5 / 12THERMAL MANAGEMENT SOLUTIONS EN-RaychemWinterGardH900-IM-H5366501/13

HEATING CABLE DESIGN

OnlyWinterGardWetH612120-VandH622240-Vheatingcables

aresuitableforusewiththeH900powerconnectionkitforroof

and gutter de-icing applications.

1. Calculate the heating cable length required.

Length =A+B+C+D+E+F+G

A Roofedgelength(ft)xfeetofheatingcableperfootofroofedge

(From Table 5)

B Roofedgelength(ft)x0.5*

CTotal gutter length (ft)

DTotal downspout length (ft) + 1 (ft)

E1 ft for each power connection

F2 ft for each splice connection

G3 ft for each tee connection

= Total heating cable length (ft)

*Roofextension:Thislengthallowstheheatingcabletoextendintothegutter

toprovideacontinuousdrainpath,orwherenoguttersarepresent,extends

beyond the roof edge to form a drip loop.

Note: Pentair Thermal Management recommends a gutter and downspouts to

provideacontinuouspathformeltedwater.

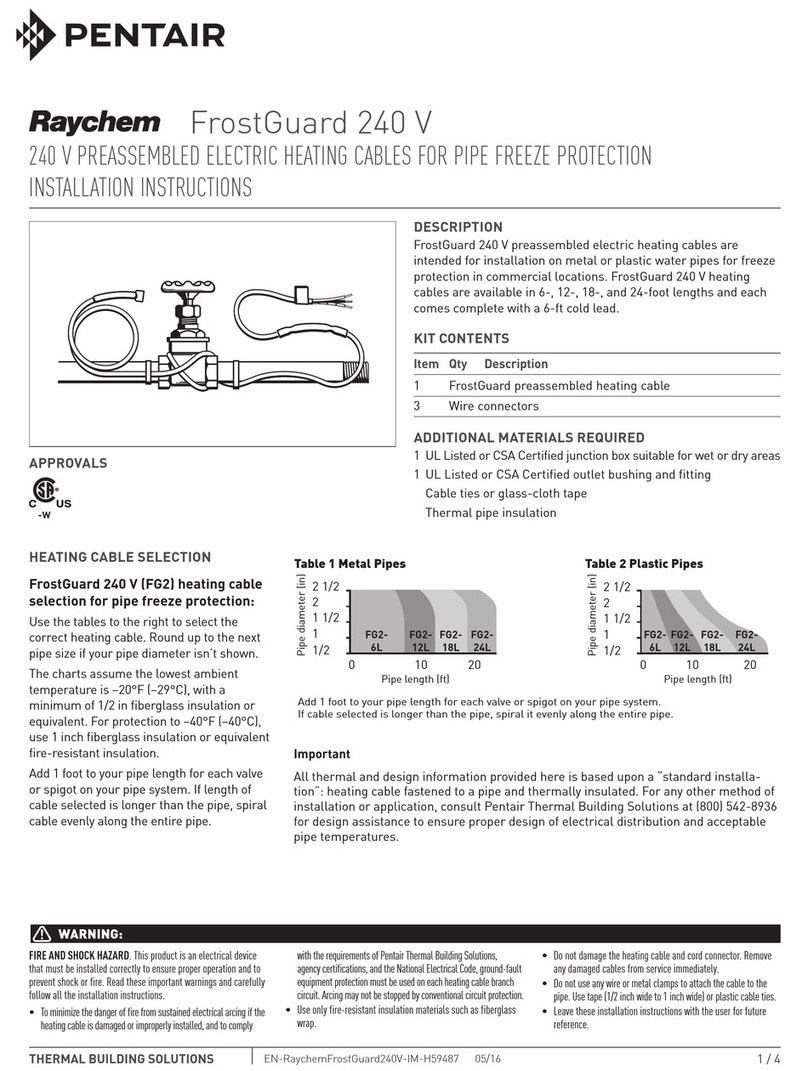

Table 5. WinterGard Wet cable length for roof de-icing

Standing seam metal roof:

Eave overhang Shingle roof 18 inch seam 24 inch seam

0 2.0 ft 2.5 ft 2.0 ft

12" 2.8 ft 2.8 ft 2.4 ft

24" 3.8 ft 3.6 ft 2.9ft

36" 4.8 ft 4.3 ft 3.6 ft

Note: Pentair Thermal Management recommends a gutter and downspouts to

provideacontinuouspathformeltedwater.

Important: For the Pentair Thermal Management warranty to be

valid,youmustcomplywithalltherequirementsoutlinedinthese

guidelines.

Alldesigninformationprovidedhereisbasedona“standard”shake

or shingle roof application. For any other application or method of

installation, consult Pentair Thermal Management at (800) 545-6258.

HEATING CABLE INSTALLATION

1. Prepare for installation.

• Storetheheatingcableinaclean,dryplace.

• UseonlythefollowingPentairThermalManagementaccessoriesto

satisfycodeandagencyrequirements:

-H900WinterGardPlug-inPowerConnectionKit(withendseal)

-H910WinterGardSpliceandTeeKit(ifsplicingorteeing)

-H915DownspoutHangers

-H913/H914RoofClips

• Carefullyplantheroutingoftheheatingcableforroofandgutter

de-icing.

• Makecertainguttersanddownspoutsarefreeofleavesandother

debris.

2. Cut the heating cable to length.

• Cuttheheatingcabletothelengthrequired.Thiscanbedonebeforeor

afteritisinstalled.Leaveaminimumof1footextraheatingcablefor

connectiontopower.Forspliceandteeconnectionsleaveaminimum

of 1 foot for each section of heating cable. WinterGard heating cable

can be cut to length without affecting its heat output per foot.

• Protecttheheatingcableendsfrommoistureandmechanicaldamage

if they will be leftexposedbeforeconnection.

3. Position and attach the heating cable.

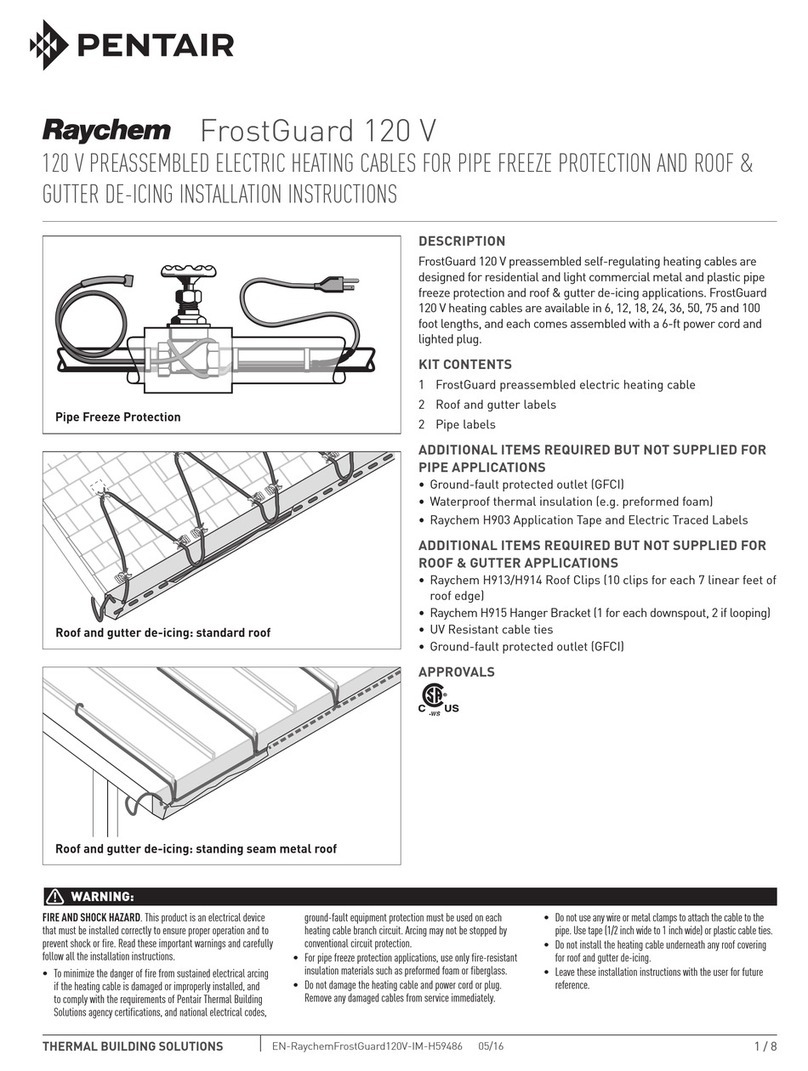

On roofs

• Looptheheatingcableontheoverhangareaoftheroof.Thisisthe

partthatextendspastthebuildingwall.Extendthebottomofeach

heatingcableloopovertheroofedgeand,usingaUV-resistantcable

tie, connect the bottom of each loop to the cable running in the gutter

to ensure a drainage channel off the roof and into the gutter and

downspout. The cable running in the gutter should remain against

thebottomofthegutter.Extendthetopofeachheatingcableloop

beyondwherethewalljoinstheroof.PentairThermalManagement

recommends2-footclip-spacingalongtheroofedge.Seethe“Heating

cable design” section (Table 5) for spacing and layout information.

• UseWinterGardH913/H914roofclipstoattachheatingcabletothe

roofsurface.Onekitcontainstendoubleroofclipsforapproximately

7linearfeetofroofedge.OneH914kitcontains50roofclipsfor

approximately35linearfeetofroofedge.

For flat roofs, the heating cable can be spaced as needed to create

runoffpathsformeltingiceandsnow.Usesingle-endedclipslocated

at3-footintervalstosecurethecabletotheroof.

Roofclipsmaybeattachedtoashakeorshingleroofwithnailsor

screws.Resealthenailorscrewholesifnecessarybeforeinstalling

heatingcableintheclips.Roofclipsmaybeattachedtoametalroof

usingscrew,nailoradhesive.(SeeH56723installationinstructionfor

more details.)

• Abarrier(snowfence)canbeplacedontheroofabovetheheating

cable.Thispreventsdamagetothecableandkeepstheinstallation

from coming loose due to ice slides. If desired, the heating cable can

beattachedtothebarrierwithUV-resistantcableties,insteadof

using roof clips. Do not use wire or other materials because they may

damage the heating cable.

In gutters and downspouts

• Runheatingcablealongguttersandintodownspouts,endingbelow

thefreezinglevel.Permanentattachmentofthecabletothegutter

bottomisnotnecessary.Looptheheatingcableindownspoutsif

convenient,suchaswhenthedownspoutisnotattheendoftherun,

orusetheH910spliceandteekittoteedownthedownspout.

• UseWinterGardH915downspouthangerstoprotecttheheatingcable

fromfrayingandfromdamagefromsharpedgesandtoprovidestrain

relief.RefertotheH915kitinstructionsforinstallationdetails.

• UseWinterGardH913/H914roofclipstorouteheatingcableinto

andoutofthegutterinsuchawayastopreventabrasiontothe

cable. Protect all cable that protrudes past the lower opening of the

downspout.

H900 DESIGN AND INSTALLATION INFORMATION FOR ROOF AND GUTTER DEICING ONLY

(WinterGard Wet H612, and H622 Heating Cables)

Example:

Roofedge: 40ft

Roofoverhang: 1ft

Roofgutter: 40ft

Downspout: 15 ft

Power connection: 2 ea

Tee connection: 1 ea

Voltageavailable: 120V

CBSizeAvailable: 15A

Start-uptemperature: 0°F

WinterGard Wet heating cable required:

ARoofedge: 40ftx2.0

(from Table 5) = 80 ft

BRoofextension: =40ftx 0.5 = 20 ft

CRoofgutter: = 40 ft

DDownspout: = 15 ft + 1 ft = 16 ft

EPower connection: 1 ft x2 ea = 2 ft

FSpliceConnections: = 0

GTee connection: 3 ft x1 ea = 3 ft

Total WinterGard Wet heating cable

required: = 161 ft**

**Thistotalexceeds100-ftmaximumcircuitlength(see

Table6),thereforetwoseparatecircuitsarerequired.