deconta D Series User manual

Instruction manual

Negative Pressure Unit

D-Range

D 60 E

D 60

D 100

D 305

D 610

D 910

D 1200

Instruction manual

Negative Pressure Unit D-range

Page 2

Table of contents

on page

1 Basic safety advices 3

2 Transport and storage 4

2.1 Delivery 4

2.2 Transport 4

2.3 Storage 4

3 Volume of delivery at purchase and rent 5

3.1 Volume of delivery 5

3.2 Return of delivery after ending of the rental time 5

4 Technical description 6

4.1 Intended use 6

4.2 Unit description 6

4.3 Control ON / OFF 7

4.4 Control SE 8

4.5 Control SRE 8

4.6 Filter description/ classification 9

4.7 Instructions regarding filter change 11

4.8 Stacking of several units 12

5 Technical data 13

5.1 Fan characteristic curve D 60 E and D60 13

5.2 Fan characteristic curve D 100 14

5.3 Fan characteristic curve D 305 15

5.4 Fan characteristic curve D 610 16

5.5 Fan characteristic curve D 910 17

5.6 Fan characteristic curve D 1200 18

5.7 Performance data 19

5.8 Connections, dimensions, weights 19

5.9 Power loss in hose lines 20

5.10 Resistor-diagram for hose lines 20

6 Assembly instructions 21

6.1 Assembly instructions with the example of D 610 21

6.2 Assembly instructions with the example of D 1200 22

6.3 Assembly of the optional annex housing (SNA+P) with the example of D 610 24

7 Initial operation 25

7.1 Control ON / OFF 25

7.2 Control SE 25

7.3 Control SRE 26

8 Maintenance 28

8.1 Maintenance 28

8.2 Filter conrtol 28

8.3 Filter change 29

9 Possible failures and their repairs 30

10 Circuit diagrams 31

10.1 Circuit diagram D 60 E 31

10.2 Circuit diagram D 60 SE 32

10.3 Circuit diagram D 100 EIN / AUS 33

10.4 Circuit diagram D 100 SE 34

10.5 Circuit diagram D 100 SRE 35

10.6 Circuit diagram D 305 EIN / AUS 36

10.7 Circuit diagram D 305 SE 37

10.8 Circuit diagram D305 SRE 38

10.9 Circuit diagram D 610 EIN / AUS 39

10.10 Circuit diagram D 610 SE 40

10.11 Circuit diagram D 610 SRE 41

10.12 Circuit diagram D 910 SE 42

10.13 Circuit diagram D 910 SRE 43

10.14 Circuit diagram D 1200 SE 44

10.15 Circuit diagram D 1200 SRE 45

11 Sound level measuring 46

12 Declaration of conformity 47

Instruction manual

Negative Pressure Unit D-range

Page 3

2 Basic safety advices

The handling of the appliance technology is only allowed for instructed staff. The exact

knowledge of the guide book is an important condition for your staff in regard to the

handling of the machine.

deconta has to engage you as the user to follow the guide book and to employ this

engineered technology only in accordance with the regulations and not in a inappropriate

way! In the event of non-observance, deconta assumes no liability.

In order to ensure the safety during the operation of the device, please respect, without

fail, the following:

Do not place in an explosive area

Necessary repairs, maintenance and cleaning, in particular in the field of electrical

equipment may only be realized by qualified staff

For all repairs the device has to be fully disconnected

The safety and security equipments have to be treated with care, ready for use.

the indicated safety advices have to be kept in a readable state and have to be

observed

The standard, legal and remaining binding rules concerning the accident

prevention and the protection of the environment have to be observed

In order to ensure safety, any changes to the machine are prohibited.

ATTENTION!

The device is not suitable for the use in a condensed, corrosive, flammable and

explosive compartment air.

We refer specifically to additional regional and national security measures and

rules by the operation of the engineered equipment.

The control of the exhaust has to be effected during the initial operation as well as at

least in 3 years interval.

Instruction manual

Negative Pressure Unit D-range

Page 4

2 Transport and storage

2.1 Delivery

The negative pressure unit is delivered from deconta works Isselburg on a pallet. In

order to protect the device against climatic influences it is wrapped with a plastic film.

Transport damages have to be documented at once during the handing over of the

carrier or another supplier. Please note the possible damages additionally on the way bill.

2.2 Transport

Transport the device only in a decontaminated state.

The device can be transported by one person.

For the easy handling, the device has got carry handles.

A specially tuned gear for the machines enables the moving on even surface (D 305, D

610, D 910, D 1200).

In order to lift the devices, there are handles on the device.

2.3 Storage

Store the device only in a decontaminated state.

In order to avoid damages, the installation has to be kept in a dried area with no access

for unauthorized persons.

Shut the suction and exhaust connections with the transport lids.

Instruction manual

Negative Pressure Unit D-range

Page 5

3 Volume of delivery at sale or rent

3.1 Volume of delivery

The volume of delivery of a negative pressure unit unless no other agreements have

been made, consists of:

Negative pressure unit

Instruction manual

Transport lid

Plastic lid

Complete filter set

Packaging

3.2 Return delivery after the termination of the rent period

For the protection of our clients and in accordance with the rules for hazmat transport,

we must insist on the following return delivery conditions:

Cleaned thoroughly (ready for use)

Completely free of adhesive rests

Complete, as described under 3.1 however without filter set

Without damages

Instruction manual

Negative Pressure Unit D-range

Page 6

4 Technical description

4.1 Use according to appropriateness

The negative pressure unit of the D-Series serves for the filtration of asbestos

contaminated air, in temperature rage up +45 °C, with external exhaust for the air. During

asbestos sanitation works within closed rooms, you must avoid that asbestos fibres leave

the sanitation area and in this way endanger humans and the environment. For this

reasons, the sanitation areas (also called dirty area) have to be separated from the clean

area with the help of a negative pressure unit and kept in dynamic negative pressure.

An integrated filtering system establishes the conditions that the asbestos concentration

in the exhausted air does not exceed max. 1000F/m³. The exhausted air is blown in the

open air.

The device is not appropriate for the filtration of flammable gas or dust.

4.2 Description of the device

The negative pressure unit serves for the filtration of asbestos contaminated air via a 3-

steps filter unit. (D 60 and D 60 E only 2-steps). The inserted Hepa filter complies with

the requirements according to EN 1822 classification H13.

By stacking of several devices, minor floor space is needed.

Smooth and easy-to-decontaminate housing

Stable and light housing

3-fold sealed hepa filter

Hepa filter according to EN 1822 classification H13

Very low emission during the change of the filter. Filter change in 3 minutes

The filter change is indicated visually via a pressure gauge (for the D 60 E via a

signal lighting)

Rustproof and powder coated housing

continuously variable control 0 - 100% (SE and SRE)

automatic soft starting, also after a power failure

all operation and function elements are shock-protected

stackable housing, ergo minor floor space

Power optimised fan with high capacity

Options:

Attachment housing for the second hepa filter (Double filtration)

Attachment housing for pocket filter

Acoustical indication for the filter change

Suction adapter

Instruction manual

Negative Pressure Unit D-range

Page 7

You can obtain the control of the negative pressure unit optionally in following models:

D 60 E:

ON / OFF

D60

manual, continuously variable control SE

D 100

ON /OFF

manual, continuously variable control SE

automatic control SRE

D 305

ON /OFF

Manual, continuously variable control SE

Automatic control SRE

D 610

ON /OFF

Manual, continuously variable control SE

Automatic control SRE

D 910

Manual, continuously variable control SE

Automatic control SRE

D 1200

ON /OFF (only for 400 V / 32 A)

Manual, continuously variable control SE

Automatic control SRE

4.3 Control ON / OFF

For the power regulation, the negative pressure unit is delivered in series with an

ON/OFF switch.

D 305

D 610

D 1200

D 60

Instruction manual

Negative Pressure Unit D-range

Page 8

4.4 Control SE

For the power regulation the negative pressure unit is delivered in series with a manual

continuously variable control.

4.5 Control SRE

For the power regulation the negative pressure unit is delivered in series with an

electronic control, in order to measure and to regulate the negative pressure. The

negative pressure is measured between the dirty area and at a reference point to be

determined (adjoining rooms) and the set point is kept by the continuous speed

regulation of the electric fan.

On reaching the maximal fan capacity, a LED Fanwill beam.

The necessary filter change will be indicated by the LED Filter

LED

„

Filter“ LED

„

Fan“

Instruction manual

Negative Pressure Unit D-range

Page 9

4.6 Description of the filter / classification

Integrated in the unit is a 3-step filtering combination (D 60 and D 60 E only 2-steps).

In particular:

Pre- and intermediate filter Pre-filter Intermediate filter

Filter class according to DIN 24185 / EN

779 G3 / EU3 G4 / EU4

Frame Cardboard frame,

47 mm width Cardboard frame,

47 mm width

Filter medium Fiber glass Synthetic

Degree of separation (Am) 85 % 90 %

Nominal rated current: 5400m³/h/m² 5400m³/h/m²

Nominal velocity in blower stream at

nominal volume 1,5 m/s 1,5 m/s

Difference of initial pressure 30 Pa 42 Pa

Recommended difference of final pressure 450 Pa 250 Pa

Temperature / Air humidity 100°C/100% RF

(relative humidity) 100°C/100% RF

(relative humidity)

Filter dimensions (in mm):

D 60 E

D 60

D 100

D 305

D 610

D 910

D 1200

-

-

305 x 305 x 47

305 x 610 x 47

610 x 610 x 47

610 x 910 x 47

610 x 910 x 47

305 x 305 x 47

305 x 305 x 47

305 x 305 x 47

305 x 610 x 47

610 x 610 x 47

610 x 910 x 47

610 x 910 x 47

Instruction manual

Negative Pressure Unit D-range

Page 10

Hepa filter, suspended matter filter (S)

Frame Plastic

Filter medium Micro fiber glass paper

Sealing mass Polyurethane

Seals Polyurethane

Filter surface

D 60 E

D 60

D 100

D 305

D 610

D 910

D 1200

2 m²

2 m²

7 m²

15 m²

31 m²

48 m²

48 m²

Filter classification H13 according to EN 1822

Degree of separation >99,95%Most Penetraded Partikel Size

Temperature / Air humidity 70°C/100% RF

(relative humidity)

Filter dimensions (in mm):

D 60 E

D 60

D 100

D 305

D 610

D 910

D 1200

284 x 284 x 150

284 x 284 x 150

305 x 305 x 292

305 x 610 x 292

610 x 610 x 292

610 x 910 x 292

610 x 910 x 292

Protective grid Grid, both sides

Instruction manual

Negative Pressure Unit D-range

Page 11

4.7 Information regarding the change of filter

The frequency of the change of filter depends on the degree of pollution of the filter. If the

sealing up of the filter increases (contamination of the filter), the air capacity decreases.

For the control of the filter during the operation, the device is equipped with a manometer

(for D 60 E a signal light).

Important: Use only approved, faultless filter!

From the following chart you can take for the change of the filter, the indications of

values for the filter as-new condition and the indications of the recommended change of

the filter. If the indication reaches the value for the recommended change of filter do

please first change the preliminary and intermediate filter. If the indication falls at 100

Pascal (for D 60 at 50 Pascal) or more, the device can be operated further. If the value

falls at lesser than 100 Pascal (for D 60 at 50 Pascal), you have to change the Hepa filter

Device As-new condition

Recommended filter

change by

D 60 350 Pascal 470 Pascal

D 100 500 Pascal 750 Pascal

D 305 650 Pascal 950 Pascal

D 610 650 Pascal 1000 Pascal

D 910 700 Pascal 1100 Pascal

D 1200 650 Pascal 900 Pascal

Instruction manual

Negative Pressure Unit D-range

Page 12

4.8 Piling of several devices

The negative pressure units of the D-range can be pilled (except D 60 E) in order to

obtain a floor space as small as possible.

D 60 and D 100 are pilled thanks to an anti-skidding centering facility.

D 305, D 610, D910 and D 1200 are connected thanks to a tight and solid screwed pilling

system

Pilling system

Instruction manual

Negative Pressure Unit D-range

Page 13

5 Technical data

5.1 Fan characteristic curve D 60 E and D 60

Technical data:

Voltage: 230 V

Frequency: 50 Hz

Speed: 2890 U/min

Air discharge: 980 m³/h free exhausting

max. discharge temperature: 45°C

0

50

100

150

200

250

300

350

400

450

500

550

600

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

V

olume flow V m³/h =>

stat. Pressure boosting PA =>

Instruction manual

Negative Pressure Unit D-range

Page 14

5.2 Fan charasteristic curve D 100

Technical data:

Voltage: 230 V

Frequency: 50 Hz

Speed: 2850 U/min

Air discharge: 1200 m³/h free exhausting

max. discharge temperature: 45°C

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

0 130 200 300 400 500 600 700 800 900 1000 1100

V

olume flow V m³/h =>

stat. Pressure boosting PA =>

Instruction manual

Negative Pressure Unit D-range

Page 15

5.3 Fan characteristic curve D 305

Technical data:

Voltage: 230 V

Frequency: 50 Hz

Speed: 2850 U/min

Air discharge: 2400 m³/h free exhaust

max. discharge temperature: 45°C

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

1050

1100

1150

1200

1250

1300

0 350 400 500 700 1000 1500 2000 2200

V

olume flow V m³/h =>

stat. Pressure boosting PA =>

Instruction manual

Negative Pressure Unit D-range

Page 16

5.4 Fan characteristic curve D 610

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

300 400 500 700 1000 2000 3000 4000 5000 7000

Volume flow in m³/h =>

stat. Pressure boosting PA =>

Technical data:

Voltage: 230 V

Frequency: 50 Hz

Speed: 2800 U/min

Air discharge: 6000 m³/h free exhausting

max. discharge temperature: 45°C

Instruction manual

Negative Pressure Unit D-range

Page 17

5.5 Fan characteristic curve D 910

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

300 400 500 700 1000 2000 3000 4000 5000 6000 7000 8000

Volume flow in m³/h =>

stat. Pressure boosting PA =>

Technical data:

Voltage: 230 V

Frequency: 50 Hz

Speed: 2780 U/min

Air discharge: 7500 m³/h free exhausting

max. discharge temperature: 45°C

Instruction manual

Negative Pressure Unit D-range

Page 18

5.6 Fan characteristic curve D 1200

0

500

1000

1500

2000

2500

3000

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000

Volume flow in m³/h =>

stat. Pressure boosting PA =>

Technical data:

Voltage: 400 V

Frequency: 50 Hz

Speed: 2900 U/min

Air discharge: 15000 m³/h free exhausting

max. discharge temperature: 45°C

Instruction manual

Negative Pressure Unit D-range

Page 19

5.7 Power data

D 60 E D 60 D100 D305 D 610 D 910 D 1200

Air power free

blowing in m³/h 980 1200 2400 6000 7500 15000

Air power with filter

in m³/h 600 900 2000 4500 6000 12000

Power connection

in Volt 230 400

Current

consumption

in Ampere 1 4 9 16 16 16

Engine power

in kW 0,17 0,55 1,5 3 3 7,5

Filter system 2-steps 3-steps

Pre-filter ----- EU 3

Intermediate filter EU 4

Hepa filter According to EN 1822 classification H13

5.8 Connections, dimensions, weights

D 60 E D 60 D100 D305 D 610 D 910 D 1200

Fan unit Filter unit

FG 5

Hose connection

exhaust ----- 150 150 300 400

450 450 2x 450 450

Hose connection

Suction -----

optional

4x 100

or

1x 150

optional

1x 300

optional

400

450

optional

2x 450 2x 450 optional

2x 450

Length in mm 565 560 920 930 1020 1160 800 720

Width in mm 440 400 420 690 725 880 720

Height in mm 440 400 840 850 1140 945 1150

Weight incl. filter

in kg 21 19,5 24 45 95 116 116

(no FG 5) 70

Instruction manual

Negative Pressure Unit D-range

Page 20

5.9 Power loss in hose lines

Following factors have adverse influence:

Hose lines too long

Bends and bows in the hose lines

Cross-section narrowing of the hose lines.

5.10 Resistance diagram for hose lines

Hose line with external spiral

Sleeky inside

in 10 mtr. Length

This manual suits for next models

7

Table of contents

Popular Fan manuals by other brands

Ayce

Ayce DF-AT0900F Original instructions

Litex Industries

Litex Industries ALD52BNK5L installation guide

Hunter

Hunter Saturn 90053 Parts guide

Vortice

Vortice VORT PRESS 110 I LL Instruction booklet

Daikin

Daikin FWB 02JT Installation and operation manual

aerauliqa

aerauliqa Quantum NEXT installation manual

Hunter

Hunter 21970 Parts guide

Emerson

Emerson SUMMERHAVEN CF850AW00 owner's manual

Progress Lighting

Progress Lighting AirPro P2564 installation manual

Swegon

Swegon PARAGON Wall VAV Installation, commissioning maintenance

Broan

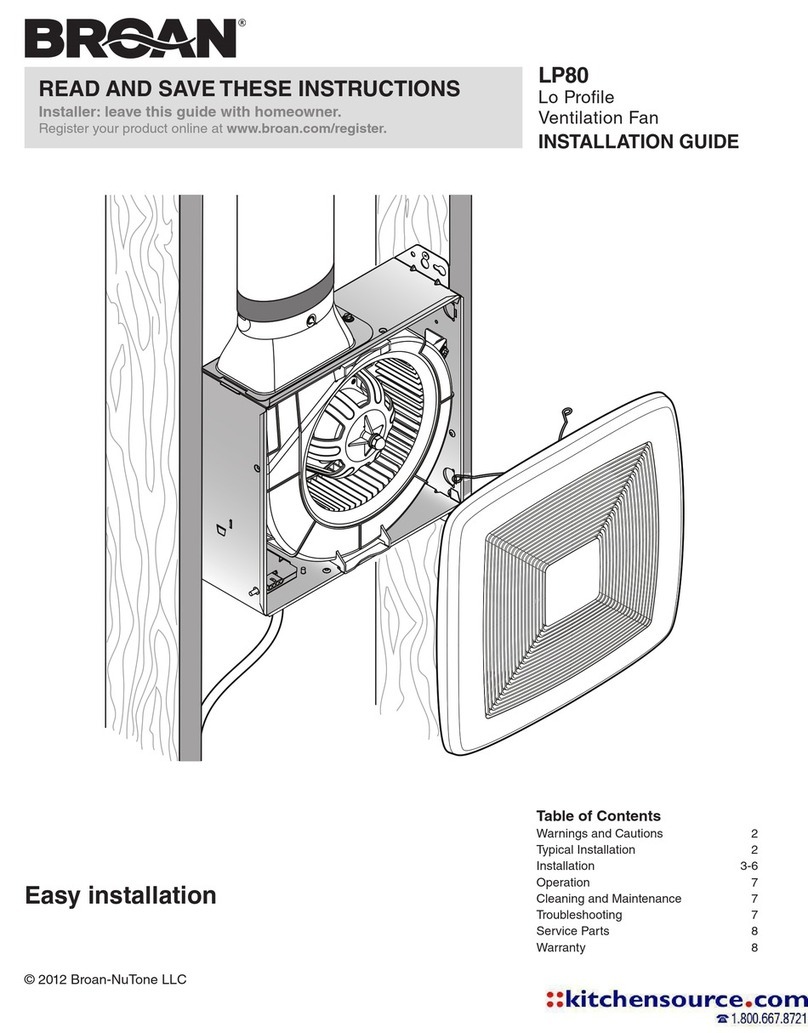

Broan LP80 installation guide

Pinnacle Climate Technologies

Pinnacle Climate Technologies MASTER INDUSTRIAL MHD-24W User's manual & operating instructions