Table of Contents

NFP - rev. 04 / 23.05.2018 page 5

Installation and Connection 22

19 General Installation Instructions..........................................................22

20 Transmitter Installation and Connection .............................................22

20.1 General........................................................................................22

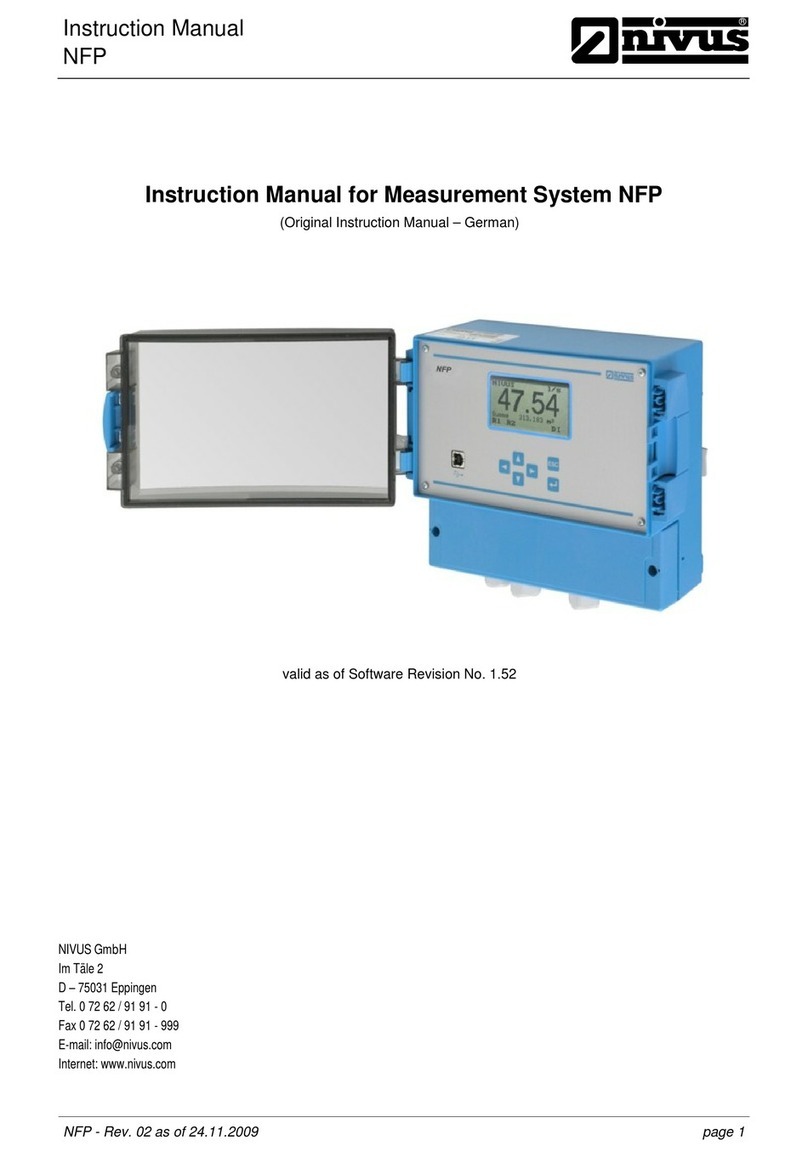

20.2 Enclosure Dimensions.................................................................23

20.3 Hints on how to avoid electrostatic discharge (ESD)..................24

20.4 Transmitter Installation................................................................24

20.5 Electrical Installation....................................................................25

20.5.1 Transmitter Connection ................................................................... 25

20.5.2 Sensor Connection.......................................................................... 28

20.6 NFP Power Supply......................................................................29

20.7 Overvoltage Protection Precautions............................................30

Initial start-up 34

21 Notes to the user.................................................................................34

22 General principles ...............................................................................34

23 Operator Panel....................................................................................35

24 Display.................................................................................................35

25 Operation Basics.................................................................................37

Parameter Setting 38

26 Basics of Parameter Setting ...............................................................38

27 Operation Mode (RUN).......................................................................40

28 Display Menu (EXTRA).......................................................................43

29 Parameter Menu (PAR).......................................................................46

29.1 Parameter Menu “Measurement Place”......................................47

29.2 Parameter Menu “Velocity”..........................................................49

29.3 Parameter menu “Digital Input”...................................................49

29.4 Parameter Menu “Analog Output”...............................................51

29.5 Parameter Menu “Relay”.............................................................53

29.6 Parameter Menu “Settings”.........................................................57

29.7 Parameter menu “Storage mode”................................................58

30 Signal Input/Output Menu (I/O)...........................................................59

30.1 I/O sub menu “Digital Inputs”.......................................................59

30.2 I/O sub menu “Analog Outputs”...................................................60

30.3 I/O sub menu “Relay” ..................................................................60

30.4 I/O sub menu “Data storage / USB” ............................................61

30.5 I/O sub menu “Measuredata” ......................................................62

30.6 I/O sub menu “v-Sensor”.............................................................63