Repair or Warranty Contact Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

Page 7

Principle of Operation

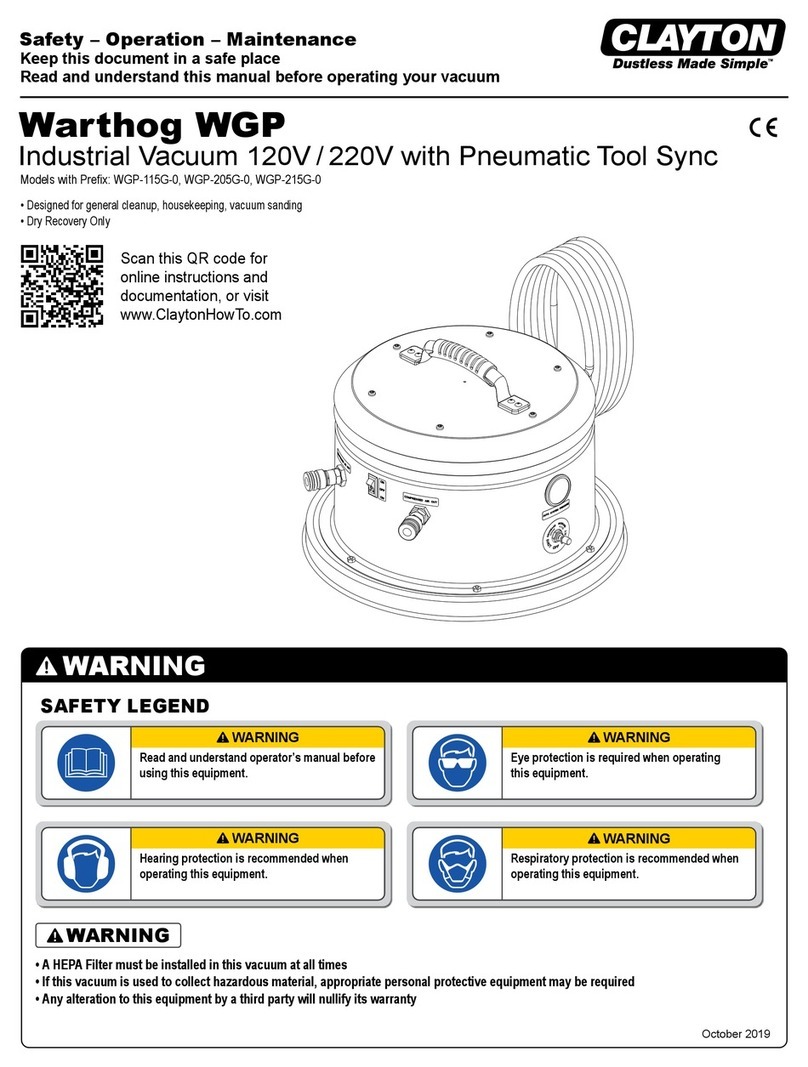

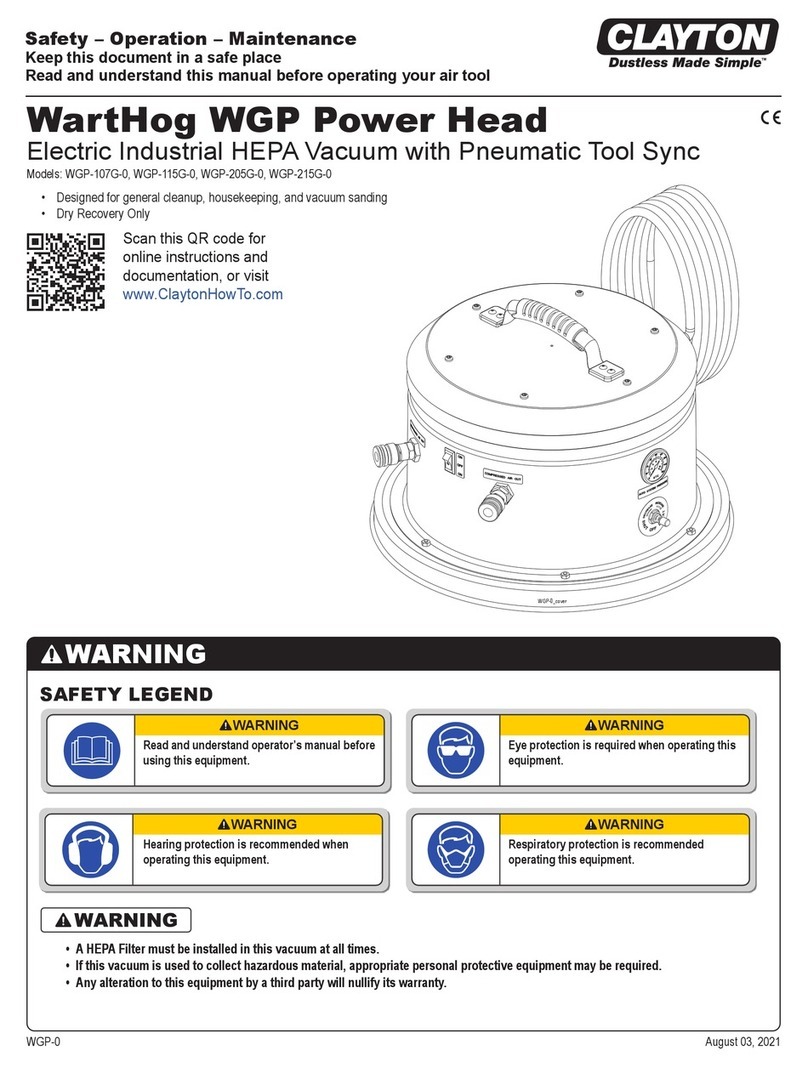

Pneumatic Tool Sync senses the ow of compressed air to a connected tool and activates the vacuum.

• When the compressed air tool is activated, the compressed air line pressure opens a pneumatic valve which activates the power head.

• The auto system pressure in the valve should be approximately 90 psi while the tool is running.

•

Delay valve.

• When the tool sync pressure reaches approximately 15 psi the valve closes and deactivates the power head.

• The Tool Sync Pressure Gauge helps the user visualize the time delay by displaying the pressure in the pneumatic valve as it drops

from 90 psi to 0 psi.

Requirements

• A compressed air supply must be connected to the Compressed Air Plug (Air In) on the power head.

• The tool must draw its compressed air from a Compressed Air Coupler (Air Out) on the power head.

• Compressed air must be clean, dry, and oil free to prevent blockage of the pneumatic system.

•

1. Attach the compressed air line source to the vacuum.

• Verify the Compressed Air Control valve on the vacuum is in the AUTO/OFF position.

• Connect one end of the compressed air line to a compressed air source.

• Connect the other end of the compressed air line to the Compressed Air Plug (Air In) on the vacuum head.

2. Attach the compressed air tool.

• Insert the compressed air line plug into a Compressed Air Coupler (Air Out) on the power head.

the airline has been connected.

• Connect the compressed air line coupler to the tool’s compressed air plug/input.

3. Test Pneumatic Tool Sync.

• Rotate the Compressed Air Control valve on the vacuum to the AUTO/OFF position and activate the air tool.

• The power head will activate.

• Deactivate the air tool.

• The vacuum will deactivate after a short delay.

4.

The Shut O Delay is preset at the factory to approximately 5 seconds.

•

•

• Rotate the Compressed Air Control valve on the vacuum to the AUTO/OFF

position and activate the air tool.

• The vacuum will power on.

• Deactivate the air tool.

• The vacuum will remain running.

•

Gauge begins to drop.

• When the tool sync pressure reaches approximately 15 psi the pneumatic valve

deactivates the power head.

• Continue to test Pneumatic Tool Sync by activating the compressed air tool.

•

•

delay, tighten the jam nut by rotating it clockwise to lock the valve in place.

5. Multiple Tools

• Pneumatic Tool Sync will work with one or two tools simultaneously.

PNEUMATIC TOOL SYNC

GL_008

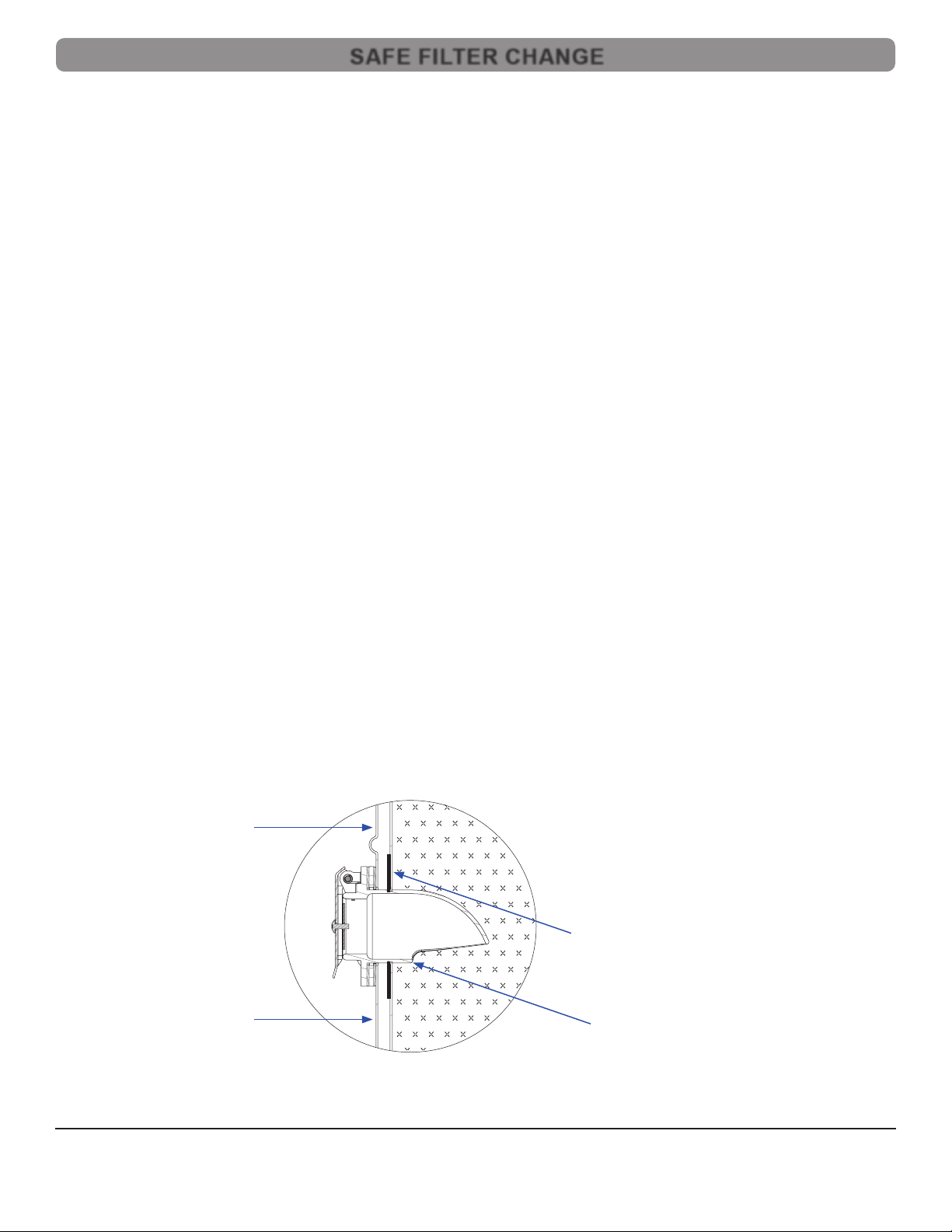

Jam Nut

Delay Valve