Delta-T SWT4 User manual

User Manual for the

Tensiometer

types SWT4 & SWT4R

Delta-T Devices Ltd

SWT4-UM-3.1

2/52

Notices

Copyright

All rights reserved. Under the copyright laws, this manual

may not be copied, in whole or in part, without the written

consent of Delta-T Devices Ltd. and UMS GmbH. Under

the law, copying includes translation into another language.

Copyright © 2009 Delta-T Devices Limited

© 2009 UMS GmbH

CE conformity

The sensors described in this document are CE marked by

the manufacturer.

Design changes

Delta-T Devices Ltd reserves the right to change the

designs and specifications of its products at any time

without prior notice.

SWT4 User Manual, Version: 3.1 Oct 2009

Delta-T Devices Ltd

Tel: +44 1638 742922

130 Low Road, Burwell

Fax: +44 1638 743155

CAMBRIDGE CB25 0EJ

U.K.

web: http://www.delta-t.co.uk

Strictly observe rules for disposal of

equipment containing electronics.

Within the EU: disposal through municipal

waste prohibited - return electronic parts

to your local distributor

SWT4 User Manual v3.1 3

Table of contents

User Manual for the 1

Tensiometer 1

Notices 2

1Introduction 5

1.1 Safety instructions and warnings 5

1.2 Unpacking 6

1.3 Foreword 6

1.4 Guarantee 6

1.5 Durability 6

1.6 SWT4 and SWT4R 7

1.6.1 Soils and soil water 7

1.6.2 Intended use 7

1.6.3 Types 7

1.7 Quick Start 8

2Sensor Description 12

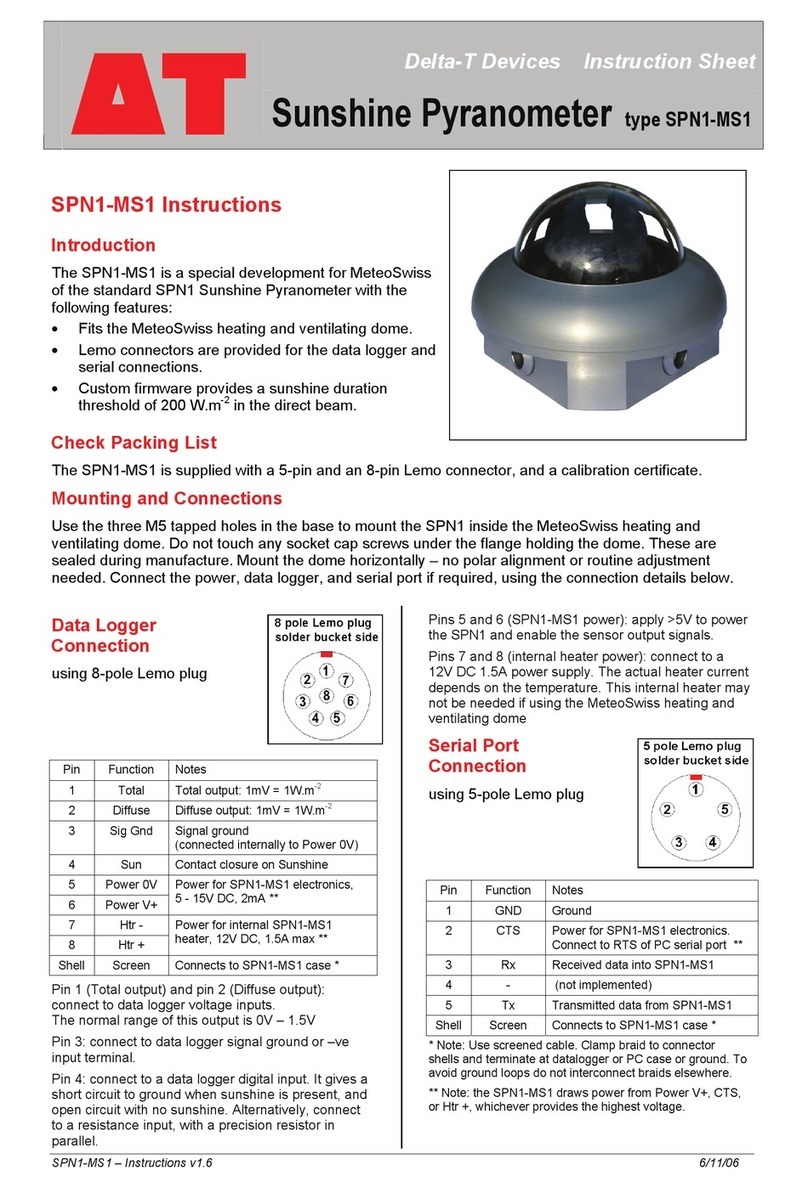

2.1 Parts 12

2.1.1 Body and shaft 12

2.1.2 Pressure sensor 12

2.1.3 Reference air pressure 12

2.1.4 The ceramic cup 13

2.2 External refilling (SWT4R only) 13

2.3 Analog output signals 14

3Installation 15

3.1 Advance planning 15

3.1.1 Selecting the measuring site 15

3.1.2 Number of Tensiometers per level 15

3.1.3 Extent of the site 15

3.1.4 Protection of refilling tubes (SWT4R only) 16

3.1.5 Use of Tube Jackets and Conduit 16

3.1.6 Ideal conditions for installation 17

3.1.7 Documentation 17

3.2 Selecting the installation angle 18

3.2.1 "Vertical" tilting downwards (SWT4R only) 18

3.2.2 "Horizontal" tilting upwards (SWT4R only) 18

3.3 Installation procedure 19

3.4 Offset correction for non horizontal installations 21

3.4.1 How to measure the zero offset of a tilted tensiometer 22

3.5 Connecting SWT4 and SWT4R 23

3.5.1 Spot reading with the SWT-MR (Infield7) 23

3.5.2 Connecting cables 23

3.5.3 Connection to a data logger 23

3.5.4 Connection to Delta-T Loggers 24

4Service and maintenance 26

4 SWT4 User Manual v3.1

4.1 Refilling 26

4.1.1 When do Tensiometers need to be refilled? 26

4.1.2 Refilling in the lab 27

4.1.3 Refilling in the field (SWT4R only) 29

4.1.4 Refilling with a vacuum pump (SWT4R only) 30

4.2 Testing 33

4.2.1 Calibration 33

4.2.2 Check the Offset 33

5Protecting the measuring site 34

5.1 Theft and vandalism 34

5.2 Cable protection 34

5.3 Frost 34

5.3.1 Protection against frost 34

5.3.2 Emptying SWT4 or SWT4R 35

5.4 Lightning protection and grounding 35

6Useful notes 37

6.1 Maximum measuring range and data interpretation 37

6.2 Temperature influences 39

6.3 Vapor pressure influence 39

6.4 Osmotic effect 39

6.5 Using Tensiometers as a piezometer 40

7Troubleshooting 40

8Appendix 41

8.1 Technical specifications 41

8.2 Wiring configuration 42

8.3 Accessories 43

8.3.1 Connecting and extension cables 43

8.3.2 Handheld measuring device 44

9Tensiometer loggers 45

9.1.1 Voltage regulators 46

9.1.2 Refill kits 46

9.1.3 Tensiometer augers 47

9.2 Units for soil water and matrix potentials 48

10 Technical Support 49

Terms and Conditions of sale 49

Service and Spares 50

Technical Support 50

Contact Details 50

11 Index 51

SWT4 User Manual v3.1 Introduction 5

1 Introduction

1.1 Safety instructions and warnings

Electrical installations must comply with the safety and EMC

requirements of the country in which the system is to be used.

Please note that any damage caused by handling errors are out of our

control and therefore are not covered by guarantee.

Tensiometers are instruments for measuring the soil water tension, and

soil water pressure and are designed for this purpose only.

Please pay attention to the following possible causes of risk:

Lightning: Long cables act as antennas and might conduct surge

voltage in case of lightning stroke –this might damage sensors

and instruments.

Frost: Tensiometers are filled with water and therefore are

sensitive to frost! Protect Tensiometers from frost at any time.

Never leave Tensiometers over night inside a cabin or car when

freezing temperatures might occur!

Tensiometers are not usually damaged when the cup is installed in

a frost-free soil horizon.

Excess pressure: The maximum non destructive pressure is

300 kPa = 3 bar = 3000 hPa. Higher pressures - which might

occur, for example, during insertion in wet clayey soils, whilst

measuring shear force, or during refilling and reassembly - will

destroy the pressure sensor!

Electronic installation: Any electrical installations must be executed

by qualified personnel.

Ceramic cup: Do not touch the cup with your fingers. Grease,

sweat or soap residues will influence the ceramic's hydrophilic

performance.

6 Introduction SWT4 User Manual v3.1

1.2 Unpacking

The SWT4 or SWT4R includes:

Tensiometer, calibrated and filled, with 4-pin plug M12/IP67 with

plug cap

This manual

Plastic bottle protecting the ceramic cup (must be half-filled with

water to keep the cup wet)

Rubber shaft water protection disk

Calibration certificate with each order for conversion of electrical to

physical values

With type SWT4R: a refill syringe

SWT4 and SWT4R are filled and ready for installation when

supplied.

See also “Accessories” on page 43.

1.3 Foreword

Measuring systems must be reliable and durable and should require a

minimum of maintenance to achieve target-oriented results and keep

the servicing low. Moreover, the success of any technical system

directly depends on it being used correctly.

At the beginning of a measuring task or research project the target, all

effective values and the surrounding conditions should be defined. This

then leads to the requirements for the scientific and technical project

management which describes all quality related processes and decides

the methods to be used, the technical and measurement tools, the

verification of the results and the modeling.

The continuously optimized correlation of all segments and its quality

assurance are decisive for the final success of a project.

We wish you good success with your projects. Please do not hesitate

to contact us for further support and information.

1.4 Guarantee

See Terms and Conditions of Sale on page 49.

1.5 Durability

The nominal lifespan for outdoor usage is 10 years, but protection

against UV-radiation and frost as well as proper and careful usage

substantially extends the lifespan.

SWT4 User Manual v3.1 Introduction 7

1.6 SWT4 and SWT4R

1.6.1 Soils and soil water

All water movement in soil is directly dependant on the soil water

tension, because water, both in the soil and on the surface, will always

move from a point of higher potential to a point of lower potential.

The majority of soil water flow take place in response to small water

tensions. Only Tensiometers allow the direct and precise measurement

of these small tensions.

Natural soils in the ground are heterogeneous. It is not just

precipitation and evaporation that matter, but also the soil texture,

particle size distribution, cracks, compaction, roots and cavities. All

these heterogeneities cause the soil water tension to vary. It is prudent

therefore to have multiple measuring points, particularly in soil

horizons close to the surface.

1.6.2 Intended use

Tensiometers measure soil water tension –a measure of the soil

matrix potential –which is the work the plant needs to do in order to

extract water from a unit volume of the soil. These Tensiometers work

from +100 kPa (water pressure) to -85 kPa (suction or soil water

tension).

If the soil gets drier than -85 kPa, the Tensiometer runs dry and must

be refilled as soon as the soil is sufficiently moist again (see Fig 6.1).

Soil water and Tensiometer water have contact through the ceramic

which is porous and permeable to water. A wetted porous ceramic

creates an ideal pore/water interface. The soil water tension is directly

conducted to the pressure transducer which offers a continuous signal.

The atmospheric reference pressure is provided through a membrane

on the cable, a unique patented method.

1.6.3 Types

The SWT4 is available in 2 versions: the standard SWT4 without

refilling tubes, and the SWT4R with refilling tubes for refilling the

Tensiometer in the field with a syringe.

Separate refilling instructions for the SWT4R are provided in section 4.

8 Introduction SWT4 User Manual v3.1

1.7 Quick Start

This section does not replace the rest of the user manual. It is only a

summary. Please read the complete manual carefully before using the

instrument, particularly Chapter 3 and 5!

1. Drilling the borehole

Mark the required drilling depth both on auger and on Tensiometer

shaft. Note: Installation depth = drilling depth / cos .

For SWT4R: For installation from the soil surface, an installation angle

of 25° to 65° from the vertical line is ideal for the optimal removal of air

from the cup (Fig. 1a). For “horizontal” installation from a manhole the

borehole should point upwards in an angle of 5° (Fig. 1b).

2. Slurrying the cup is only reasonable in clayey soils and only if the

bore hole is larger than the ceramic cup (24 mm). In coarse sand or

pebbly soils, a fine-pored slurry might create a water reservoir which

slows down the response. With the special Tensiometer gouge auger

type SWT4-AUG slurrying is unnecessary because of the accurate fit

of the Tensiometer into the hole.

3. Take off the protective plastic bottle from the Tensiometer cup. Tilt

and pull the bottle off carefully. If necessary, carefully turn it counter-

clockwise only! (as marked on the bottle)

Turn the bottle counter-clockwise only when you remove the bottle

but also when you reassemble the bottle (see arrow on bottle

label).

4. Insert the SWT4 or SWT4R into the hole to the depth mark with

constant gentle pressure and without using force.

In clayey soils a dangerous overpressure might develop. So

monitor the Tensiometers pressure with a type SWT-MR

(INFIELD7) Manual Readout Unit or a data logger.

Do not exceed -2 bar ( -200 kPa, -2000 hPa) during insertion.

Do not turn the Tensiometer after it is inserted into the ground -

this might loosen the cup.

SWT4 User Manual v3.1 Introduction 9

Note for SWT4R Tensiometers:

Pay attention to the engraved black spot on the shaft’s top end that

marks the position of the exit opening of the external filling inside

the cup:

a) Downwards installation: If the position of the cup will be lower than

the end of the shaft, the black mark must exactly face up! The optimal

installation angle is between 25° and 65°.

b) Upwards installation: If the position of the cup will be higher than the

end of the shaft, the black mark must exactly face down! The optimal

installation angle is about 5°.

Fig. 1a) Downwards installation Fig. 1b) Upwards installation

5. Push down the shaft water retaining disk to a position directly on

the soil surface.

6. For SWT4R: Slide a thermal insulation tube over the capillary

filling tubes.

7. If the plug is not connected right away leave the protective cover

on the plug. Dirt will influence the impermeability and water tightness is

only assured when the plug is kept clean.

8. Connect the Tensiometer signal wires to either a data logger or the

SWT-MR/Infield7

See also: “Wiring Configuration”on page 42

GP1-PGA1 Quick Start Guide (for GP1 Logger users)

LS2Win Software online help (for DL2e Logger users).

10 Introduction SWT4 User Manual v3.1

Please note:

Especially in loamy, clayey soils a high pressure can occur just by

inserting the SWT4 or SWT4R into the borehole. Thus, the

pressure values should be continuously observed during

installation with an SWT-MR/Infield7 Manual Readout Unit or a

data logger.

Keep it less than -200 kPa, i.e. -2000 hPa

The less air left inside the cup and the better the soil's conductivity

is, the faster the Tensiometer will respond to tension changes.

If the soil is dryer than -90 kPa (-900 hPa), it does not make sense to

refill the Tensiometer immediately. Wait until any Tensiometer that is

installed in the next lower level again reaches the reading it had when

the upper Tensiometer dried out.

SWT4 User Manual v3.1 Introduction 11

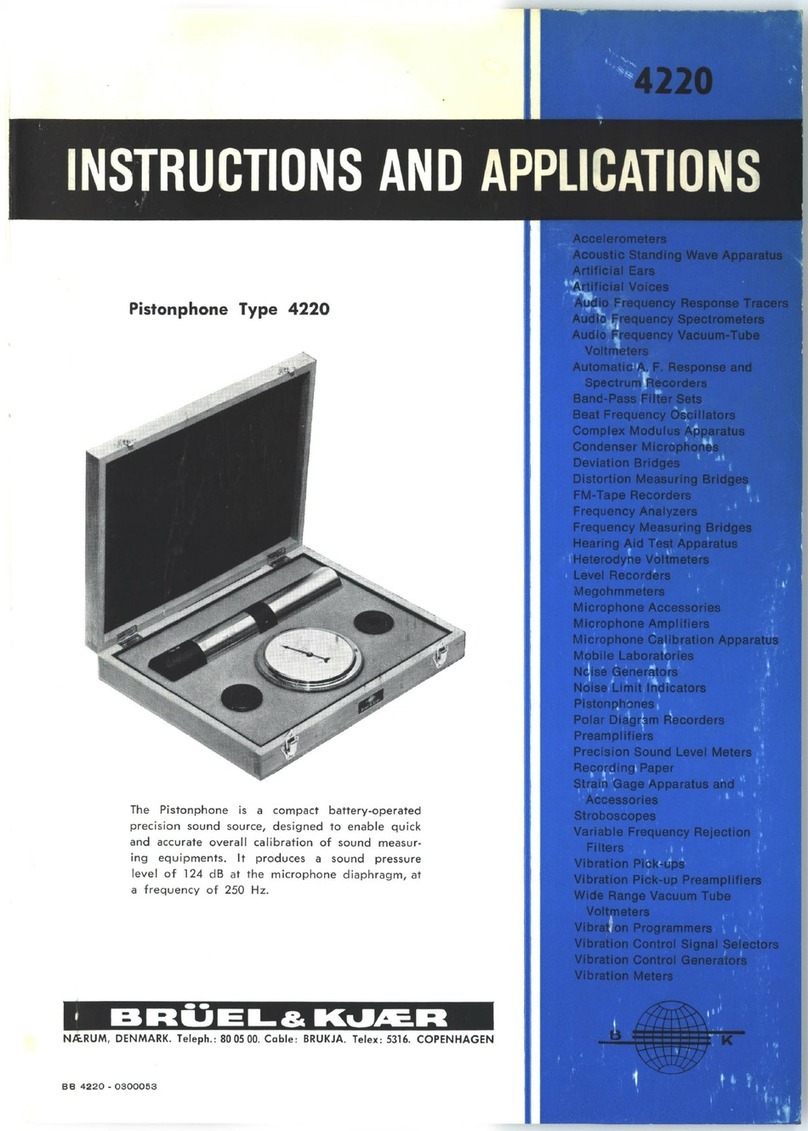

External syringe refilling (SWT4R only)

Installed SWT4R can be refilled or ventilated through

the two capillary tubes (stainless steel) without being

removed from the soil. The tubes can be extended.

With the supplied refilling syringe a measuring range of

at least -80 kPa can be assured. With the special

Refilling Kit SWT4-RK2 a range of -85 kPa can be

assured.

Reference air pressure

The reference atmospheric air pressure is conducted

to the pressure transducer via the water impermeable

(white) Teflon membrane and through the cable. The

membrane must always have contact to the air and

should never be submersed into water.

Cable gland (IP67)

SWT4 and SWT4R can be completely buried if

required. If buried, cables and tubes should be

protected. Special cable glands are available for

making tight seal to with plastic protection tube for the

cable - see Accessories on page 43.

Transparent acrylic shaft

One-piece shafts from 10 cm to 200 cm are available.

Shafts over 200 cm are divided with threaded adapter

and are available up to nearly any length.

Pressure transducer

Position of the pressure sensor opening, position of

the temperature sensor and the ventilation tube.

High grade porous ceramic cup

Filled with degassed water, with refilling tube.

Sensor body with electronic

The incorporated piezoelectric pressure sensor

measures the soil water tension against atmospheric

pressure. Direct connection to any power supply:

e.g. battery, TVB1 or TVB-M, power supply unit

12 Sensor Description SWT4 User Manual v3.1

2 Sensor Description

2.1 Parts

2.1.1 Body and shaft

The pressure transducer is integrated in the sensor body. The

electronics are completely sealed and thus well protected against

moisture. The shaft is made of transparent blue acrylic plastic and has

a very high durability and impact resistance.

2.1.2 Pressure sensor

The piezoelectric pressure sensor measures the soil water tension

against the atmospheric pressure. Atmospheric pressure is conducted

via a white air-permeable membrane on the cable, through the cable,

to the reference side of the pressure sensor.

The maximum permissible, i.e. non-destructive, pressure is 3 bar

(300 kPa, 3000 hPa). Higher pressure will damage the sensor and

absolutely must be avoided! High pressures can appear for

example when cup and sensor are reassembled, when inserted in

wet, clayey soils, or in tri-axial vessels used for measuring shear

forces.

2.1.3 Reference air pressure

The reference atmospheric air pressure is conducted to the pressure

transducer via the air permeable (white) Teflon membrane in-line in

the cable. The membrane does not absorb water. Water will not pass

through the membrane into the cable, but condenation inside the cable

can leave the cable through the membrane.

The white membrane on the cable must always have contact to air

and should never be submersed under water.

SWT4 User Manual v3.1 Sensor Description 13

2.1.4 The ceramic cup

To transfer the soil water tension as a negative pressure into the

Tensiometer, a semi-permeable barrier is required. This must have

good mechanical stability, be permeable to water and impermeable to

gas (when wet).

The Tensiometer cup consists of ceramic Al2O3sintered aluminium. A

special manufacturing process guarantees homogeneous porosity with

good water conductivity and very high hardness. Compared to

conventional porous ceramic the cup is much more durable.

The bubble point is at least 1500 kPa (15 bar, 15,000 hPa). If the soil is

dryer than -1500 kPa air can enter, the negative pressure inside the

cup decreases, and the readings go down to 0 kPa.

With these characteristics this material has outstanding suitability to

work as the semi-permeable diaphragm for Tensiometers.

The cup has a lifetime guarantee against breakage.

Ceramic cup: Do not touch the cup with your fingers. Grease,

sweat or soap residues will influence the ceramic's hydrophilic

performance.

2.2 External refilling (SWT4R only)

The SWT4R is equipped with 2

stainless-steel capillary tubes

which are led through the cable

gland and the shaft. Each one has

an opening that ends inside the

ceramic cup. This allows easy

refilling of the SWT4R while it

remains installed in the ground.

Tube 1 ends at the very tip of the

cup, tube 2 ends next to the

pressure transducer opening.

Outside, both tubes are connected together with a short rubber tube.

Any air bubbles will ascend and accumulate either in the ceramic’s tip

around tube 1 (upwards installation angle) or next to opening 2

(downwards installation angle). Accordingly the air is removed either

through tube 1 or 2 (please see chapter 3.2).

1

2

14 Sensor Description SWT4 User Manual v3.1

2.3 Analog output signals

The pressure transducer offers an linear output signal. As the output

signal directly depends on the supply voltage, the supply voltage needs

to be constant and stabilized.

As the pressure transducer is a Wheatstone full bridge, it has to be

connected in a certain way.

See also Connecting SWT4 and SWT4R on page 23

and the user manual for your display unit or data-logger before

connection.

Black mark on tube

SWT4 User Manual v3.1 Installation 15

3 Installation

3.1 Advance planning

3.1.1 Selecting the measuring site

The installation spot should be representative of the soil horizon!

Therefore, in heterogeneous soils, soil samples should be taken and

classified before or during installation.

On farmed sites with vegetation, root spreading and root growth during

the measuring period must be considered. Fine roots will grow around

the Tensiometer cup as this is a poor but still secure source of water.

Therefore, avoid the root zone or move the Tensiometer from time to

time depending on the root growth.

Disturbing effects like the edge of a field, slopes or hollows must be

avoided or taken into account when interpreting the data.

3.1.2 Number of Tensiometers per level

The deeper the level, the less the variation is in water potential. In

lower sandy or pebbly horizons just one Tensiometer per depth is

sufficient. Close to the surface about 3 Tensiometers per level are

recommended.

Guiding principle: More heterogeneous sites and soil structures

require a higher number of Tensiometers.

3.1.3 Extent of the site

A large number of well-spaced samples will help reduce sampling

errors in heterogeneous soils.

To obtain a differential description of the soil water situation, at least 2

Tensiometers are recommended per horizon, one in the upper and one

in the lower level.

The maximum recommended cable length for SWT4 and SWT4R is 40

meters.

Accuracy: long cables reduce the accuracy.

Lightning: cables act as antennas and should always be as short as

possible.

16 Installation SWT4 User Manual v3.1

3.1.4 Protection of refilling tubes (SWT4R only)

A recent study by Prof. Wolfgang Durner showed that refilling tubes

must be protected from heating up and solar radiation.

If a bubble grows inside a refilling tube, temperature changes will lead

to an expansion of the air, resulting in a variation of the reading.

Therefore, refilling tubes should be as short as possible and should be

thermally protected, either by providing an insulating protection or by

burying the tubes.

Thermal effect:

As long as the Tensiometer and its tubes are

freshly and completely filled it will work

perfectly. Any air trapped inside the upper

parts of the tube will expand when heated up

by solar energy. This causes a drop of the

water tension and some water will flow from

the cup into the ground.

Thus, readings will fluctuate around the actual

reading during solar radiation, specially with

low water potentials. Furthermore, under

permanent solar exposure the tubes get sticky

and brownish.

Slide the supplied thermal insulation tube over the shaft end and the

refilling tubes as shown in above photo!

3.1.5 Use of Tube Jackets and Conduit

Tube Jackets: These are useful with shafts

longer than 2 m, in pebbly soils or gravel, and

for horizontal installations from inside a well or

pit hole. The tube jacket should end 30 to 50

cm away from the cup so that no leakage or

condensation is conducted to the cup. The

inner diameter of the jacket should be at least

35 mm.

Thermal inuslation

tube

Tube Jackets

SWT4 User Manual v3.1 Installation 17

Conduit: This pictures shows an example of

the use of flexible cable conduit (trunking) to

protect the tensiometer cables.

3.1.6 Ideal conditions for installation

For the installation of Tensiometers, the ideal conditions are:

Frost-free soil.

Wet coarse clay or loess (wind deposited soil).

Low gravel content. The more gravel in a soil the more often the

drilling has to be repeated to reach the required depth.

3.1.7 Documentation

For every measuring spot you should:

Measure out the position where the pressure sensor will be

placed. (A must for installations below the ground surface).

Take documentary photos before, during and after installation.

Save a soil sample.

Write down installation depth and angle with each sensor

identification (serial number).

Mark all connecting cables with the corresponding sensor

identification, serial number or logger channel on each end.

Clip-on numbered rings are available as

an accessory.

Contact Delta-T for more information.

18 Installation SWT4 User Manual v3.1

3.2 Selecting the installation angle

Ideally, a Tensiometer installation should not disturb the flow of water.

To prevent the preferential flow of water along the shaft Tensiometers

should be installed at an angle.

3.2.1 "Vertical" tilting downwards (SWT4R only)

When installed from the surface, an angle of 25° to 65° from the

vertical is optimal for refilling. In an absolutely vertical position air

bubbles might hide inside the edges of the cup adapter. Still, they

could be removed completely with a hand vacuum pump (contact

Delta-T for details).

In this position, the refilling tube is the shorter stainless steel tube with

the black mark. Water is injected Into this tube for refilling.

Before inserting the Tensiometer, orient the shaft so the black mark

near the shaft end points upwards.

Do not rotate the shaft after it is inserted into the ground as this

might loosen the cup.

3.2.2 "Horizontal" tilting upwards (SWT4R only)

When installed horizontally from inside a well or pit hole, the

Tensiometer must point upwards! This means the cup is in a higher

position than the end of the shaft. An upward angle of approx. 5° is

ideal for refilling. Note that now de-airing and refilling tube are

switched: the refilling tube is the longer stainless steel tube without the

black mark. Water is injected into this tube for refilling.

Before inserting the Tensiometer, turn the shaft so the black mark

near the shaft end points downwards.

Do not turn the shaft after it is inserted into the ground as this might

loosen the cup.

Note that with a horizontal installation the (optional) filling indicator

will not react until the cup is almost empty.

SWT4 User Manual v3.1 Installation 19

3.3 Installation procedure

For the installation of the Tensiometer in the field the following tools

are required:

Tensiometer auger with diameter 25 mm, ideally the SWT4-AUG

Gouge Auger with shaped blade tip.

Rule, spirit level, angle gauge, marker pen.

Notebook, camera for documentation of site and soil profile.

Perhaps PE-plastic bags for taking soil samples from the site.

Thermal insulation tubes for installations from soil surface.

Cable protection conduit.

Tube Jackets if required (inner diameter > 35 mm).

Please observe the following notes:

Do not touch the cup with your fingers. The ceramic should not have

contact with grease or soap as this will influence the hydrophilic

performance.

Do not leave the cup in air for more than 5 minutes as Tensiometer

water will evaporate and the Tensiometer will need to be refilled.

Procedure:

1. Mark the required drilling depth on auger and Tensiometer shaft.

The reference point is the center of the cup. Drill a hole with the

desired depth on the chosen measuring spot. Auger in steps. Take

care when drilling the last 20 cm, remove and save this soil. Water

will not run along the shaft if the Tensiometer is installed in an

angle because the water will drain into the soil before it reaches

the cup.

Read the chapter "Selecting the installation angle" for the best

installation angle on page 18.

2. When using augers with a diameter of over 25 mm, mix a paste of

water and crumbled soil material taken out of the borehole. Fill the

paste into the bottom area of the borehole by using a simple pipe

with outer diameter 2 cm.

20 Installation SWT4 User Manual v3.1

3. Now remove the protective plastic bottle from the Tensiometer cup.

Important: Only turn the bottle counter-clockwise when taking the

bottle off - and also when putting it back on again!

Save the plastic bottles: Do not store the Tensiometer without the

protective plastic bottle since the cup empties quickly! The bottle

must be filled with some water for storage!

4. Connect the Tensiometer to a readout unit. Carefully insert the

SWT4/SWT4R into the borehole up to the stop while continuously

observing the pressure signal.

Do not use any force. Do not hit the Tensiometer - this may damage

cup and pressure sensor.

Especially in clayey soils the pressure reading must be monitored as

high pressures might build up! The pressure should not exceed 200

kPa (2000 hPa) (because >300 kPa is fatal!)

Note for SWT4R Tensiometers:

Important: Pay attention to the engraved black spot on the shaft’s top

end that marks the position of the exit opening of the external filling

inside the cup:

a) Downward tilting installations: If the position of the cup will be lower

than the end of the shaft, the black mark must exactly face up!

b) Upward tilting installations: If the position of the cup will be higher

than the end of the shaft, the black mark must exactly face down!

Fig. 3a) Downwards installation Fig. 3b) Upwards installation

This manual suits for next models

1

Table of contents

Other Delta-T Measuring Instrument manuals