9

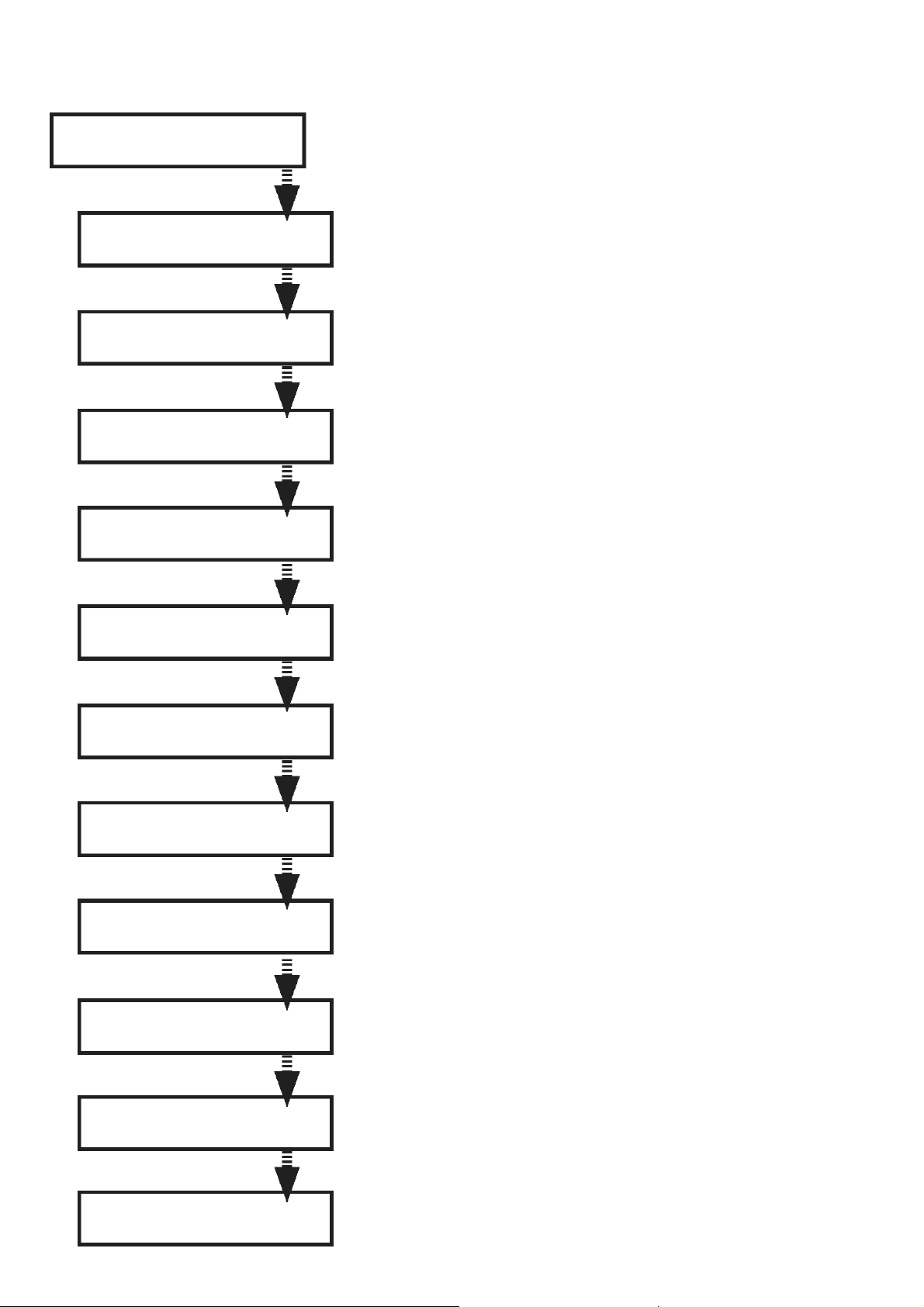

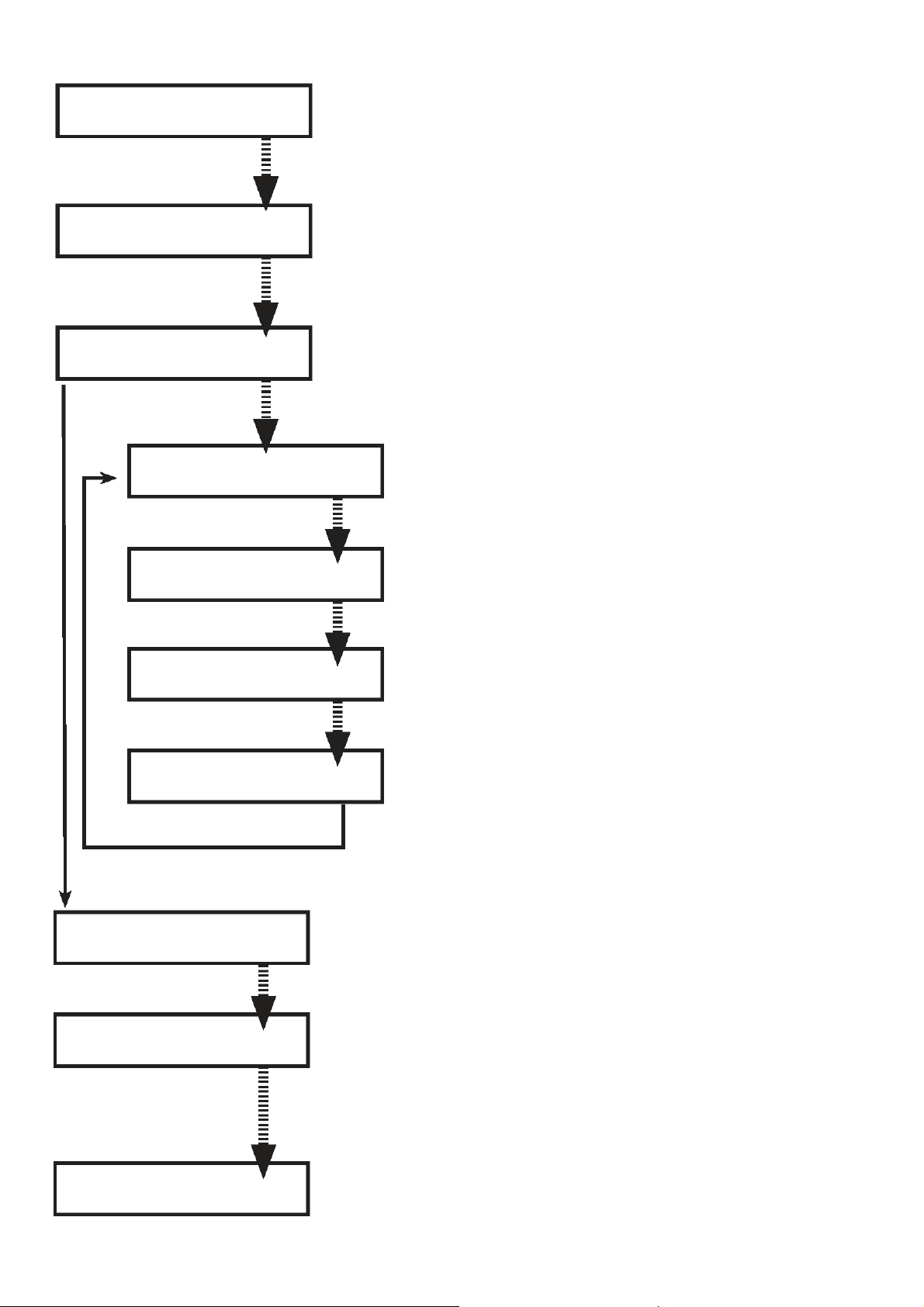

3.1 Programming by the user

D On the main page press on the MENU key to access the

programming pages

Press the OK key to go to ENERGY SAVING mode and reduce

power consumption. Press OK to restart the machine

The machine automatically eliminates water remaining in the

internal piping immediately after the heating phase so that only

fresh water is used to make the coffee

This function is used to choose the message display language.

This function is used to set the contrast in order to be able to

view the instructions clearly

The hardness of the water used to make the drinks varies from

region to region. This is why the machine should be set to the

correct degree of hardness for the water being used

This function is used to check the water filter (if one is used) by

warning the user when replacement is needed. The

“REINITIALISE” command should be used every time a new filter

is fitted.

This function is used to make warmer or hotter coffee by setting

water temperature (high, medium and low)

This function is used to set the dose of coffee (quantity) to grind

when making an expresso (strong, regular, weak)

This function is used to set the dose of coffee (quantity) to grind

when making a coffee (strong, regular, weak)

This function is used to set the dose of coffee (quantity) to grind

when making a large coffee (strong, regular, weak)

The pre-humidifer process increases the coffee aroma thus giving

the coffee an excellent taste. This function is used to humidify

the coffee before preparing it.

Select product

Machine ready

Energy savings À

Rince

Rince À

Language

Language À

Contrast

Contrast À

Water hardness

Water Hardness À

Water filter

Water filter À

Temperature

Temperature À

Expresso aroma

Expresso aroma À

Coffee aroma

Coffee aroma À

Large coffee aroma

Large coffee aroma À

Pre-humidifier

Pre-humidifier À

Total coffees