DEHN + SÖHNE DRC MCM XT User manual

Operating Manual

Status Display

With Integrated Service Console

For the Stationary Monitoring Device

DRC MCM XT

DEHN + SÖHNE

Issued by : DEHN + SÖHNE GmbH + Co.KG.

BA 1669 / V 1.1.0.0 – Update 03/10 / Id.-No. 056286

© 2010 DEHN + SÖHNE / protected by ISO 16016

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 2 of 49 Date of issue: 10.03.10

Index:

Terms and definitions ................................................................................................4

Literature / References...............................................................................................5

1 Application.........................................................................................................6

2 LifeCheck

®

..........................................................................................................7

3 DRC MCM XT Monitoring Device......................................................................7

4 Installation........................................................................................................10

4.1 System requirements................................................................................................................ 10

4.2 Installation procedure................................................................................................................ 10

4.2.1 Installing the .NET-Framework

®

2.0 environment................................................................. 11

4.2.2 Installing the DRC MCM XT status display with integrated service console......................... 11

5 Operation of "Status Display with integrated Service Console".................12

6 Status Display..................................................................................................12

6.1 Settings for the Status Display.................................................................................................. 13

6.1.1 Setting the communication interface..................................................................................... 13

6.1.2 Language selection ............................................................................................................... 14

6.1.3 Use of local schemata (locales) in MS Windows

®

................................................................. 16

6.2 Entering the system description................................................................................................ 17

6.3 Loading the last program settings............................................................................................. 19

6.4 Activating the log function......................................................................................................... 19

6.5 Help function............................................................................................................................. 20

6.6 Exit program.............................................................................................................................. 21

6.7 Status monitoring and status indication.................................................................................... 21

6.7.1 Starting status monitoring and status indication.................................................................... 21

6.7.2 Status display........................................................................................................................ 23

6.7.2.1 Status of DRC MCM XT monitoring devices......................................................................... 23

6.7.2.2 Status of the protective devices (Blitzductors

).................................................................... 24

6.7.3 Resetting the operating state indication................................................................................ 25

6.8 Printing the current system status (test report)......................................................................... 26

6.9 Evaluating the log file................................................................................................................ 26

6.10 Changeover to Service Console............................................................................................... 28

7 Service Console...............................................................................................29

7.1 Settings of the service console................................................................................................. 31

7.1.1 Setting of bus address of DRC MCM XT monitoring device................................................. 31

7.2 General operating procedure.................................................................................................... 33

7.2.1 Requirements for testing....................................................................................................... 33

7.2.2 Preparing and sending a command ...................................................................................... 33

7.3 Function of the service console ................................................................................................ 36

7.3.1 Inquiring the version number of a DRC MCM XT monitoring device.................................... 36

7.3.2 General test of all protection modules assigned to a DRC MCM XT.................................... 37

7.3.3 Single test of a protection module......................................................................................... 38

7.3.4 Determining the current number of a protection module....................................................... 39

7.3.5 Programming a protection module........................................................................................ 40

7.3.6 Programming all portection modules of a DRC MCM XT...................................................... 42

7.3.7 Resetting a protection module............................................................................................... 46

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 3 of 49 Date of issue: 10.03.10

Legal Notes

Windows

®

, Windows

®

98, Windows

®

ME, Windows

®

2000 and Windows XP

®

and

Windows Vista

®

are registered trademarks of the Corporation.

MS .NET Framework

®

and MS Visual Basic

®

2005 are registered trademarks of the

Microsoft Corporation.

DEHN + SÖHNE GmbH + Co.KG. claims no own exclusive rights with regard to the

aforementioned trademarks. Any omissions are unintentional. All other trademarks

mentioned in the present text are property of the respective owner.

Note:

The information provided in the present document may be modified without advance

notice. DEHN + SÖHNE GmbH + Co.KG. cannot be held liable for any changes made.

Furthermore DEHN + SÖHNE GmbH + Co.KG. assumes no responsibility for any

damage caused by computer programs and warns of viruses and data losses that

may arise due to programming errors. This can be avoided by performing a data

backup.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 4 of 49 Date of issue: 10.03.10

Terms and definitions

Blitzductor

®

Surge protection module manufactured by DEHN + SÖHNE

DEHNrecord DRC LC M3

DEHNrecord DRC LC M3 is a compact hand-held reader with integrated RFID

technology for non-contact testing of surge protection modules (Blitzductors

®

).

DEHNrecord DRC MCM XT

DEHNrecord DRC MCM XT is a compact monitoring device with integrated RFID

technology for stationary testing of surge protection modules (Blitzductors

®

).

HW

Hardware

LifeCheck

®

Test for correct functioning of the surge protection modules during system operation

without removing them.

Microsoft .NET- Framework

®

2.0

Library basically independent from programming languages for developing and

performing applications and services that are based on Microsoft .NET technology

(e.g. PC application programs and so-called web services).

RFID

Radio Frequency Idendification – Identification procedure per radio technology which

allows for non-contact reading and saving of data.

RS485

Industrial 2-wire bus system for connecting external devices

SPD

Surge Protection Device – surge protection module

SW

Software

VB2005

Microsoft Visual Basic

®

2005 – Programming language of Microsoft Windows

operating system using the .NET technology.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 5 of 49 Date of issue: 10.03.10

Literature / References

/1/

Operating manual for DEHNrecord DRC MCM XT

Issued by : DEHN + SÖHNE

/2/

Operating manual for DEHNrecord DRC LC M3+

Issued by : DEHN + SÖHNE

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 6 of 49 Date of issue: 10.03.10

1 Application

DEHNrecord DRC MCM XT

/1/

is a compact monitoring device in an XT enclosure

with integrated RFID technology (Radio Frequency Identification) for non-contact

testing of surge protection modules. This device is marked with the LifeCheck

symbol.

LifeCheck

®

symbol:

The following surge protection modules are equipped with LifeCheck

®

technology:

-Blitzductor

®

CT; Type: BCT MLC

-Blitzductor

®

XT; Type: BXT ML

Only surge protection modules (SPDs) with integrated LifeCheck

®

function can be

tested with DEHNrecord DRC MCM XT monitoring device!

SPDs with LifeCheck

®

symbol don’t have to be removed for function testing. They can

be tested during system operation (e.g. in the distribution cabinet).

Figure 1 : DEHNrecord DRC MCM XT stationary monitoring device

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 7 of 49 Date of issue: 10.03.10

2 LifeCheck

®

Protection modules with LifeCheck

®

symbol provide an additional circuit consisting of

a combined RFID based transmission and monitoring unit. Thermal and electrical

overloads of the surge protective device will be reliably detected and monitored.

3 DRC MCM XT Monitoring Device

Up to 10 surge protection modules can be assigned to one DRC MCM XT XT

monitoring device

/1

. DEHNrecord DRC MCM XT checks the operating state of this

"group" of protection modules permanently without contact. An integrated LED

indicates the result, which is transmitted by remote signalling via a changeover

contact. Both the LED indicator and remote signalling contact provide only a general

information about the operating state of all protection modules assigned to the

monitoring device ("All protection modules alright" or "Replacing of protection modules

required").

Figure 2 : Stationary monitoring device with 10 Blitzductors

®

As delivered, Blitzductors

®

XT and CT cannot be used with the DRC MCM XT

monitoring device. Assignment of the Blitzductors

®

to the respective monitoring

devices is effected by correspondingly programming of the RFID transponders in the

Blitzductors

®

. When programming the transponder, a definite password each,

containing bus address of the assigned monitoring device and current number of the

respective Blitzductor

®

will be generated and stored in the transponder. During

operation, the transponder then only reacts on enquiries containing its password.

With the RS485 bus interface integrated into the device, up to 15 DRC MCM XT

monitoring devices can be combined to one system. Within this system, one device

will be configurated as "master" and all others as "slaves". The "master" controls the

monitoring of all DRC MCM XT devices connected to the same bus. For this purpose it

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 8 of 49 Date of issue: 10.03.10

calls up continuously all "slaves", one after another (with ascending bus address) for

testing the protection modules assigned to them.

In addition to the monitoring devices, a PC or laptop can also be connected to this

RS485 bus by means of an adequate adapter (see

/1/

).

As far as the "Status Display with integrated Service Console" program has been

installed on the PC or laptop, the following functions of this program can be applied:

•Status indication chart

-

of all DRC MCM XT monitoring devices connected at the RS485 bus

-

of all protection modules assigned to a DRC MCM XT

•Entering a system description (e.g. headlines, comments, SPD description with

type designation and identification No. etc.)

•Saving and loading of system descriptions

•Logging of all state changes of an SPD in a file (log function)

•Printing of the actual system status e.g. as test report

•General testing of all protection modules assigned to a DRC MCM XT

•Single testing of a protection modules

•Determining the serial number of a protection module

•Programming the protection modules of a DRC MCM XT

•Reprogramming a protection module (to delivery status)

•Requesting the version number of the DRC MCM XT monitoring device

•Language switching (German / English integrated, any other user-defined

language can be loaded as text file)

The program "Status Display with Integrated Service Console" has been designed

primarily for the service staff of DEHN + SÖHNE or likewise trained staff.

Common users should apply DEHNrecord DRC LC M3 for programming and

administrating the Blitzductors

®

(see

/2/

).

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 9 of 49 Date of issue: 10.03.10

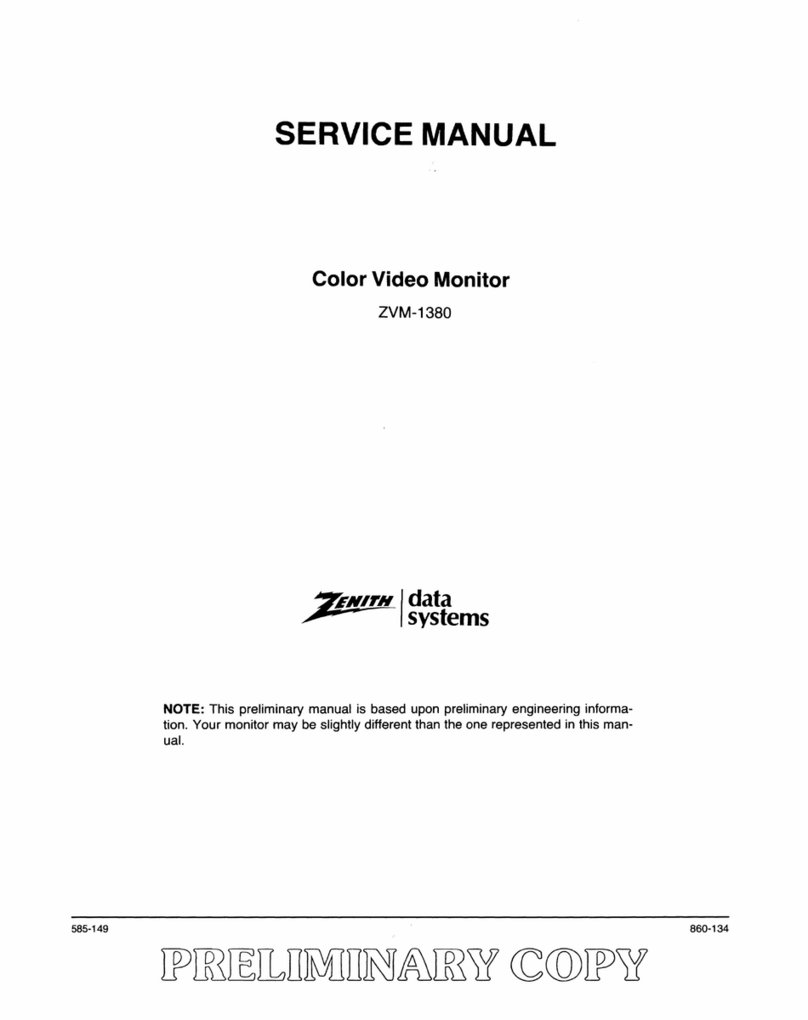

Figure 3 : DRC MCM XT program Status Display with integrated Service

Console

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 10 of 49 Date of issue: 10.03.10

4 Installation

For installing the programme, the following requirements have to be fulfilled.

4.1 System requirements

A common PC is required with a .NET Framework compatible Microsoft operating

system such as

-Windows

®

98

-Windows

®

ME

-Windows

®

2000 with SP3

-Windows XP

®

with SP2

- Windows Vista

®

with SP1

Please note, that Windows

®

95 and Windows

®

NT will not be supported.

The processor used in the PC should be at least a Pentium III processor, 700 MHz.

The graphic board must support min. 1024x768 pixels and 256 colours.

The minimum capacity of the central memory should be 256 MB. Furthermore, a CD

drive and a RS485 interface adapter will be needed.

Installation will require approx. 8 MB fixed-disk storage (or approx. 100 MB if there is

no .NET Framework

®

2.0 installed yet).

.NET Framework

®

2.0, on its part, requires Microsoft Software Installer (MSI) (min. 3.0

Version) as well as Microsoft Internet Explorer (min. 5.01 Version). If not already

installed, the DEHN installation program will automatically initiate the download of

Microsoft Software Installer and .NET Framework

®

2.0 from the Microsoft website and

install them on the PC.

This, however, requires access to the Internet to complete the installation procedure.

4.2 Installation procedure

To install the software, the CD delivered has to be put into a CD drive of the PC. The

CD drive has then to be opened in Windows

®

Explorer and the installation procedure

has to be started by double-clicking the "install.bat" file.

During the installation procedure, the system is checked in the first instance, if .NET-

Framework

®

2.0 has already been installed. If not, the program will be downloaded

from the Microsoft website. Afterwards, the DRC MCM XT status display will be

installed.

Note:

Before installing the program, the driver delivered together with the required RS485

interface adapter should be installed.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 11 of 49 Date of issue: 10.03.10

4.2.1 Installing the .NET-Framework

®

2.0 environment

If not installed yet, Microsoft Software Installer and .NET Framework

®

2.0 will be

downloaded automatically from the Microsoft website and their installation will be

initiated.

The duration of this procedure highly depends on the capacity of the central memory

in the processor as well as the speed of the Internet access (download volume

approx. 35 MB), however, at least approx. 5 minutes.

At the beginning of the download, Microsoft points out the terms of licence the user

has to accept. After accepting the terms, the download will be started first and then the

installation will be initiated.

After installing the software, the installation routine might request the user to reboot

the system. After confirming this procedure, the system will be rebooted and the

installation of the DRC MCM XT status display is then continued automatically.

4.2.2 Installing the DRC MCM XT status display with integrated service console

Finally, the DRC MCM XT status display with integrated service console is installed.

As soon as the window showing a security warning is opened, click the "Install" button

to continue the procedure.

The application is installed and will be restarted automatically afterwards.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 12 of 49 Date of issue: 10.03.10

5 Operation of "Status Display with integrated Service Console"

When installing the program according to instructions, a new item "DEHN + SÖHNE

GmbH + Co.KG." was created in the Windows

®

start menu under "Program". Clicking

this item the program can be started.

The program consequentially consists of the two different function complexes

•Status Display

and

•Service Console

Status Display and Service Console have own user interfaces between which you can

toggle.

6 Status Display

After starting the user interface of the status display opens and shows the following

window.

In the "Status Display" mode the program is operated as passive subscriber at the

RS485 bus

/1/

and is just monitoring the data communication of the DRC MCM XT

monitoring devices -> "monitoring mode".

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 13 of 49 Date of issue: 10.03.10

The status display comprises the following functions:

•Central settings for

-

language choice

-

communication settings for the RS485-Bus

•Entering a system description (e.g. headlines, comments, SPD description with

type designation and identification no., etc.)

•Saving and loading of system descriptions

•Graphic operating state indication

-

of all DRC MCM XT monitoring devices connected to the RS485 bus

-

of all protection modules assigned to a DRC MCM XT

•Logging of all state changes of an SPD in a file (log function)

•Printing of the actual system state e.g. as test report

As soon as the program has started, the following settings have to be made.

6.1 Settings for the Status Display

Every time after starting the program, the communication interface has to be set first

before using the program.

6.1.1 Setting the communication interface

In order to enable the program to determine the current state of the DRC MCM XT

monitoring devices and the assigned surge protection modules for indication, the

program has to listen in the data communication of the monitoring devices (via the

RS485 bus) (thus the program is a passive bus subscriber). For this purpose, it has to

be ensured under "Select COM-Port" that the correct communication port was

selected for the RS485 interface adapter, as otherwise no connection can be

established.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 14 of 49 Date of issue: 10.03.10

The same COM port as determined before in the system control has to be selected

(refer also to

/1/

).

It has to be really ensured that:

•the PC laptop is connected with the RS485 bus of DRC MCM XT via the

installated RS485 interface adapter

•the monitoring devices are activated and started

The RS485 interface adapter is automatically loaded and activated by Windows

®

as

soon as the interface adpater is plugged in. The driver will also be deactivated with

every switch-off or disconnection and deleted from memory. The interface can then no

longer be addressed although it might still be indicated.

If the interface cannot be addressed any more despite of still being connected,

plugging the interface adapter out and in again might often help. After a short period of

time, the COM port can be set again under "Select COM port" .

6.1.2 Language selection

The program contains texts in German and English. At the first starting, the program

checks automatically which regional and language options are set in the Windows

®

system control. If the set language is not German, the program automatically selects

"English" as preferred setting and starts in this language.

The preferred language can always be selected on the menu bar of the program.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 15 of 49 Date of issue: 10.03.10

Additionally any other language the user determines can be installed. For this purpose

the user first has to extend a prefinished form file which includes all needed texts in

English by the texts in the language he prefers.

The file "user_defined_language.txt" has the following structure:

[user defined texts]

DRC MCM XT Status Display=?1

DRC MCM XT Service Console=?2

Select COM port=?3

Please select COM port first=?4

bus address=?5

type=?6

SPD status=?7

Enter description=?8

Enter title=?9

..........

The texts in the wanted language will be entered after the English text as from the "?".

Example (French) :

Enter description = ?8 -> Enter description = Entrer la désignation

Entering is effected with a suitable text editor (e.g. MS Wordpad). All available

character sets can be used for entering. The use of character sets from "foreign local

schemes" (e.g. Chinese) follows the specifications of MS Windows

®

(see brief

instruction 6.1.3).

The user provided language file can be selected and loaded after pressing the

- button. Switching to the corresponding language will be promptly.

Note :

In the form data file all foreign language texts are preoccupied with a "?" and a current

number. If the loaded file remains unchanged the current number allows for

determining the position of the respective text within the user surface.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 16 of 49 Date of issue: 10.03.10

6.1.3 Use of local schemata (locales) in MS Windows

®

In the following a brief summary on the use of local schemata (locales) in MS

Windows

®

. A detailed help file is available in MS Windows

®

.

Entering and display of foreign character sets

====================================

A.) Settings in MS Windows

®

1.) System control -> Select regional and language options

2.) Select register 'Language'

3.) Additional language support -> Select as required

4.) Text services and entering languages -> Click... Details ->

a.) Under register 'Settings' -> Installed services -> required input area

schemes

b.) under register 'Extended' -> Compatibility configuration -> Select 'Support

extended text services in all programs'

B.) Editing of the text file 'user_defined_language.txt'

1.) Open data file (e.g. with Windows Editor or Wordpad)

2.) Select desired area scheme

3.) Enter texts in the desired language after the ' = '

4.) Save the data file

!!! Make sure that the file is saved as Unicode text document

a.) e.g. with Windows Editor :

- use 'Save under '

- Type of file = 'Text files(*.txt)'

- Coding = Unicode

b.) e.g. with Windows Wordpad

- use 'Save under '

- Type of file = Unicode text dokument

C.) Entering the system description/SPD description within the program

1.) Select the desired area scheme as under B.)

2.) Enter the texts

3.) Save data with menu level 'System description -> Save project '

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 17 of 49 Date of issue: 10.03.10

6.2 Entering the system description

In a next step texts according to the user’s requirements can be entered in the

provided fields (see also 6.1.3).

The monitored system, for example, can thus be clearly described (e.g. in the field

provided for entering the title), the name of the person in charge and the assignment

of the Blitzductors

®

can be determined. The texts are used both in the log and as a

screen copy.

For each of the maximum 15 monitoring devices of a DRC MCM XT a short

description (e.g. place of installation) can be entered in the operating surface. Double-

clicking the short description or clicking one of the respective buttons on the right of

the operating surface a window opens where the description of all SPDs assigned to

this monitoring device can be entered.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 18 of 49 Date of issue: 10.03.10

For safety reasons entering of texts is blocked per default. Clicking the button

"Modification approval" texts can be entered again or changed. After release the

button colour shows RED and the button signals "Apply entries". After clicking the

button "Apply entries" the texts are taken over into the program. This button also

blocks the input automatically again. The texts saved in the program, however, are

only saved in the respective file on saving the system description (see following

section). Clicking the button "Close" quits the window SPD description. Before the

window closes, as a precaution, the option of acceptance of the possibly changed

texts is indicated again. Text changes not accepted, they are cancelled on closing of

the window.

All text inputs can be filed on the PC in an arbitrary data file as system description

(menu level "System description").

Thus an own data file can be created, administrated and saved for each monitoring

system (menu levels "New project" and "Save project"). At any time the system

description can be read into the Status Display again (menu level "Load project").

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 19 of 49 Date of issue: 10.03.10

When creating a new project, the presettings for the texts are reloaded.

6.3 Loading the last program settings

Except for the first program start, both, the last-used language and the last-used

system description are automatically loaded at any following program start.

6.4 Activating the log function

The Status Display allows for the logging of the status change of all DRC MCM XT

monitoring devices or of the assigned SPDs in a file on the PC. After clicking the

"Log ON" button any file can be selected where the status changes are stored in

form of a clear text.

As soon as the logging is activated the button shifts to "Log OFF" and in the menu

bar a printer is iconed.

DEHN + SÖHNE Operating Manual Status Display With Integraded Service Console

protected by ISO 16016 Page 20 of 49 Date of issue: 10.03.10

After closing the log function or the status display, this text file can be opened and

printed with the according program (e.g. Editor Notepad, Wordpad, MS Word etc.)

(see also 6.9)

Note

:

If beside the SPD status changes also the initial state of the system shall be logged, it

is absolutely necessary to activate logging before the first clicking of the "Start" button

(see 6.7.1).

6.5 Help function

Clicking the "Info" button on the "Help" menu level opens a window showing

information about the program version, date of issue and provider, or choosing the

"Manual" button, this document can be opened as online operating manual.

Table of contents