Derale Perfomance 15551 User manual

15551-InstructionSheet

Derale Performance, Los Angeles, CA 800.421.6288 www.derale.com

INSTALLATION INSTRUCTIONS

ENGINE OIL COOLER KIT

PART # 15551

KIT CONTENTS

QTY. DESCRIPTION

1 Oil Cooler

1 Spin-On Adapter

1 Adapter Plate

1 Ports Up Filter Mount

1 O-ring (Spin-On Adapter)

1 O-ring (Adapter Plate)

1 Snap Ring

1 3/4-16 Filter Nipple

4 1/2” NPT x 1/2” Hose Barb

3 #14 Sheet Metal Screws

QTY. DESCRIPTION

1 3/4-16 Hex Sleeve Nut

1 13/16-16 Hex Sleeve Nut

1 18mm x 1.5 Hex Sleeve Nut

1 20mm x 1.5 Hex Sleeve Nut

1 22mm x 1.5 Hex Sleeve Nut

10ft 1/2” OEM Spec Hose

5 6” Zip Ties

6 Hose Clamps

4 Mounting Rods

4 Foam Pads

4 Mounting Clips

(Page 1)

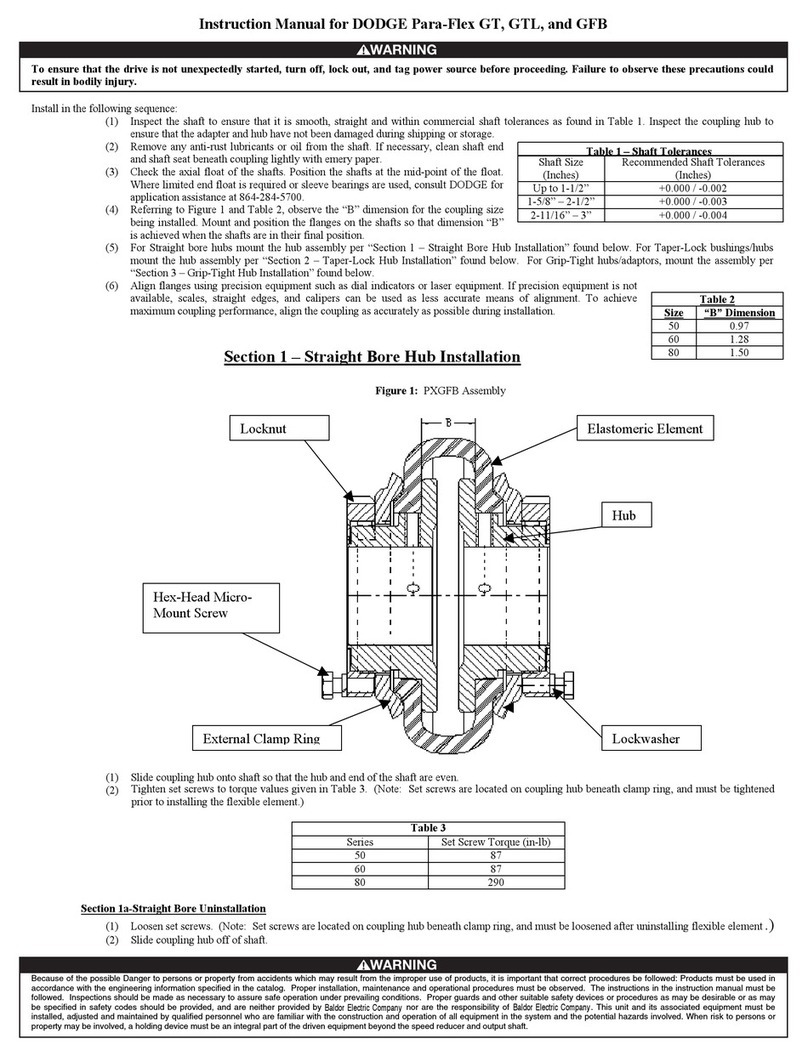

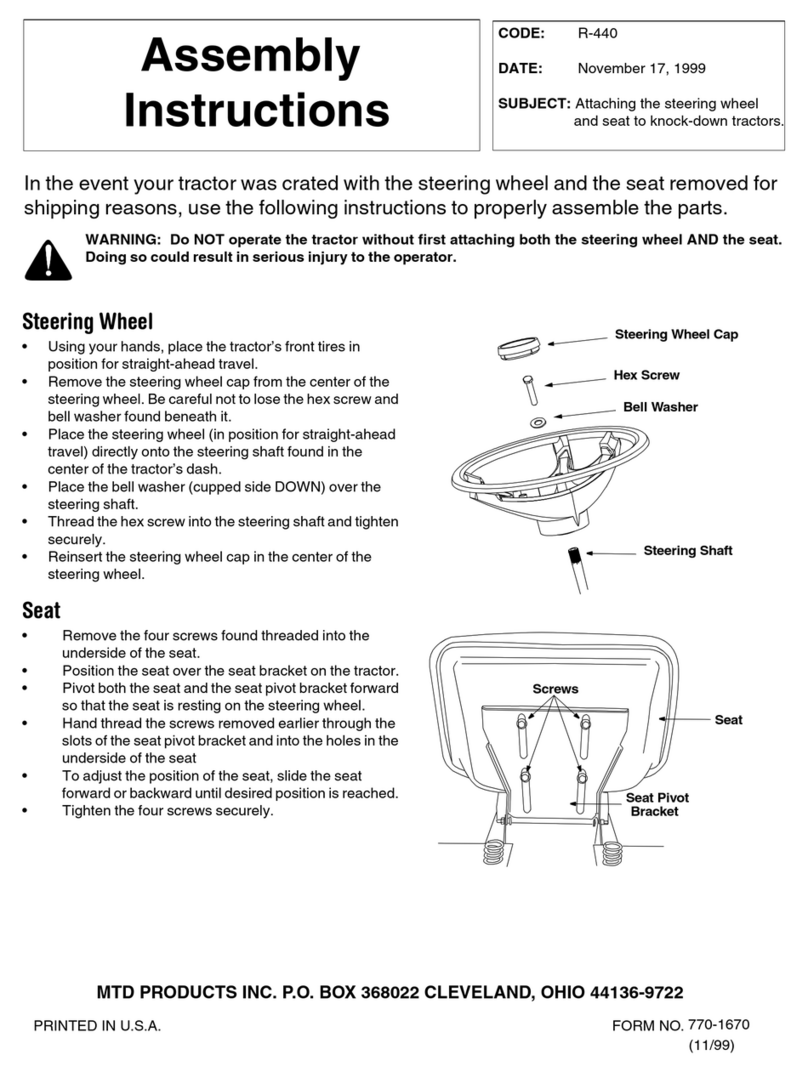

The Oil Cooler can be mounted in multiple locations on your vehicle. Reference Diagram # 1

for possible cooler positions. #1 is the ideal location, #2 is second best and #4 being the last

choice.

Note: The Cooler core will flow in either direction, there is no specified inlet or outlet port.

Diagram #1

TOOLS NEEDED

Standard Screw Driver or

5/16” Nut Driver

Dyke Pliers

Drill and 3/16” Bit

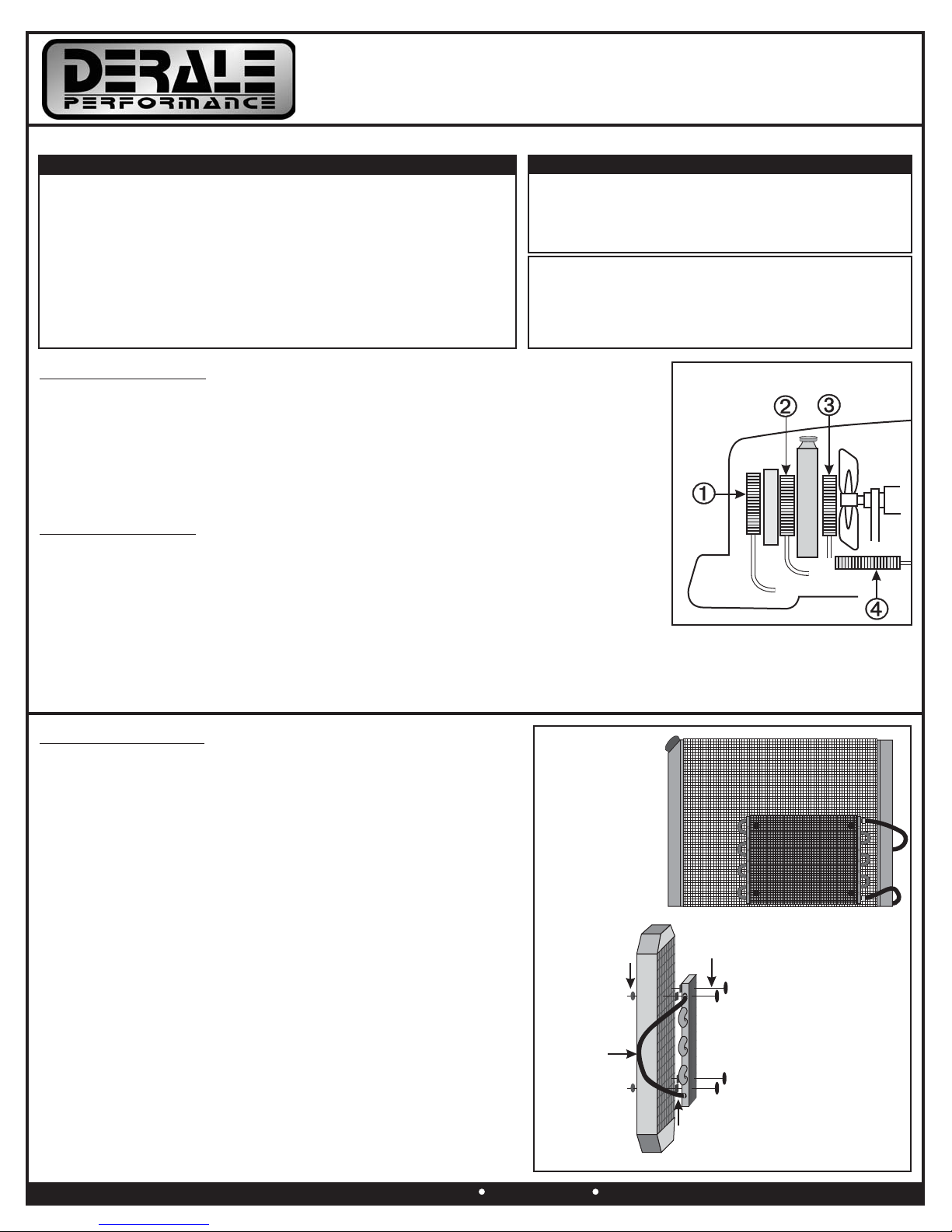

COOLER MOUNTING

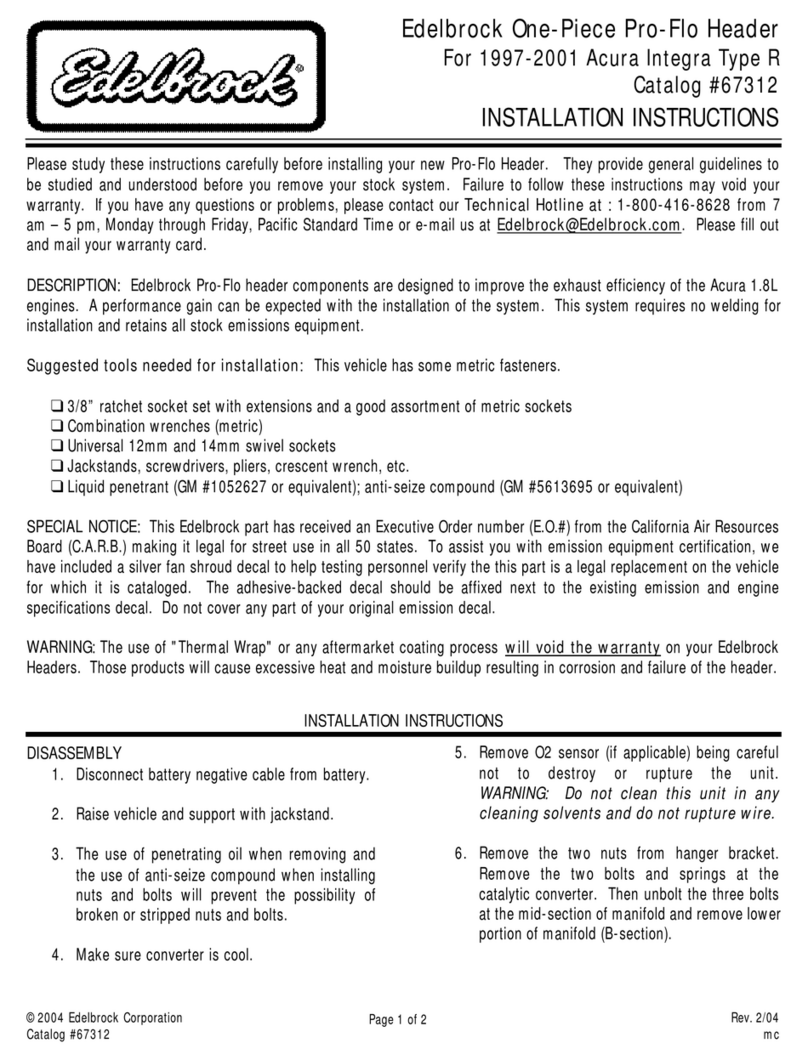

(See Diagram #2)

1. Identify the 4 Mounting Rods, 4 Mounting Clips and

4 1x1 Foam Pads.

2. One by one, Install the 4 Mounting Rods thru the Transmission

Cooler.

3. Take the 1x1 Foam Pads supplied, peel off the paper lining & slide

them onto the Mounting Rods, sticking them against the

Transmission Cooler.

4. Take the Cooler Assembly with attached looped hose and hold in

the desired location.

5. Install the 4 Mounting Rods thru the Radiator/Condenser core.

Warning: Do not use excessive force when pushing the Mounting Rods

through the Radiator/Condenser. Excessive force could cause

damage to the fins and possibly puncture a tube.

6. Take the Mounting Clips supplied, making sure they are in the

correct direction (Derale writing out) install onto the Mounting Rods

and cinch them until the 1x1 Foam Pads are slightly compressed.

7. Cut off any excess Mounting Rods.

7/8” Open End Wrench

11/16” Open End Wrench

1 1/8” Socket

Thread Sealant Tape

Please read these instructions completely before starting the installation.

COOLER LOCATION

When selecting the best location for your vehicle, always consider a location that will

deliver the maximum airflow.

PRE-INSTALLATION

1. Identify the 1/2” NPT x 1/2” Barb Fittings.

2. Using Thread Sealant Tape or suitable sealant, install the two 1/2” NPT x 1/2” Barb Fittings

onto the Spin-On adapter, and two 1/2” NPT x 1/2” Barb Fittings onto the Ports Up filter mount.

3. Identify the 1/2” x 10ft. OEM Spec Hose and Hose Clamps.

4. Slide one hose clamp on each end of the supplied Hose.

5. Using a dab of oil lubricate each end of the hose and install hose onto the the cooler forming a

loop.

6. Secure in place using the Hose Clamps. (See Diagram #2)

Diagram #2

IMPORTANT

This kit is designed to fit vehicles with engine block oil

filter landings ranging from 2 1/2” to 3 1/2”, which

represents 90% of all vehicles.

Mounting

Rods

1x1

Foam Pads

Mounting

Clips

4’ Hose

Derale Performance, Los Angeles, CA 800.421.6288 www.derale.com

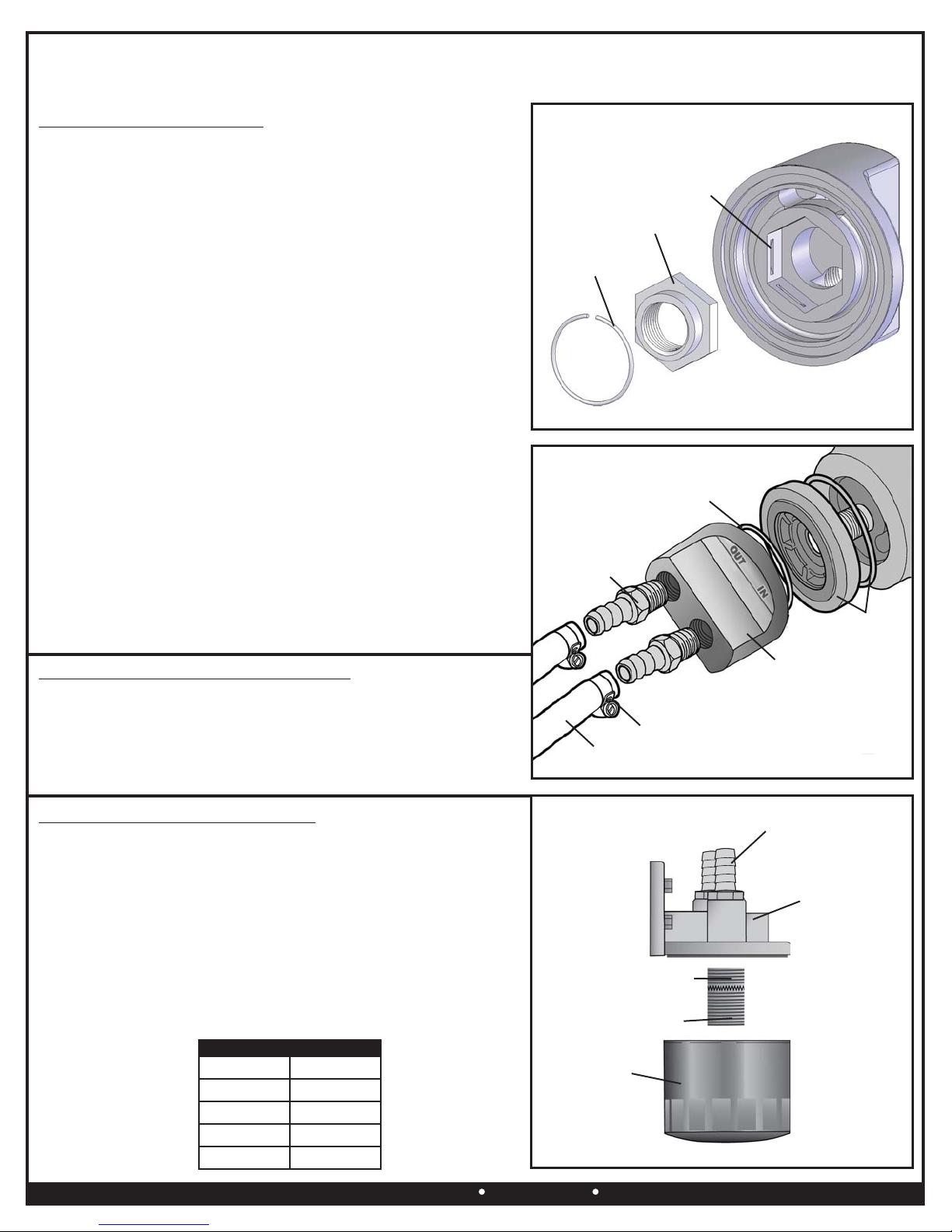

SELECTING COMPONENTS

To easily select the correct components for your application, follow the

steps below. Then proceed to the INSTALLATION section.

Selecting the Spin-on Adapter and/or Adapter Plate

1. Remove the factory oil filter from the vehicle.

2. Using a rag, clean the oil filter landing on the engine.

3. Take the supplied Spin-on Adapter and Adapter Plate.

4. To determine if your application uses the supplied Adapter Plate,

first hold the Adapter Plate up to the oil filter landing on the engine

block. The casting needs to seat directly onto the landing without

obstruction. If the Adapter Plate is too large, then disregard the

Adapter Plate and O-ring. (See Diagram #4)

5. Take the supplied Spin-On Adapter and hold it up the oil filter

landing on the engine block. The casting needs to seat directly onto

the landing without obstruction.

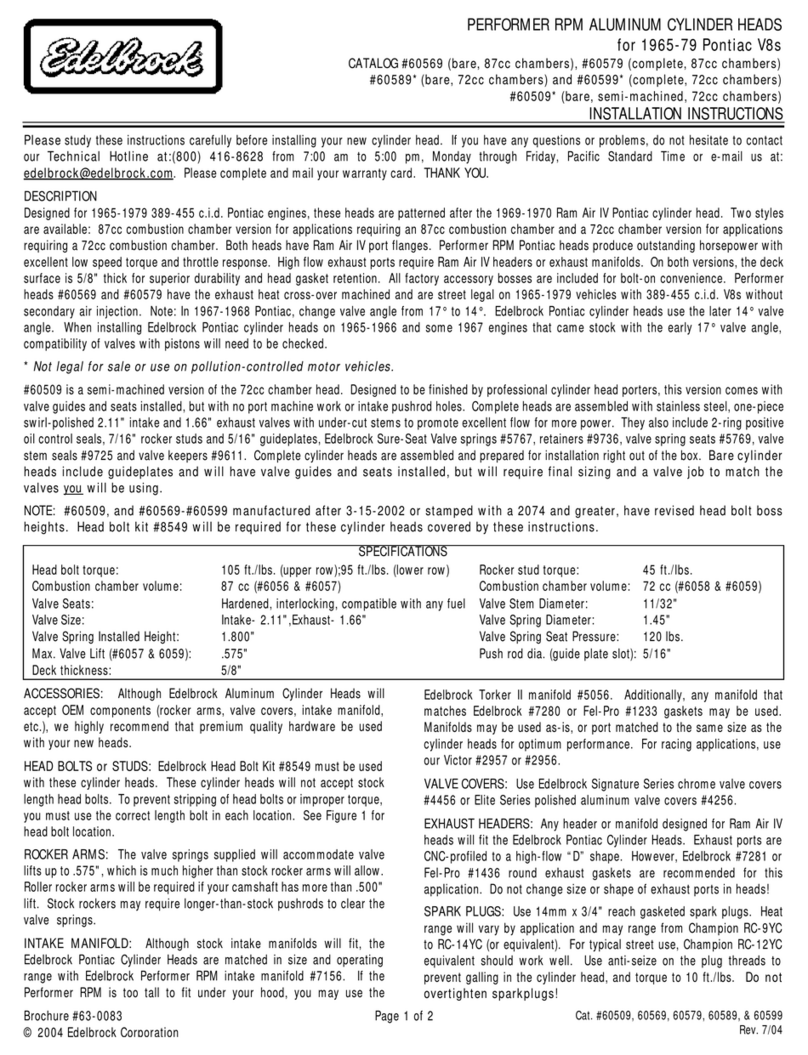

Selecting the Sleeve Nut

1. Take the 5 supplied Sleeve Nuts, try and screw each Sleeve Nut

onto the filter nipple on the engine block until the correct size will

completely thread onto the nipple. Once you have located the

correct Sleeve Nut, disregard the remaining 4 Sleeve Nuts.

2. Take the Sleeve Nut and slide it into the Spin-on Adapters hex

feature. Sleeve Nut will only install correctly in one direction.

(See Diagram #3)

3. Take the supplied Snap Ring and carefully install into the snap ring

groove of the casting making sure it is securely fastened.

(See Diagram #3)

Warning: It is recommended that you were the proper eye protection

when installing Snap Ring.

SPIN-ON ADAPTER INSTALLATION

1. Apply a light coat of oil onto the O-ring(s).

2. Take the O-ring and install into the groove on the Spin-On

Adapter and Adapter Plate (if used).

3. Install onto the engine. (See Diagram #4)

4. Hand Tighten with the same force used in tightening a factory oil filter.

(Page 2)

Important: The Adapter Plate & O-ring are designed to fit vehicles with a 3 1/2” filter landing. Primarily 1963-2007

GM SB & BB V-8 engines.

There are 5 supplied Sleeve Nuts in this kit. Only 1 Sleeve Nut will be used for your application.

Snap

Ring

Hex Sleeve

Nut

Snap Ring

Groove

Optional

Adapter Plate

& O-ring

Hose

Clamp

1/2” Hose

1/2” NPT x 1/2”

Hose Barb

Spin-On

Adapter

Spin-On

Adapter

O-ring

Diagram #4

Diagram #3

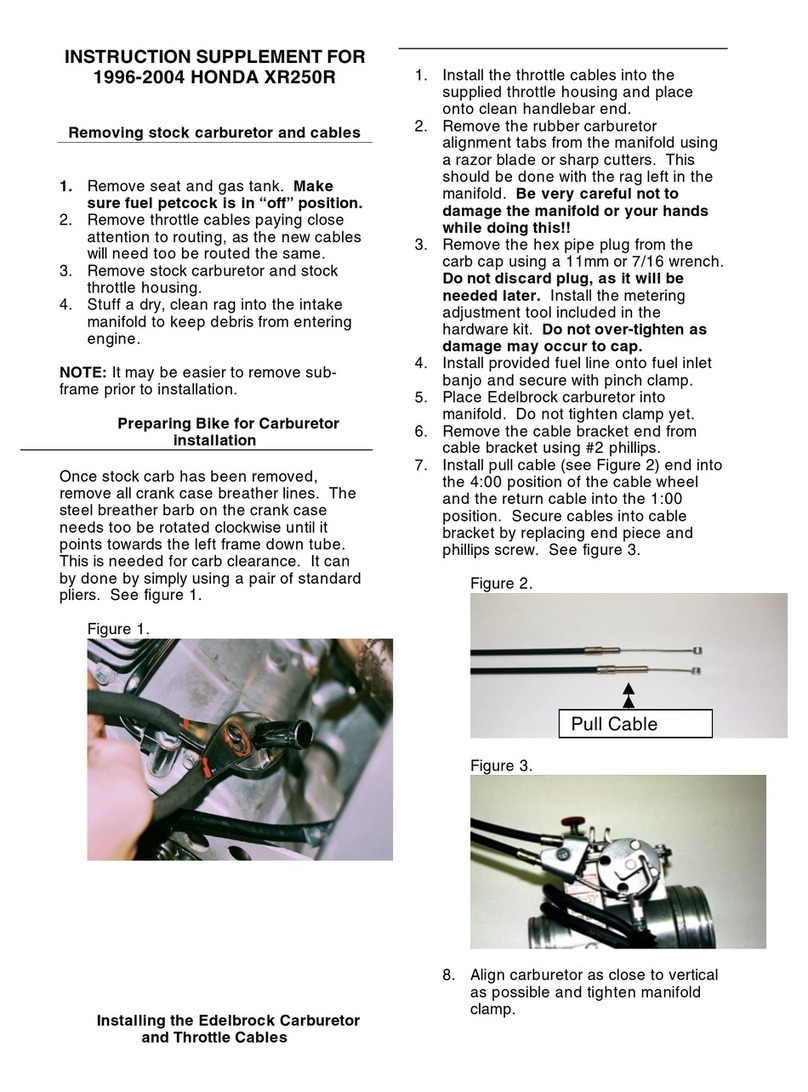

FILTER MOUNT INSTALLATION

1. Choose a convenient location for the Ports-Up Filter Mount. Make

sure there is enough space for future servicing of the oil filter.

Suggested Locations: Firewall, Radiator Support, Fender well.

2. Take the 3/4-16 Filter Nipple supplied, making sure the shorter end

of threads is installed onto the Ports-Up Filter Mount.

(See Diagram #5)

3. Using the filter mount as a template, mark and drill three 3/16” holes.

4. Using the #14 Sheet Metal Screws provided, install the Ports-Up

Filter Mount onto the vehicle.

Important: The new Filter Mount is designed to accept a 3/4-16 oil

filter Use Derale Part # 13092 or reference chart below for.

manufacturers part numbers.

Diagram #5

Oil Filter

3/4-16

Filter Nipple

Filter Mount

Short End Screws

into Filter Mount

1/2” NPT x 1/2”

Hose Barb

BRAND

AC

Fram

Motorcraft

Purolator

PART #

PF2

PH8A

FL1A

PER1A

OIL FILTER CHART

Derale Performance, Los Angeles, CA 800.421.6288 www.derale.com

VEHICLE TESTING

1. Start the engine and quickly check all connections for leaks.

2. Turn-off the engine and check oil level.

3. Add oil as needed.

ROUTING HOSES

Note: The Cooler core will flow in either direction; there is no specified inlet or outlet port.

Important: The oil flow direction should go in the following order: Engine, Ports Up Filter Mount, Oil Cooler, and then back to the

Engine. (See Diagram #6)

1. Using the remaining four Hose Clamps supplied, route the looped hose from the Oil Cooler along the frame toward the Ports

Up Filter Mount and/or the Spin-on Adapter.

Note: When routing hoses, be sure to keep all hoses away from sharp edges, moving parts and hot engine components. Hoses

should be routed carefully and should not be bent in less than a 5” radius.

2. Attach either hose coming from the Oil Cooler to the “OUT” port on the Ports Up Filter Mount.

3. Attach the remaining hose on the Oil Cooler to the “IN” port on the Spin-on Adapter.

4. Attach a hose from the “OUT” port on the Spin-on Adapter to the “IN” port on the Ports Up Filter Mount.

5. Apply a light coat of oil onto the O-ring of your new oil filter and install on the Ports Up Filter Mount.

Warning: Installation of accessories should only be undertaken by those with mechanical knowledge and are familiar with working on

vehicles. Always use eye protection (goggles, safety glasses or shield). Park the vehicle in a well lit area, on level ground and apply the

parking brake. Only work on a cold vehicle that has been sitting overnight, failure to do so will result in severe burns and injury. Before starting

the vehicle, make sure no tools or any other items are left under hood that could interfere with or be drawn into moving parts of the engine.

Failure to follow instructions can lead to severe damage and personal injury.

(Page 3)

Spin-On

Adapter

Ports Up

Filter Mount

Oil

Cooler

Fire Wall

Diagram #6