Because of the possible Danger to persons or property from accidents which may result from the improper use of products, it is important that correct procedures be followed: Products must be used in

accordance with the engineering information specified in the catalog. Proper installation, maintenance and operational procedures must be observed. The instructions in the instruction manual must be

followed. Inspections should be made as necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety devices or procedures as may be desirable or as may

installed, adjusted and maintained by qualified personnel who are familiar with the construction and operation of all equipment in the system and the potential hazards involved. When risk to persons or

property may be involved, a holding device must be an integral part of the driven equipment beyond the speed reducer and output shaft.

Instruction Manual for DODGE Para-Flex GT, GTL, and GFB

To ensure that the drive is not unexpectedly started, turn off, lock out, and tag power source before proceeding. Failure to observe these precautions could

result in bodily injury.

Install in the following sequence:

(1) Inspect the shaft to ensure that it is smooth, straight and within commercial shaft tolerances as found in Table 1. Inspect the coupling hub to

ensure that the adapter and hub have not been damaged during shipping or storage.

(2) Remove any anti-rust lubricants or oil from the shaft. If necessary, clean shaft end

and shaft seat beneath coupling lightly with emery paper.

(3) Check the axial float of the shafts. Position the shafts at the mid-point of the float.

Where limited end float is required or sleeve bearings are used, consult DODGE for

application assistance at 864-284-5700.

(4) Referring to Figure 1 and Table 2, observe the “B” dimension for the coupling size

being installed. Mount and position the flanges on the shafts so that dimension “B”

is achieved when the shafts are in their final position.

(5) For Straight bore hubs mount the hub assembly per “Section 1 – Straight Bore Hub Installation” found below. For Taper-Lock bushings/hubs

mount the hub assembly per “Section 2 – Taper-Lock Hub Installation” found below. For Grip-Tight hubs/adaptors, mount the assembly per

“Section 3 – Grip-Tight Hub Installation” found below.

(6) Align flanges using precision equipment such as dial indicators or laser equipment. If precision equipment is not

available, scales, straight edges, and calipers can be used as less accurate means of alignment. To achieve

maximum coupling performance, align the coupling as accurately as possible during installation.

Section 1 – Straight Bore Hub Installation

Figure 1: PXGFB Assembly

Tighten set screws to torque values given in Table 3. (Note: Set screws are located on coupling hub beneath clamp ring, and must be tightened

prior to installing the flexible element.)

Table 3

Series Set Screw Torque (in-lb)

50 87

60 87

80 290

Section 1a-Straight Bore Uninstallation

(1) Loosen set screws. (Note: Set screws are located on coupling hub beneath clamp ring, and must be loosened after uninstalling flexible element

.)

(2) Slide coupling hub off of shaft.

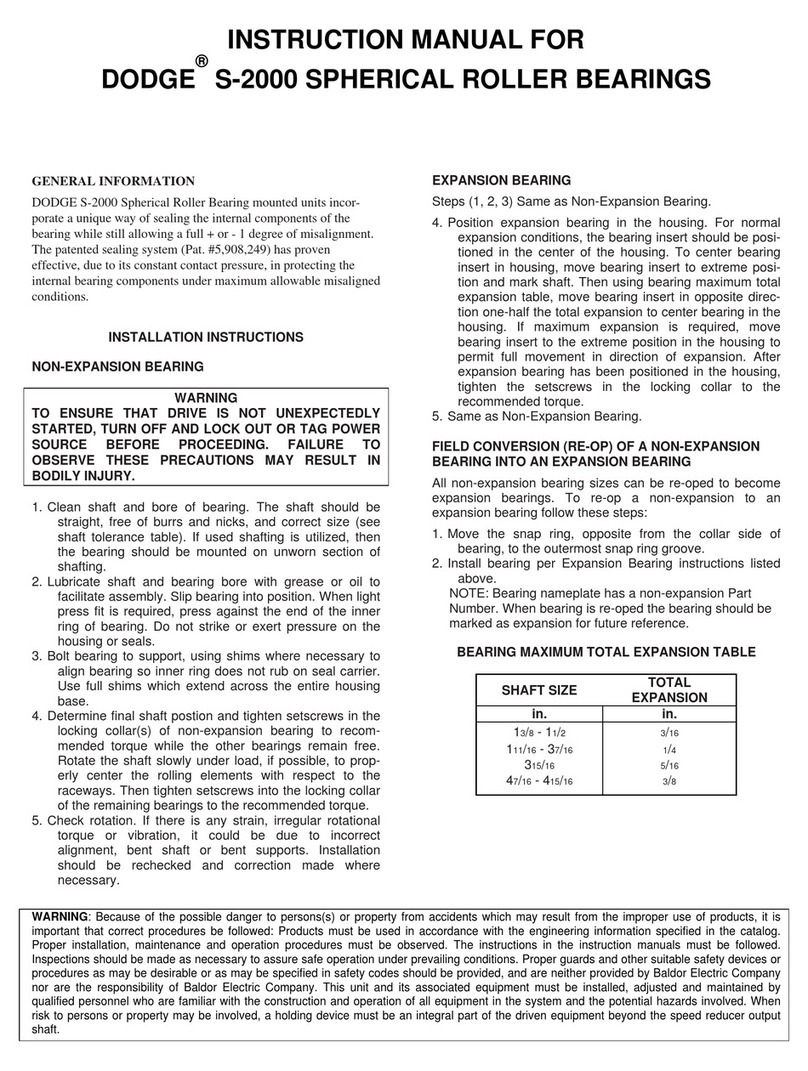

Table 1 – Shaft Tolerances

Shaft Size

(Inches)

Recommended Shaft Tolerances

(Inches)

Up to 1-1/2” +0.000 / -0.002

1-5/8” – 2-1/2” +0.000 / -0.003

2-11/16” – 3” +0.000 / -0.004

Table 2

Size “B” Dimension

50 0.97

60 1.28

80 1.50

External Clam

Rin

Locknu

Hex-Head Micro-

Mount Screw

Elastomeric Elemen

Hub

Lockwashe

Slide coupling hub onto shaft so that the hub and end of the shaft are even.(1)

(2)

WARNING

WARNING

Baldor Electric Company

. This unit and its associated equipment must bebe specified in safety codes should be provided, and are neither provided by nor are the responsibility of

Baldor Electric Company