User manual - METER SRT-L70

CONTENTS

1. BASIC REQUIREMENTS AND USER SAFETY........................................................................................3

2. GENERAL CHARACTERISTICS................................................................................................................4

3. TECHNICAL DATA......................................................................................................................................4

4. DEVICE INSTALLATION............................................................................................................................6

4.1. UNPACKING.......................................................................................................................................6

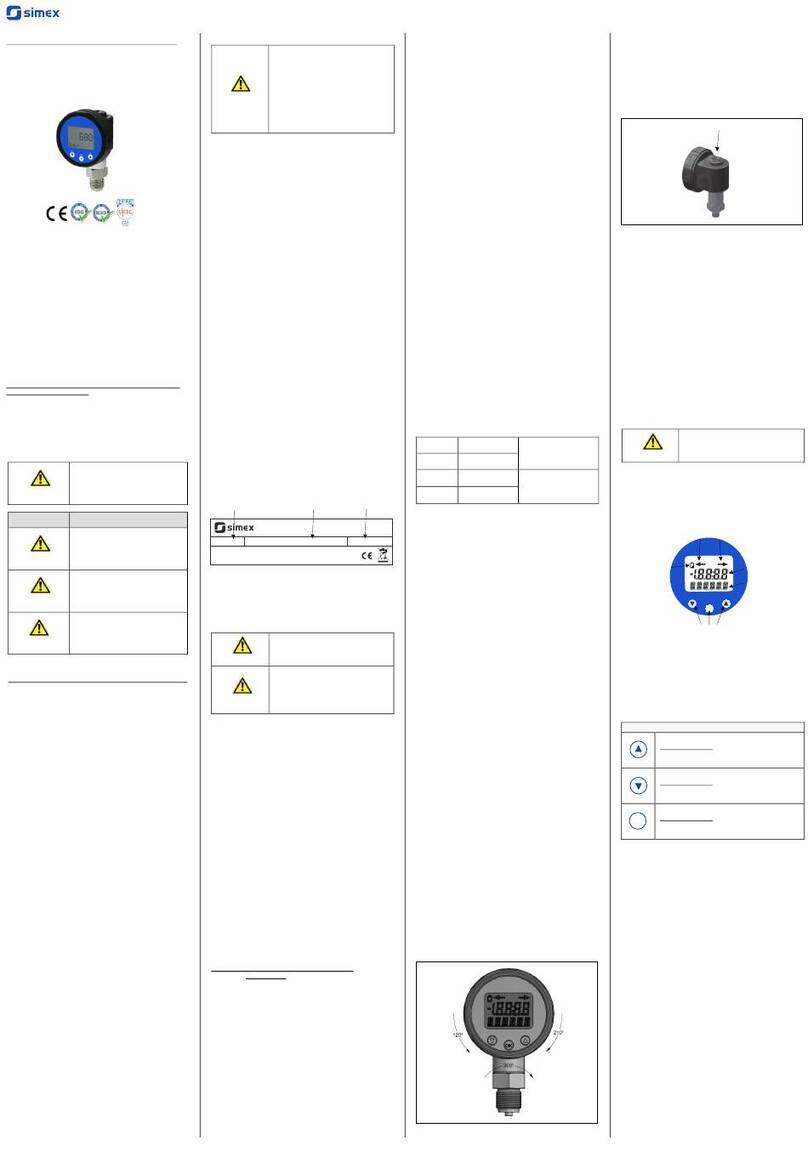

4.2. ASSEMBLY........................................................................................................................................6

4.3. CONNECTION METHOD...................................................................................................................6

4.4. MAINTENANCE................................................................................................................................10

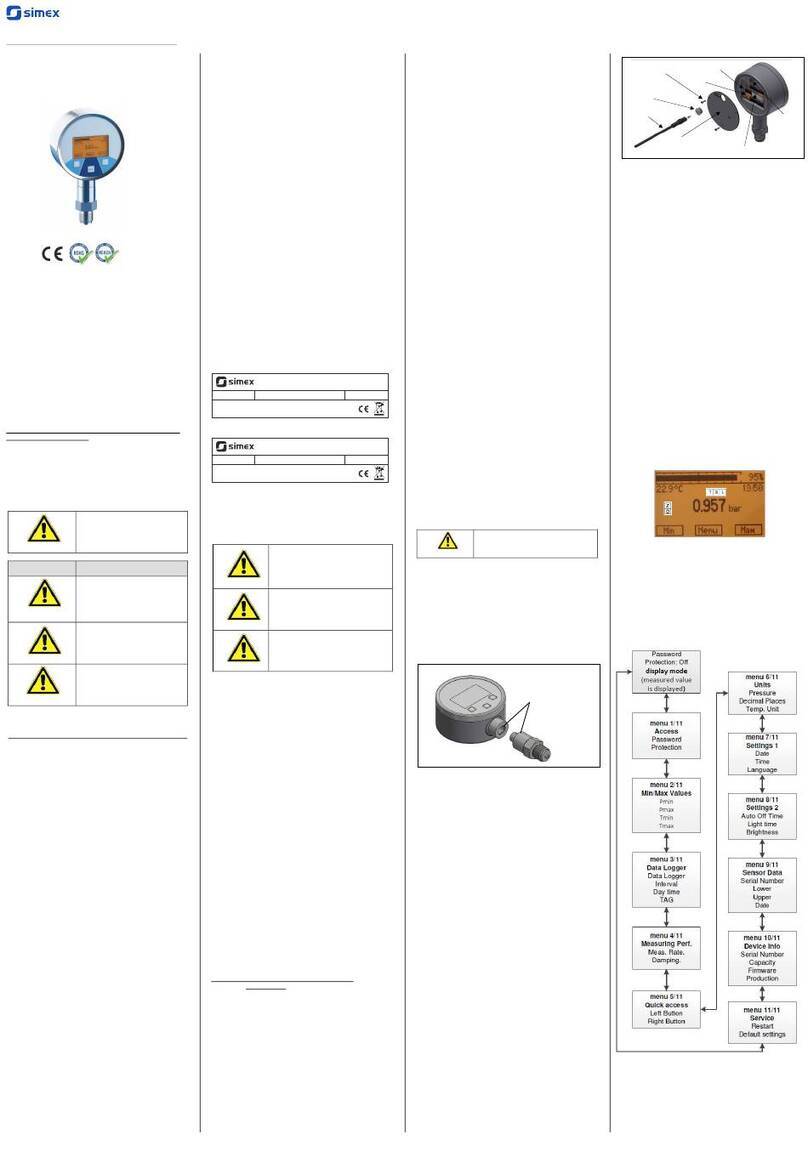

5. FRONT PANEL DESCRIPTION................................................................................................................11

6. PRINCIPLE OF OPERATION...................................................................................................................11

6.1. MEASUREMENT MODE..................................................................................................................11

6.2. DETECTION OF THE PEAK VALUES............................................................................................12

6.3. CONTROL OF THE RELAY OUTPUTS..........................................................................................13

6.3.1. One hreshold mode................................................................................................................15

6.3.2. Two hresholds mode..............................................................................................................16

7. DEVICE PROGRAMMING.........................................................................................................................17

7.1. PROGRAMMING MENU..................................................................................................................17

7.2. PARAMETERS EDITION.................................................................................................................18

7.2.1. Numeric parame ers (digi change mode)...............................................................................18

7.2.2. Numeric parame ers (slide change mode)..............................................................................18

7.2.3. Swi ch parame ers (“LIST” ype).............................................................................................19

7.3. MENU DESCRIPTION.....................................................................................................................19

7.3.1. “rEL1” menu.............................................................................................................................20

7.3.2. “inP ” menu..............................................................................................................................22

7.3.3. ”bri” parame er.........................................................................................................................22

7.3.4. ”HOLd” menu...........................................................................................................................22

7.3.5. ”SECu” menu...........................................................................................................................23

7.3.6. ”rS” menu.................................................................................................................................23

7.3.7. ”Edi ” parame er......................................................................................................................24

7.3.8. ”dEFS” parame er....................................................................................................................24

7.3.9. ”SErv” menu............................................................................................................................24

7.4. MENU STRUCTURE........................................................................................................................25

8. THE ALARM LED......................................................................................................................................26

. THE MODBUS PROTOCOL HANDLING.................................................................................................26

9.1. LIST OF REGISTERS......................................................................................................................26

9.2. TRANSMISSION ERRORS DESCRIPTION....................................................................................29

9.3. EXAMPLES OF QUERY/ANSWER FRAMES.................................................................................29

10. DEFAULT AND USER'S SETTINGS LIST.............................................................................................32

2