Accessories & Packing List .............................................................................

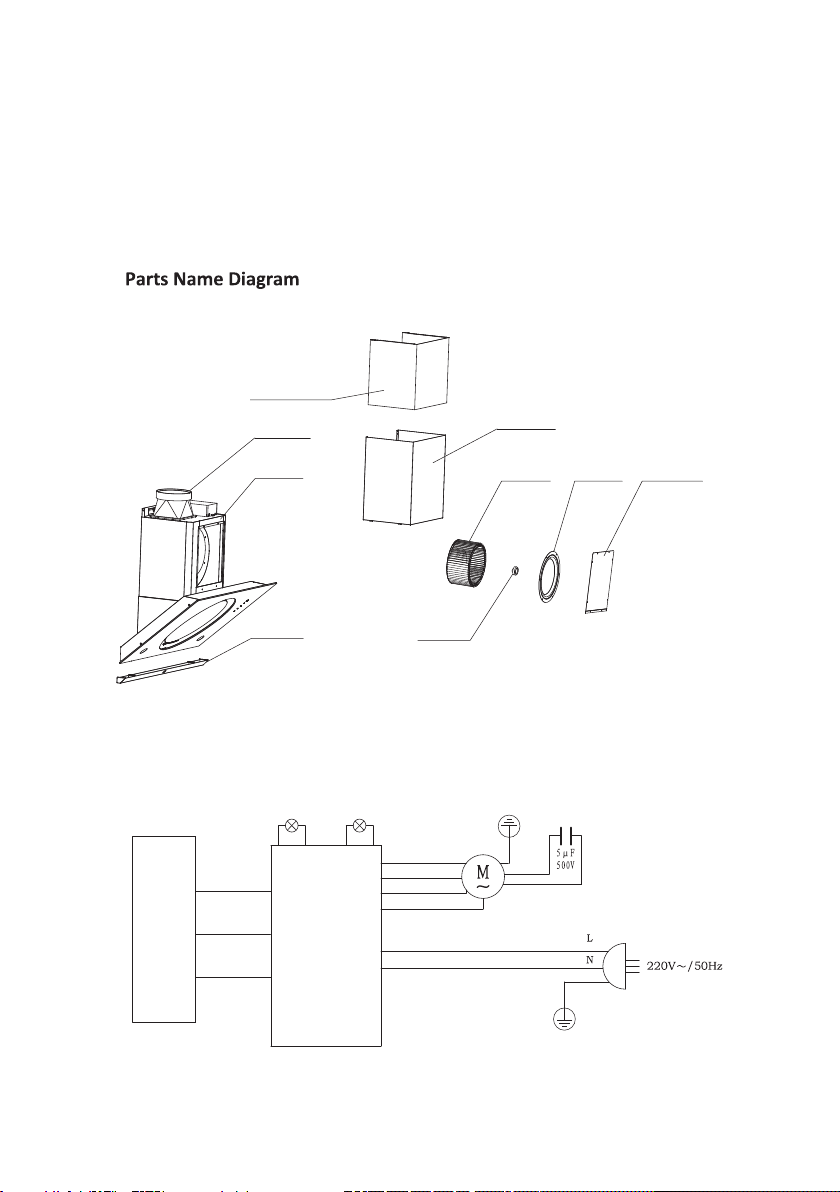

Parts Name Diagram .......................................................................................

Electrical Circuit Diagram ................................................................................

Main Technical Parameter .............................................................................

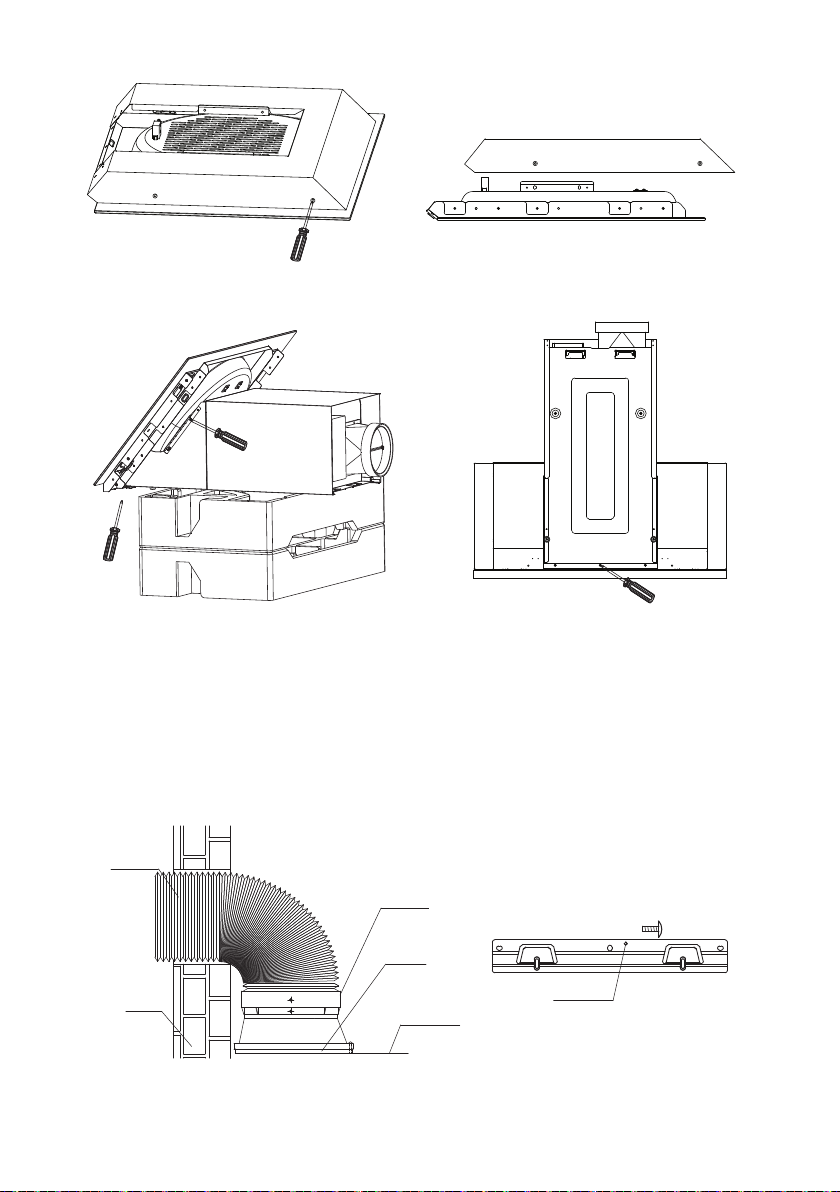

Installation Diagram..........................................................................................

Installation Steps.............................................................................................

Safety Instructions...........................................................................................

Oprating Instructions........................................................................................

Detachable Parts..............................................................................................

Troubleshooting................................................................................................

1

1

1

2

2

3

5

5

6

7