DDK Ltd. CM10-AP2S-S User manual

CM10-AP××S-×(D6)

Angle Plug Connector

(Weight saving type

Cri p Type)

Cable Asse bly Manual(Standard Type)

Date of Issue: February 16, 2009

Material No. TC-604

DDK td.

2ND Production engineering department assembly group

14 Matsuyama-cho, Moka-shi, Tochigi

TE : 0285-82-4463

No.

’08.3.26

’08.5.13 No.T-2205

Revision

Date Revision No.

C 16/02/09

New Issue

Material No. Page

TC-604 1/11

Contents

Page

1.

Outline................................................................................................................................................. 2

2.

Specifications ...................................................................................................................................... 2

2-1.

Applicable connector .................................................................................................................. 2

3.

Cable Assembly Process .................................................................................................................... 2

3-1.

Cutting a cable............................................................................................................................ 2

3-2.

Stripping a cable sheath ............................................................................................................. 2

3-3.

Inserting parts ............................................................................................................................. 3

3-4.

Stripping a core wire ................................................................................................................... 3

3-5.

Crimping a contact...................................................................................................................... 4

3-6.

Inserting a contact ...................................................................................................................... 5

3-7.

Tightening an angle back shell ................................................................................................... 6

3-8.

Inserting a bushing and a cable clamp....................................................................................... 8

3-9.

Tightening a clamp nut ............................................................................................................... 9

Material No. Page

TC-604 2/11

1. Outline

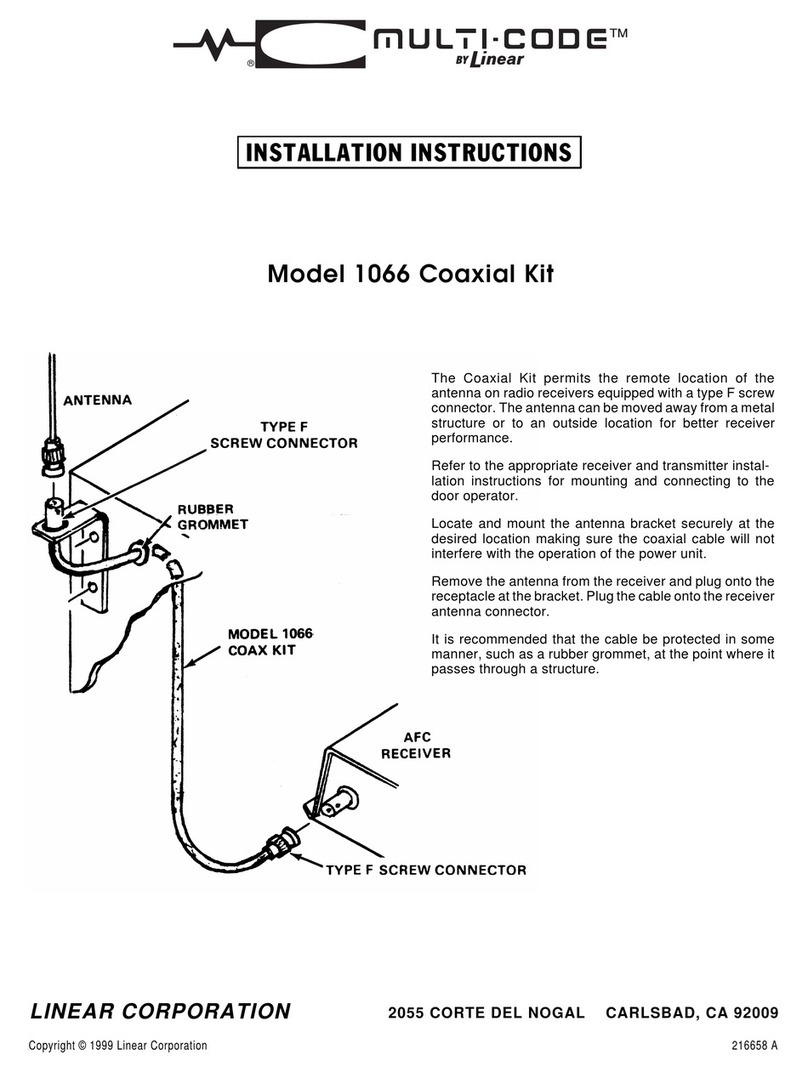

This Cable Assembly Manual explains how to assemble the wire to the CM 10 angle plug connector.

(Crimp Type)

2. Specifications

2-1. Applicable connector

Connector name Drawing number

CM10-AP2S-S(D6) 115J-AP12162-1

CM10-AP2S-M(D6) 115J-AP12162-2

CM10-AP2S- (D6) 115J-AP12162-3

CM10-AP10S-S(D6) 115J-AP12160-1

CM10-AP10S-M(D6) 115J-AP12160-2

CM10-AP10S- (D6) 115J-AP12160-3

3. Cable Assembly Process

3-1. Cutting a cable

Cut the cable to the following dimensions:

Note! Not to change cable length.

3-2. Stripping a cable sheath

Strip the cable sheath to the length A as shown below.

Note! Take care the cable peel length.

Take care not to da age anything.

* When aking CM10-AP10S(D6), strip the cable for No. 10 ter inal in a way that akes the A

length 1 longer than other cables. (To avoid the cable tension when inserting a contact to

the housing in a later process.)

Product name A length

CM10-AP XX S-S(D6)

CM10-APXX S-M(D6)

30±0.5mm

CM10-AP XX S- (D6) 45±0.5mm

A

(A+1mm for No. 10 terminal only)

Cable core Sheath

*Cable length after cutting = easure ent A for CM10-AP××S (D6)+ Cable length

= A + Cable length Product name A length

CM10-AP XX S-S(D6)

CM10-APXX S-M(D6)

40±0.5mm

CM10-AP XX S- (D6) 55±0.5mm

Cable length

Material No. Page

TC-604 3/11

3-3. Inserting parts

Insert the clamp nut, the cable clamp, the bushing and the angle back shell to the cable stripped.

Note! Pay attention to the direction each part is inserted.

Make sure that every part is inserted.

* To insert the angle back shell, bend the cable.

3-4. Stripping a core wire

Strip the cable’s core wire to the length 3.0 to 3.5mm.

Note! Do not istake the length of the core wire to be stripped.

Do not leave cut or scratch to the cable core.

Bushing Cable clamp

Clamp nut

Angle back shell Cable

Insert

Cable

Bend

Angle back shell

Sheath

Core wire

3.0 to 3.5 Cable core

Material No. Page

TC-604 4/11

3-5. Crimping a contact

With the crimping tool or crimping machine, crimp each contact on each cable.

Note! Make sure that the core wire does not co e out of the contact.

When soldering, ake sure that the solder does not stick to the circu ference of the solder

cup.

When using a drain wire, attach a heat shrink tube to the drain cable after soldering.

* When aking CM10-AP10S(D6), the cable for No. 10 ter inal is 1 longer than other

cables.

(To avoid

the cable tension when inserting a contact to the housing in a later

process.)

* The difference in the total A length of the cables for other than No. 10 ter inal ust be 1

or less.

Product name A length

CM10-AP××S-S(D6)

CM10-AP××S-M(D6)

39 to 42mm

CM10-AP××S- (D6) 54 to 57mm

Contact

Cable

Heat shrink tube

A

Difference of total length :less than 1mm

(except for No.10)

Crimping drain wire

Connector name

Applicable contact

Contact

crimping

tool

Crimp

machine

Applicable

cable

Crimp height

(Wire section)

AWG20 1.05

CM10-#22SC(C1)(D8) 357J-50446T

AP-A50539T

AWG22 0.94

AWG23-24 0.71

AWG26 0.67

CM10-AP10S-X(D6)

CM10-#22SC(C2)(D8) 357J-50447T

AP-A50540T

AWG28 0.64

AWG16 1.25

AWG18 1.15

CM10-AP2S-X(D6)

CM10-#22SC(C3)(D8) 357J-50448T

AP-A50541T

AWG20 1.05

Material No. Page

TC-604 5/11

Terminal No.

Contact

ance

CM10

-

A

P10S

-

X

(D6)

ance

Terminal No.

Contact

3-6. Inserting a contact

Insert the contact into the specified terminal number point in the housing.

(Insert grounding wire or drain wire into terminal No. 10).

* When the contact catches the housing, you will hear a snap.

* Pulling the wire for confir ing the correct position.

Note! Before inserting the contact, check that the cla p nut, cable cla p, bushing and angle back

shell is inserted.

Take care not to insert the contact upside down as shown below.

* Insert the contact so that the ter inal

nu ber face the sa e direction.

However, in case of CM10-AP2S(D6), insert the

contact so that the lance and the ter inal

nu ber face the opposite direction.

* Using a pull out tool for pulling up inserted contact.

Tool No.: 357J-50548T

Refer to the instruction anual in case of using

pull up tool.

* As Lance falls down easily after pulling up,

set up to original position before re-insert.

Terminal No. 10 only

(Grounding wire or drain wire)

Housing

Contact Cable

Insert

Core wire

CM10

-

A

P

2

S

-

X

(D6)

Material No. Page

TC-604 6/11

Adhesive

(To be coated to two

threads of the

circumference)

Angle back shell

Back shell coupling

Angle back shell

Back shell coupling

Plug shell concavity and

convexity

Back shell concavity and

convexity

3-7.

Tightening an angle back shell

(1) To prevent loosening, the adhesive should be applied to the angle back shell by two threads around the

circumference.

●

Recommended adhesive: 1401B (Three Bond Co., td.)

(2) Rotate and temporarily tighten the back shell coupling by setting the connector and the angle back shell

to the specified angle.

* When tightening te porarily, atch the concavity and convexity of the plug shell with those of the

angle back shell.

(You can confir the correct connection of concavity and convexity

waving lightly back shell just

before inserting to BS coupling.)

Material No. Page

TC-604 7/11

* Recommendation:

Tightening guide

(357J-52658T)

Angle back shell

Angle back shell

tightening wrench

Torque wrench

Fix the back shell

Fix the back shell

Back shell coupling

19

Set

Set

Tighten

* Reference dimension for

fixing the back shell

(Back shell 2

surface width)

(3) Fix the 2 surface width of the angle back shell on the tightening guide.

(4) Set the back shell wrench adjusting to the 2 surface width of the back shell coupling.

(5) With the wrench, tighten the back shell coupling to the angle back shell.

Recommended tightening torque: 5Nm

Note! When setting the work to the wrench, adjust it to the 2 surface width.

To re ove, take the reverse steps.

Note! To change the angle of the back shell, do it by changing the engaging position of the

concavity and convexity of the plug shell and the back shell.

Recommended jigs and tools : Back shell wrench (357J-51333T)

Bit (357J-51344T)

Torque wrench (C 6N x 8D), Tonichi Mfg.)

* Recommended tightening guide: (357J-52658T)

15

Material No. Page

TC-604 8/11

3-8.

Inserting a bushing and a cable clamp

Insert the bushing and the cable clamp to the back shell.

Note! After the Bushing insert, confir that cable position should be inside of Bushing.

Insert

Cable clamp

Bushing

Cable

Material No. Page

TC-604 9/11

*Recommended

adhesive

(to be coated on

2 threads of the

circumference) Tighten

temporarily

* Reference dimension for fixing the back shell

3-9.

Tightening a clamp nut

(1) Temporarily tighten the clamp nut on the angle back shell.

*To prevent loosening, the adhesive should be applied to the angle back shell.

Reco ended adhesive: 1401B (Three Bond Co., Ltd.)

(2) Fix the 2 surface width of the angle back shell on the tightening guide.

(3) Set the tightening wrench adjusting the 2 surface width of the clamp nut.

(4) With the wrench, tighten the clamp nut on the angle back shell.

Recommended tightening torque: 5 Nm

Note! To set the work to the wrench, adjust the 2 surface width.

In case of squeezing the cla p nut with excessed torque provided as above,

the cla p nut ay be broken. Please use the torque wrench.

To re ove, take the reverse steps.

Recommended jigs and tools : Clamp nut wrench (357J-51334T)

Bit (357J-51345T)

Torque wrench (C 6N×8D, Tonichi Mfg.)

* Recommended tightening guide :(357J-52658T)

Torque wrench

Fix the angle back shell

Angle back shell

Clamp nut

Set

Tightening wrench

Fix the angle back shell

Set

Tighten

19

(Back shell 2

sruface width)

* Recommendation:

Tightening guide

(357J-52568T)

15

Material No. Page

TC-604 10/11

*To connection

(1) Set the mark of each other’s connectors.

(2) Each other’s key (concavity and convexity) are fit in. Push it straight, take care not to tilt.

*To re ove, rotate the coupling and pull out to straight.

Receptacle connector key

Convexity Plug connector key

(Concavity)

Push it straight

Coupling

(2)

Pull out to straight

(1)

Rotate the coupling

Receptacle connector

mark

Plug connector

mark

Material No. Page

TC-604 11/11

*When using a conduit

(1) Tighten the nipple of conduit connector on the plug connector (CM10).

(2) Set the conduit on the nipple of conduit connector.

(3) Fix the conduit to the plug connector (CM10). If the conduit is used in a moving part, fix the conduit with a

saddle, etc. so that no load is applied to the plug connector (CM10) and to the conduit connector. If the

conduit is fixed with a saddle, etc., make sure that no load is applied to the fixing area. Set the protective

cover (rubber etc.,) on the conduit to avoid cable damage.

Recommended conduit & connector : NIPPON F EX CO. TD

Conduit

Tipe:VF Tipe:SR Tipe:FBN Tipe:EM

Tipe:VFS Tipe:SRK etc.,

Connector

Tipe:RCM

* NIPPON F EX CO., TD home page → http://www.nipolex.co.jp

(1)

Plug

connector

Conduit

Connector

(nipple)

Cable

(2)

Plug connector

Conduit

connector

Conduit

Plug connector

Conduit

Conduit

connector

Protective cover

(Rubber etc.)

Saddle

(3)

This manual suits for next models

11

Table of contents

Popular Cables And Connectors manuals by other brands

Masimo

Masimo LNC MP Series Directions for use

National Instruments

National Instruments SH160DIN-3XDB50F installation instructions

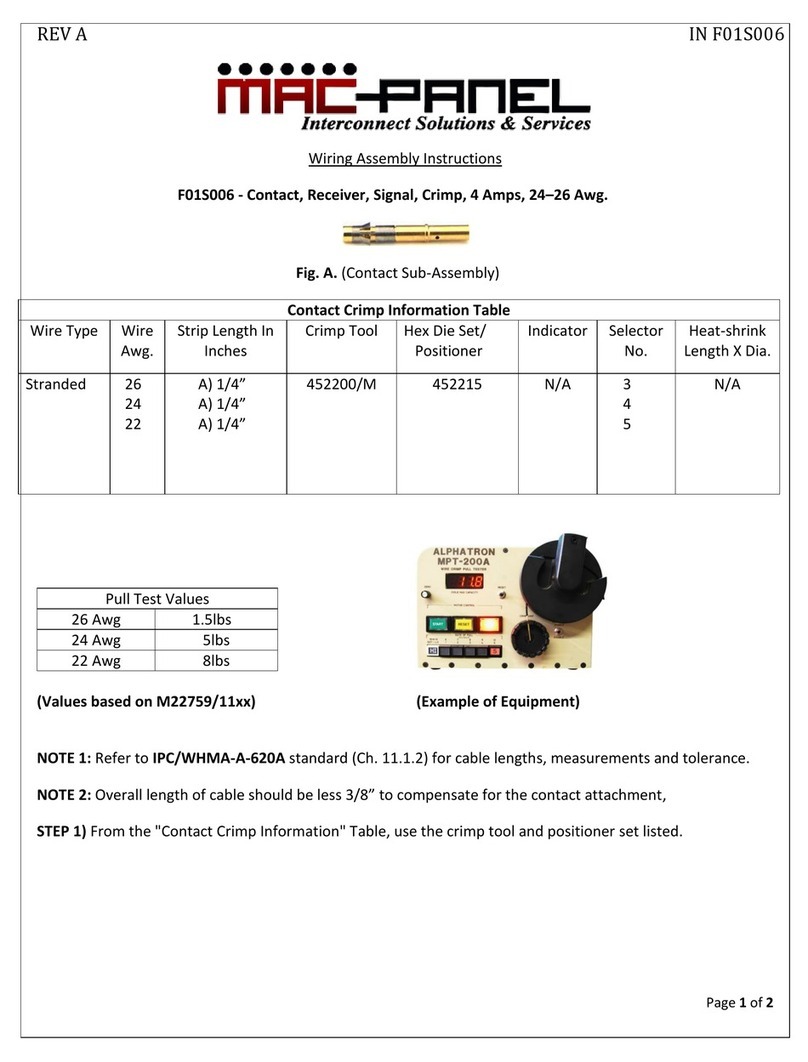

MAC Panel

MAC Panel F01S006 Wiring Assembly Instructions

Digitus

Digitus DS-45327 Quick installation guide

Altinex

Altinex Tilt'nPlug TNP600 Series user guide

Furious FPV

Furious FPV Smart Cable user manual