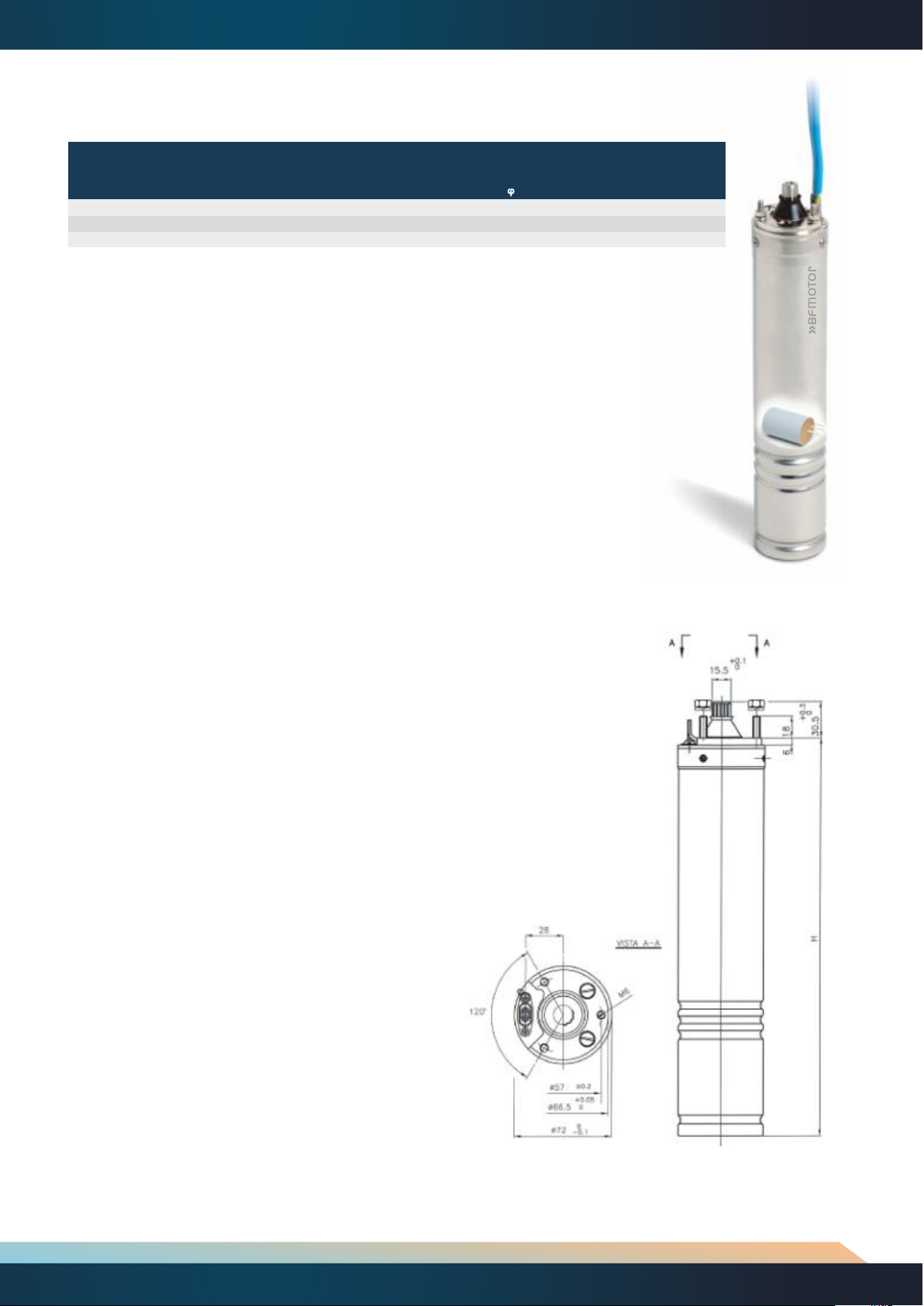

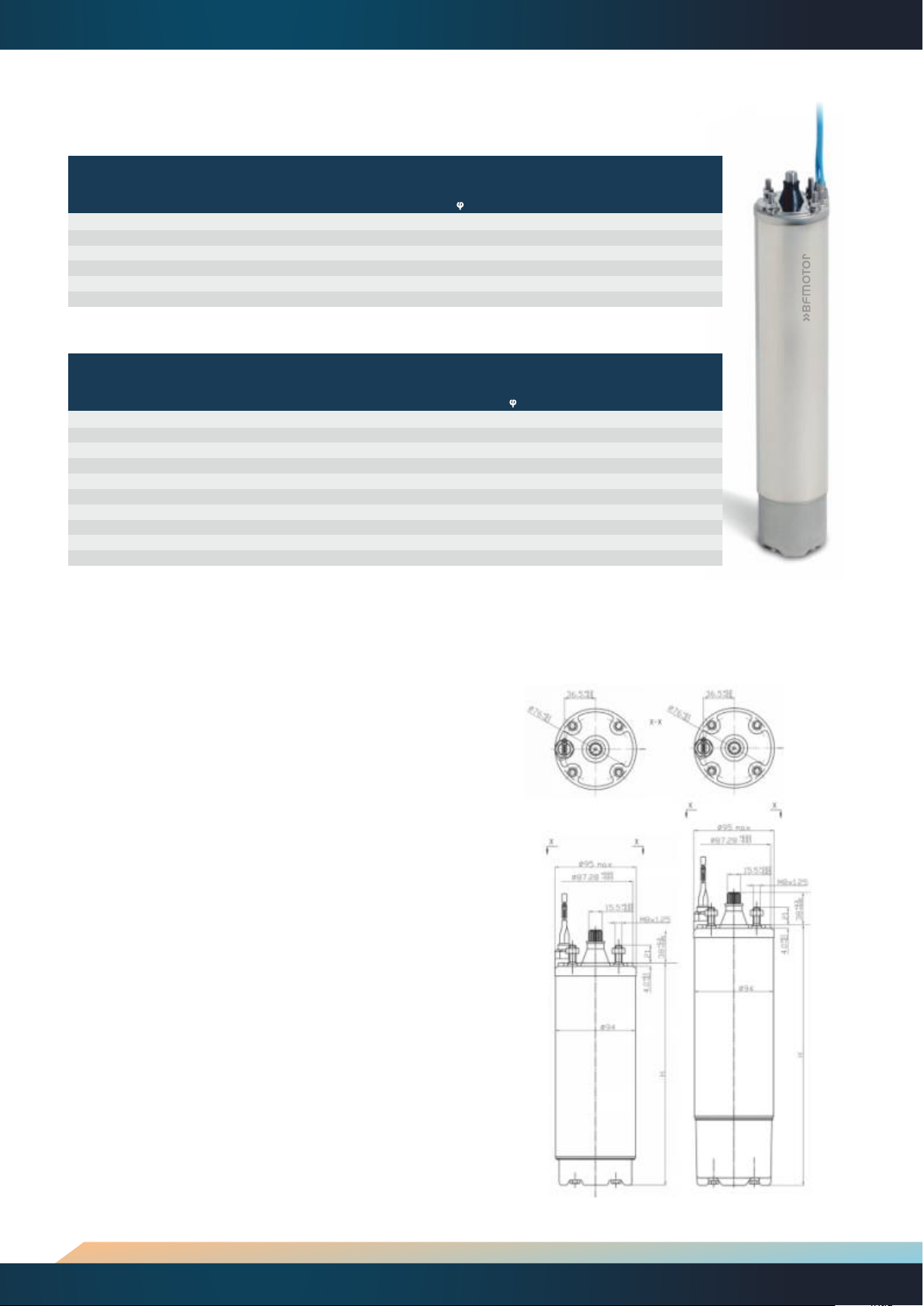

SUBMERSIBLE MOTORS 4" Rewindable Oil Filled - BF Motor

Single-phase

Ref.

7,0

7,6

8,7

10,3

12,0

14,2

Thrust (N)

1500

1500

1500

1500

1500

4400

Volt (v)

220-230

220-230

220-230

220-230

220-230

220-230

RPM

2860

2855

2855

2855

2855

2820

EFF

%

53

61

63

67

65

68

In (A)

3,4/3,6

4,2/4,5

5,8/6,0

8,0/8,2

10,8/11,0

14,6/14,8

HP

0,5

0,75

1,0

1,5

2,0

3,0

2653000005000

2653000007500

2653000010000

2653000015000

2653000020000

2653000030000

0,37

0,55

0,75

1,1

1,5

2,2

KW

BFMotor - 50HZ - 4" Rewindable Oil Filled

0,94

0,94

0,96

0,97

0,98

0,96

COS

325

325

350

385

420

520

Lenght

(mm)

Condenser

μF

16

20

35

40

50

70

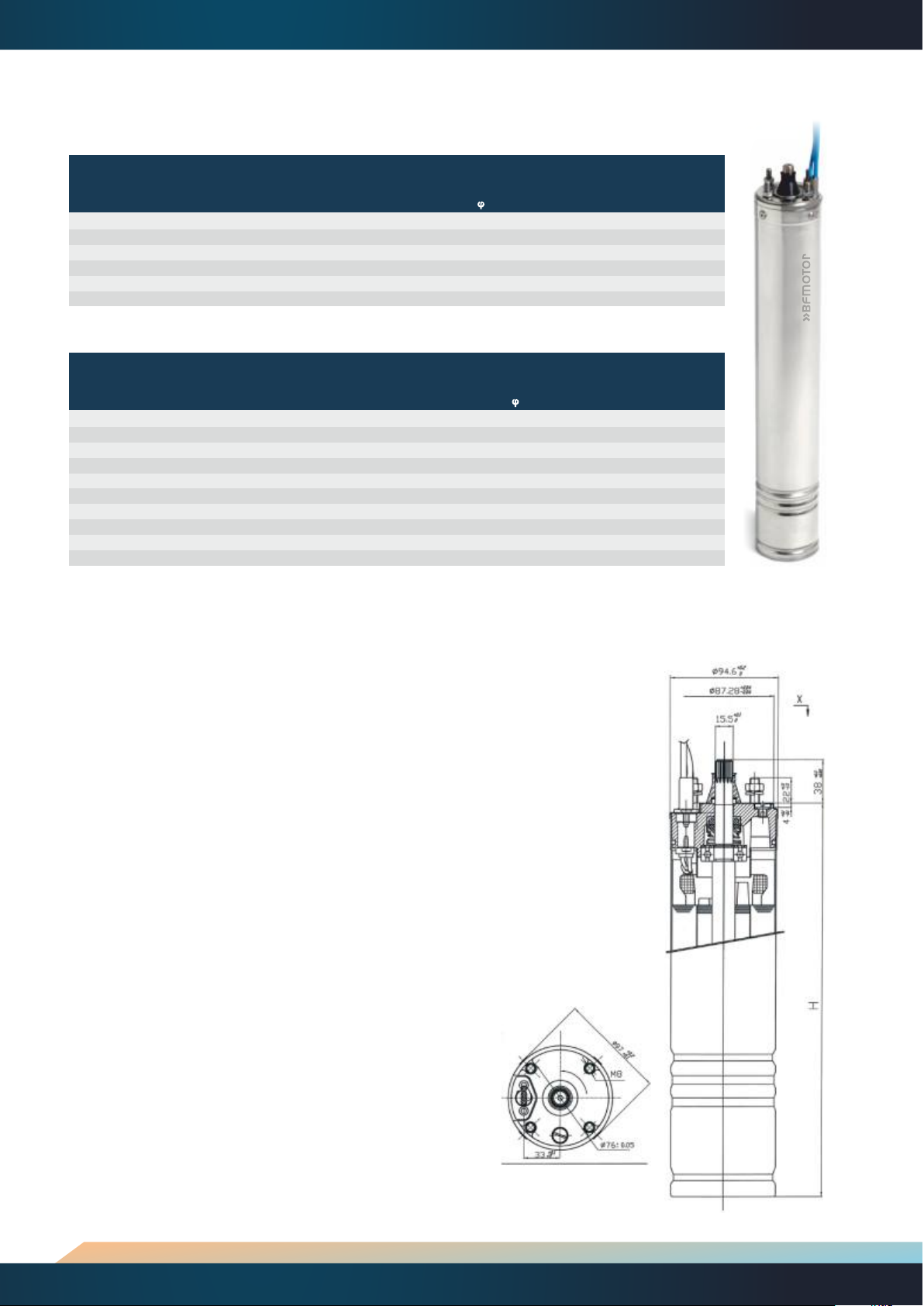

Threephase

BFMotor - 50HZ - 4" Rewindable Oil Filled

Volt (v)

380-400

380-400

380-400

380-400

380-400

380-400

380-400

380-400

380-400

380-400

RPM

2840

2830

2830

2820

2820

2850

2860

2825

2820

2820

EFF

%

58

62

67

67

68

78

78

78

78

76

COS

0,72

0,75

0,74

0,74

0,72

0,82

0,80

0,82

0,83

0,78

In (A)

1,4/1,6

1,9/2,0

2,4/2,6

3,2/3,4

4,4/4,6

5,6/5,8

7,7/7,8

9,7/9,8

13,5/13,8

19/19,5

HP

0,5

0,75

1,0

1,5

2,0

3,0

4,0

5,5

7,5

10,0

KW

0,37

0,55

0,75

1,1

1,5

2,2

3,0

4,0

5,5

7,5

2653000005010

2653000007510

2653000010010

2653000015010

2653000020010

2653000030010

2653000040010

2653000055010

2653000075010

2653000100010

Ref.

1500

1500

1500

1500

1500

5000

5000

5000

5000

7500

Thrust (N)

325

325

325

350

385

383

418

468

538

810

Lenght

(mm)

6,5

7,0

7,6

8,7

10,4

12,0

13,1

15,6

18,9

27,0

Weight

(Kg)

Weight

(Kg)

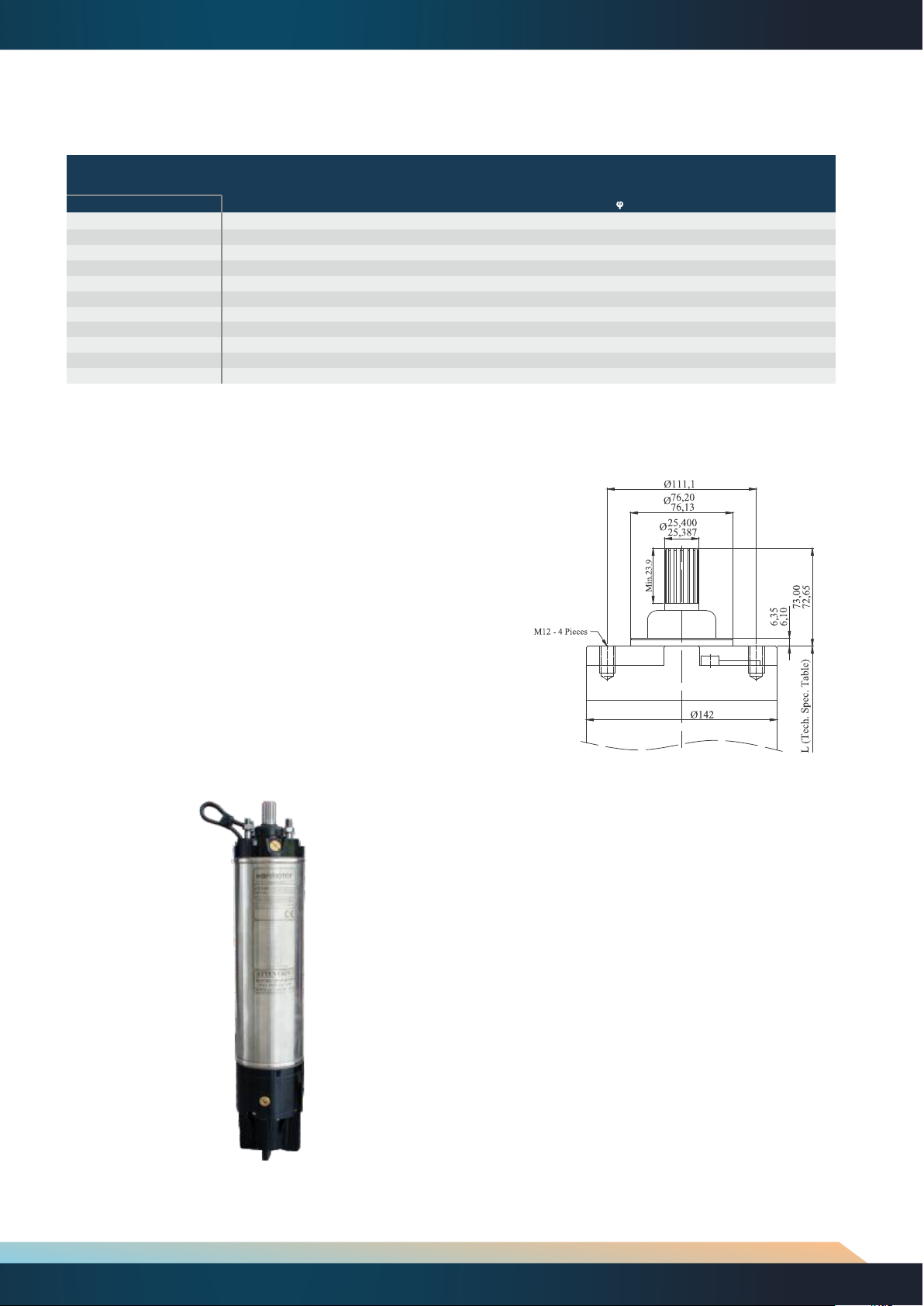

• Degree of protection IP68 / Class B insulation.

• Over-dimensioned sand slinger.

• Suitable for horizontal operation.

• Axial Thrust: - 1500 N from 0,37kW to 2,2kW - 2500 N

from 2,2kW to 5,5kW - 5000 N from 2,2kW to 5,5kW - 7500

N from 2,2kW to 7,5kW.

• Maximum depth immersion: 150 m.

• Temp. Max. 35 ° with water cooling flow min. 0.8 m / s.

• Number of starts per hour: max. 30 at regular intervals.

• Coolant: Dielectric non-toxic high quality lubricant.

• Single phase motor available in both version CSCR &

PSC.

• Winding: Enameled copper - class F insulation.

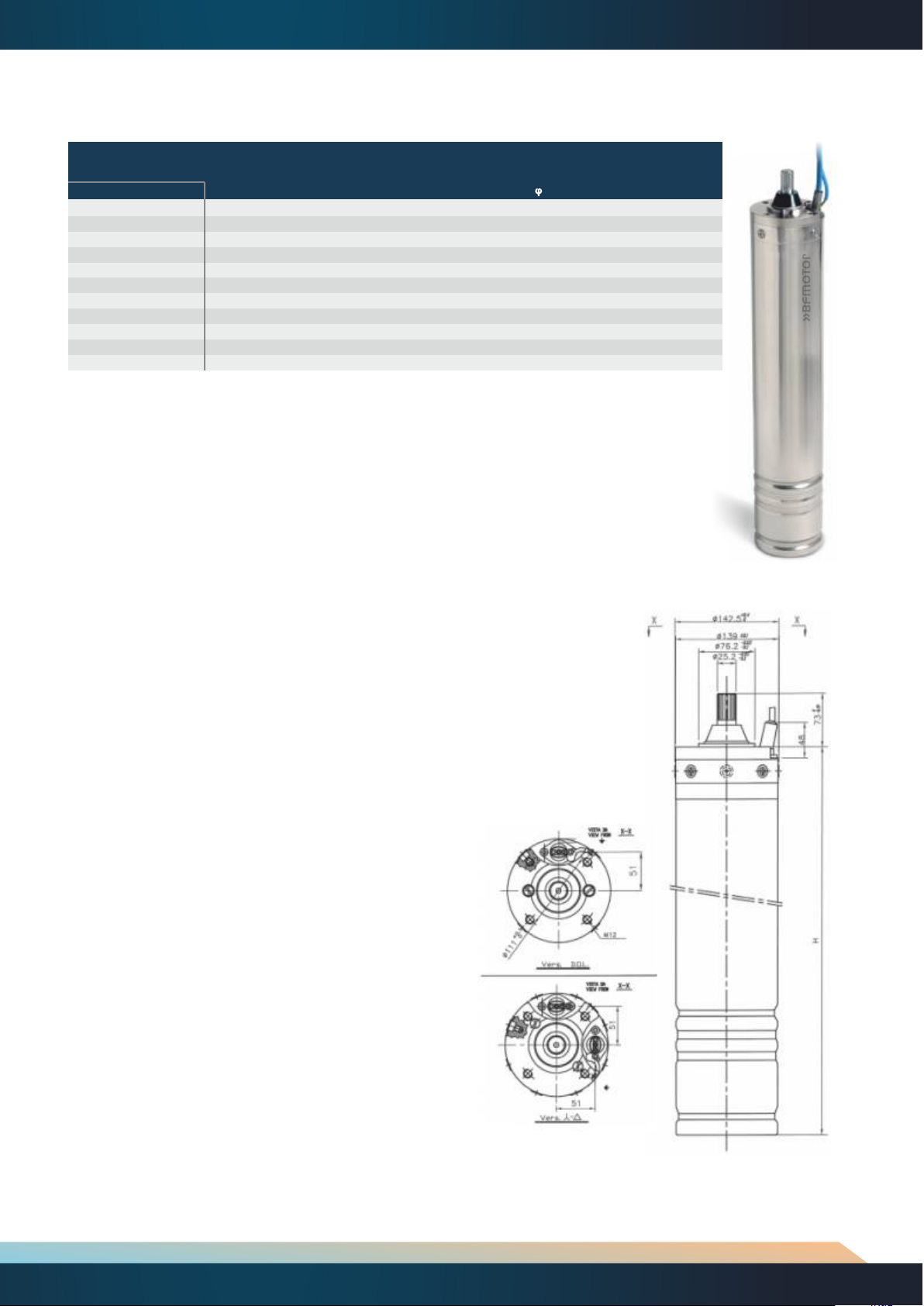

Motor range versions

• Three Phase: 0,37kW (0,5hp) to 4kW (5,5hp), 380-

415V/50Hz - 460V/60 Hz

• Shaft extention and coupling: NEMA Standard.

• Voltage variation: +/- 10%.

• Rewindable.

• Motor shaft: SS 304.

• Upper bracket: Nickel-plated cast iron. Ss304 cover

sheet / Brass / SS316 Available.

• Single Phase: 0,37kW (0,5hp) to 4kW (5,5hp), 220-

230V/50Hz (or 60Hz)

Thecnical Features

• Mechanical seal: graphite / ceramic. SiC/SiC or SiC/Al

mechanical seal available as option.

• Other voltage and frequencies available upon request.

• Motor case: SS 304.

• Motor cable length: 1,75 to 4 m according to the motor

size (3 wires plus ground).

• High quality radial and thrust ball bearings.

www. b ritef i l.com

6