Decagon AQUA LAB VSA User manual

Vapor Sorption

Analyzer

Quick Start Guide

VSA Quick Start Guide

1. Getting Started—

• Place the AquaLab VSA on a at surface. Use the bubble

level(Figure 1: Adjustment and bubble level) and use the

adjustable feet to level the instrument. The small rubber

feet on the back of the lower plate are to prevent tip-over

and do not need to be touching the table.

• Use the AquaLab VSA where environmental temperature

and humidity remain fairly stable.

Figure 1: Adjustment and bubble level.

• The AquaLab VSA needs to be on a stable platform and

evaluated to verify shipping did not damage the scale

performance. To test scale stability:

1. Turn on the VSA and allow instrument to warm

up for 2 hours.

2. Navigate to the Diagnostics screen in the

Conguration menu and press .

3. Scroll down to the screen that shows the weight.

Readings should vary no more than 0.5 mg.

Adjustment feet:

Two on front and one

on the middle back.

Bubble Level

Lower Block

VSA Quick Start Guide

4. Lightly tap the table with one nger. If the readings

vary more than 0.5 mg after tapping, the table is

probably too unstable for accurate weight readings

during a test and will need to be made more rigid

or another location found for this equipment.

Contact your AquaLab distributor if the scale

readings are unstable after placing the unit on a

stable structure.

Figure 2: Desiccant installation

• Desiccant tubes are installed by orienting the tube so that

the black colored valve inserts into the black receiving hole

as shown in Figure 2. Before insertion make sure that the

desiccant tube lid is rmly sealed onto the desiccant tube.

(See Manual for instructions) Lift the tube into the area

above the desiccant receiver and then insert the tube into

the mating holes while shaking the tube slightly. Once in

place, the desiccant tube is sealed for ow purposes and

may move side to side if contacted.

Desiccant Cartridge

Desiccant Receiver

Black Valve

Black Receiving Hole

VSA Quick Start Guide

Figure 3: Tank ll extension

• Remove the black plug on the clear plastic tank ll

extension located on the back right of the VSA.

(Figure 3). Fill the tank with deionized water until full.

Finger tighten the water ll plug once nished.

• To remove the water from the water tank, the water tank

drain plug is used.

• Figure 3 shows the location of a lter that will need to be

removed from time to time when dust builds up on it. The

housing around the lter is a snap on housing that is easily

removed.

Water Fill Plug

Water Tank Fill Extension

Upper Horizontal Drilled Hole

Water Tank Drain Plug

Fan Filter

VSA Quick Start Guide

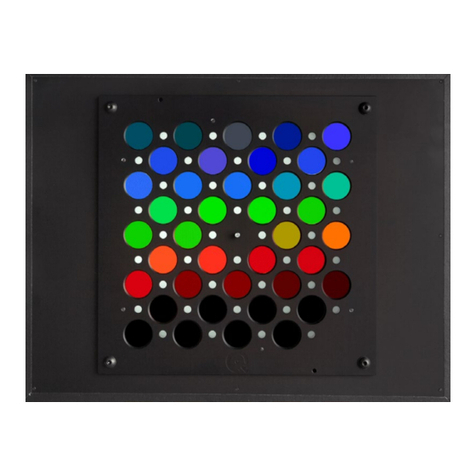

Figure 4: Sample cup and lower block assembly

• Figure 4: assembly illustrates the proper positioning of the

parts in the lower block. The air cylinder is placed into

the bore of the base block. It should slide into the block

easily and settle at the bottom of the bore. The weigh

pan connects to the scale and holds the sample cup. For

best results, verify cleanliness of all parts.

2. AquaLab VSA Performance Verication overview—

• AquaLab VSA performance and cleanliness should be

checked frequently; before each isotherm test is

recommended.

• Press until you are at the Measurement Tab.

• Use AquaLab Verication Standards to verify performance

or adjust linear offset.

Sample Cup Lid

Only used for sample storage and

must be removed during tests.

Sample Cup

Stainless steel cups are

recommended. Plastic cups

absorb moisture over time.

Weighing Pan

Air Cylinder

Base Block Bore

VSA Quick Start Guide

• To verify, remove weigh pan and then place sample cup

containing one of AquaLab’s verication standards in

sample chamber. Close lid and carefully avoid spillage; See

Figure 5.

• Move latch left or press to start a reading. The

pinwheel spins to indicate a measurement is running.

The aw reading for the standard and the temperature

displays when nished. Make sure the aw reading

on the standard is within +/-0.005 of the correct aw for the

standard. (+/- 0.02 if cap sensor is used)

• If an offset adjustment is needed, refer to chapter 7 in the

user’s manual.

Figure 5: Sample chamber

3. Sample Preparation—

• Fill sample cup no more than half full (~7ml).

Do Not Overll!

• Sample size can be between 500 and 2,000 mg. We

recommend 1000 mg.

• Ensure the rim and outside of sample cup are clean.

Lid

Base

VSA Quick Start Guide

• Ensure sample temperature is within 4 °C of chamber

temperature.

4. Starting a Test—

• Before starting a test, set the Volatiles: Yes/No option in

the configuration menu. If your sample has volatiles,

select “Yes” otherwise select “No”.

• On the main screen, select the test wizard .

• Following several warnings, begin configuring the test by

providing a name for the test using the arrow keys

and then press . (The name of a previous test will appear

by default.)

• Enter initial moisture content if known (optional). Press to

continue or to go back.

• Setup each stage of the isotherm test. A stage is used to

adjust the isotherm settings for an individual sample (up to

20 stages). Each stage is setup with the isotherm method

(DDI or DVS) and the settings for that portion of the

isotherm. Once a stage is created, it can be modified or

deleted anytime before the test is started.

i.e. For milk powder, Stage 1 could use the DDI method to

ramp quickly from 0.1 to 0.4 awand Stage 2 could use the

DVS method to step from 0.4 to 0.8 awslowly in 0.05 aw

increments.

•To setup a new stage, select “new” and press . A screen

with several parameters will appear. If a previous test

has been run, the stages for that test will be listed by

default. These stages can be used as-is or updated with new

settings. If you need to delete a stage, go to the specific

stage and press . Scroll down to the bottom of the stage

settings select “Delete” and press .

• Select the isotherm method as either Dynamic Dew Point

Isotherm (DDI) or Dynamic Vapor Sorption (DVS). DDI

will create a dynamic isotherm and DVS will create a

static or equilibrium isotherm. The other choices will

adjust based on which method is selected.

VSA Quick Start Guide

• For DDI method

• To choose the starting aw, press with “Start”

highlighted and then cycle to the desired value using

the up and down arrows. Any value between 0.03 and

0.95 aw can be chosen including “current”. Choosing

“current” means that the stage will start at the initial aw

of the sample. Press when nished.

• To choose the nal aw, press with “Final” highlighted

and then cycle to the desired value using the up and

down arrows. Any value between 0.03 and 0.95 awcan

be chosen including current (see “current” denition

above). Selecting a nal aw that is lower than the

starting aw will result in desorption, while selecting a

nal aw higher than the starting aw results in adsorption.

Press when nished.

• To choose the temperature of the stage, press with

“Temperature” highlighted and then cycle to the

desired temperature using the up and down arrow keys

(hold down arrows for accelerated scrolling). You may

choose any temperature between 15 and 60 °C, 25 °C is

default. Each stage can run at a unique temperature.

• To choose the desired aw resolution, highlight

“Resolution” press with “Resolution” highlighted and

then cycle to the desired value using the up and down

arrows. You may choose any value between 0.003

and 1.0 aw. The resolution for DDI determines the target

aw resolution. Setting a higher resolution value makes

the test faster, but decreases the aw resolution. We

recommend a DDI resolution of 0.01 aw.

• To choose the air ow rate, press with “Flow”

highlighted, and then cycle to the desired value using

the up and down arrows. Any value between

10-163 ml/min can be selected. Higher ow rates will

speed up the test, but may result in lower data

resolution and non-equilibrium conditions. The

default value of 100 ml/min is suitable for most

products.

VSA Quick Start Guide

• To choose to include a timeout setting, press with

“Timeout” highlighted, and then cycle to the desired

value using the up and down arrows. Any value between

5.0 min to 30 days can be selected. The timeout

determines the maximum time allotted to move from

the starting aw to the nal aw (DDI only) and is optional.

The default value is off, which means there is no

timeout value.

• To choose to have the isotherm loop, press with

“Loop” highlighted to toggle between on and off.

Turning loop on causes the isotherm to automatically

return to the start aw (with the same settings) once

the nal aw has been achieved. This would create both

an adsorption and desorption curve (or vice versa

depending on the starting direction).

• For DVS method

• To choose the starting aw, press with “Start”

highlighted, and then cycle to the desired value using

the up and down arrows. Any value between 0.03

and 0.95 aw can be chosen including “current”.

Choosing “current” means that the stage will start at

the initial aw of the sample. Press when nished.

• To choose the nal aw, press with “Final”

highlighted, and then cycle to the desired value using

the up and down arrows. Any value between 0.03

and 0.95 aw can be chosen including current

(see“current” denition above). Selecting a nal aw

that is lower than the starting aw will result in

desorption, while selecting a nal aw higher than the

starting aw will result in adsorption. Press when

nished.

• To choose the temperature of the stage, press with

“Temperature” highlighted, and then cycle to the

desired temperature using the up and down arrow

keys. Any temperature between 15-60°C can be

chosen. Each stage can run at a unique temperature.

• To choose the desired aw step, press with “Step”

highlighted and then cycle to the desired value using

VSA Quick Start Guide

the up and down arrows. Choosse any value between

0.003 and 1.0 aw. The step setting for DVS determines

the aw values for equilibration and consequently the

resolution. If starting aw is 0.1 and has a step setting of

0.10 aw results in humidity being controlled to 0.1, 0.2,

0.3 … up to the nal aw, remaining at each level until

either equilibrium is achieved based on the trigger value

or it reaches the timeout value. Setting a higher

value makes the test faster, but decreases the quantity

of equilibtation points.

• To choose the trigger %dm/dt value that indicates

equilibration, press enter with “Trigger” highlighted

and then cycle to the desired value using the up and

down arrows. The trigger can be shut off or be any

value between 0.001-1%/hr. Choose the number of

events required to meet the trigger value. The trigger

value represents an acceptable change in mass per

change in time to indicate equilibrium for a given step.

Setting a higher value will make the test faster, but

may not result in complete equilibrium. If the trigger

is turned off, the sample will be held at each step for

the time indicated by the timeout setting.

• To choose to include a timeout setting, press with

“Timeout” highlighted and then cycle to the desired

value using the up and down arrows. You can select any

value between 5.0 min to 30 days. The timeout

determines the maximum time allotted for each aw step

NOT the time from starting aw to nal aw. The default

value is off, which means there is no timeout value

and only the trigger value determines the end of step.

If you set both a trigger value and timeout value,

whichever VSA reaches rst determines the end of step.

• To choose to have the isotherm loop, press with

“Loop” highlighted to toggle between on and off.

Turning loop on causes the isotherm to automatically

return to the start aw (with the same settings) once

the nal aw has been achieved. This would create

both an adsorption and desorption curve (or vice versa

depending on the starting direction).

VSA Quick Start Guide

•The delete entry is used to remove an unwanted stage.

• Follow the message on the screen to place an empty

stainless steel cup in the chamber and seal it. Press to

tare the cup.

• Follow the message on the screen to place the sample in

the cup and press to weight the sample.

• Press to begin the test.

5. Running a water activity test— (Can not be done when

isotherm test is running)

• Remove the weighing pan.

• Press until you are at the Measurement Tab (2nd tab).

Move latch left and/or press to start a reading. The

pinwheel will spin indicating a measurement is running.

• The aw reading for the sample and the temperature will

display when nished.

• To change between dew point and capacitive readings,

you will need to toggle the Volatiles Yes/No option in

the Conguration Tab.

Volatiles = Yes g Capacitive Sensor

Volatiles = No g Dew Point Sensor

Note: Accuracy changes to +/- 0.02 when volatiles “Yes”

is selected.

2365 NE Hopkins Court

Pullman, Washington 99163 USA

1-509-332-2756

www.aqualab.com

14510 | 13-01-16

Table of contents

Other Decagon Measuring Instrument manuals