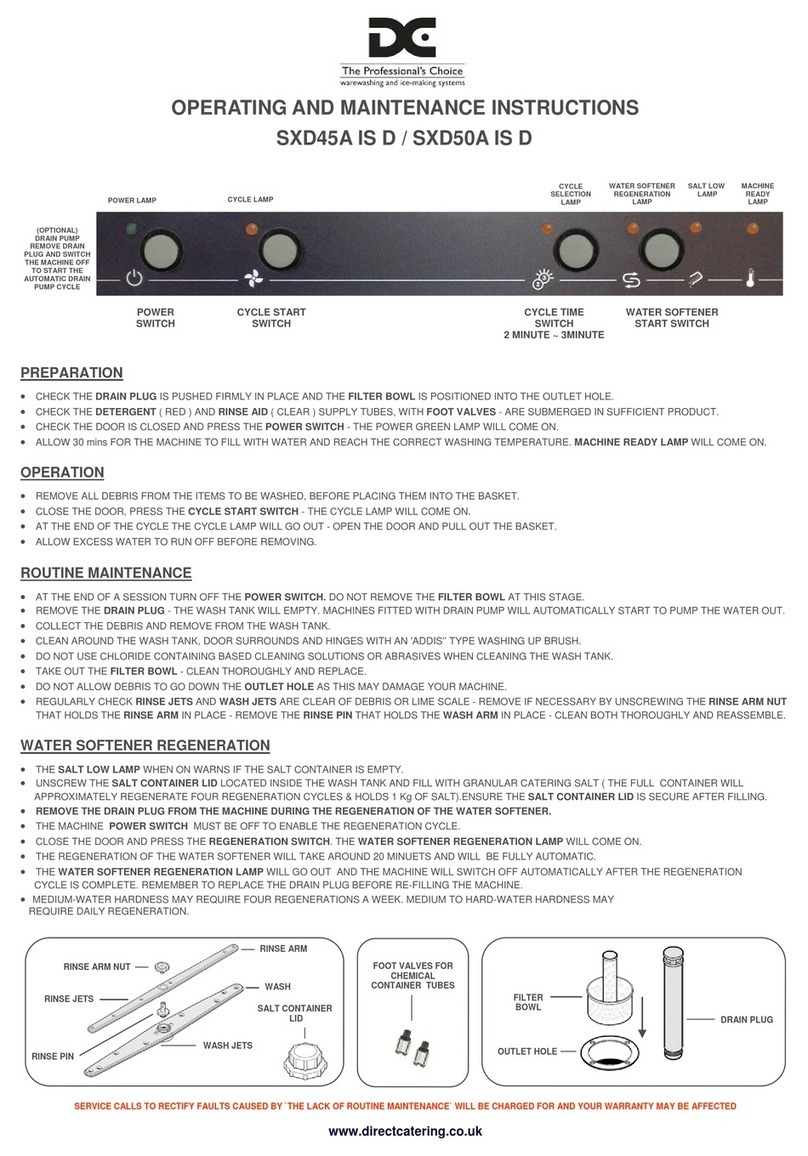

REGULARLY CHECK RINSE JETS AND WASH JETS ARE CLEAR OF DEBRIS OR LIME SCALE - REMOVE IF NECESSARY BY UNSCREWING THE RINSE ARM NUT THAT HOLDS THE

RINSE ARM IN PLACE - REMOVE THE RINSE PIN THAT HOLDS THE WASH ARM IN PLACE - CLEAN BOTH THOROUGHLY AND REASSEMBLE.

SERVICE CALLS TO RECTIFY FAULTS CAUSED BY `THE LACK OF ROUTINE MAINTENANCE` WILL BE CHARGED FOR

AND YOUR WARRANTY MAY BE AFFECTED

www.directcatering.co.uk

WATER SOFTENER

REMEMBER TO REGENERATE THE EXTERNAL WATER SOFTENER IF FITTED REGULARLY. ENSURE THAT THE WATER VALVES ARE TURNED BACK ON TO SUPPLY

THE MACHINE WITH MAINS PRESSURE SOFTENED WATER.

(OPTIONAL DRAIN PUMP)

REMOVE DRAIN PLUG THEN

SWITCH THE MACHINE OFF

TO START THE AUTOMATIC

DRAIN PUMP CYCLE

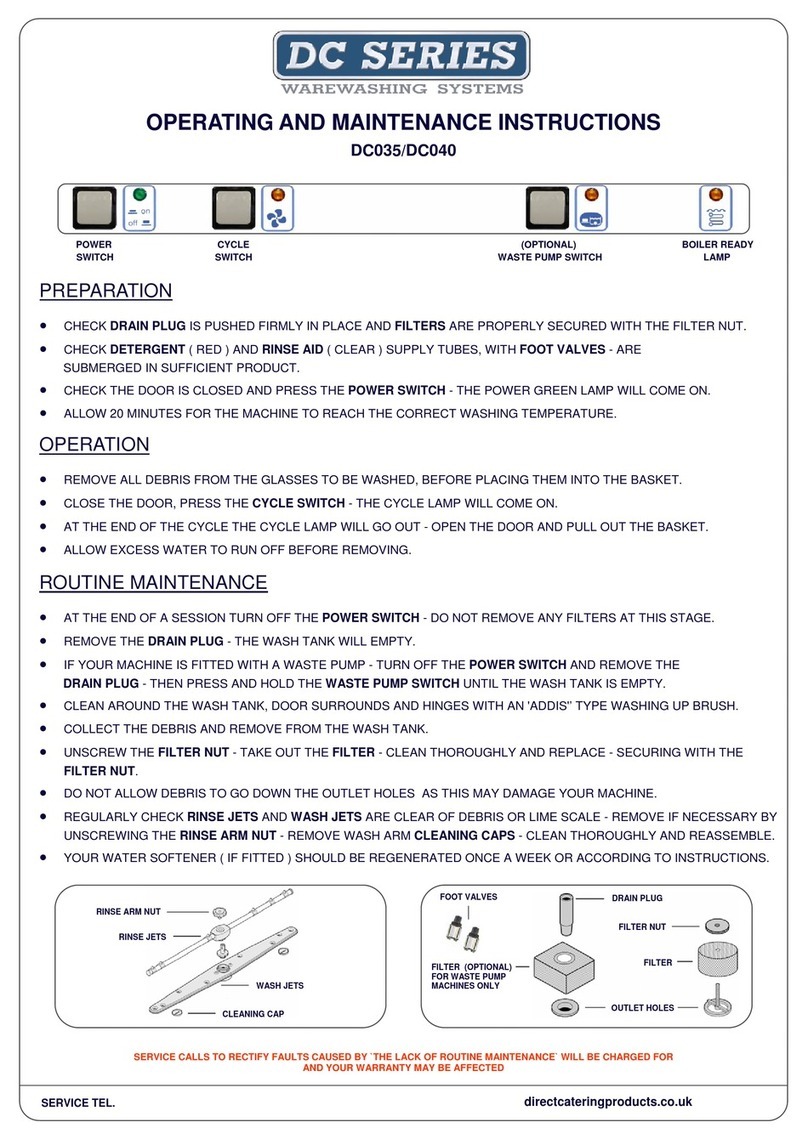

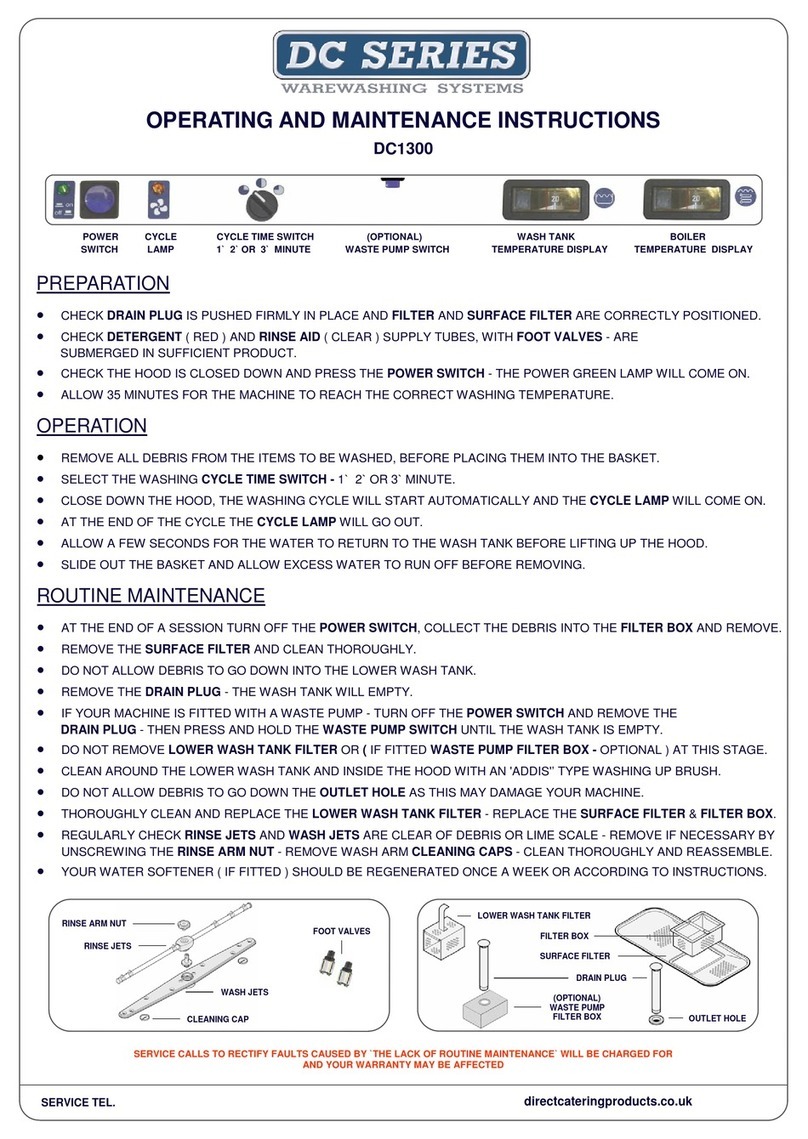

MAIN FILTER

OUTLET HOLE

FOOT VALVES FOR

CHEMICAL

CONTAINER TUBES

RINSE ARM NUT

RINSE

JETS

WASH JETS

RINSE PIN

RINSE ARM

WASH ARM

FIXED FILTER

DRAIN PLUG

POWER

LAMP

WASH CYCLE

LAMP

MACHINE READY

LAMP

POWER

SWITCH

CYCLE START

SWITCH

COLD RINSE

SWITCH

OPERATING AND MAINTENANCE INSTRUCTIONS

SD40 (COLD RINSE)

Instruct the staff on the use of this machine with the operators instructions provided

(see overleaf)

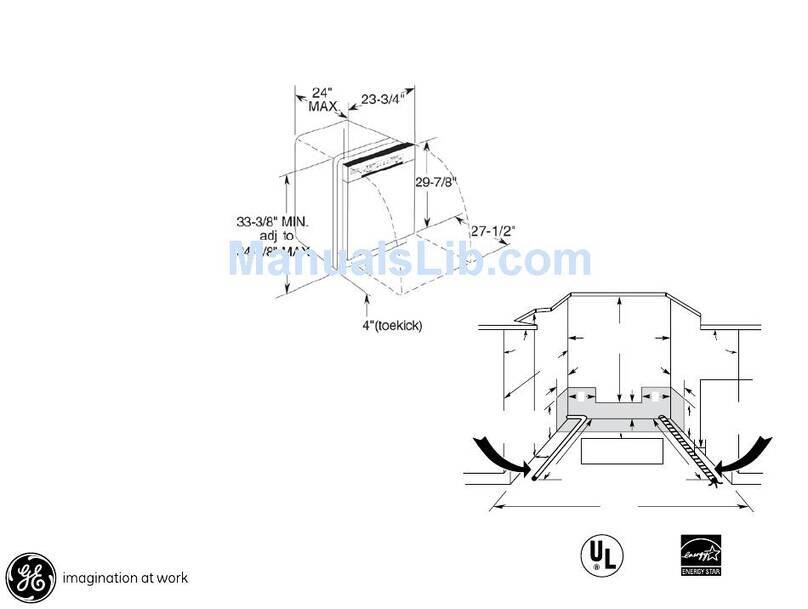

Preparing the location & machine

• Verify the intended or existing electrical connections agrees with the specifications on the machine id. plate located on the right side panel of the machine.

• Check the machine and stand (if supplied) will fit in/under the location for installation.

• Clear the location where the machine will be installed, remove any unused tubes or redundant plumbing that will not be used for the new installation.

• Clear a location for the Detergent & Rinse aid chemicals (as close to the machine as possible, this can be to the left or right).

• Remove any redundant wiring (if removing old machine) WARNING! be sure the electrical power has been turned off at the breaker/main fuse box.

• Remove the protective plastic covering from the machine & keep the packaging materials and pallet until the installation is complete.

Water supply

• Place the machine near to the location (allowing room behind the machine to connect the water and waste hoses).

• Connect the mains cold water hose 3/4 BSP (supplied) from the machine to a mains water shut off tap (not supplied). This shut off tap should already be

fitted to the existing plumbing on site.

• If connecting a water softener use an extra mains cold water hose to connect from the machine to the softener and then to the mains water shut of tap.

Gravity waste

• Connect the waste hose directly into the waste outlet. This can be sealed into the pipe.

• A “running trap ” or “P trap” must be used to prevent odours returning into the machine.

• The hose can be shortened but enough slack should be left to allow the machine to be pulled out for servicing.

• The waste outlet “running trap ” or “P trap” level should be around 100mm below the water level inside the machine

to allow proper drainage.

• Make sure drain hose is kink-free and not liable to be crushed when the machine is pushed into place.

Pumped waste

• Connect the waste hose directly into the waste stand pipe. This should be approximately 400mm above the water

level inside the wash tank of the machine.

• Insert the waste hose into the stand pipe using the high loop hook. (supplied).

• Do not seal the waste hose into the stand pipe, this must be plumbed as an “open to air “ connection.

• A “running trap ” or “P trap” should be used to prevent odours returning into the machine.

• Make sure drain hose is kink-free and not liable to be crushed when the machine is pushed into place.

Electrical connections

• Connect the mains cable supplied with the machine to the 13amp socket or hard wire into 25amp or three phase

supply 16amps per phase as required by the machine specifications.

• Electrical supply 25amp or three phase supply must be connected by a qualified electrician or catering engineer

trained for this type of machine. There should be a suitably rated mains on/off switch fitted close to the machine.

Detergent and Rinse aid dosing pump priming and adjustment

• Remove the lower front panel of the machine to access the peristaltic dosing pump.

• Check the red detergent tube & clear rinse aid tubes do not fowl the cooling fan on the waste pump (if fitted).

• As the wash tank fills with water turn both adjustments to maximum temporarily to prime the machine with chemicals.

The 3 way rinse aid injector is pressurised by the wash pump, when the wash pump finishes a controlled amount is injected into the

rinse water system. To prime the rinse aid injector chemical pump first alow the machine to fill and begin heating then adjust the dial

to maximum,start and stop the wash cycle “Wash pump” to draw the chemical through the chemical tubes and into the rinse aid

injector. Remember to adjust the dial back to normal per cycle dosing amounts.

• Rinse aid hydraulic injection adjustment anti clockwise to increase. Clockwise to reduce quantity.

• Reduce the detergent adjustment to (3 - 5) test the washing results and increase the adjustment if necessary.

• As a guide only allow 2mm to 3mm of foam to be visible on the wash tank water surface at the end of a wash cycle.

WARNING! Failure to adjust the peristaltic dosing pump correctly will result in poor results or damage to the machine.

Too much rinse aid can result in foaming and cause cloudiness or streaks on glasses or dishes.

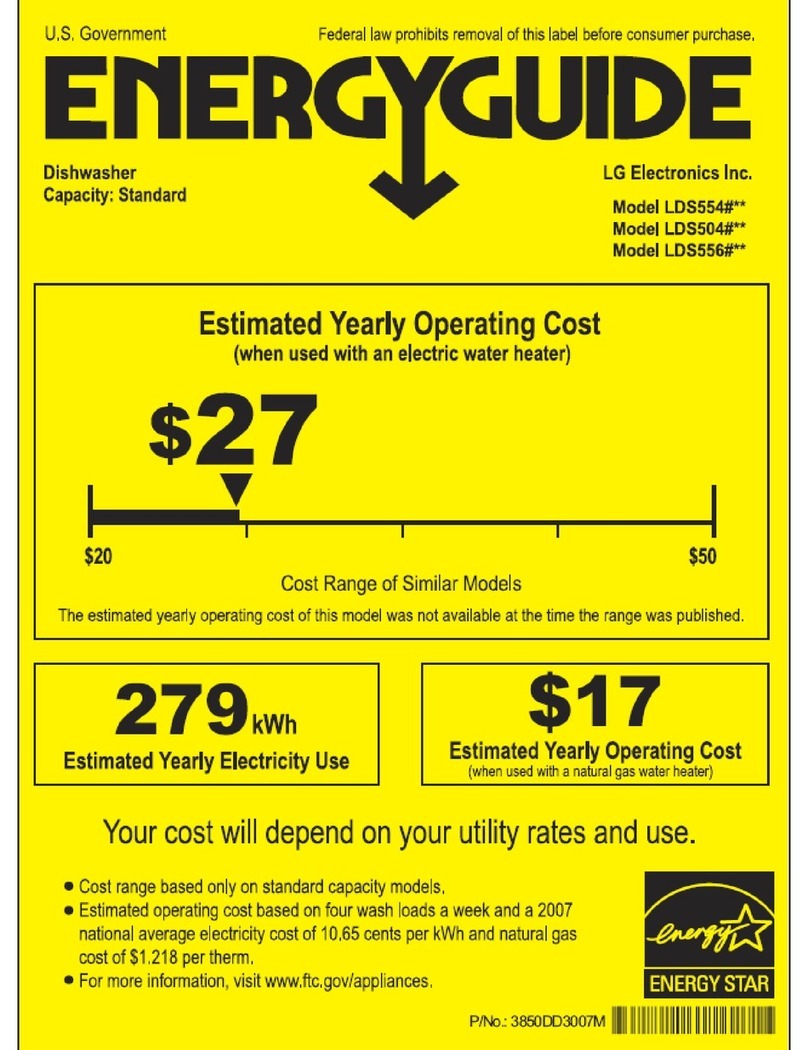

Hard water conditions will adversely affect washing performance and cause spotting on glasses or dishes.

To maximize the performance of the machine it is recommended that a water softener be fitted to improve the detergent and

rinse aid results and eliminate lime scale build up inside the machine.

Chemical products & suppliers may vary in the concentration and quality of there detergent and rinse aid, it is important that

adjustment are made with this taken into consideration. Changing supplier or concentration of the chemicals used in the

DC SERIES WARE WASHING INSTALLATION AND COMMISSIONING GUIDE

Pre-test

• Turn on the water supply to the machine and check for any leaks. Turn on the mains power supply and then the

machine on/off switch, the wash tank will start to fill and the boiler will begin to heat. The boiler amber lamp will go

out when the adjusted boiler temperature is reached (see commissioning the machine).

Dosing pumps adjustment

Commissioning the machine

• Adjust the rinse boiler thermostat temperature dial to 82c or as required. The wash tank thermostat will be factory set to 60c.

• The safety overload surface thermostat for boiler (NC) set to 110c

• Run through several cycles, the machine will wash and then move onto the rinse part of the cycle before finishing.

• Check for waste pump (if fitted) & dosing pump activation at the end of each cycle.

• Check temperatures for the rinse boiler and wash tank. Run several full basket loads through the machine and study

the results at the end of the wash cycle, adjust dosing pumps or temperatures accordingly.

• The machine ready lamp is connected to an independent surface thermostat fitted to the wash tank (NO) set at 42c

• Thermostop boiler rinse facility activated by connecting P7 on the pcb timer from 240v from the boiler thermostat output.

• The machine will start washing and calculate the cycle length and continue onto rinse when boiler temp is high.

WARNING

Removing the lower front or top panel will expose

an electric shock risk.Installation and servicing

must be carried out by qualified catering engineers

trained for this type of machine.

Gravity waste

100mm

Pumped waste

400mm

100mm

General safety

• The following installation procedures have been produced in conjunction with the user instructions and safety regulations book supplied with this machine.

• Installation and servicing must be carried out by qualified catering engineers trained for this type of machine.

• Earth bonding must be fitted to the lower rear bonding point of the machine and any tables and sinks connected to the machine.

• Direct Catering Products Ltd. will not be liable for any harm,injury or loss to property or persons, or consequences of incorrect installation or servicing.

Min Max

1

2

3

4

5

6

7

Adjustment

Detergent (Red tube)

Wash tank surface- thermostat

60c Normally closed

Rinse boiler thermostat

Adjustable 0 - 90c

Safety overload surface thermostat

110c Normally closed

Wash tank fitted surface thermostat

42c connected only to the machine

ready lamp - Normally open

Thermostop boiler controlled = p7

Rinse aid (Clear tube)

3/4 bsp external non return

valve for mains water

Follow arrow flow direction

Adjustment dial

Table of contents

Other DC Dishwasher manuals