TABLE OF CONTENTS

FEATURE INFORMATION ..................................................................................................................

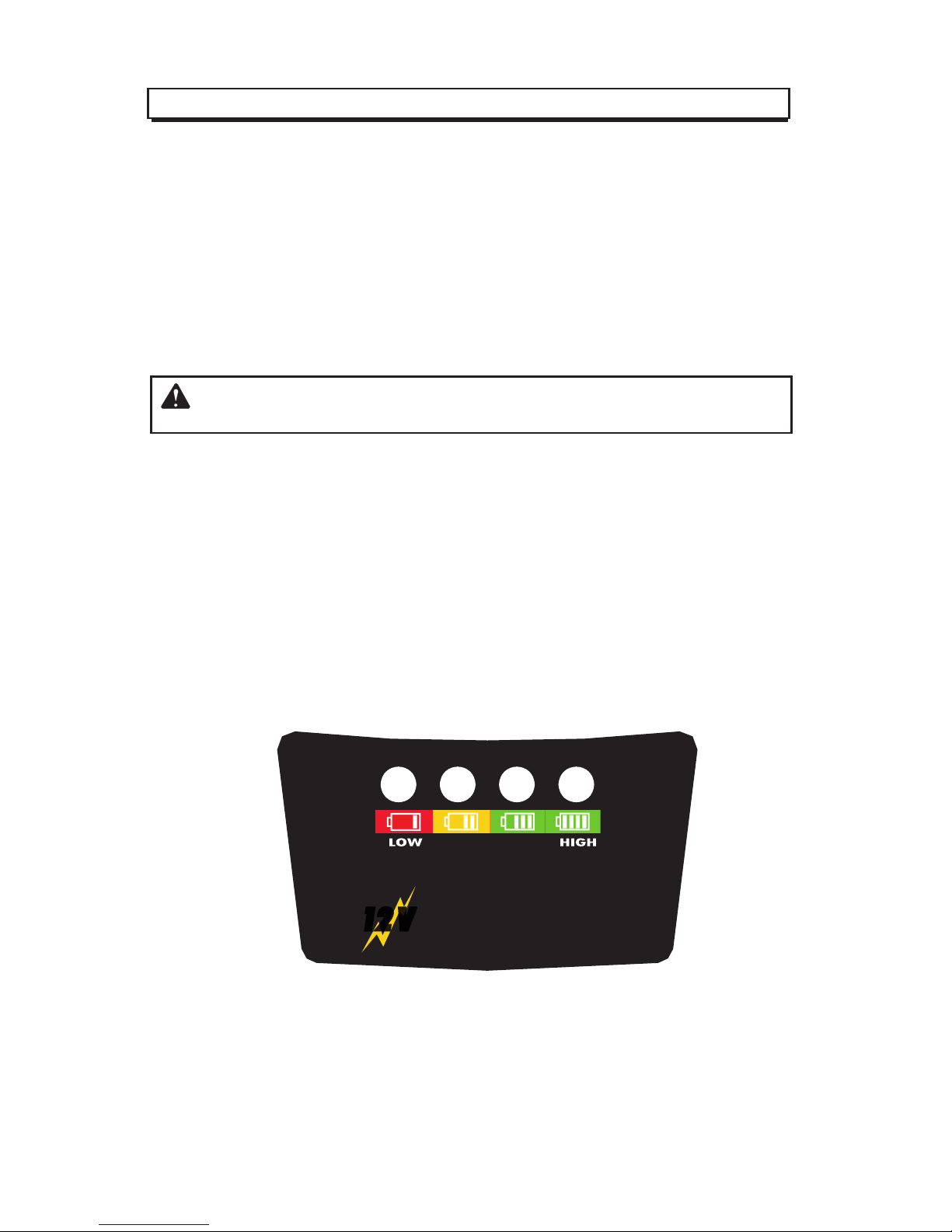

BATTERY .........................................................................................................................................

4-6

7

8-9

3

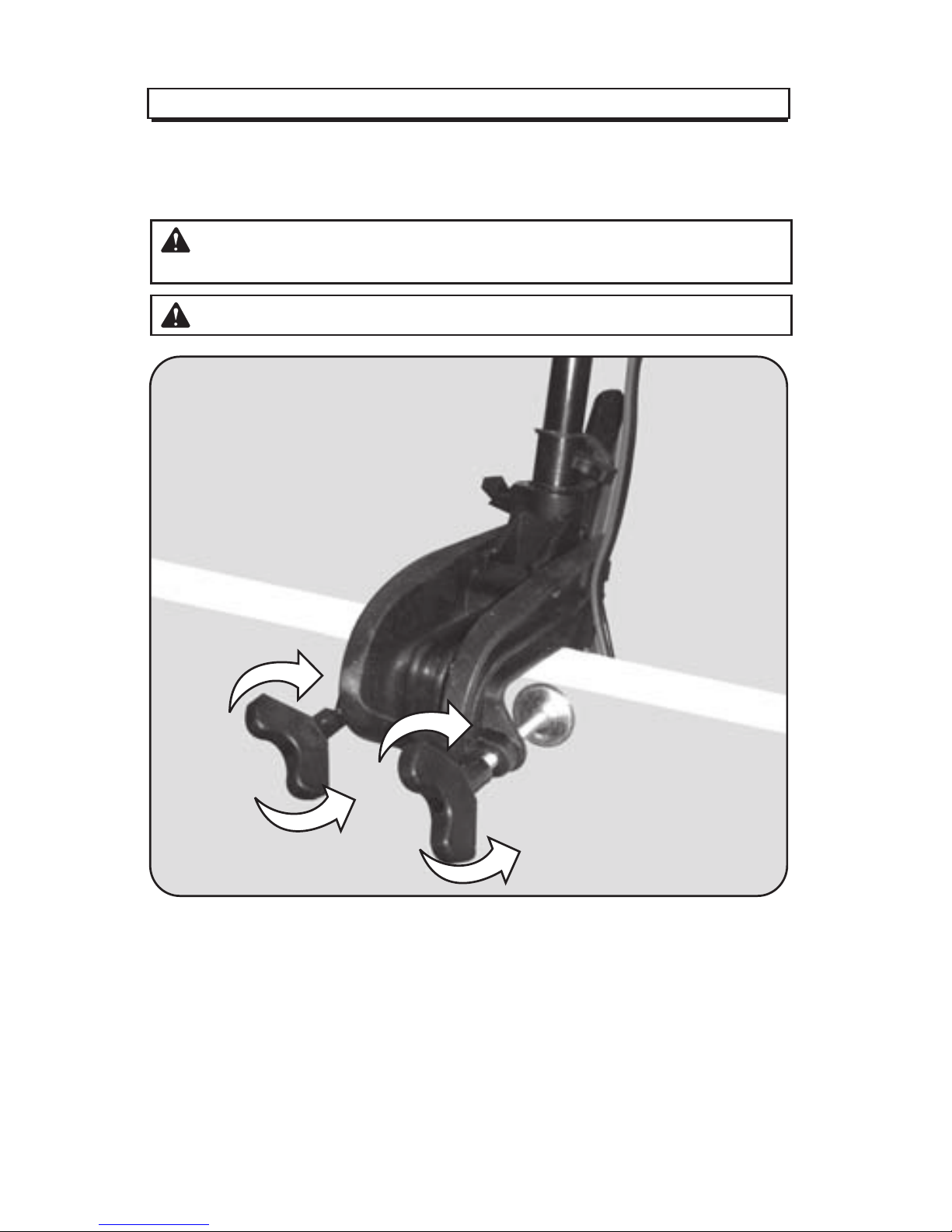

ADJUSTMENT ..................................................................................................................................

OPERATION .........................................................................................................................................

10

PROPELLER REPLACEMENT ..........................................................................................................

MAINTENANCE ..................................................................................................................................

EXPLODED VIEW ..............................................................................................................................

PARTS LIST .......................................................................................................................................

SPECIFICATIONS

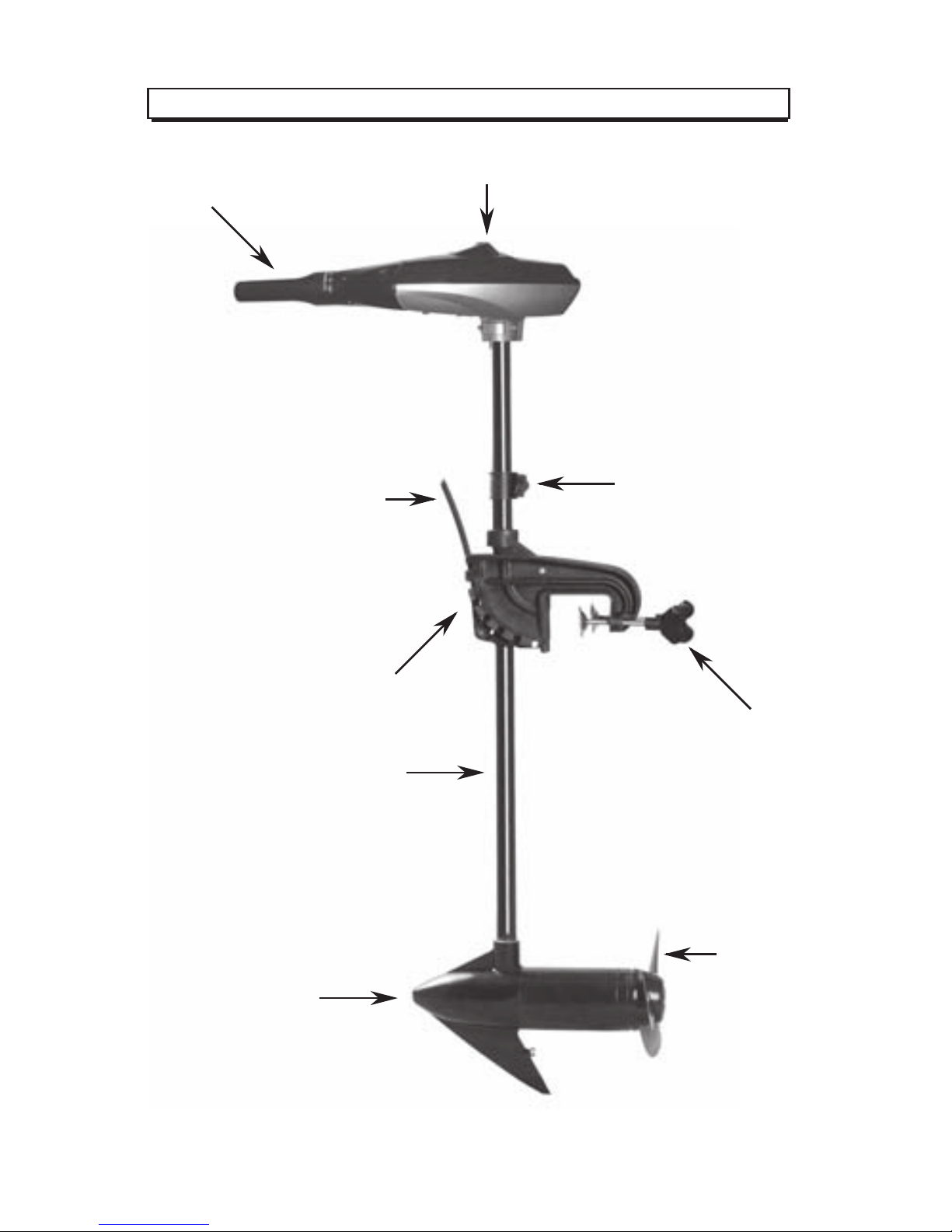

MODEL NO .................................................................................................................................

MOTOR ..........................................................................................................................................

90010

THRUST ......................................................................................................................................

12 V

55 lbs

PROP SPEED ......................................................................................................................2000 RPM

FORWARD SPEED .............................................................................................................5 SPEEDS

REVERSE SPEED .............................................................................................................. 3 SPEEDS

NOTE: To be used with Deep Cycle 12 V marine battery (Sold Separately).

2

SPECIFICATIONS ............................................................................................................................... 2

TROUBLESHOOTING.........................................................................................................................

LIMITED WARRANTY.........................................................................................................................13

12

11

14

15