dentalfarm PRO-3 SHAKE Operating instructions

PROFESSIONAL VACUUM CLEANER

PRO-3 Shake

USER AND MAINTENANCE MANUAL

1. DESCRIPTION

PRO-3 is a powerful and reliable professional vacuum cleaner, indicated for serving those

machines which generate dust in the the Dental Lab as well as of the Jewellery branch.

The high-speed, one-stage motor provides rapid suction and conveys dust towards the

stainless steel housing, where the 3 filtering stages are located. Coarse particles stop on a

first paper bag, the smaller ones stop on a second nylon sack and the finest (and the most

dangerous) ones stop on the surface of the internal microfiltering cartridge.

This model features a very important utility: an electromagnetic filter stirrer which shakes

the microfiltering cartridge and removes sediment from its pleated surface. This results in a

longer use of the machine without accessing the inside of the unit.

PRO-3 can be easily connected to dry model trimmers, interior trimmers, sandblasters,

cutting machines, workbenches. Double connection is featured, as well.

This unit is to be used for suction of dust and small debris. Do not use for suction

of liquids.

2. TECHNICAL REFERENCE REGULATIONS AND TEST MODES

Suction units of the range PRO-3 (PRO-3 and PRO-3 Shake) are mass-manufactured by

DENTALFARM in compliance with technical and safety rules in force, as provided for by

the 2006/42 EEC Community Directive on machinery.

Careful inspection and full routine testing is carried out singularly on each machine which

is furtherly tested by an automatic test installatio assuring compliance with the fixed limits.

NOISE LEVEL – Values measured according to norms EN 60704 -1 (1996) / EN 60704 -2

- 1 (2000). Measurement A of the acoustic pressure level of this unit is ≤69 dB (A).

3. TECHNICAL SPECIFICATIONS

Description PRO-3 PRO-3 Shake

dimensions 380x380x620h 380x380x800h

Dimensions (packed) 400x400x730h 400x400x930h

weight 10,0 kg 13,5 kg

Weight (packed) 12,5 kg 16,0 kg

motor 1.000W 1.200W

volume 150m3/h 170m3/h

noise level <69 dB (A) <69 dB (A)

4. DEMOLITION AND WASTE DISPOSAL

According to International regulations, this unit has been classified as AEE

(electric and electronic device, whose correct operation depends on electric

currents and electromagnetic fields) and as a consequence, at the end of its

lifetime, it can not be treated as normal waste material but it must be disposed

separately, complying with the Directive 2002/96/CE.

5. GENERAL PRECAUTIONS

• The packing components can be potentially dangerous (for instance plastic bag) :

keep them out of the reach of children and other non-conscious persons.

• WARNING: this unit can be used for suction of dry dust only. It cannot be used in the

open air or in presence of moisture.

• Every use differing from that indicated in the manual can be potentially dangerous and

is to be avoided.

• When the unit is running, avoid to position the air intake near eyes, ears, mouth or

other delicate parts of the body.

• Completely assemble the unit before use.

• Ensure that the electric socket complies with the plug of the machine.

• Ensure that the tension value stated on the motor group corresponds to the network

used to connect the unit.

• WARNING: do not suck up inflammable substances (chimney ash) or explosive, toxic

or dangerous materials.

• Do not suck up substances which could damange the sack (pieces of glass, metal,

etc.)

• Do not suck up liquid substances

• Do not leave the machine running without supervision.

• Always disconnect the plug from the electric socket before carrying out any

maintenance operation or when the machine is accessible to children and non-

independent persons.

• Do not pull or lift the machine by the electric cable.

• Do not immerge in water for cleaning and do not wash with water jets.

• Regularly check the supply cable to detect any possible damage, as cracks or wear.

In case of damages, replace the cable before further use.

• When using electric extensions, ensure that these lay on dry surfaces and are

protected from water splashes.

• Maintenance and repair operations should always be carried out by trained

technicians. Spare parts which will be needed must be original.

• The Manufcaturer declines any kind of responsibility for damages which can be

caused to thing or persons as a consequence of non-compliance with the indications

listed in this manual, or in case of improper use of the unit.

6. LIST OF COMPONENTS AND ACCESSORIES ON DEMAND

LIST OF COMPONENTS

A SUCTION GROUP (MOTOR) I ELECTROMAGNETIC STIRRER

B ELECTRIC COMMUTATOR L NYLON SACK

C SUPPORT FOR ELECTRIC CABLE M DEFLECTOR

D SUCTION INTAKE N PAPER BAG

E METAL HOUSING O FLEXIBLE PIPE

F 3-WAY-FITTING WITH CAP P SIMPLE SLEEVE

G LOCKING HOOKS Q CONNECTION HOSE ADAPTER

H MICROFILTERING CARTRIDGE

LIST OF ACCESSORIES ON DEMAND

1501101 PACK OF 10 FILTERING PAPER BAGS FOR PRO-3 SUCTION UNIT

1501501 KIT FOR DOUBLE CONNECTION - 3 m flexible pipe, a simple sleeve and a

hose adapter.

1501502 KIT FOR CONNECTION TO SANDBLASTER – a high-capacity flange and a

new adjustable air intake, to be fitted on the machine.

7. INSTALLATION INSTRUCTIONS

1. The suction unit has got wheels, so that it can be easily moved next to the machine to

be served.

2. Undo the hooks (G) fixing the suction group (A) to the housing (E), install the paper bag

(N) on the deflector (M) located on the air intake (D) and the polyester sack (L) around

the pleated cartridge (H). Close again and reassemble carefully.

3. Fit the 3-way-pipe-fitting (F) on the air intake (D).

4. Connect the coupling (P) of the flexible pipe (O) on one of the three openings of the 3-

way pipe-fitting.

5. Safety connect the flexible pipe to the suction collector located on the machine to be

served. To make this operation easier, the rubber sleeve (Q) mounted on the end of the

pipe has 3 different diameters: choose the appropriate one and crosscut the rest, then

tighten with a hose clamp.

6. It is recommended not to keep a too high distance between the machin producting dust

and the suction unit; also, avoid syphons or curves in the connection pipe, as these

could collect a lot of dust and cause a loss of efficiency. If necessary, shorten the pipe

(the sleeves are screwed on the pipe spiral).

7. Connect the power supply cable to an approved, grounded socket.

The different machines which can be connected to the suction unit are likely to generate

different quantity of dust: this can be due to the dimension and the type of the suction

element they are using, to the quality of the material which is being treated, to the

technology of the machine itself. Beyond this, we will have to consider that some

operations are carried out in completely closed units, other at open air. All these

combinations of factors cause different concentrations of dust particles and it will be

therefore necessary to measure out the volume of air getting to the motor, in order to

ensure proper suction and depuration.

When only one unit is connected, it is recommended to keep open the free inlet of the 3-

way pipe-fitting in order to let in a bigger volume of air. When a sandblaster is connected, it

will be necessary to open an air intake on the opposite side of the unit to work as a suction

chimney.

In case a double connection is needed, ask for the specific kit (code 1501501) and

proceed as for the first installation.

8. INSTRUCTIONS FOR USE

Before starting working and generating dust, switch on the main shutter (B) of the

suction unit and ensure the depression generated by the motor is sufficient (that indicates

that the filters are not saturated).

/!\

ATTENTION

This unit can be used only for suction of dry dust and it cannot be

used or stored in the open air or in presence of moisture.

/!\

ATTENTION

Do not suck up inflammable, explosive, toxic or dangerous

substances.

9. MAINTENANCE

/!\

ATTENTION

Before carrying out any maintenance operation on the machine or on

the installations, disconnect the cable from the socket in order to

completely insulate the equipment from the electrical network. In case

of any doubts or possibility of error, please contact our Technical

service in order to avoid any damages or risks.

A reduction of the evacuation speed indicates that the filtering elements are almost

saturated; in that case, operate the electromagnetic stirrer in order to let the dust sediment

drop into the filtering bag.

However, it is convenient to inspect periodically the internal filtering elements and carry out

ordinary maintenance.

Open the hooks fixing the upper part of the unit to the metal housing:

1. lift up the top of the unit

2. extract the microfiltering cartridge

3. pullo out the polyester sack, empty it and, if necessary, wash it (mount it again only

when it has completely dried up).

4. Remove the paper bag and throw it away with all its content.

5. Remove all impurities deposited on the bottom of the housing.

6. Mount another paper bag.

7. Re-assemble all elements as originally positioned.

Every 3-4 times when performing the above operation, it will be convenient to deeply clean

the microfiltering cartridge. By rotating the fixing knob, the cartridge can be extracted from

its seat and blowed from the inside with compressed air, thus elminating a higher quantity

of dust. When doing this, we recommend also to blow the motor group in order to clean up

all evacuation conducts.

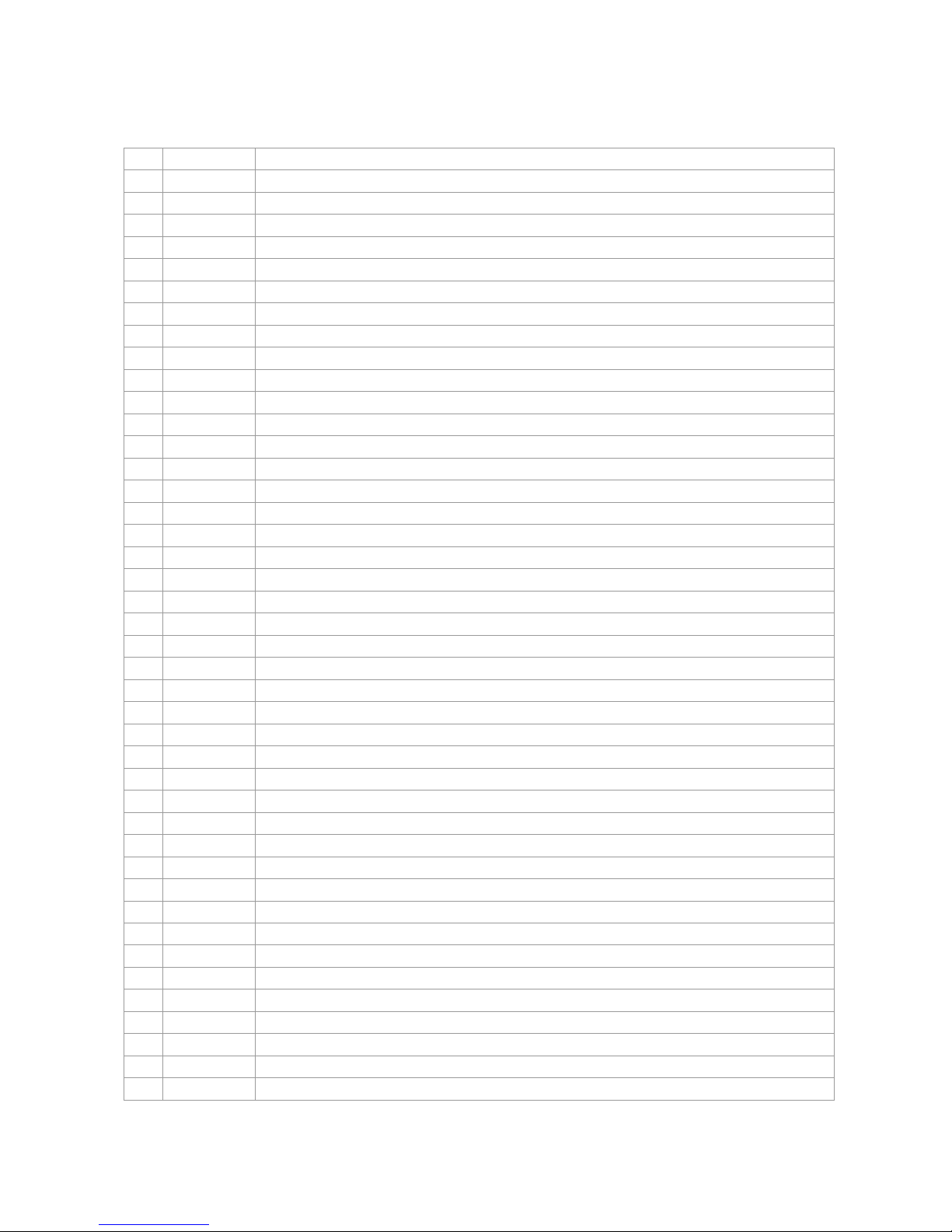

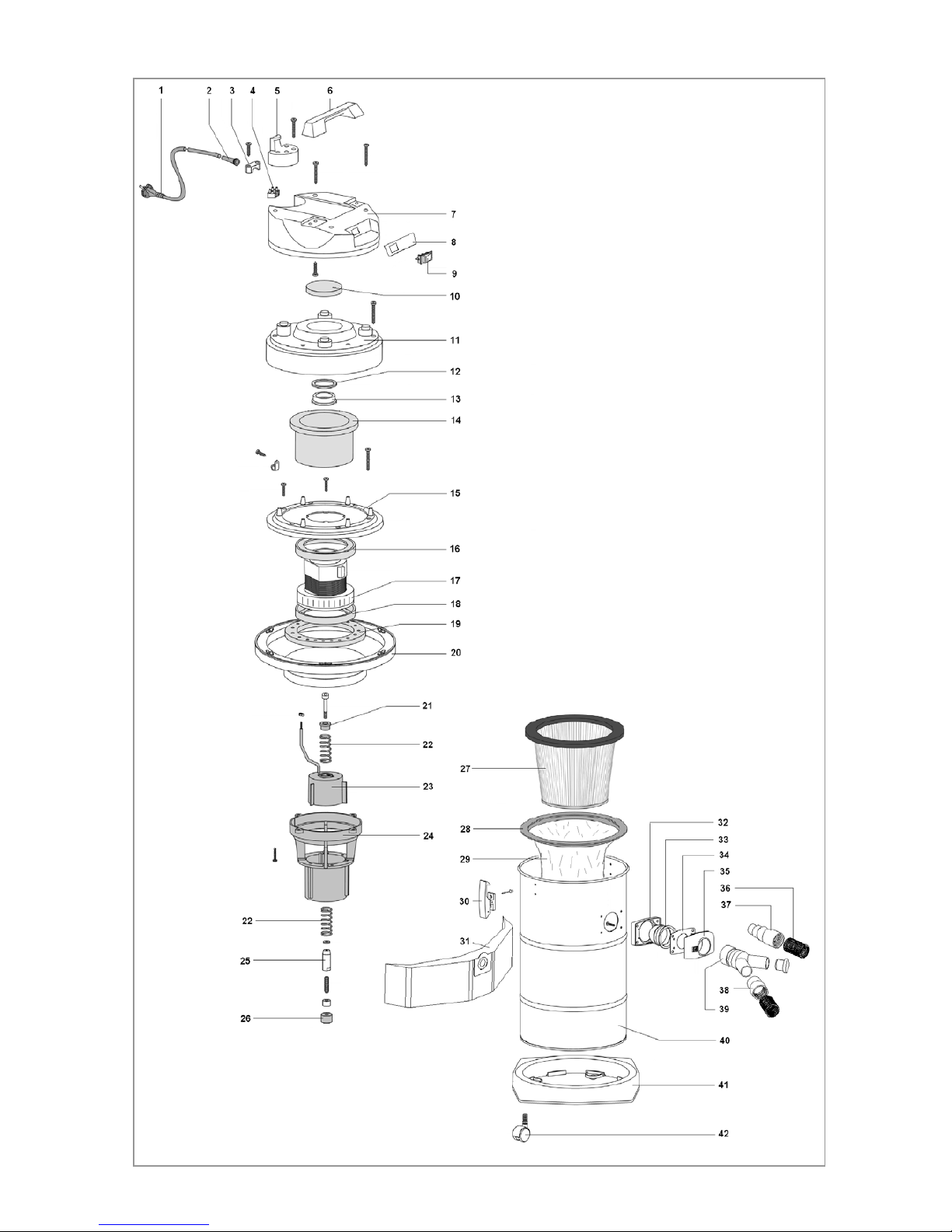

10. EXPLODED DRAWING AND SPARE-PART LIST

No. CODE DESCRIPTION

1 1501050 2x1 electric cable with plug

2 1501051 Fair-lead

3 1501052 Cable locking ring

4 1501053 Terminal board

5 1502021 Hook for cable

6 1502022 Handle

7 1502020 Cover

8 1501002 Brand label

9 1501013 Change over switch

10 1502023 Cover cap

11 1502024 Motor compartment cover

12 1502033 Spacer washer

13 1502034 Ring H = 7

14 1501032 Sound-absorbing filter

15 1502025 Motor support

16 1502035 Seal H = 5.5

17 1501015 Motor type BS280 1200W

18 1501016 Seal H = 16

19 1502036 MTP filter

20 1502026 Base with gasket

21 1502037 Spacer

22 1502038 Spring

23 1502039 Electromagnet

24 1502040 Body of filter shaking device

25 1502042 Piston

26 1502043 Rubber toecap

27 1501008 Filter cartridge

28 1502029 Filter cartridge support ring

29 1501010 Nylon filter bag

30 1502041 Plastic hook complete

31 1501101 Paper filter bag (pack of 10 pcs.)

32 1501037 Seal R205

33 1501038 Deflector

34 1501040 Seal D38

35 1501039 Filler

36 1501004 Suction pipe D. = 29 x L = 3m

37 1501006 Universal reduction sleeve

38 1501005 Sleeve for pipe D. = 29

39 1501003 Y-fitting with cap

40 1502030 PRO-3 Shake drum

41 1502031 Base for drum

42 1501054 Wheel

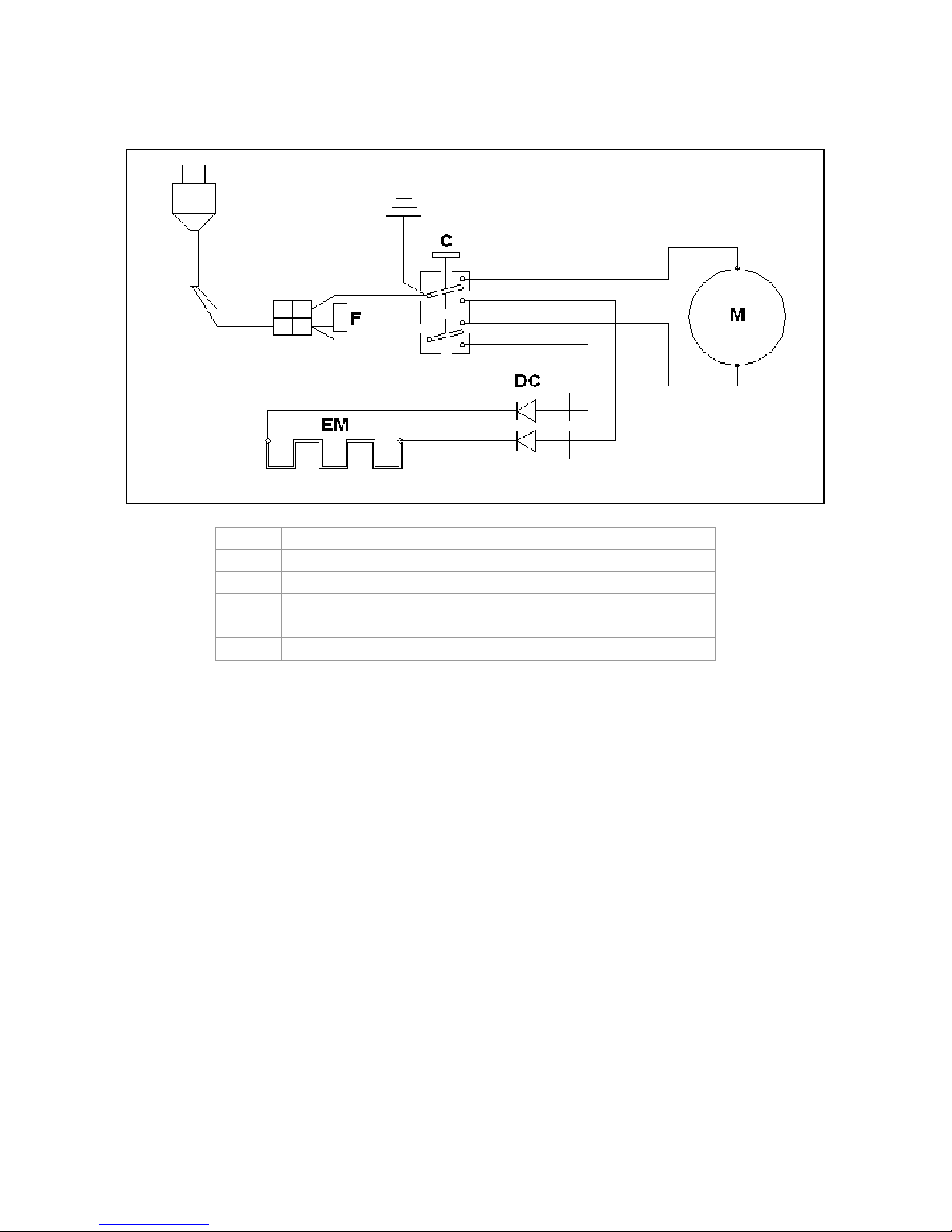

11. WIRING DIAGRAM

REF. DESCRIPTION

F Anti-jamming filter

C Change-over switch

M Motor

DC Rectifier board

EM Electromagnet

DENTALFARM s.r.l.

Via Susa, 9/a - 10138 TORINO - ITALY

TECHNICAL COMMERCIAL SERVICE - (+39) 011/4346588

TECHNICAL SUPPORT - 011/4346632

FAX 011/ 4346366

Website: www.dentalfarm.it

Table of contents