de manincor FK600 Manual

englishespañol

USER AND MAINTENANCE HANDBOOK

Thermocookers and Thermostoves

INSTRUCCIONES DE USO Y MANTENIMIENTO

Termococinas y Termoestufas de leña

2

INDEX english

NORMAS DE SEGURIDAD 16

1. IDENTIFICACIÓN DEL APARATO 16

1.1 PLACA DE IDENTIFICACIÓN 16

1.2 TABLA DE DATOS TÉCNICOS 16

1.3

DESCRIPCIÓN TERMOCOCINAS SERIE CLASSICA 17

1.4

DESCRIPCIÓN TERMOCOCINAS SERIE ECO 17

1.5 DESCRIPCIÓN TERMOESTUFAS 17

2. INSTALLATION 18

2.1 MOVIMIENTO Y COLOCACIÓN 18

2.2 DISTANCIA DE SEGURIDAD 18

2.3 SERIE ECO: REGULACIÓN DEL BLOQUEO DE LA

DE LA PUERTA DE FUEGO 19

2.4 LA SALIDA DE HUMOS 19

CARACTERÍSTICAS DE LA SALIDA DE HUMOS 19

DIMENSIONES DE LA SALIDA DE HUMOS 19

CONEXIÓN AL CAÑÓN DE LA SALIDA DE HUMOS 20

2.5

CONEXIÓN HIDRÁULICA 20

CONEXIÓN A UNA INSTALACIÓN DE VASO CERRADO

21

CONEXIÓN A UNA INSTALACIÓN DE VASO ABIERTO

22

3. INSTRUCCIONES DE USO 23

EL COMBUSTIBLE 23

PRIMER ENCENDIDO 23

3.1 NORMAS DE USO 23

PUESTA EN FUNCIONAMIENTO 23

FUNCIONAMIENTO 24

VELOCIDAD DE LA COMBUSTIÓN 24

3.2 USO DEL HORNO 24

3.3 CONSEJOS ÚTILES 24

3.4 QUÉ HACER SI... 25

4. MANTENIMIENTO 26

4.1

LIMPIEZA ORDINARIA Y CONTROLES PERIÓDICOS 26

4.2 MANTENIMIENTO DE LA PLANCHA RADIANTE 26

4.3 PLACA Y OTRAS PARTES EXTERNAS 27

5. GARANTÍA 27

ÍNDICE español

SAFETY RULES 4

1. IDENTIFICATION OF THE APPLIANCE 4

1.1 IDENTIFICATION PLATE 4

1.2 TABLE OF TECHNICAL SPECIFICATIONS 4

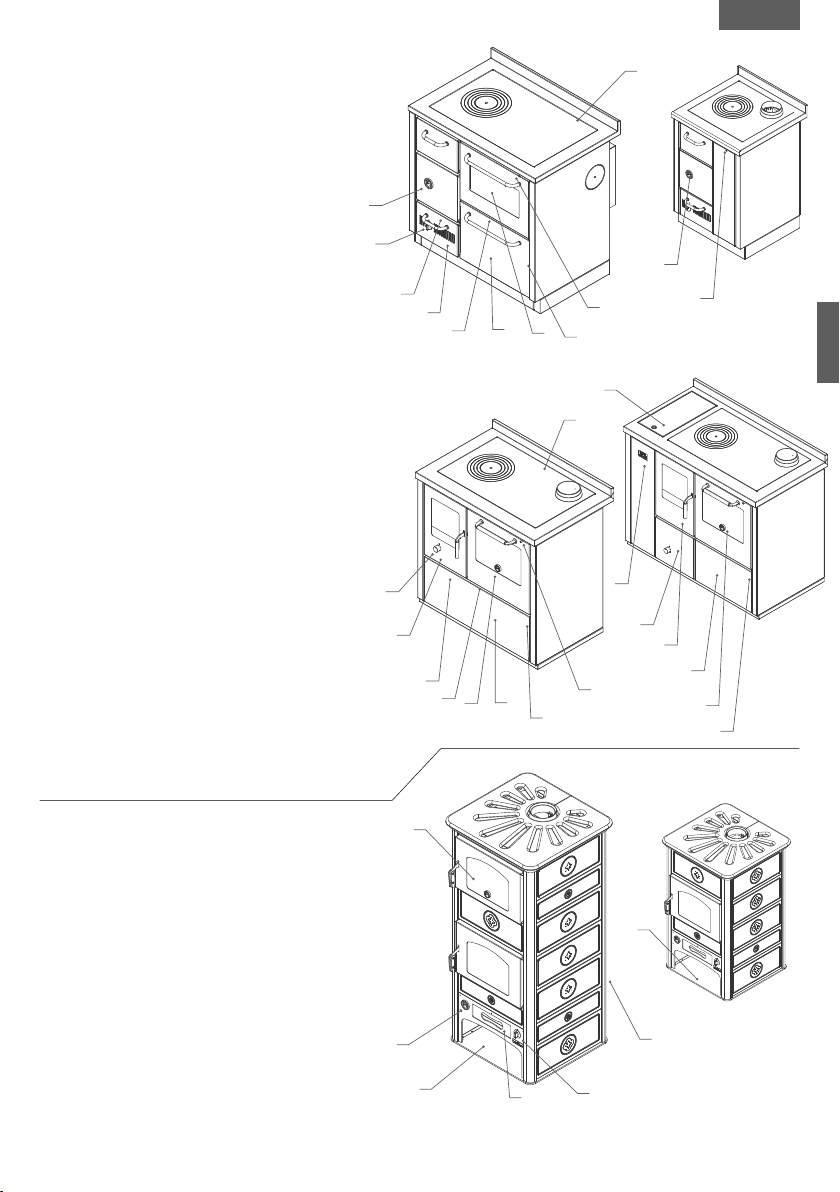

1.3 D

ESCRIPTION OF THE CLASSICA THERMOCOOKER

5

1.4 DESCRIPTION OF THE ECO THERMOCOOKER 5

1.5 DESCRIPTION OF THE THERMOSTOVE 5

2. INSTALLATION 6

2.1 HANDLING AND INSTALLATION 6

2.2 SAFETY CLEARANCE 6

2.3 ECO SERIES: ADJUSTING THE FIREDOOR LOCK 7

2.4 THE FLUE SYSTEM 7

FLUE PIPE CHARACTERISTICS 7

FLUE PIPE DIMENSIONS 7

CONNECTION TO THE FLUE PIPE 8

2.5 HYDRAULIC CONNECTION 8

CONNECTION TO A CLOSED SYSTEM 9

CONNECTION TO AN OPEN-CUP SYSTEM 10

3. INSTRUCTIONS ON USE 11

FUEL 11

INITIAL USE 11

3.1 OPERATING INSTRUCTIONS 11

INITIAL START-UP 11

OPERATING INSTRUCTIONS 12

COMBUSTION SPEED 12

3.2 USING THE OVEN 12

3.3 USEFUL NOTES 12

3.4 TROUBLESHOOTING 13

4. MAINTENANCE 14

4.1 ROUTINE CLEANING AND CHECKS 14

4.2 MAINTENANCE OF THE COOKING PLATE 14

4.3 STRUCTURE AND OTHER EXTERNAL PARTS 14

5. GUARANTEE 15

englishespañol

4

1. IDENTIFICATION OF THE APPLIANCE

1.1 IDENTIFICATION PLATE

There is an identification plate on the right-hand side of the wood box that indicates the model number and serial number.

For models without wood box, the plate is at the back.

1.2 TABLE OF TECHNICAL SPECIFICATIONS

SAFETY RULES

RULES AND/OR INSTRUCTIONS MARKED WITH THIS

SYMBOL ARE ASSOCIATED WITH SAFETY!

The following rules and precautions help you to avoid the

risks associated with use of this appliance:

• The appliance must be installed according to the rules in

section 2 of this handbook;

• Installation must be carried out in conformity with all rules at

the workplace, as well as with all domestic and European

regulations;

• Make sure the flue is suitable before connecting the cooker to

it;

• It is strictly forbidden to use chemical products for lighting

the cooker – such as alcohol, oil, petrol, etc.

• Do not put in too much fuel as this can produce excessive

heat and overheat the appliance, causing potential

damage;

• The cooking plate can reach high temperatures of up to

around 400 °C; be careful therefore and do not touch it

without appropriate protection – the same applies to the

other components such as the fire chamber and oven doors

and their respective handles, glass surfaces and the flue pipe;

• Do not put any plastic bottles or spray cans on top or in the

immediate vicinity of the appliance (risk of fire and

explosion);

• Warn children of the risks and keep them away from the

stove when it is in operation;

• Place sheet metal protection on the floor under the fill

opening, especially if the floor is made of lino or wood;

• Use only natural fuel such as: wood, blocks of compressed

wood and lignite briquettes;

• Do not burn any plastics, treated wood (e.g. chipboard) or

textiles;

• Clean the flue on a regular basis.

THERMOCOOKERS

TECHNICAL SPECIFICATIONS um

FK600

FK900

FKA900 EK90

EKB110

External dimensions: LxPxH cm 60/80x60x85 90/110x60x85 90/110x60x86 90x60x86 110x60x86

Heating plate: LxP cm 48x45 74x45 74x45 74x45 74x45

Boiler capacity lt 20 20 20 20 39

Net weight/with packaging kg 170/185 230/250 230/250 230/250 230/250

Required flue depression mbar 0.12 0.12 0.12 0.12 0.12

Nominal thermal output (Max.) kw 14 (22) 14 (22) 12 (20) 12 (20) 16,5 (25)

Water heating capacity (Max.) kw 10,5 (18) 10,5 (18) 9 (16) 9 (16) 8,8 (15)

Co at 13% O² % 0.21 0.21 0.21 0.21 0.09

Mean flue gas temperature °C 254 254 263 263 230

Flue gas mass flow g/s 20.5 20.5 18.3 18.3 11.0

Efficiency % 70 70 70 70 85

FLUE CONNECTION

Above Ø 140 mm

Rear Ø140 mm

Side Ø 140 mm

FLUE CONNECTION

Above Ø 150 mm

THERMOSTOVES

TECHNICAL SPECIFICATIONS um SK60 ZK60 SK60F ZK60F

External dimensions: LxPxH cm 68x66x108 68x66x108 68x66x145 68x66x145

Boiler capacity lt 26.5 26.5 26.5 26.5

Net weight kg 260/280 260/280 320/340 320/340

Required flue depression mbar 0.12 0.12 0.12 0.12

Nominal thermal output (Max.) kw 13.9 (24.5) 13.9 (24.5) 17.1 (26.5) 17.1 (26.5)

Water heating capacity (Max.) kw 12.5 (20.5) 12.5 (20.5) 13.4 (20.5) 13.4 (20.5)

Co at 13% O² % 0.06 0.06 0.06 0.06

Mean flue gas temperature °C 205 205 210 210

Flue gas mass flow g/s 12.9 12.9 15.2 15.2

Efficiency % 85 85 85 85

Internal diameter of the tested chimney: D = 150 mm

5

As to the position of connections on the stove, please request the data sheet to the dealer or download that directly from the website www.demanincor.com

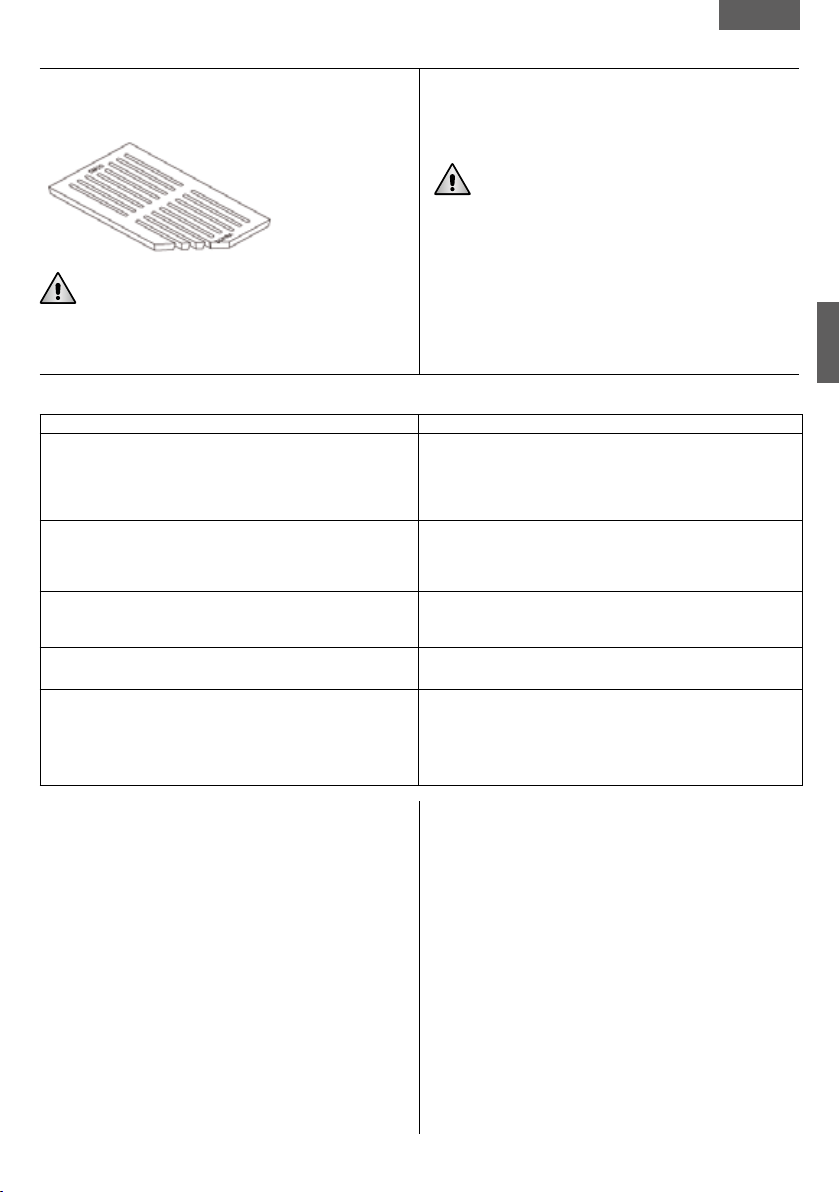

ACCESSORIES PROVIDED

• Scraper for cleaning the flue gas pass

(excluding mod. FK600)

• Bar for moving the rings

• Steel brush

• Baking pan

• Oven glove

• Grill handle (mod. FK600,FK900 and EKB110)

1.4 DESCRIPTION OF THE ECO THERMOCOOKER

a. Cast iron coking plate

b. Height-adjustable hearth grille (mod.EKB110)

c. Oven with thermometer

d. Oven light switch

e. Starter for starting the cooker up from scratch

f. Thermostatic control of the primary air

g. Water heater thermometer

h. Wood drawer

i. Ash drawer

j. Access for cleaning the flue gas circuit

k. Electronic control unit (mod.EKB110)

l. Integrated open tank (mod.EKB110)

1.3 DESCRIPTION OF THE CLASSICA THERMOCOOKER

a. Cast iron coking plate

b. Height-adjustable hearth grille

(excluding mod. FKA900)

c. Oven with thermometer

d. Oven light switch

e. Starter for starting the cooker up from scratch

f. Thermostatic control of the primary air

g. Water heater thermometer

h. Wood drawer

i. Ash drawer

j. Access for cleaning the flue gas circuit

1.5 DESCRIPTION OF THE THERMOSTOVE

a. Oven with thermometer

b. Thermostatic control of the primary air

c. Water heater thermometer

d. Ash drawer

e. Thermostat with contacts for controlling outside equipment

(recirculation pump,etc.); NA – NC contacts

f. Rack container for trays

english

ACCESSORIES PROVIDED

• Baking pan

• Oven glove

FK900

FK600

SK60F-ZK60F

SK60-ZK60

hd

i

b

d

a

e

c

e

b

j

g

g

f

e

a

f

c

f

EKB110

EK90

hdc

d

c

h

b

i

k

j

f

i

ge

a

l

6

If the cooker is to be installed between other units, leave a

gap of at least 2 mm on each side as the cooker tends to

expand with heat.

For built-in furniture is recommended to use special 25 mm

stainless steel side spacer and if necessary the profile in steel

for the top.

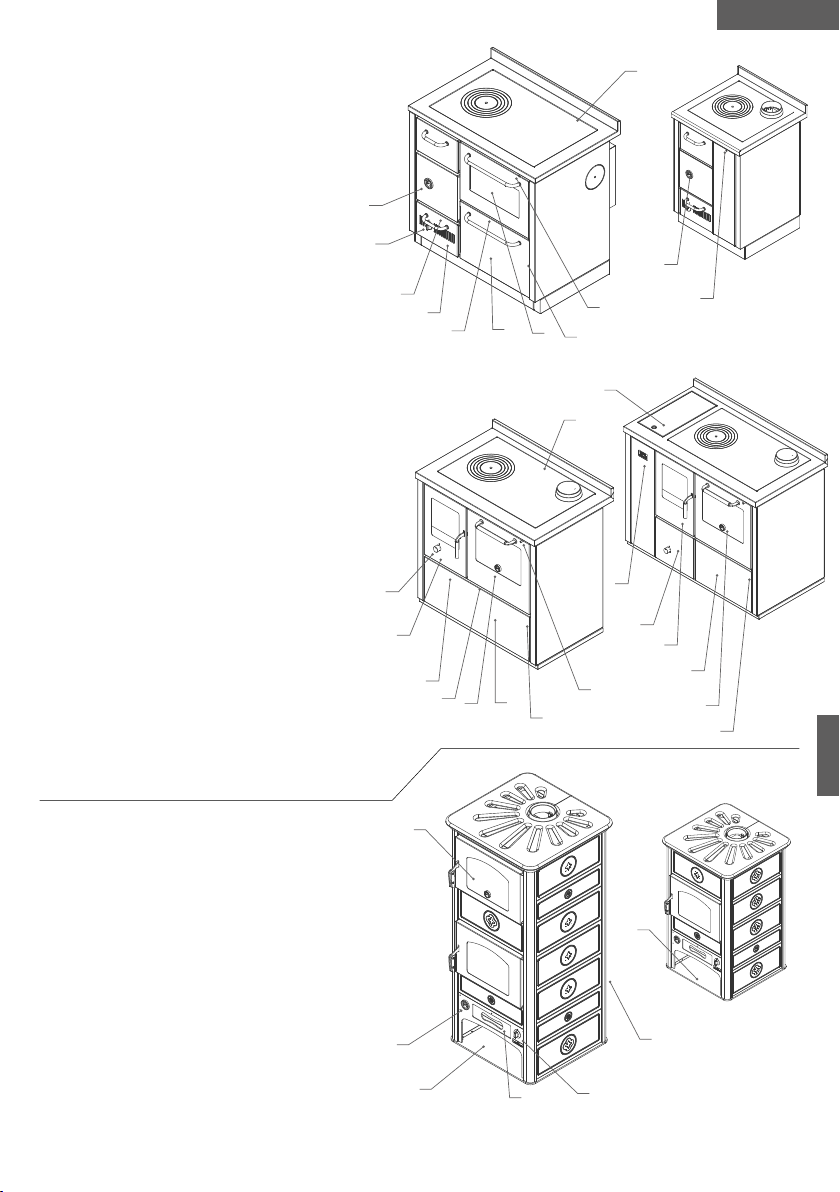

CLASSICA PRODUCTS

Place the cooker on the floor, pull out the wood drawer,

remove the 4 screws on the plinth cover (2 on each side),

remove the plinth cover, install the cooker in the required

position, connect it to the flue, and level the cooker by

adjusting the feet using a 4 mm allen wrench.

The ECO thermocooker has a fixed plinth.

WARNING: failure to comply with these instructions will void

your warranty.

2.1 HANDLING AND INSTALLATION

Make sure the flue is suitable before connecting the cooker

to it (see chapter 2.4).

WARNING: do not lift the cooked by its handrail.

NOTES:

• the appliance must be installed on a floor of sufficient

weight-bearing capacity. If it is not satisfactory, take the

appropriate measures (e.g. weight distribution plate);

• the appliance must be installed to ensure easy access for

cleaning the same appliance, the gas discharge pipes and

flue pipe.

• the appliance cannot be connected to a shared flue pipe.

• air extraction devices must not be used in the same room as

the appliance, unless there is a suitable air ventilation

system.

• install the appliance in a room of a size suited to its potential

and that is sufficiently ventilated (window or specific air vent).

2. INSTALLATION

45 °

R

D

R

P

L

45 °

R

D

R

P

L

45 °

R

D

R

P

L

2.2 SAFETY CLEARANCE FROM INFLAMMABLE MATERIALS

From the side wall L600 mm

From rear wall

P200 mm + reflective steel

plate of 20/10

P0 mm + 80 mm calcium

silicate insulating board

Floor F0 mm

Front

R> 600 mm

Minimum distance air from

inflammable built-in furniture

C25 mm

C=25 mm

L=600 mm

High temperature zone

7

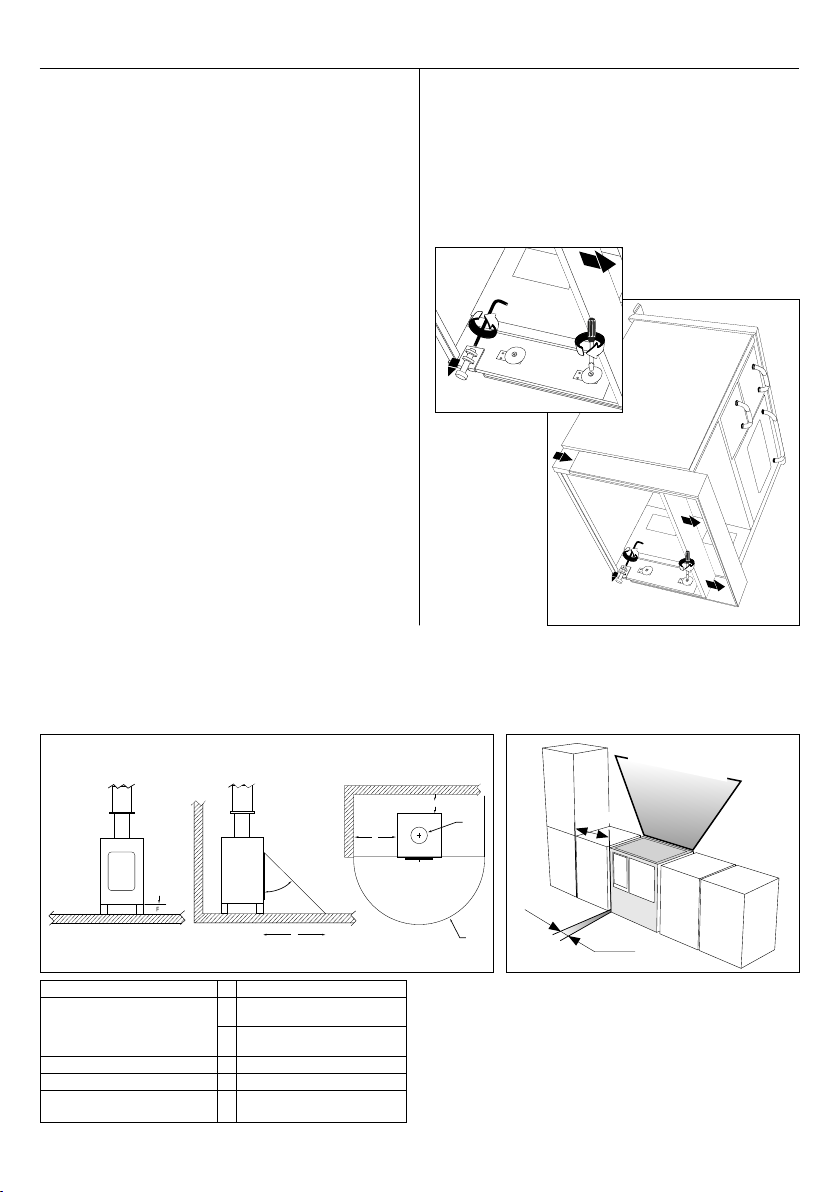

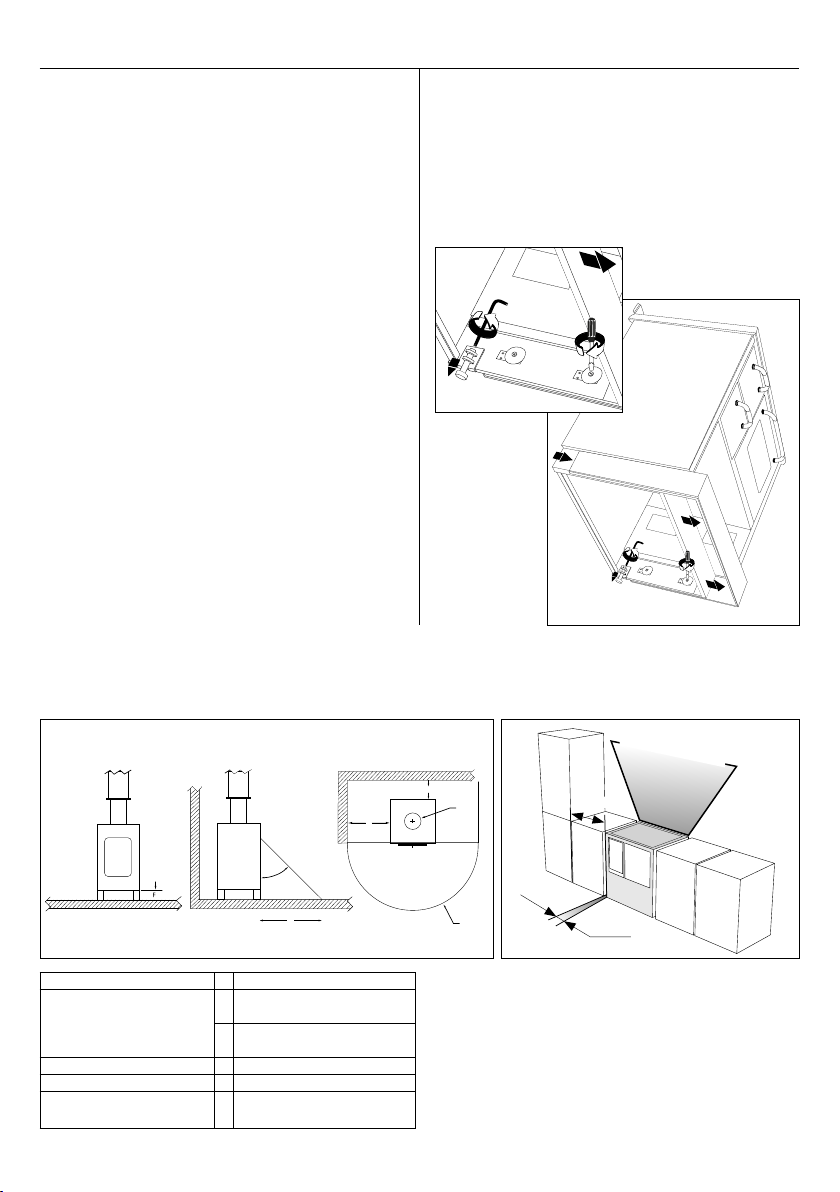

2.3

ECO SERIES:

ADJUSTING THE FIREDOOR LOCK

• use a Phillips screwdriver to undo the top and bottom screws

• use a 3 mm hexagonal allen wrench and:

- tighten to reduce play of the closure

- loosen to increase play of the closure

• re-attach the two screws

2.4 THE FLUE SYSTEM

FLUE PIPE CHARACTERISTICS

It is essential that the flue is suitable for the appliance to

work correctly.

The flue system should be inspected by a technician expe-

rienced in flues before installing the appliance, and then be

checked at least once a year.

The flue pipe must conform to the regulations in force

and be kept in perfect condition.

Below are several instructions on fitting the flue pipe.

Non-compliance with these could compromise the applian-

ce’s yield and cause problems with combustion:

• Its height must not be less than 4/5 linear metres from

the connection to the stove to the base of the chimney pot;

the flue can be narrower if its height is any greater.

• It must be properly sealed and insulated; make sure the

inspection panels close properly and that there are no cracks

on any part of the flue pipe.

• The inside of the pipe must be smooth and the same width

all the way up.

• The flue must be as straight as possible and the chimney pot

must be in a suitable position and at an appropriate pitch, as

indicated in the diagrams and examples below.

• The chimney pot must be double the width of the flue pipe.

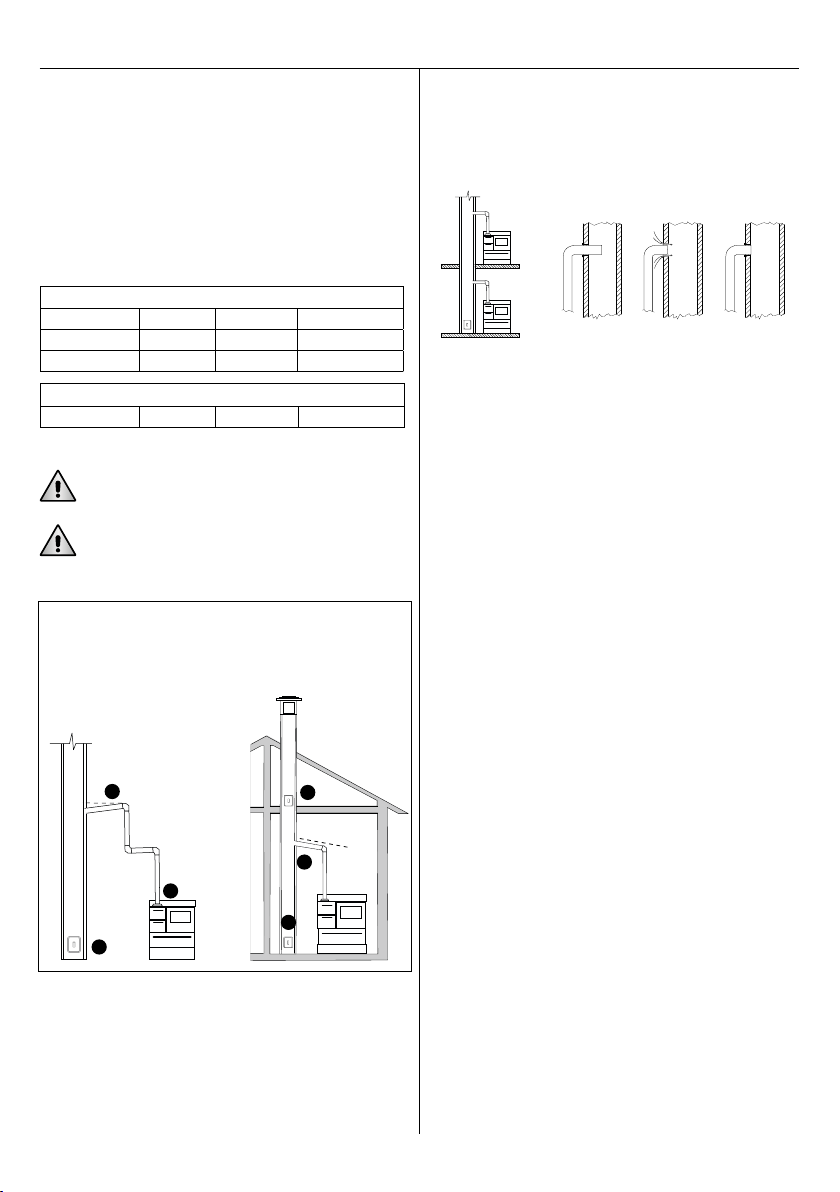

FLUE PIPE DIMENSIONS

Guideline for sizing the flue as a function of it’s height:

FLUE PIPE (H) THERMOCOOKERS THERMOSTOVES

< 4 m Draw not

guaranteed Draw not

guaranteed

4 m < 6 m Ø 160 mm Ø 200 mm

> 6 m Ø 150 mm Ø 180 mm

If this is not feasible you should contact a flue specialist.

CROSS-SECTION: the flue pipe’s cross-section depends on

the height of the flue and the thermal power of the installed

cooker.To ensure the optimal yield of our cookers we recom-

mend you use circular flue pipe with smooth interior lining

and of the same length all the way up.

INSULATION: flue draught pressure also depends on the dif-

ference in the temperature of the hot flue gases and that of

the air outside.The flue pipe must be insulated to restrict

absorption of heat into the walls and therefore avoid conden-

sation, which can cause tarry residues. Use only suitable heat-

and corrosion resistant materials conforming to building and

fire-prevention regulations.You should not use flue pipes

comprising simple or flexible metal tubes, cement tubes for

vents, etc.

DEPRESSION: the optimal depression (flue draught

pressure) is 0.15 mbar.

a. Flue’s refractory

interior lining or

stainless steel

(min.T400)

b. Prefabricated

external casing

c. Insulation material

c

d

Roof

pitch

Reflux area

0.5 m above

the ridge

b

Roof pitch

15° adistance > 1,85 m bdistance 1,85 m

c1 m min. d0,5 m

30° adistance > 1,3 m bdistance 1,3 m

c1,2 m min. d0,8 m

45° adistance > 1,5 m bdistance 1,5 m

c2 m min. d1,5 m

60° adistance > 1,2 m bdistance 1,2 m

c2,6 m min. d2,1 m

a

english

8

• the pipe must not be narrower at the end;

• the end of the pipe must not protrude into the flue.

At a depression below 0.15 mbar, the fire will burn too slowly

and form carbon residue excessive gases.If instead

depression is any greater, combustion will be too fast and not

transmits much heat to the boiler, the heating plate and the

oven, and will make large operating times impossible.

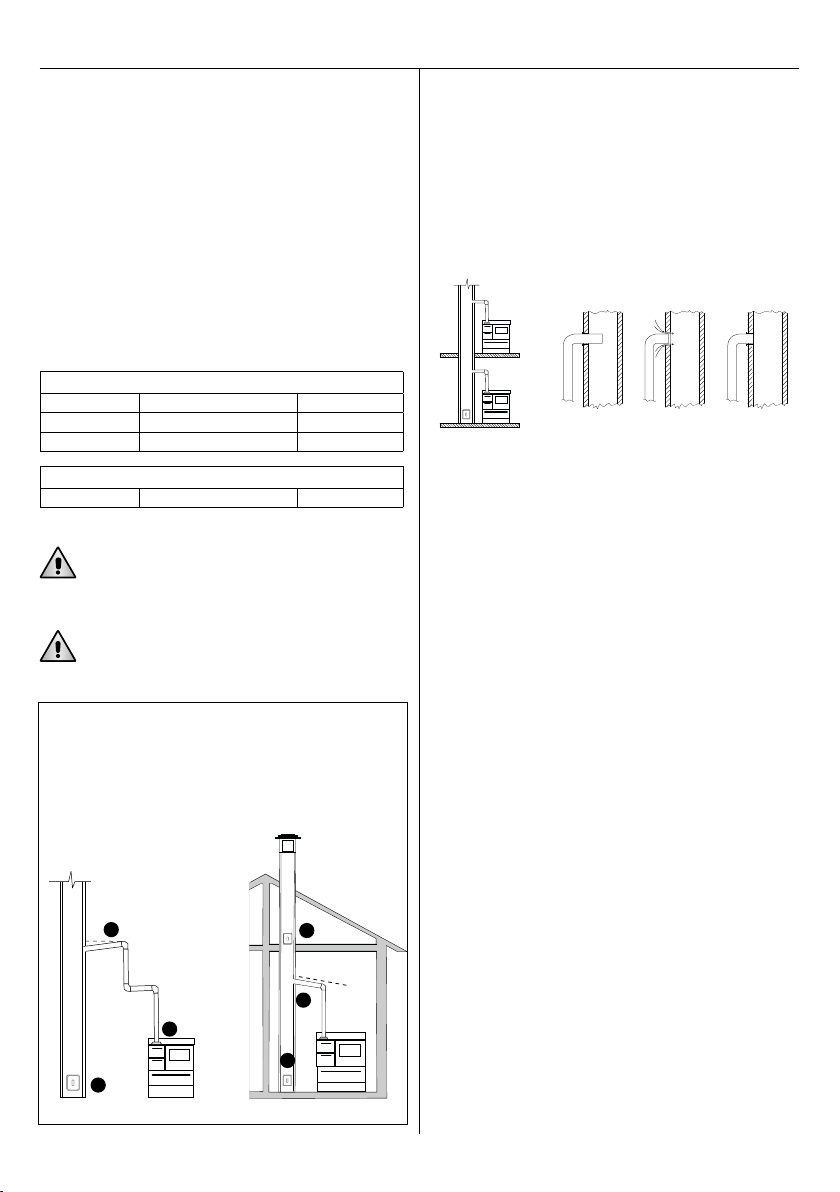

CONNECTION TO THE FLUE PIPE

The cooker is delivered with the connection corresponding to

the flue exit chosen when ordering:

EACH COOKER SHOULD HAVE ITS OWN FLUE PIPE; DO NOT

USE THE SAME FLUE PIPE FOR MORE THAN ONE APPLIANCE.

THE COOKER SHOULD BE CONNECTED TO THE FLUE PIPE

AVOIDING AS FAR AS POSSIBLE ANY BENDS, DIVERSIONS AND

DOWNWARD OR HORIZONTAL SECTIONS.

Connecting pipes must be perfectly sealed to each other and

to the stove and flue pipe.These precautions must be taken:

• use a seal to avoid infiltration of air into the flue;

THERMOCOOKERS

Above Fix Cast Iron Ø 140 mm

Rear Fix Cast Iron Ø 140 mm

Side Telescopic Steel Ø 140 mm

THERMOSTOVES

Above FiX Steel Ø 150 mm

2.5 HYDRAULIC CONNECTION TO THE HEATING

SYSTEM

The appliance must be installed by a qualified hydraulic

technician in accordance with regulations on cookers

that use solid fuels.

Thermocookers and thermostoves are endowed with boiler to

use the heating produced by the device through a system

with fluid vector for heating and for the production of hot

water.The appliance must be designed according to UNI

10412-2:2006 law by a qualified thermal technician and

must be installed by experienced people according to exist-

ing laws in particular to UNI 10683:2005 law.

The appliance are endowed with all the necessary predisposi-

tions for a correct installation, every external component (as

pumps, valves, acoustic alarms, pressure switches) must be

obtained by third parts according to the specifies of designer

and installer.

Before the lighting of the thermal cooker it is compulsory to

make the connections to the heating system.The use of the

appliance with empty or not connected to the system boiler

causes the irreversible damaging of the boiler itself.

Anyway, it is necessary to connect the going connector, the

return connector and the discharge connector (necessary to

empty the boiler in case of maintenance), the other connec-

tors according to the kind of system that you make could be

not necessary and so in this case you must cover them.

DeManincor accepts no liability for damage or harm to

objects or persons if the system is not fitted properly or does

not respond to regulations in force.

YESNO

1. Pipe is too long and

on inclined plane

2. Pipe narrower than outlet hole

3. Leaky cleaning panel

4. Sealed connections

5. Inspection

6. Cleaning

3

1

2

5

4

6

+ 3 %

Pipe too

far in Unsealed

connection correct

connection

NO NO YESNO

9

RECOMMENDATIONS

• the detailed design of the system must be carried out by a

heating engineer.

• we recommend applying simple patterns of proven

effectiveness and providing the system with useful elements to

check correct operation: temperature probes, mixing valves,

thermometers, etc.;

• the heat distribution circuit (radiators or radiant floor panels)

must be designed to prevent the return line from entering

directly into the boiler;

• provide for an adequate anti-condensation circuit or a

lukewarm return line: the supply temperature of the boiler

water should be kept at about 70/80°C with a return line not

below 55°C;

• we recommend using a heat storage tank to increase the

autonomy between one charge and the next one and absorb

the peaks of energy;

• at regular intervals, it is advisable to clean the combustion

chamber and heat exchangers inside the boiler to keep them in

good working order.

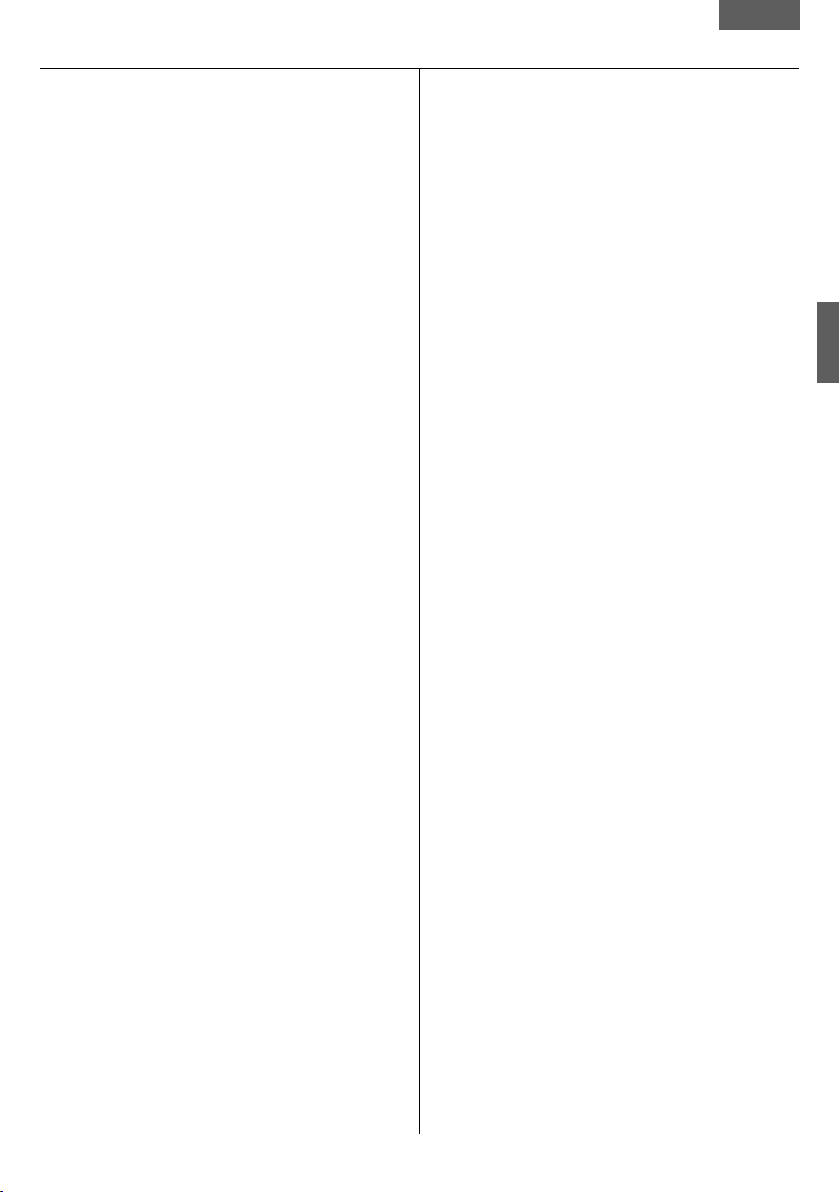

INSTALLATION MODES

The technical law UNI 10412-2 has introduced the possibility to

install the solid combustion based devices matched with devices

with closed expansion tank, endowed with thermal discharge with

emergency exchanger inside the boiler. Thermal cookers and ther-

mal stoves are endowed with all the predispositions for the ther-

mal discharge.

Thermocookers and thermostoves can be installed with open

expansion tank.

SAFETY

On every solid combustible based boilers it is not technically

possible to break the combustion immediately as happens

for boilers based on liquid or gas combustible according to

necessity. For this reason, it is mandatory to swallow always

the produced heating also even if the heating system does

not request that and also in case of lack of AC power. On

contrary, the water in the boiler could boil without possibility

of outlet, with serious danger of explosion of the boiler and

serious injury risk for the people present near the thermal

cooker. For this reason,we recommend to follow strictly the

norm UNI 10412-2, in the various cases. We also suggest

inserting a boiler/puffer in the hydraulic system in order to

accumulate the heating.

Here below you find a few examples of installation diagrams.

The system should be designed by a heating technician.

CONNECTION TO A CLOSED SYSTEM

According to standard UNI 10412/2 (March 2009), a solid

fuel appliance can be installed on a closed water piping sys-

tem providing the appliance has a thermal discharge system

with additional circuit in the heater (coil).

The thermal discharge system allows to cool directly the boil-

er when it is necessary by making flow cold leaking water in

a separate circuit inside the boiler.

All the components of the thermal discharge system external

to the thermal cooker must be obtained by third parts accord-

ing to the specifies of designer and installer.

To make this auxiliary system it is necessary to make the

going and return connections, the detector that rules the

device must be inserted in the apposite connection bulb.The

system, to be effective, must be able to work and must have

availability of cold water also in case of lack of AC power.

All safety devices must be accessible after installation of the

appliance in order to guarantee proper maintenance and

functional verification. Functionality of equipments must be

regularly checked: at least once per year.The thermal dis-

charge circuit must not be used for the production of hot

water for domestic use.

The thermo stoves and thermo cookers FKA900 and EK90

are already configured for closed-cup installation,as they

always have an exchanger with a built-in coil.

Standard cookers FK600 and FK900 are not equiped with a

thermal discharge system in their boiler. So, you have to

clearly specify if you need it when ordering the cooker.

The FK80P, FK110P and FKA110P models have a safety sys-

tem with thermal discharge, safety valves, pumps and plate

exchangers to separate the primary and secondary circuits

and instantly produce domestic hot water.

Along with the anti-condensation function, these models, fit-

ted with an electronic control unit, allow for interaction with a

gas boiler.

As the EKB110 model has a built-in open cup, it does not

require additional safety systems.

english

10

To reduce condensation on the walls of the combustion

chamber,the temperature of the return water should be

kept above the minimum temperature of 55°C.

If fitting a control thermostat for the recirculation pump, set

the intervention value to 65˚C..

CONNECTION TO AN OPEN-CUP SYSTEM

If they do not feature a safety thermal discharge:

THE DEVICE MUST BE CONNECTED TO AN OPEN

HYDRAULIC CIRCUIT

for automatic protection against overheating in the event of a

fault or a block or a power cut affecting the circulation pump.

VSP= Overpressure valve T= Thermometer M= Manometer

CONNECTION TO A CLOSED SYSTEM

Cold water

C

M

Y

CM

MY

CY

CMY

K

impianto 2.2_ita.pdf 1 17/07/14 15:14

Drain

Thermic

exhaust valve Thermostove

Thermocooker

Circulating

thermostat

Feed

Feed Collector

Return Collector

Cold water

Hot sanitary water

Boiler

Closed

expansion tank

Anti-condensation

valve

Return

C

M

Y

CM

MY

CY

CMY

K

impianto 1.pdf 1 17/07/14 15:14

Open expansion tank

Cold water

Hot sanitary water

Boiler

Feed

Collector

Return

Collector

Circulating

Thermostat

Feed

Return

THERMOCOOKER

OR

THERMOSTOVE

Loading duct

Safety

duct

Anti-condensation Valve

11

3. INSTRUCTIONS ON USE

INITIAL NOTES:

• do not use the appliance as an incinerator or in any way for

which it was not intended;

• do not use fuel other than that recommended;

• do not burn any plastics or treated wood (such as chipboard)

or textiles;

• do not use liquid fuel;

• the appliance, especially its outer surfaces, can become

extremely hot to the touch when in use; handle with care to

avoid burning yourself;

• do not put any plastic bottles or spray cans on top or in the

immediate vicinity of the appliance (risk of fire and

explosion);

• warn children of the risks and keep them away from the stove

when it is in operation;

• do not make any unauthorized changes to the appliance;

• do not put in too much fuel as this can produce excessive

heat and overheat the appliance, causing potential damage;

• use only original spare parts approved by the manufacturer.

WHATTO DO IN THE EVENT OF A FIRE IN

THE FLUE PIPE

The use of damp and inappropriate fuel or operating the

stove at too low a capacity can cause easily inflammable sub-

stances, such as and soot, to accumulate in the flue pipe.

This can in the long term be a potential cause of fire in

the flue pipe!

In the event of this happening:

• shut off the flow of primary and secondary air;

• make sure everybody leaves the apartment or house;

• call the fire brigade (telephone number: 115 in Italy).

FUEL

The appliance is designed for burning solid fuel: wood,

blocks of compressed wood and lignite briquettes. We

recommend you use reasonably small pieces of wood that

have been seasoned for at least two years in a ventilated and

covered area.They should ideally measure 6-10 cm in diame-

ter and 25-30 cm in length.

We advise you bring wood into the house a few days before

burning it so the heat in the home will dry it out more

quickly.

INITIAL USE

The flue system should be inspected by a technician expe-

rienced in flues before installing the appliance, and then be

checked at least once a year.

CHECK THE GRILL IS IN ITS CORRECT POSITION IN THE

HEARTH: THE NARROW END OF THE SLITS SHOULD

FACE UPWARDS.

3.1 OPERATING INSTRUCTIONS

WARNING: when you use the cooker for the first time, it is

normal for condensation to form due to humidity in the

refractory materials. Start with a small fire and keep the fill

opening and ash drawer ajar for a few hours to encourage

evaporation.

If condensation persists the causes could be as follows:

• use of wet, very damp or unseasoned wood;

• flue defects that let the gases cool down and create

condensation; these defects should be found and eliminated;

• return water temperature under 55°C due to too low a

fire or because the system is absorbing too much heat:

prepare the anti-condensation circuit.

IMPORTANT:

CONSTANT CONDENSATION AFFECTS THE

THERMOCOOKER’S YIELD AND THE DURATION OF THE

HEAT EXCHANGER, FORFEITING THE GUARANTEE.

LIGHTING A FIRE WHEN THERE IS NO WATER IN THE

CIRCUIT AND IN THE BOILER CAN CAUSE SERIOUS,

IRREPARABLE DAMAGE TO THE HEATER.

INITIAL START-UP

In order to make easier the fire ignition in a cold appliance

it is necessary to:

• (thermocookers) raise the grill to its highest position using

the respective handle;

• (thermocookers) pull the starter to let the gases enter the flue

pipe directly;

• fully open the primary air source, by turning the control

unclockwise all the way round;

• load the kindling and igniting material: balls of newspaper

or other small dry fuel;

• light the fire;

• WARNING: (hearth with glass door) to prevent the glass

from getting dirty leave the door ajar with the handle in

closed position (see photo 5) and wait for ten minutes or so

for the glass to heat up and thereby avoid condensation on

the inside due to the difference in the temperature of the

flames and the internal surface of the glass;

• when the fuel is burning brightly and the flue has heated up

sufficiently (this may take 30 minutes or more), close the

starter and put in some larger pieces of wood.

In certain situations, as when lighting the fire for the first time in

the day or when there is poor flue draught pressure due to bad

weather, it is not a bad idea to leave the ash drawer slightly ajar.

DO NOT USE ALCOHOL OR OTHER FUELTO ENCOURAGE

OR SPEED UP THE FIRE.

english

12

OPERATING INSTRUCTIONS

LIGHTING THE FIRE IS THE MOST CRITICAL PHASE FOR

GENERATING FLUE DRAUGHT PRESSURE; AFTER THIS YOU

SHOULD KEEP MONITORING THE FIRE.

It is possible that the wood will not catch fire and that

your initial fire might go out after a few minutes.This is

because the flue pipe is cold and there is insufficient flue

draught pressure.Start your fire again using easily

combustible material: thin dry sticks, shrubs, pine cones and

newspaper are ideal for this first phase.

When the wood has caught fire, regulate the primary air

supply by turning the thermostatic control, so that the logs

burn well with tall flames. Avoid too great a flue draught

pressure but also don’t let combustion get too slow as this

can result in the deposit of soot in the stove.

Make sure there is always a good bed of glowing

embers at the bottom of the stove and add wood as soon as

the previous logs have turned into embers: the bed of

embers maintains the temperature required for igniting

more wood and ensures correct combustion.Always arrange

the logs crosswise so that air can pass between them and

ensure good oxygenation.Try and keep the flames burning;

most heat is generated by the combustion of the gases. If the

flames die down completely, unburned gases are produced

that waste energy and pollute.

COMBUSTION SPEED

You can adjust the air control devices and grill to increase or

decrease combustion speed and therefore the heating or

cooking temperature:

• Fast combustion: primary air control open (fully

anticlockwise)

• Slow combustion: primary air control closed (fully clockwise)

• In the summer: (thermocookers only) if minimal heat is

required, for cooking and hot water only, it is a good idea to

raise the fire grill to its highest position as this limits the

combustion chamber and helps to save on fuel.

AVOID OVERLOADING THE APPLIANCE.

A relatively small and well oxygenated fire will burn better

and produce more heat than a large stack of wood blocking

the hearth.

IMPORTANT: during fast combustion make sure there

is no more than 3 kg of wood in the stove at all times.

A greater amount of fuel requires you to reduce the

combustion speed proportionally by acting on the

air control.

Adding more fuel without changing the combustion speed

will produce thermal power greater than the cooker -environ-

ment exchange capacity. This will not only waste fuel but

could also damage and deform the appliance.

The ideal load for efficient and clean combustion is 3-4 kg of

wood per hour for thermocookers and 4-6 kg for thermosto-

ves. Bigger loads go to the exclusive benefit of operating

times.

Excessive residual ash quantity indicates a poor combustion.

Transparent smoke coming out of the chimney indicates a

clean burning, whilst opaque or dark smoke shows an excess

of unburned material.

WARNING: Thermal shock caused by a sudden increase in

temperature can form small cracks in the refractory bricks.

These cracks will not compromise the structure and resistance

of the bricks or cooker in any way.

When combustion has ended, close the primary air lever

and any secondary air slits to prevent the heat in the stove

escapes with the flow of air in the flue.

Lack of flue draught pressure. A column of cold air could

form in the flue pipe for a variety of reasons. These could be

low atmospheric pressure, humidity, strong winds or

depression in the house (e.g. if the hood above your kitchen

stove is switched on).

In the event of low atmospheric pressure or rain,the flue

draught pressure will not be nearly as good as on a clear day

or during a cold, dry winter. Humidity can also form in the

flue pipe if the stove is not used for a long period of time. It

is worth keeping the stove’s doors ajar to let air circulate in

the flue pipe.

3.2 USING THE OVEN

The oven always needs to be pre-heated for cooking.Add a

suitable amount of fuel to the combustion chamber, open

the primary air control to obtain the required temperature.

Leave the fire to burn for about an hour with the primary air

valve open and then wait for about ten minutes after the fla-

mes have died down in the combustion chamber.

Keep the temperature constant by adding thin wood to the

stove measuring about 3 cm in diameter at a rate of one or

two pieces every ten minutes.

3.3 USEFUL NOTES

COOKING PLATE

The cast iron cooking plate must never become incandescent.

Always use receptacles with flat heavy bases (for

maintenance see chapter 4.2)

HEARTH GRILL

Poking the embers on the iron grille in the combustion

chamber will make the ash fall through into the ash drawer

below.This clears the way for the supply of primary air to the

combustion chamber – particularly important when starting

up your fire.

The slits in the grill have two specific functions: they let

combustion air pass through and, at the same time, enable

the disposal of the embers and ash.

13

3.4 TROUBLESHOOTING

THE VARIOUS REASONS THE STOVE MIGHT NOT

WORK PROPERLY

THE FLUE PIPE

• Too short. The flue pipe stretches from the connection with

the stove to the base of the chimney pot. If the flue pipe is too

short, increasing its internal width will never compensate for

the reduction in height as that will only increase heat

dispersion, lower the temperature of the gases and potentially

compromise flue draught pressure. You are better advised to

use a flue pipe of the correct width and increase its height by

1 or 2 metres to ensure decent flue draught pressure.

• Too long. This doesn’t generally affect flue draught pressure;

however the flue pipe should be well INSULATED to minimize

heat dispersion.

• Too wide. A flue pipe that is too wide will have a

proportionally larger surface area that will encourage the

gases to cool down and therefore compromise flue draught

pressure. One option is to put a stainless steel pipe of

suitable width inside the existing flue pipe and, after

connecting it to the stove, fill the gap between the two pipes

with heat-resistant granular insulation material.

• Too narrow. IToo narrow. In this case you will not be able to

exploit the stove’s potential. We can only suggest that you

reconstruct the flue pipe according to the required

specifications.

• Tight sections. Changes in the pipe’s width will cause a loss

of flue draught pressure, slowing down and potentially

preventing the gases from leaving the flue.

• Too many bends. Bends cause a loss of flue draught

pressure, preventing the gases from leaving the flue. For each

bend you need to increase the height of the flue pipe by 50

centimetres so as to ensure optimal flue draught pressure.

• Excessive deviations. Deviations affect the discharge of

gases and should generally be avoided.

The slits are wide enough to let through the ash and any

dead embers; while the walls of the slits are conical so as to

not block the flow of air.

THE GRILL MUST BE POSITIONED WITH THE NARROW

SIDE OF ITS SLITS FACING UPWARDS.

INTERNAL ASH DRAWER

The ash drawer must be emptied on a regular basis to

prevent the iron grill from overheating.

THERE MAY STILL BE SOME GLOWING EMBERS

IN WITH THE ASH.

PROBLEM POSSIBLE CAUSE

The stove does not work

It is not connected properly to the flue

The flue pipe does not conform

Other appliances are connected to the flue pipe

The hearth grill is the wrong way round

The hearth grill is blocked with ash

Smoke comes out of the plate

No flue draught pressure

It is not connected properly to the flue

The starter and/or primary air valve is closed

The plate’s seals have come loose or are broken

Condensation in the hearth The wood is damp or not properly seasoned

The flue is too wide

Poor flue draught pressure

The fire lights with difficulty The starter is not fully open

The flue is cold (due to a long period of inactivity)

The oven does not get sufficiently hot

Poor or insufficient flue draught pressure

The internal pipes are clogged

The starter is open

Excessive flue draught pressure

english

14

4. MAINTENANCE

4.1 ROUTINE CLEANING AND CHECKS

The cooker is at its most efficient when all the surfaces and

pipes the gases come in contact with are kept perfectly clean.

The boiler must be cleaned whenever the yield decreases.

We advise regular maintenance by a qualified technician. Clean

and check the cooking plate and the iron doors’ fibreglass seals

on a regular basis.

All maintenance and cleaning must only ever be carried out

when the stove has fully cooled down::

• (thermocooker) Remove the iron cooking plate and clean

underneath thoroughly with the provided steel brush;

• scratch and brush all surfaces of the boiler;

• (thermocooker) Remove the pressurized door under the oven

and use the small shovel to clean the flue-ways, removing all

the ash at the base (only for mod.FK900);

• vacuum-clean all accessible areas.

CLEANING THE CERAMIC GLASS OF THE

COMBUSTION CHAMBER’S DOOR

Eliminate all traces of soot on the inner side of the ceramic

glass using a soft cloth dampened with a little clean ash, or

with a suitable product in the event of stubborn traces of tar.

Dry well afterwards.

Clean the outer side of the ceramic glass with a damp cloth

or,if necessary, with a little neutral detergent. Dry well

afterwards.

ECO MODELS: EXTRACTTHE OVEN DOOR

• extract the door’s lock using a screwdriver if necessary

• turn the lock to its locking position

• close the door as far as the lock permits

• remove the door by lifting it and pulling it towards you

4.2 MAINTENANCE OF THE COOKING PLATE

When you first use the cooker, the cast iron plate will gra-

dually change colour,starting with the hottest part and, after

a while, the colder parts. The plate eventually becomes all

one colour.Clean the heating plate with any type of deter-

gent; then rinse it only if it is slightly warm so that the humi-

dity can evaporate naturally. Grease the entire plate with a

cloth soaked in oil.

The heating plate is made of iron so prolonged contact with

humidity will cause a thin layer of rust to form on its surface.

This can be removed as follows:

• rub the surface of the plate with 120 grit abrasive paper

• rub the surface with food oil

• clean with a dry cloth.

• Horizontal sections. These should be avoided or kept as

short as possible and always at a minimum gradient of 2 cm

per metre.You are advised to assess the depression to

guarantee sufficient gas evacuation.The flue pipe should be

increased in proportion to requirements.

• Obstruction in the flue pipe. When the stove is not used for

a long period of time, and especially during the summer, you

might find that birds, wasps or bees will nest in the chimney

pot; in which case you will have trouble lighting the stove

again. Moreover,a poorly or improperly made flue pipe may

cause instances of crumbling plaster or cracks through which

air enters.

CLEANING THE FLUE PIPE. THE FLUE PIPE MUST BE

CLEANED ON AN ANNUAL BASIS. THE BEST TIME IS AT

THE END OF WINTER.

AIR RECOVERY

• No air recovery. The stove can still be lit but soon burns up

the available oxygen, reducing combustion and causing the

gases to build up and come out of the stove. The purity of the

ambient air is compromised as a result. In this case you

definitely need an outside air vent.

• Insufficient air recovery. If there is insufficient air recovery,

combustion is poor and gases will come out of the stove

especially when you open the door to add more wood. If the

stove is installed in a room with double-framed doors or

double-glazed windows, a suitable air vent must be installed

to ensure a good flow of air.

OTHER REASONS

• The position is too windy. You need to install a

WINDPROOF chimney pot, otherwise any change in the

direction of the wind will compromise evacuation of the

gases.

• Presence of two flue pipes in the same room or in two

adjacent rooms. The flue pipe with the more powerful

draught pressure will draw the gases from the one with the

least powerful one; as a result gases will come out of the

stove with the poorer flue draught pressure.

• Presence of a ventilating hood in the room. If there is

insufficient air recovery, the air will be retrieved by the stove

causing smoke. If you switch on the hood while the stove is in

use, you must leave a window ajar for all the time the

ventilating hood is in operation.

• Poor connections. Narrow sections, internal edges, imperfect

joints and sharp bends might accidentally be created when

connecting the stove to the flue that could impede the

evacuation of the gases.

• Uninsulated flue pipe. Gases passing through an

uninsulated flue pipe will cool down and compromise flue

draught pressure.This causes atmospheric pollution,

condensation and the deposit of unburned products inside

the pipe, affecting its efficiency.

15

5. GUARANTEE

MANUFACTURER’S DECLARATION

The DeManincor firm guarantees the appliance has passed

all the in-house tests and inspections and that is it therefore

up to standard and without any manufacturing or material

defects.

GENERAL TERMS

The guarantee is valid for 2 years from the date of purchase.

It applies only to the original purchaser and is non-

transferable.The guarantee covers original manufacturing

defects and applies to all of the product’s components.

The warranty on the boiler only is extended to 5 years.

To request a service under the terms of the guarantee, the

customer must present a valid proof of purchase (payment

receipt, invoice, etc.).

CONDITIONS

The request must be made through an authorized dealer.

The DeManincor firm has the final say on what action should

be taken to resolve any problems under the terms of the

guarantee.

Any defective parts that are replaced remain the property of

the DeManincor firm.

The DeManincor has the final say on whether the service

under the terms of the guarantee should be done at the

customer’s or its own premises.

For services offered under the guarantee, the customer is

required to pay the minimum charges according to the going

rates.This is not the case however if the cooker is purchased

less than four months previously.

For repairs at DeManincor’s assistance centres, the customer

is required to pay for the transport costs.

IMPERFECTION OR DEFECT IN THE MATERIALS

Imperfection or defect in the materials must be signalled

within 8 days since the customer receives the products and

anyway this implies only the obligation to replace what

provided, excluding any additional responsibility.

COMPONENTS NOT COVERED BY THE GUARANTEE

The following are not covered:

• damage to parts attributable to negligence, carelessness or

ineptitude, in particular deterioration to the heating plate

caused by improper or lack of maintenance;

• damage to parts attributable to non-compliance with the

instructions in this handbook;

• damage to parts attributable to transportation and failure

to comply with some or all domestic and local regulations;

• damage to parts attributable to improper installation,

insufficient capacity or faults with the electrical, hydraulic

and gas connections, and inefficiency of the flues and

discharge systems;

• the guarantee does not cover parts repaired by anyone not

authorized by the DeManincor firm;

• technical services requested attributable to inefficiency of

the flue and/or connecting pipes are not covered by the

g

uarantee and charged according to the going rates;

• consumer parts like gaskets,glass, grids, refractory bricks, etc.

SERVICES AFTER THE GUARANTEE

Any services after the period of the guarantee or which do

not fall under the terms of the guarantee will be charged

according to the going rates. In this case the cost of any

replacements will also be charged.

RESPONSIBILITY

The DeManincor firm cannot accept any liability for any direct

or indirect harm or damage to persons or objects caused by

product defects if the rules set down by domestic or local law

or by this handbook have not been complied with.

COMPETENT COURT

Disputes and litigations are always settled at the court

of Trento.

PRODUCT MODIFICATIONS

The characteristics of the products described in the

catalogues and this user and maintenance handbook are

purely indicative. DeManincor aims to constantly improve

upon its products and therefore reserves the right to make

any changes and improvements it considers necessary

without obligation for forewarning. DeManincor is also not

obliged to apply previous or current changes to products

already or in the progress of being constructed and assigned

to customers.

4.3 STRUCTURE AND OTHER EXTERNAL PARTS

The stainless steel parts should be cleaned when cold with

neutral detergents or with vinegar in the case of persistent

stains. You must avoid using abrasive or acid products

that could damage the surface. Dry with a soft cloth, fol-

lowing the grain of the glazing.

The external parts can be cleaned easily with water and neu-

tral detergent. Do not use aggressive or abrasive chemical

products; any spills from pans or other should be cleaned

immediately.

english

16

1. IDENTIFICACIÓN DEL APARATO

1.1 PLACA DE IDENTIFICACIÓN

En el costado derecho del cajón de la leña se ha aplicado una placa de identificación que lleva el modelo y el número de

matrícula. Para los modelos sin cajón de la leña la placa está en la parte posterior.

1.2 TABLA DE DATOS TÉCNICOS

NORMAS DE SEGURIDAD

¡LAS NORMAS Y/O INSTRUCCIONES MARCADAS CON ESTE

SÍMBOLO ESTÁN RELACIONADAS CON LA SEGURIDAD!

El uso del aparato de leña puede conllevar peligros que hay que prevenir,

observando las siguientes reglas y precauciones.

• el aparato debe instalarse respetando las reglas descritas en la sección 2

de este manual de instrucciones;

• la instalación tiene que respetar toda la normativa local, incluida la que se

refiere a las Normas nacionales y europeas;

• llevar a cabo la conexión a la chimenea solamente una vez que se

haya comprobado que es adecuada;

• queda terminantemente prohibido utilizar productos químicos

para encenderla, como alcohol, petróleo, gasolina, etc.;

• no efectuar cargas exageradas de combustible; además de emitir

una excesiva cantidad de calor, el aparato será sometido a un

recalentamiento que podría dañarlo;

• la plancha radiante alcanza temperaturas elevadas, alrededor de

400º C; prestar atención y evitar tocarla sin una protección adecuada,

igual que las demás partes, como las puertas del fuego y del horno

y sus pomos, cristales y el tubo de salida de humos;

• en el aparato y en las inmediatas proximidades nunca hay que colocar

botes de plástico ni bombonas con espray (peligro de incendio y

explosión)

• hay que informar a los niños previamente sobre estos

inconvenientes y hay que tenerlos lejos de la cocina cuando esté

encendida;

• a la altura de la boca de carga,colocar un suelo,sobre todo si fuera de

linóleo o de madera,una protección de chapa;

• quemar solamente combustibles naturales, como: madera, tronquitos

de madera prensados y briquetas de lignito;

• no quemar de ninguna manera materiales plásticos,materiales de

leña tratada (por ejemplo, paneles conglomerados) ni productos

textiles;

• llevar a cabo con regularidad la limpieza de la chimenea.

TERMOCOCINAS

CARACTERÍSTICAS TÉCNICAS um

FK600

FK900

FKA900 EK90

EKB110

Dimensiones externas: L x P x H cm 60/80x60x85 90/110x60x85 90/110x60x86 90x60x86 110x60x86

Plancha de cocción: L x P cm 48x45 74x45 74x45 74x45 74x45

Capacidad de la caldera lt 20 20 20 20 39

Peso neto/con embalaje kg 170/185 230/250 230/250 230/250 230/250

Tiro necesario en chimenea mbar 0.12 0.12 0.12 0.12 0.12

Potencia calorífica nominal (max) kw 14 (22) 14 (22) 12 (20) 12 (20) 16,5 (25)

Potencia calorífica al agua (max) kw 10,5 (18) 10,5 (18) 9 (16) 9 (16) 8,8 (15)

Co al 13% O²% 0.21 0.21 0.21 0.21 0.09

Temperatura gas de salida °C 254 254 263 263 230

Flujo gas de salida g/s 20.5 20.5 18.3 18.3 11.0

Rendimiento % 70 70 70 70 85

CONEXIÓN

Superior Ø 140 mm

Posterior Ø140 mm

Lateral Ø 140 mm

CONEXIÓN

Superior Ø 150 mm

TERMOESTUFAS

CARACTERÍSTICAS TÉCNICAS um SK60 ZK60 SK60F ZK60F

Dimensiones externas: L x P x H cm 68x66x108 68x66x108 68x66x145 68x66x145

Capacidad de la caldera lt 26.5 26.5 26.5 26.5

Peso neto/con embalaje kg 260/280 260/280 320/340 320/340

Tiro necesario en chimenea mbar 0.12 0.12 0.12 0.12

Potencia calorífica nominal (max) kw 13.9 (24.5) 13.9 (24.5) 17.1 (26.5) 17.1 (26.5)

Potencia calorífica al agua (max) kw 12.5 (20.5) 12.5 (20.5) 13.4 (20.5) 13.4 (20.5)

CO al 13% O² % 0.06 0.06 0.06 0.06

Temperatura gas de salida °C 205 205 210 210

Flujo gas de salida g/s 12.9 12.9 15.2 15.2

Rendimiento % 85 85 85 85

Diámetro interior chimenea de prueba: D = 150 mm

17

Para las alturas de las conexiones solicite la ficha técnica al revendedor, que también se puede descargar en nuestro sitio de internet.

ACCESORIOS DE SERIE

Con la cocina se entregan de fábrica los siguientes accesorios:

• Rascador para la limpieza de chimenea (exepto mod. FK600)

• Atizador para mover las anillas

• Cepillo de acero inoxidable

• Parrilla y fuente del horno

• Guante para horno

• Manilla para levantar la parrilla (mod. FK600, FK900 y EKB110)

1.4 DESCRIPCIÓN TERMOCOCINAS SERIE ECO

a. Plancha de cocción en hierro fundido radiante

b. Parrilla fogón regulable en altura (mod.EKB110)

c. Horno con termómetro

d. Interruptor luz de horno

e. Starter para encender la cocina en frío

f. Regulación termostática del aire primario

g. Termómetro de temperatura del agua en la caldera

h. Cajón provisión leña

i. Cajón cenizas

J. Acceso limpieza recorrido humos

k. Unidad de control electronica (mod.EKB110)

l. Vaso abierto integrado (mod.EKB110)

1.3 DESCRIPCIÓN TERMOCOCINAS SERIE CLASSICA

a. Plancha de cocción en hierro fundido radiante

b. Parrilla fogón regulable en altura (exepto FKA900)

c. Horno con termómetro

d. Interruptor luz de horno

e. Starter para encender la cocina en frío

f. Regulación termostática del aire primario

g. Termómetro de temperatura del agua en la caldera

h. Cajón provisión leña

i. Cajón cenizas

J. Acceso limpieza recorrido humos

1.5 DESCRIPCIÓN TERMOESTUFAS

a. Horno con termómetro

b. Regulación termostática del aire primario

c. Termómetro de temperatura del agua en la caldera

d. Cajón cenizas

e.

Termostato con contactos preparados para mando del aparato

externo (bomba de recirculación, etc.); contactos NA – NC.

f. Zona de almacenaje leña

g. Acceso limpieza recorrido humos

ACCESORIOS DE SERIE

• Parrilla y fuente del horno

• Guante para horno

EKB110

EK90

FK900

FK600

SK60F-ZK60F

SK60-ZK60

hd

i

hd

b

d

a

e

c

c

d

c

e

h

b

b

i

k

j

j

f

i

g

g

g

f

e

e

a

l

a

f

c

f

español

18

En caso de que la cocina se introduzca al lado de otros

muebles, dejar al menos 2 mm de distancia por cada

lado,ya que con el calor las dimensiones de la encimera de

la cocina podrían aumentar por efecto de la dilatación.

Para encajarla entre los muebles, se aconseja utilizar la corre-

spondiente aleta aireada y si fuera necesario, el perfil de acero

inoxidable para la placa.

PRODUCTOS SERIE CLÁSICA

Colocar la cocina en el suelo,sacar el cajón de leña, quitar

los 4 tornillos que sujetan el cubre-zócalo (2 en cada lado),

quitar el cubre-zócalo, posicionar la cocina y efectuar el

enganche a la chimenea, nivelar la cocina ajustando las

patas a la base mediante una llave Allen del 4.

ATENCIÓN:no respetar estas indicaciones anula la garantía.

2.1 MOVIMIENTO Y COLOCACIÓN

Llevar a cabo la conexión a la chimenea solamente una vez

que se haya comprobado que es adecuada, como se describe

en el capítulo 2.4.

ATENCIÓN: no levantar la cocina cogiéndola por el tirador.

ADVERTENCIAS:

• el aparato tiene que estar instalado en un suelo con una

capacidad de carga adecuada. Si la construcción existente no

cumple este requisito, deberán tomarse medidas adecuadas

(ej. plancha de distribución de carga)

• la instalación del aparato tiene que garantizar un fácil acceso

para la limpieza del mismo,de los conductos del gas de salida

y de la salida de humos

• el aparato no es adecuado para instalarlo en una salida de

humos compartida

• los dispositivos de extracción del aire no deben ser usados en

la misma habitación del aparato, a menos que haya una

adecuada alimentación de aire de ventilación

• colocar el aparato en un local de dimensiones adecuadas según su

potencialidad,ylosuficientementeventilado(ventanaotomadeaire

específica)

2. INSTALACIÓN

De la pared lateral L600 mm

De la pared posterior

P200 mm + plancha en acero

reflectante de 20/10

P0 mm + 80 mm

panel ignífugo

de silicato de calcio

Del suelo F0mm

Frente

R> 600 mm

Distancia mínima en aire de

mueble empotrado inflamable

C25 mm

45 °

R

D

R

P

L

45 °

R

D

R

P

L

45 °

R

D

R

P

L

2.2 DISTANCIAS DE SEGURIDAD DE MATERIAL INFLAMABLE

C=25

mm

L=600 mm

Zona sometida a altas temperaturas

19

2.3

SERIE ECO:

REGULACIÓN DEL BLOQUEO DE LA

MANILLA DE LA PUERTA DE FUEGO

• con un destornillador de estrella, aflojar el tornillo superior y

inferior

• mediante una llave Allen hexagonal del 3:

- apretar para reducir el juego del cierre

- apretar para reducir el juego del cierre

• fijar los dos tornillos anteriormente aflojados

2.4 LA SALIDA DE HUMOS

CARACTERÍSTICAS DE LA SALIDA DE HUMOS

Uno de los elementos más importantes para el correcto funciona-

miento del aparato es una chimenea adecuada.

Llamar a un técnico preparado (un fumista) antes de la insta-

lación del aparato para que controle el equipo de humos y

también periódicamente, como mínimo una vez al año.

La salida de humos tiene que realizarse respetando las

normas vigentes y debe mantenerse en perfecta eficiencia.

Se recuerdan algunas de las características fundamentales de

la salida de humos que,si no se respetan, podrán disminuir el

rendimiento del aparato y crear problemas a la combustión:

• la altura nunca debe ser inferior a los 4/5 metros lineales,

medidos desde la conexión de la cocina hasta la base del

caballete; cuanto más aumente la altura, menor podrá ser la

sección

• tendrá que estar bien aislada y perfectamente estanca;

controlar el cierre de las portezuelas de inspección y que no

haya grietas en toda su superficie

• paredes internas lisas y sección constante en toda su longitud

• la chimenea tiene que estar realizada de la manera más vertical

posible y tener un caballete adecuado para que sobresalga

adecuadamente desde la vertiente del tejado en relación con su

inclinación y su posición, como se muestra en los siguientes

esquemas y ejemplos

• el caballete tendrá que tener una sección de salida doble

respecto a la de la salida de humos.

DIMENSIONES DE LA SALIDA DE HUMOS

Indicaciones aproximadas para las dimensiones de la salida

de humos en función de la altura:

SALIDA DE HUMOS [H]

TERMOCOCINAS TERMOESTUFAS

< 4 m

Tiro no garantizado Tiro no garantizado

4 m < 6 m Ø 160 mm Ø 200 mm

> 6 m Ø 150 mm Ø 180 mm

En caso de que no se pudieran respetar estas dimensiones, pón-

gase en contacto con un técnico fumista.

SECCIÓN: la sección de una salida de humos depende de la

altura de la chimenea y de la potencia térmica de la cocina

instalada. Para obtener las mejores prestaciones de nuestras

cocinas, se aconseja usar salidas de humos con forma circu-

lar,con paredes internas lisas y de sección constante durante

toda su longitud.

AISLAMIENTO:

el tiro de una chimenea depende también

de la diferencia de temperatura de los humos calientes con

el aire exterior. Es importantísimo aislar el cañón de la salida

de humos para limitar la absorción de calor de las paredes,

evitando de este modo fenómenos de condensación con for-

mación de depósitos de alquitrán. Use solamente materiales

adecuados, resistentes a la temperatura y a la corrosión, y

que respondan de todas maneras a todas las normas de fab-

ricación y prevención contra incendios. No son adecuadas las

salidas de humos en tubo metálico sencillo o flexible, en

tubo de cemento para respiraderos,etc.

español

a.

Chimenea interna en material

refractario o en acero

inoxidable (min. T400)

b.

Bloque exterior prefabricado

c.

Aislante

a

c

d

Inclinación

techo

Zona de

reflujo

0.5 m

por encima de la

cumbre

b

Inclinazione

tetto

15° adistancia > 1,85 m bdistancia 1,85 m

c1 m min. d0.5 m

30° adistancia > 1,3 m bdistancia 1,3 m

c1,2 m min. d0.8 m

45° adistancia > 1,5 m bdistancia 1,5 m

c2 m min. d1,5 m

60° adistancia > 1,2 m bdistacia 1,2 m

c2,6 m min. d2,1 m

20

Los tubos de conexión tienen que estar perfectamente sella-

dos entre ellos y en las conexiones con la cocina y la salida

de humos, prestando atención, por lo tanto a las siguientes

precauciones:

• presencia de un florón de empalme para evitar infiltraciones

de aire en la chimenea;

• la sección del tubo terminal nunca debe reducirse;

• el terminal no debe penetrar en el cañón más allá del grosor

de la pared de la chimenea.

CAÍDA DE PRESIÓN:

la caída de presión (tiro) optima necesa-

rio para las cocinas de DeManincor es de 0,12 mbar.

Con valores inferiores, el fuego será demasiado lento, con

formación de depósitos carbonosos y excesiva producción de

humo.

Con valores superiores, se obtendrá una combustión demasia-

do rápida,con una escasa transmisión del calor a la plancha

de cocción y al horno , y la imposibilidad de obtener grandes

autonomías de funcionamiento.

LA CONEXIÓN AL CAÑÓN DE LA SALIDA DE HUMOS

Conla cocinaviene laconexióncorrespondiente alasalida dehumos

especificada en el momento del pedido:

CADA COCINA TIENE QUE LLEVAR SU CAÑÓN DE SALIDA

DE HUMOS; NO UTILIZAR NUNCA LA MISMA CHIMENEA

PARA VARIOS APARATOS.

LA CONEXIÓN DE LA COCINA A LA CHIMENEA TIENE QUE

LLEVARSE ACABO EVITANDO EN LA MEDIDA DE LO POSIBLE

LAS CURVAS,LAS DESVIACIONES,LAS INCLINACIONES HACIA

ABAJO Y LOS TRAMOS HORIZONTALES

.

TERMOCOCINAS

Superior Fijo en hierro fundido Ø 140 mm

Posterior Fijo en hierro fundido Ø 140 mm

Lateral Telescopio en acero Ø 140 mm

TERMOESTUFAS

Superior Fijo en acero Ø 150 mm

2.5 CONEXIÓN HIDRÁULICA A LA INSTALACIÓN

DE CALEFACCIÓN

La instalación del aparato debe respetar las normas

establecidas para las calderas por combustibles sólidos y

ser realizadas por un instalador hidráulico cualificado.

Las termococinas y las termoestufas están equipadas con una

caldera para aprovechar el calor producido mediante una

instalación con fluido caloportador de agua caliente.

La instalación la tiene que diseñar un termotécnico habilita-

do según la normativa UNI 10412-2 y la tiene que instalar

personal especializado según las leyes en vigor y según la

normativa UNI 10683.

El aparato cuenta con todas las predisposiciones necesarias

para una instalación correcta, cualquier componente externo

(como bombas, válvulas, termostatos, manómetros, sistemas

de alarma acústica y vaso de expansión) se debe comprar por

separado según las indicaciones específicas del diseñador o

del instalador.

Antes de la puesta en funcionamiento es obligatorio realizar

las conexiones a la instalación de calefacción. La utilización

con la caldera vacía o no conectada a la instalación comporta

el daño irreversible de la caldera.

Es cualquier manera es necesario conectar a la instalación el

conector de ida, el conector de retorno y el conector de

descarga (necesario para vaciar la caldera en caso de

mantenimiento).

Los otros conectores podrían no ser necesarios, en función

del tipo de instalación que se va a realizar, y en estos casos

se deben tapar.

La empresa DeManincor no responde por posibles daños a

cosas o personas si la instalación no se realiza correctamente

o no respeta las normativas vigentes.

SINO

1.

Recorrido demasiado largo en con trapendiente

2.

Tubo con diámetro menor del orificio de salida

3.

Fuga de aire de la puertecilla de limpieza

4.

Juntas selladas

5.

Inspección

6.

Limpieza

3

1

2

5

4

6

+ 3 %

Tubo

demasiado

introducido

Contera no

sellada Inserción

correcta

NO NO SINO

This manual suits for next models

8

Table of contents

Languages:

Popular Stove manuals by other brands

ACR Electronics

ACR Electronics Wychwood WYC1GAS User, installation & servicing instructions

Charnwood

Charnwood C4 Operating & installation instructions

CARRON

CARRON CAST IRON STOVE Installation and operating instructions

Lokaterm

Lokaterm VANCOUVER user manual

Brunner

Brunner IRON DOG 07 user guide

OUTR

OUTR MEDIUM 40 Assembly and operation manual