Decagon AquaLab User manual

Vapor Sorption

Analyzer

User‘s Manual

Version 2

Table of Contents

1. Introduction.................................................................... 1

About this Manual ...............................................................1

Warranty.............................................................................1

Customer Support...............................................................2

Seller’s Liability ...................................................................3

2. About the VSA ............................................................... 4

Moisture Sorption Isotherms ...............................................4

Measurement Method.........................................................5

Specifications......................................................................7

3. Theory............................................................................ 8

Moisture Sorption Isotherm Methods...................................9

4. Getting Started............................................................. 22

Instrument Setup...............................................................23

5. User Interface and Menus............................................ 28

Isotherm Tab.....................................................................28

Measurement Tab.............................................................29

Configuration Tab .............................................................29

Data Tab...........................................................................43

6. Cleaning and Maintenance .......................................... 46

Desiccant cartridge desiccant replacement.......................46

Cleaning the Testing Chamber..........................................48

7. Verification of Calibration..............................................54

Water Activity Verification ..................................................54

Verification Standards........................................................55

When to Verify for Linear Offset.........................................56

8. Running a Test .............................................................65

Becoming Familiar with Stages..........................................65

Running a Moisture Sorption Isotherm Test.......................65

For DDI method............................................................................69

For DVS method...........................................................................72

Using DDI to investigate Glass Transition..........................75

Creating a Working Isotherm Using the VSA .....................75

Editing a Running Isotherm Test........................................76

Running a Water Activity Test............................................78

9. VSA Downloader Software ...........................................79

Connect.............................................................................79

Configure and Start a New Test.........................................79

Download and Export ........................................................80

10. Troubleshooting..........................................................81

Diagnostic Screen..............................................................97

Appendix A .....................................................................101

Index...............................................................................102

AquaLab Vapor Sorption Analyzer

1. Introduction

1

1. Introduction

The AquaLab Vapor Sorption Analyzer (VSA) is an automatic

isotherm generator from the world leaders in water activity

measurement. The VSA is the only automatic isotherm generator

that can generate isotherms using both the Dynamic Vapor

Sorption (DVS) method, which generates equilibrium isotherms,

and the Dynamic Dewpoint Isotherm (DDI) method, which

generates dynamic isotherms. By combing both methods in one

instrument, the VSA makes it possible to investigate both

dynamic matrix changes due to water sorption and the kinetics of

those changes. This manual is for VSA operation and to be

informative regarding the capabilities of your VSA.

About this Manual

Included in this manual are instructions for setting up your VSA

which includes setting up an isotherm test, running a test, col-

lecting data, and analyzing data. Please read the manual before

operating the VSA to ensure your instrument performs to its full

potential.

Warranty

The VSA has a one year warranty on parts and labor. Your

warranty is automatically validated upon receipt of the

instrument. Decagon will contact you within the first 90 days of

your purchase to see how the VSA is working for you.

AquaLab Vapor Sorption Analyzer

1. Introduction

2

Customer Support

If you ever need assistance with your VSA, or if you just have

questions or feedback, there are several ways to contact us.

Customer service representatives are available to speak with

you Monday thru Friday, between 7am and 5pm Pacific time.

NOTE: If you purchased your VSA through a distributor, please

contact them for assistance.

E-mail:

Phone:

1-509-332-5601

Fax:

1-509-332-5158

If contacting us by email or fax, please include as part of your

message your instrument‘s serial number, your name, address,

phone, and fax number.

Note to Our VSA Users

This manual is written to aid the end user in understanding the

basic concepts of moisture sorption isotherms, enabling them to

use our instruments with confidence. Every effort has been made

to ensure the content of this manual is correct and scientifically

sound.

AquaLab Vapor Sorption Analyzer

1. Introduction

3

Seller’s Liability

Seller warrants new equipment of its own manufacture against

defective workmanship and materials for a period of one year

from date of receipt of equipment. The results of ordinary wear

and tear, neglect, misuse, accident and excessive deterioration

due to corrosion from any cause are not to be considered a

defect. The seller‘s liability for defective parts shall in no event

exceed the furnishing of replacement parts F.O.B. from the

factory where originally manufactured. Material and equipment

covered hereby which is not manufactured by Seller shall be

covered only by the warranty of its manufacturer. Seller shall not

be liable to Buyer for loss, damage or injuries to persons

(including death), or to property or things of whatsoever kind

(including, but not without limitation, loss of anticipated profits),

occasioned by or arising out of the installation, operation, use,

misuse, nonuse, repair, or replacement of said material and

equipment, or out of the use of any method or process for which

the same may be employed. The use of this equipment

constitutes Buyer‘s acceptance of the terms set forth in this

warranty. There are no understandings, representations, or

warranties of any kind, express, implied, statutory or otherwise

(including, but without limitation, the implied warranties of mer-

chantability and fitness for a particular purpose), not expressly

set forth herein.

AquaLab Vapor Sorption Analyzer

2. About the VSA

4

2. About the VSA

The VSA Isotherm Generator is an automatic moisture sorption

isotherm generator that can generate both dynamic and

equilibrium moisture sorption isotherms.

Moisture Sorption Isotherms

The relationship between water activity (aw) and moisture

content at a given temperature is called the moisture sorption

isotherm. This relationship is complex and unique for each

product due to different interactions (colligative, capillary, and

surface effects) between the water and the solid components at

different moisture contents. An increase in awis almost always

accompanied by an increase in water content, but in a non-linear

fashion. Moisture sorption isotherms are sigmoidal in shape for

most foods, although foods that contain large amounts of sugar

or small soluble molecules have a J-type isotherm curve shape.

Isotherms provide information about product quality and safety.

A few uses for isotherms include:

1. Monolayer moisture content determination.

2. Determine critical water activity or moisture content.

3. Limits for crispness, hardness, and flow properties.

4. Optimize moisture contents at a safe water activity that

maximizes moisture and avoids over drying.

5. Determine shelf-life and storage stability of a product.

6. Predict packaging requirements based on sorption

properties of a product.

7. Determine kinetics of sorption and water vapor diffusion

coefficients

AquaLab Vapor Sorption Analyzer

2. About the VSA

5

8. Determine the equilibrium water activity of a mixture of dry

ingredients.

9. Determine the degree of crystallinity of powders.

10. Determine the level of amorphous material in a product.

11. Determine critical water activities for phase transitions.

12. Determine the relationship between water activity and glass

transition temperature.

13. Determine the relationship between water activity and

crystallization.

14. Determine hysteresis levels for a product.

15. Determine the moisture sensitivity of a product.

16. Determine the equilibrium moisture content at a given water

activity.

17. Allow rapid moisture content determination from water

activity analysis through an isotherm curve.

Measurement Method

The VSA is the only automatic isotherm generator that can

create isotherms using both dynamic and static methods. To

produce dynamic isotherms, the VSA uses the Dynamic

Dewpoint Isotherm (DDI) method. To produce static or

equilibrium isotherms, the VSA uses a controlled humidity and

balance system commonly referred to as Dynamic Vapor

Sorption (DVS).

The DDI method for dynamic isotherms is a water activity and

gravimetric analysis method that controls neither water content

nor water activity, but dries or wets the sample and measures

water activity and water content during the wetting or drying

process. Water content is determined by weighing the sample

using a high precision magnetic force balance. Water activity is

AquaLab Vapor Sorption Analyzer

2. About the VSA

6

determined using Decagon‘s patented chilled-mirror dewpoint

sensor. Drying of the sample is imposed by flowing dry air from a

desiccant tube across the sample. Wetting of the sample is

imposed by saturating the air with water before it enters the

chamber and flows across the sample. The water reservoir is

mounted to the temperature controlled lower block to ensure

humidity saturation and minimize temperature fluctuation.

The DVS method for static or equilibrium isotherms consists of

tracking sample weight change as the sample is exposed to

different controlled humidities. The sample is held at each

humidity for a preset time interval or until a steady state weight

change is achieved, the goal being to achieve equilibrium

between the sample water activity and the controlled humidity.

Typically, several humidity levels are chosen and preset during

the setup process. The instrument then tracks equilibrium

progress at each humidity level and automatically steps to the

next humidity when equilibrium requirements are achieved.

Weight change vs. time data is recorded allowing for determining

kinetics of sorption for each humidity level. Using less stringent

equilibrium settings for weight change or setting a reduced time

interval at each step will speed up the isotherm test, but may

give non-equilibrium results. In addition, setting smaller steps in

humidity will increase the data resolution of the isotherm, but at

the expense of much longer test times.

The VSA is a stand-alone instrument with an integrated pump

system that eliminates the need for an external gas cylinder,

however an external gas source can be used if desired. The

instrument consists of a case which houses the power supply, air

pump, balance, temperature controlled sample chamber, sensor

block, sensor and temperature control electronics, water

AquaLab Vapor Sorption Analyzer

2. About the VSA

7

reservoir, and desiccant supply. Setup is as simple as plugging

the instrument in, installing the desiccant tubes, and filling the

water reservoir. Test parameters can be set using an onboard

interface or using a connected computer and VSA software

package.

Specifications

Water Activity (Relative Humidity) Range: 0.03 to 0.95 aw(3%

to 95% RH) for 15 to 50°C , 0.03 to 0.90 awfor 50 to 60°C

Water Activity (Relative Humidity) Accuracy: ±0.005 aw(0.5

%RH) (for volatiles setting, ±0.02 aw)

Water Activity (Relative Humidity) Repeatability: ±0.003 aw

(0.3% RH) (for volatiles setting, ±0.02 aw)

Sample Weight Range: 500-5000 mg

Temperature Control Range: 15 to 60°C at STP. Instrument

Control (sample temperature may vary)

Temperature Operating Range: 0 to 60°C

Humidity Operating Range: 10-90% non-condensing

Universal Power: 110 V to 220 V AC. 50/60Hz

Size (Footprint): 38.1 x 26.7 x 30.5cm (15 x 10.5 x 12in. (L x W

x H))

Weight: 33 pounds

Weight Resolution: ± 0.1mg

AquaLab Vapor Sorption Analyzer

3. Theory

8

3. Theory

Water profoundly influences product attributes such as quality

and safety. To completely understand water relations in a

product requires an understanding of the amount of water

(moisture content) that can be held at a given energy state

(water activity). Moisture sorption isotherms describe the

relationship between water activity and moisture content at a

constant temperature. The nature of this relationship depends on

the interaction between water and other ingredients. The amount

of water vapor that can be absorbed by a product depends on its

chemical composition, physical-chemical state, and physical

structure. Consequently, the isotherm shape is unique to each

product type due to differences in capillary, surface, and

colligative effects (Figure 1). Products that lie in the low water

activity portion of the isotherm are often referred to as dry, those

in the range of 0.60 aw to 0.90 aw are intermediate moisture

products, and those having water activities higher than 0.90 are

high water activity products.

For ease of interpretation, isotherms are often identified by

Brunauer classifications (Brunauer, 1945). Most food and

pharmaceutical products fall under type I, II, or III. Type I

isotherms are typical of very hygroscopic materials. Type II

(sigmoidal) isotherms are typical for intermediate moisture

products. Type III (J-shaped) isotherms are typical for crystalline

and coated materials. These general classifications proved

useful when conducting isotherms on every product was not

feasible due to time and labor constraints. However, with

automation and improved speed, isotherms can easily be

conducted on any product and the uniqueness of each isotherm

AquaLab Vapor Sorption Analyzer

3. Theory

9

often proves more valuable than placing them in a common

classification.

0

5

10

15

20

25

30

35

40

45

50

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Water Activity

Moisture Content (% d.b.)

Icing Creme Filling Cake Wood Pulp Granola Bar Milk Powder

Figure 1. Moisture adsorption isotherms for icing (♦), crème filling (■),

cake (▲), wood pulp (♦), granola bar (*), and milk powder (●) showing

that the isotherm shape is unique to the product.

Moisture Sorption Isotherm Methods

Constructing an isotherm consists of collecting water activity and

moisture content data at various points along the water activity

range. The range of water activities used will depend on the

situation, but normally run from 0.10 awup to 0.90 aw. This can

be accomplished by controlling water activity levels using

saturated salt slurries or mechanical humidifiers and determining

equilibrium moisture content at each water activity level.

Equilibrium is assumed when the weight of the sample stops

changing. This process is often accomplished using sealed

chambers such as desiccators and the equilibration process can

AquaLab Vapor Sorption Analyzer

3. Theory

10

take weeks. Additional challenges with this manual method

include difficulty tracking the weight of the samples, removing the

samples for weighing exposes them to ambient humidity, and at

high humidities, there is the possibility of mold growth. Deca-

gon‘s VSA Isotherm Generator uses the DVS method described

above to speed up and automate the construction of equilibrium

isotherms, eliminating the challenges of manual determination. In

additional to equilibrium moisture contents at a given water

activity, equilibrium isotherms provide information about kinetics

of sorption and water vapor diffusion properties.

Moisture sorption isotherms can also be determined using

dynamic methods such as the DDI method used by the VSA.

The DDI method directly measures water activity while

gravimetrically tracking weight, so there is no dependence on

equilibration to known water activity levels to determine water

activity. Adsorption occurs as saturated wet air is passed over

the sample. Desorption is accomplished as desiccated air is

passed over the sample. After a short period of time, airflow is

stopped and a snapshot of the sorption process is taken by

directly measuring the water activity and weight. The advantages

of this method are increased analysis speed since the sample

does not have to wait for equilibration to a known water activity

and an unmatched level of resolution. This makes it possible for

dynamic isotherms to produce high resolution isotherms in a

matter of days instead of the weeks it would take to make a

comparable isotherm using equilibrium techniques. The high

resolution of dynamic isotherms makes them valuable for

observing sudden changes in sorption properties associated with

matrix changes such as glass transition.

AquaLab Vapor Sorption Analyzer

3. Theory

11

The dynamic nature of the DDI method means that moisture

contents may or may not be at equilibrium and it is possible for

there to be differences between dynamic and equilibrium

isotherms. For samples with fast vapor diffusion, penetration by

water vapor into the whole sample is rapid and isotherms using

the DDI method for these types of products will be comparable

equilibrium methods. However, for samples with slow diffusion

rates, moisture movement through the sample is slow and

complete diffusion of moisture into and out of the sample may be

slow enough to give the appearance of vapor equilibrium in the

headspace during water activity analysis. In reality, the moisture

has not had time to be completely absorbed by the sample.

Isotherms for these types of samples developed using the DDI

method may have lower moisture contents during adsorption and

higher moisture contents during desorption than equilibrium

isotherms, resulting in higher levels of apparent hysteresis.

Combining DVS and DDI in one instrument

A unique and important feature of the AquaLab VSA is that it can

generate both dynamic and equilibrium isotherms. As explained

above, both DVS and DDI methods have advantages and

disadvantages. While the data they generate will agree in some

cases, it is the uniqueness of the results from each method that

gives them value. There is information that can only be obtained

from dynamic isotherms such as critical water activities for glass

transition. Similarly, there is information that can only be

obtained by equilibrium isotherms such as kinetics of sorption.

Therefore, to provide the most information about the moisture

characteristics of a material, both types of isotherms are needed.

The VSA can provide both DVS and DDI isotherms and even run

them both on one sample.

AquaLab Vapor Sorption Analyzer

3. Theory

12

Hysteresis

Figure 2 shows two isotherms, one obtained by wetting a sample

from complete dryness and the other obtained by drying a

sample from saturation. The arrows show the direction of the

process. The water content at each water activity is higher during

desorption (drying from high water content) than adsorption

(wetting from low water content). This phenomenon is called

hysteresis. The curves in Figure 2 represent limits or bounding

isotherms since they begin at water activities near zero and one.

If a drying process reduces the water activity of a sample only

part way to dryness, and the sample is then re-wet, it follows a

path between the wetting and drying boundary curves, as shown

in Figure 3. These curves are called scanning curves, and there

can be an infinite number of them depending on where drying

stops and starts.

Figure 2. Full isotherm showing hysteresis.

AquaLab Vapor Sorption Analyzer

3. Theory

13

0.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

0 0.2 0.4 0.6 0.8 1

Water Activity

Moisture Content (%d.b.)

Figure 3. Scanning adsorption curves resulting from drying to

different water activities.

These observations help clarify the point that an isotherm is not

a single valued function. The water content for any given water

activity value depends on the wetting and drying history of the

sample.

It is possible to obtain isotherm data which appear to show

hysteresis by failing to allow a sample to equilibrate at each step,

or by inducing changes in the water binding properties of the

matrix by wetting or drying. We prefer to treat these cases

separately, and reserve the term hysteresis for situations where

equilibrium is reached, but water contents of wetted and dried

samples still differ because of their history.

Several plausible models exist for hysteresis. Theories are

based on; capillary condensation of porous solids, phase

AquaLab Vapor Sorption Analyzer

3. Theory

14

changes of non-porous solids, structural changes within a solid

matrix, and supersaturation of some solutes during desorption.

Depending on the composition of the sample, these theories

explain why the water content of a desorption process is greater

than that for a wetting process.

1. Capillary condensation of porous solids theory is illustrated

by the ‗ink bottle‘ model, in which pores and capillaries fill

and empty differently. Such a pore fills when the water

activity corresponding to the energy state of the larger

radius is exceeded, but will empty only when the water

activity drops below the energy state of the narrow neck

radius.

2. A phase change of non-porous solids is illustrated by the

fact that desorption from rubbery state can reach equilibrium

faster due to increased molecular mobility, while adsorption

into a glassy material can be slow due to restrictions in

molecular mobility.

3. Structural changes within a solid matrix occur when the

material swells and polar sites once obscured are now

exposed to ‗bind‘ with water. For example, hydrated protein

contains many sites for water ‗binding‘ before desorption

while dehydrated protein have limited polar sites for water

‗binding‘ prior to adsorption.

4. Some solutes may supersaturate below their crystallization

water activity (non-equilibrium condition) and thus, hold

more water as awis lowered. Foods with high sugar content

frequently exhibit this phenomenon.

AquaLab Vapor Sorption Analyzer

3. Theory

15

Non-Equilibrium

If diffusion of water into (adsorption) or out of (desorption) a

material is slow and sufficient time is not allowed for complete

diffusion, there will be a large amount of apparent hysteresis that

could be reduced by allowing sample equilibration.

Matrix Changes

Figure 4 shows three different isotherm curves of spray-dried

milk powder with different maximum water activities and different

sorption histories. The boundary isotherm with a 0.80 aw

maximum experienced a phase change at 0.43 aw, indicated by a

sharp inflection point in the curve. The desorption curve for this

isotherm appears to show hysteresis, especially below a water

activity of 0.60. However, an isotherm, run on a sample wetted to

a maximum water activity below the phase change, exhibits very

little hysteresis. The lack of hysteresis in this isotherm indicates

that the matrix changes that occur at 0.43 aware completely

responsible for the apparent hysteresis.

Water in a sample is bound to particle surfaces by various

bonding mechanisms. When the configuration of particle

surfaces changes due to a phase change, binding sites change

and the amount of water which can be bound at a given energy

of water also changes. An isotherm curve of the phase changed

sample does not show further phase transitions since simply

drying the sample does not return it to an amorphous state.

These matrix changes represent a true physical change in the

material. They are not reversible by drying, no matter how many

drying cycles occur. Differences between the adsorption and

AquaLab Vapor Sorption Analyzer

3. Theory

16

desorption curves in the initial isotherm is not true hysteresis

since the sample matrix has experienced a physical change.

Differences between sorption curves in the subsequent

isotherms represent true hysteresis.

0

5

10

15

20

25

0 0.2 0.4 0.6 0.8 1

Water Activity

Moisture Content (% d.b.)

Figure 4. Moisture sorption isotherms for spray-dried milk

powder showing a change in hysteresis due to a phase change

at 0.43 aw. When the isotherm is ended prior to the phase

change at 0.43 aw (■), there is little hysteresis. When the

isotherm is ended above the phase change (), there is

apparent, but not actual hysteresis due to the phase change.

Subsequent isotherms run on the sample after experiencing a

phase transition (▲) do not show an inflection point, are

repeatable, and exhibit only small levels of hysteresis.

Working Isotherms

Full boundary isotherms give information about the physical

characteristics of a product, show hysteresis, and are important

in establishing critical control points, but in many cases a

working isotherm will prove very useful. A working isotherm

Other manuals for AquaLab

1

Table of contents

Other Decagon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sennheiser

Sennheiser RV 54 Bedienungsanleitung

PRECISION DIGITAL

PRECISION DIGITAL Loop Leader PD683 instruction manual

PROLEC

PROLEC Liftwatch Rail Operator's manual

ProMinent

ProMinent DULCOMETER DMT Series operating instructions

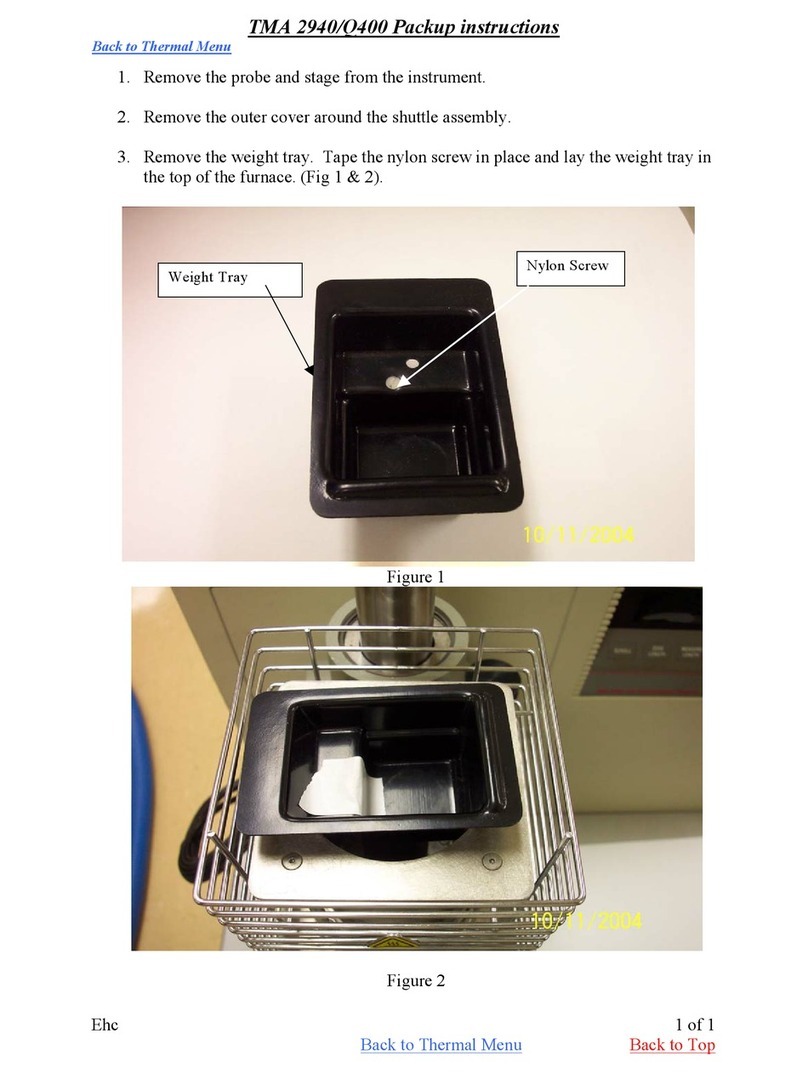

TA Instruments

TA Instruments TMA 2940 instructions

Traceable

Traceable Digi-Sense 98767-05 instructions