Derbi ATV DXR 200 Instruction manual

ATV DXR 200

WORKSHOP MANUAL

1

The work-shop (or service) manual is mainly for NACIANAL MOTOR, S.A.U. Area importers and their net-

work dealers & service stations to fulfill the necessary maintenance and repairs information.

1. Due to continuous launch of new models, formation in this manual may be subject to change without

notice. For any further information regarding this manual or the products, please contact the Territorial

Distributor or Area Importer.

2. All details of this manual are based on the latest product information available at the time of approval

for printing. Maker reserves the right to make changes at any time without notice and without incurring any

obligation.

3. This manual has been specially prepared to provide the necessary information for the Area importer,

dealers, and their qualified mechanics of proper maintenance and repair details.

4. This manual covers all series of products (RAM 125/150) that user has to find out what details belong to.

By: Sales and Service Department NACIANAL MOTOR, S.A.U.

* The images reflected in this manual can vary of the acquired pattern.

For Area Importer and Territorial Distributor:

* All rights reserved. No part of this manual may be reproduced or unauthorized use in any form or by any

means, without prior permission of the Maker, NACIONAL MOTORS. S.A.U.

http: www.derbi.com

NACIONAL MOTOR, S.A.U.

3

PART 1. GENERAL INFORMATION

l-0l. Service Precautions

1-02.Briefing Service Information

1-03.Cleaning

1-04.Storage

PART 2. SPECIFICATION

2-01.General Specification

2-02.Location & Cable Routing

2-03.Torque Value

2-04.Special Tools -- OPTION (reference)

PART 3. PERIODIC MAINTENANCE AND ADJUSTMENT

3-01.Caution of periodic maintenance

3-02.Owner’s manual and tool kit

3-03.Periodic maintenance table

3-04.Engine oil (4-stroke)

3-05.Spark plug inspection

3-06.Air cleaner cleaning

3-07.Idle speed adjustment

3-08.Throttle lever adjustment

3-09.Speed limited adjustment

3-10.Front drum brake inspection

3-11.Rear disc brake - fluid inspection

3-12.Front brake lever free play adjustment

3-13.Parking brake adjustment

3-14.Clutch adjustment

3-15.Drive chain slack check and adjustment

3-16.Cable inspection and lubrication

3-17.Upper and lower arm pivot lubrication

3-18.Steering shaft inspection & lubrication

3-19.Ton-in adjustment

3-20.Front shock absorber adjustment

Pág. 9

Pág. 11

Pág. 12

Pág. 13

Pàg. 14

Pág. 16

Pág. 19

Pág. 21

Pág. 23

Pág. 23

Pág. 24

Pág. 26

Pág. 28

Pág. 29

Pág. 31

Pág. 31

Pág. 31

Pág. 31

Pág. 31

Pág. 33

Pág. 33

Pág. 35

Pág. 35

Pág. 37

Pág. 37

Pág. 37

Pág. 39

Pág. 39

4

3-21.Rear shock absorber adjustment -- option

3-22.Tire inspection

3-23.Tire wear limit

3-24.Wheel removal and installation

3-25.Replacing the headlight

3-26.Replacing the rear-light

3-27.Battery charging system

3-28.Battery removal

3-29.Fuse

3-30.Fuel tank

3-31.Engine Adjustment

PART 4. ENGINE DETAILS

4-01.Fuel System and Carburetion

4-02.Lubrication System

4-03.Engine Removal/Installation

4-04.Cylinder Head/Valve

4-05.Cylinder/Piston

4-06.Starter/Generator/L Crankcase/Start Clutch/Camshaft

4-07.Clutch/Gear Shift Mechanism

4-08.Crankcase/Crankshaft/Transmission/Starter Spindle

PART 5. CHASSIS DETAILS

5-01.Front Wheel/Front Brake

5-02.Rear Wheel/Rear Axle

5-03.Rear Brake

5-04.Steeling System

5-05.Front Shock Absorber and Front Arm

5-06.Rear Shock Absorber and Swing-Arm

5-07.Drive Chain and Sprocket

Pág. 39

Pág. 41

Pág. 42

Pág. 43

Pág. 43

Pàg. 43

Pág. 43

Pág. 45

Pág. 45

Pág. 45

Pág. 47

Pág. 52

Pág. 57

Pág. 61

Pág. 65

Pág. 73

Pág. 81

Pág. 87

Pág. 93

Pág. 104

Pág. 111

Pág. 119

Pág. 123

Pág. 130

Pág. 136

Pág. 143

5

PART 6. ELECTRIC DETAILS

6-01.Service Precautions(Electric Devices)

6-02.Ignition System

6-03.Charging System

6-04.Starting System

6-05.Lights/Instruments/Switches

PART 7. TROUBLE-SHOOTING

7-01.Engine does not start or hard to start

7-02.Poor performance (especially at low and idle speed)

7-03.Poor performance (engine lacks power)

7-04.Poor performance (at high speed)

7-05.Poor charging (battery over discharge or overcharge)

7-06.Spark plug has no function

7-07.F. or R. Brake Performance Poorly

7-08.Shock Absorber Malfunction

7-09.Instable Handling

PART 8. APPENDIX:

8-01.Notes of Pre-Delivery Inspection

8-02.UPDATE information - 170cc & BLAST model

8-03.UPDATE information - EEC 92\61 On Road Model

Pág. 149

Pág. 153

Pág. 159

Pág. 165

Pág. 171

Pàg. 179

Pág. 180

Pág. 181

Pág. 184

Pág. 185

Pág. 186

Pág. 187

Pág. 187

Pág. 188

Pág. 189

Pág. 191

Pág. 192

6

1-1 IMPORTANT SAFETY MESSAGE

BE SURE TO INFORM THE END-USER FOLLOWS;

1 . TO READ THE OWNER MANUAL CAREFULLY AND COMPLETELY BEFORE OPERATING THE ATV. . MAKE

SURE THE END-USER UNDERSTAND ALL INSTRUCTIONS.

2. PAY ATTENTION TO THE WARNING AND CAUTION. LABELS ON THE ATV.

3. ANY ATV OVER 90cc SHOULD NOT BE RIDDEN BY ANYONE UNDER 16 YEARS OF AGE. (or REFER THE

LOCAL RIDING LAWS AND REGULATIONS)

1-2. IMPORTANT INFORMATION

FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THE OWNER MANUAL CAN RESULT IN SERIOUS

INJURY OR DEATH.

The important information shown in this manual in texts or symbols is described as follows;

Failure to follow “ 1 WARNING “ instructions could result in severe injury or death to the ATV rider, an on-

looker, or a worker inspecting or repairing the ATV.

“ CAUTION “ marks special precautions that must be taken to avoid damage 10 the ATV.

“ NOTE “ provides principal information.

“ OPTION or APPENDIX “ provides others specification of product.

1-3. IMPORTANT NOTICE

The ATV is designed and built for OFF-ROAD use only. It is illegal and risky to manual this ATV on any public

street, road or highway. Any Working Machine or On-Road base usage should follow the area laws and re-

gulations, which all details should be provided and informed by each Area Importer.

Be sure to check the local area riding laws and regulations before riding this ATV.

7

8

9

PART 1. GENERAL INFORMATION

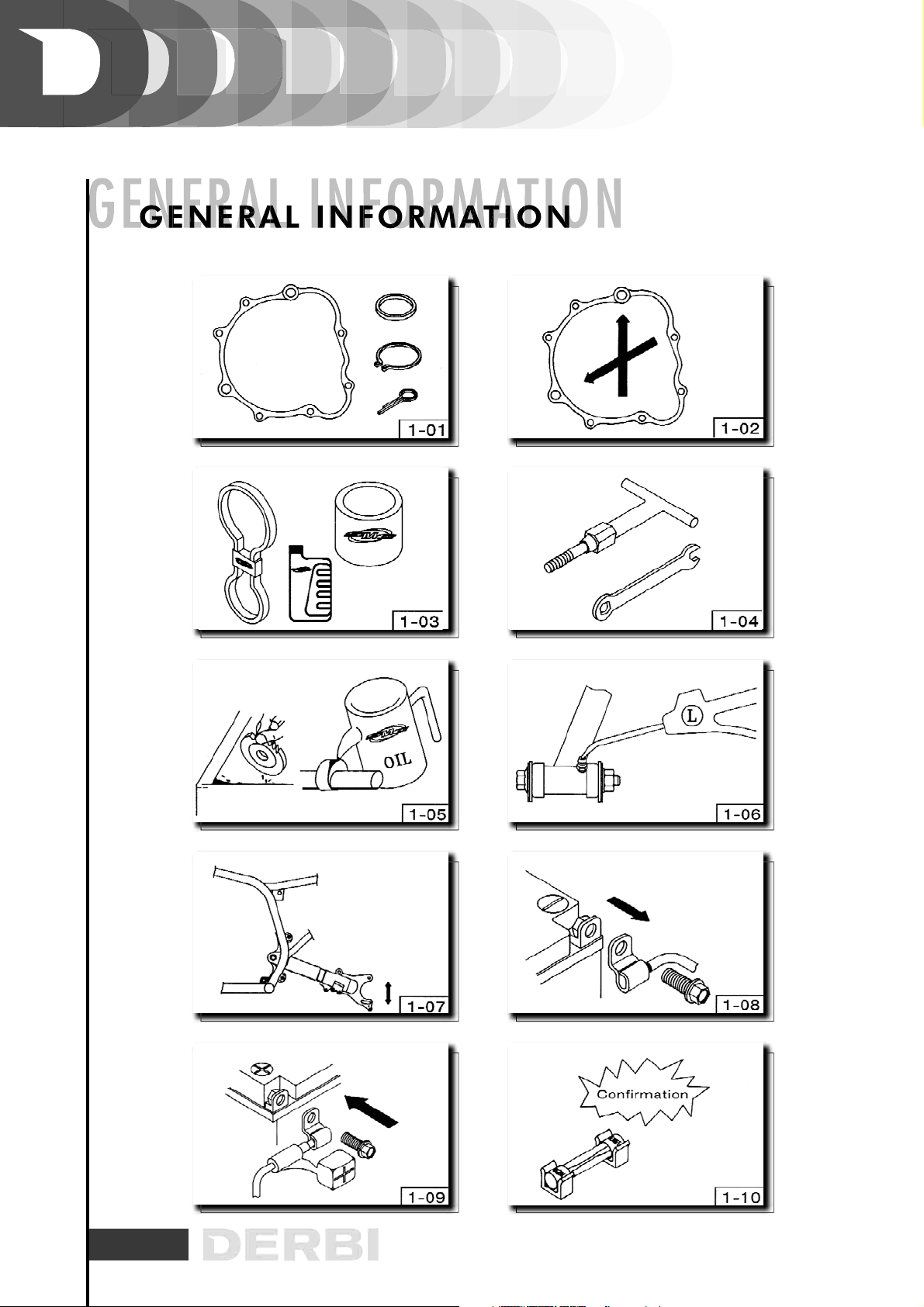

1-1. SERVICE PRECAUTIONS

01. Be sure to use the new gaskets, o-rings, ring clamps, cotter pins... during the re-assembly or any service.

(Fig. 1-01).

02. When tightening bolts, screws, or nuts, should start with large diameter boles to smaller ones. Be tighten

to the specified torque diagonally. (Fig. 1-02)

03. Only use genuine parts and lubricants as Maker’s suggestion (Fig. 1-03)

04. On servicing vehicle, be sure to use the special or common tools (Fig. 1.04)

05. After disassembly, be cleaned all the removed parts. Lubricate sliding surfaces with engine oil on engine

parts before reassembly (Fig. 1-05).

06. Apply designated greases and lubricants to the specified lubrication points. (Fig. 1-06)

07. After reassembly, check all parts for proper tightening and operation. (Fig. 1-07)

08. Disconnect battery negative (-) terminal before operation. (Fig. 1-08)

09. When connecting the battery, the positive (+) terminal should be connected first. After connection, apply

grease to battery terminals. The terminal caps shall be installed securely. (Fig. 1-09)

10. If the fuse is burned out, only replace the new fuse with the specified capacity. (Fig. 1-10)

11. When using a spanner or other tools, make sure not to damage the vehicle’s surface.

12. After service operation, check all connecting points, fasteners and lines for proper connection and

installation.

PART

1.

GENERAL

INFORMATION

10

11

1-2. BRIEFING SERVICE INFORMATION

WARNING

TO AVOID THE ENGINE RUNNING DURING REPAIR OR SERVICE, THE EXHAUST SMOKE CONTAINS POISO-

NOUS CARBON MONOXIDE GAS WHICH MAY CAUSE SERIOUS INJURY OR DEATH.

SOLUTION

1. Never run the engine in a close area.

2. If need to run the engine, be sure the working area is well ventilated and do not allow any flames or spark

in working area.

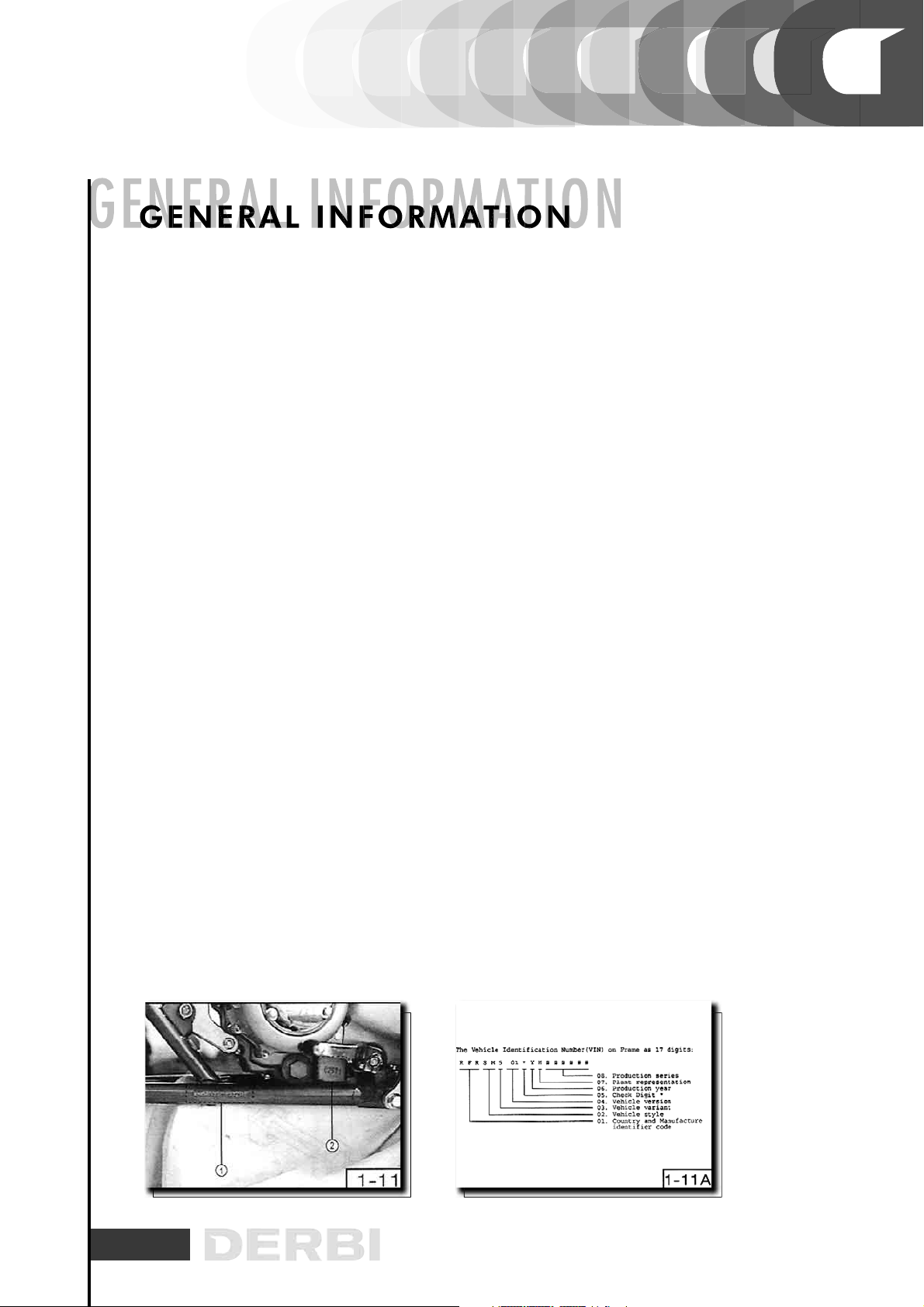

1-2-1. Identification numbers(Fig. 1-11, I-IIA)

01. The vehicle identification number (VIM) marks on the frame.

02. Engine number is marked on the engine.

1-2-2. Engine : details refer to Pare 4

01. Cylinder compression: 13 Kg./cm2

02. Idle speed: 1.500 +/- 100 rpm

03. Valve clearance: IN =0,05 mm EX = 0,05 mm

04. Ignition timing: 15 degree/I,500 rpm

05. Engine oil (4-stroke): disassembly = 1.1L change = l.0 L

1-2-3. Chassis/Frame: details refer to Part 5

01. Front brake lever free play: 10-20mm

02- Rear brake pedal free play : 10-20mm

03. Brake fluid: DOT 3 or DOT 4

1-2-4. Tire pressure --- details refer to Part 3

01. Front tire: 30 kPa (0.30kgf/cm 2;4.4psi)

02. Sear tire: 25 kPa (0 .25kgf/cm 2 ; 3 . 6psi)

1-2-5. Lubrication portion -- refer to Pare 4 & 5 details

12

1-3. CLEANING

Clean ATV regularly to protect the surface finishes and check for the damage, wear, and oil or brake fluid

leakage will enhance ATV overall appearance and general performance.

01. Block off the end of the exhaust pipe to preven 1 water entry. Next. make sure the spark plug and fuel

caps are fastened.

02. If engine case is greasy, apply de-greaser with a paint brush. Do not apply de-greaser to the chain,

sprockets or wheel axles.

03. Use only enough pressure to rinse the dirt.

CAUTION

HIGH PRESSURE WATER OR AIR MAY DAMAGE CERTAIN PARTS SUCH AS WHEEL BEARINGS, BRAKES,

TRANSMISSION SEALS AND ELECTRICAL DEVICES.

04. Use the cool water to remove dirt. Once the majority of the dirt has been taken off, wash all surfaces with

warm water and mild, detergent-type soap.

05. Rinse the ATV off immediately with clean water and dry all surfaces with a chamois, clean towel or soft

absorbent cloth.

06. Dry the chain and lubricate it to prevent rust.

07. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and glossy.

08. Automotive wax can be used on all painted and chrome plated surfaces. Avoid combination cleaner-

waxes.

09. When finishing, start the engine and let it run for several minutes. Finally, test the brakes.

WARNING

POTENTIAL HAZARD: OPERATION WITH WET BRAKES AFTER WASHING.

AWARENESS

WET BRAKES MAY HAVE REDUCED STOPPING ABILITY, INCREASING THE CHANCE OF AN ACCIDENT.

SOLUTION

TEST THE BRAKES AFTER WASHING. APPLY THE BRAKES SEVERAL TIMES AT SLOW SPEEDS TO LET FRICTION

DRY OUT THE LININGS.

13

1-4. STORAGE

Before long term storage (says 60 days or more), be sure to check the ATV for needed repairs and have it

corrected.

01. Change engine oil and oil filter.

02. Drain the fuel from tank and carburettor.

03. Clean the spark plug and put about 20-25cc engine oil (SAE 10W30 or 20W40) into the cylinder. Start

engine for a few seconds.

04. Spray anti-rusty (rust-inhibiting) oil into the inside of fuel tank.

05. Clean the drive chain thoroughly and lubricate it.

06. Lubricate all control cables.

07. Remove the battery. Be sure to re-charge battery before storage. Do not put the battery on hot or cold

place.

08. Check the tire pressure and block up the frame to raise all wheels off the ground.

09. Wash and dry the ATV and wax all painting surfaces.

10. Cover a plastic bag over the exhaust pipe.

11. Do not apply oil to any rubber parts or the seat cover.

NOTE

MAKE ANY NECESSARY REPAIRS BEFORE STORING THE ATV.

14

PART 2. SPECIFICATION

2-1. GENERAL SPECIFICATION

Dimension L/W/H: 1.610 / 1.35 / 1.010 mm or 634/40. 7/39. 7in

Seat height 770 mm or 30.3in

Wheel base 1.080 mm or 42.5in

Min. ground clearance 120 mm

Min. turning radius 3.000 mm

Weight (125/50) 152 Kg. / 154 Kg.

Engine 4 Stroke Air-Cooled

Cylinder Single - Forward Inclined

Bore * Stroke 125 cc: 56,5 x 49,5 mm; 150 cc: 62 x 49,5 mm

Displacement: 124,5 cm3; 149,5 cm3

Carburettor DTG-017 o PD-19D KEIHIN

Spark DR-8EA NGK

Starting Electric

Ignition C.D.I.

Generator ACG Fly Wheel Magneto

Battery YUASA YTX 7A-BS

Engine Oil 4 Stroke (qualified synthetic oil)

Engine Oil capacity 1,10 l.

Air- Filter Wet type element

Transmission National 5 speeds

Primary reduction Helical gear

Primary red. Ratio 4,055 (73/18T)

Secondary reduction drive chain

Secondary red. Ratio 3,333 (40/12T)

Operation Left foot operation

Gear ratio

1st: 2,769 (36/13T)

2nd: 1,882 (32/17T)

3rd: 1,272 (28/20T) or 1,4 (28/20T)

4th: 1,130 (26/23T)

5th: 0,960 (24/25T)

PART

2.

SPECIFICATION

15

Clutch type Wet, multi-blade

Operation Left hand operation

Fuel type Unleaded gasoline

Fuel tank capacity 8,0 L (1,76 lmp gal; 2,12 US gal)

Reserve fuel 2,0 L (0,44 lmp gal; 0,53 US gal)

Chassis type Steel tube frame

Caster angle 9.0 degree

Trail 40mm (1.57 in)

Suspension (F/R) double A wishbone/swing arm

Shock absorber coil spring, oil damper

Brake system (F/R) double drum/single disc

Front drum brake Right hand operation

Rear disc brake Right, foot operation

Rim steel

Front 10 x 5,5 AT

Rear 8 x 8,0 AT

Wheel travel (F/R) 180mm (7.09in)/180mm (7.09in)

Headlight type bulb type

Front 12V 18W/18W x 2

Rear 12V 21W x 1

Indicator (neutral) 12V 3,4W x 1

Fuse 15A, 250V

NOTE

THE ATV Z-S DESIGNED FOR OFF-ROAD USE MAINLY. TO MATCH DIFFERENT AREA REGULATION, ATV

MAY CHANGE OR INSTALL EXTRA DEVICE TO MATCH AREA SPECIAL REQUIREMENT SUCH AS “WORKING

MACHINE” OR “ON ROAD”.

FOR ANY QUESTIONS REGARDING THE DIFFERENT SPECIFICATION, PLEASE CONTACT THE AREA

IMPORTER.

16

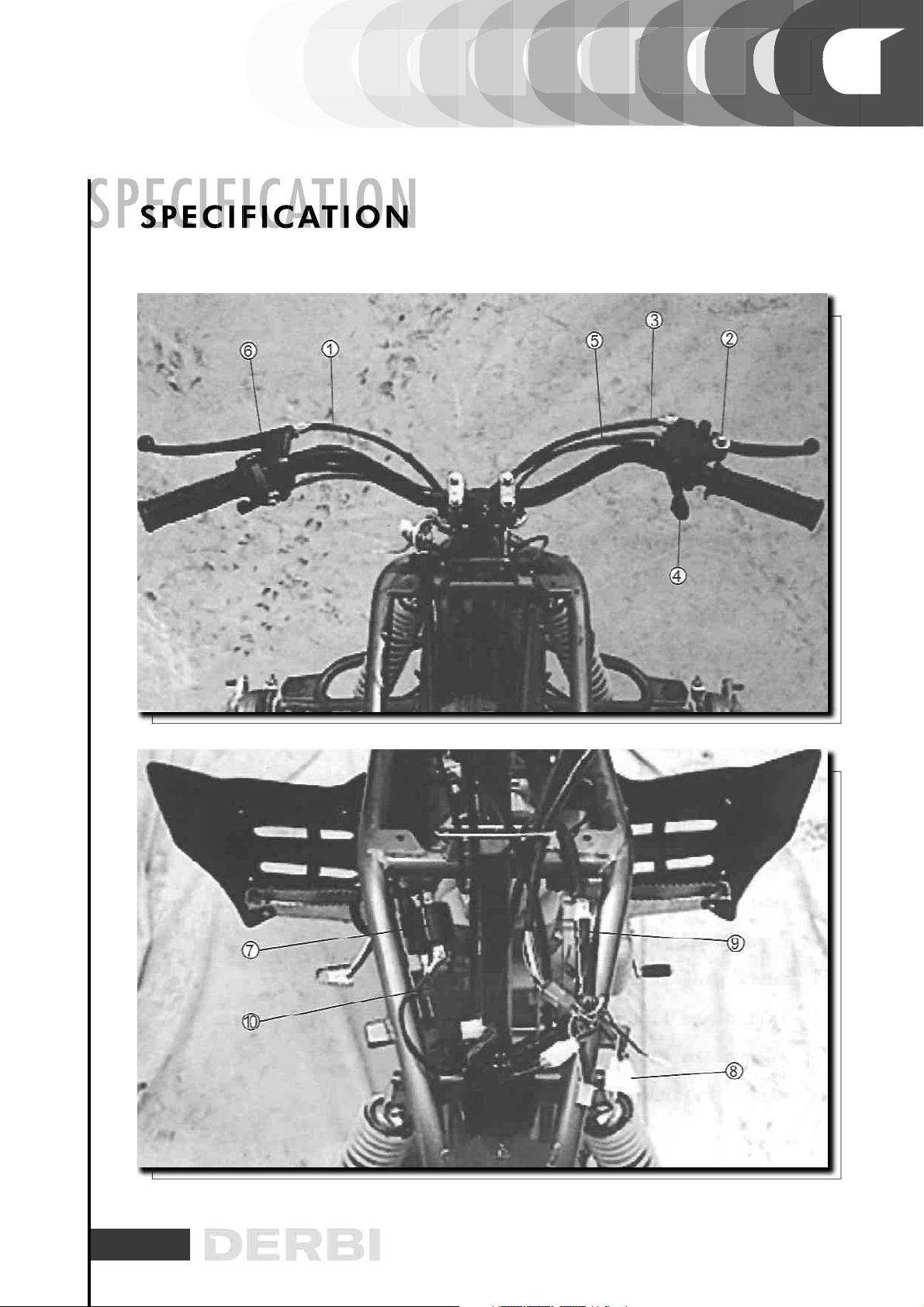

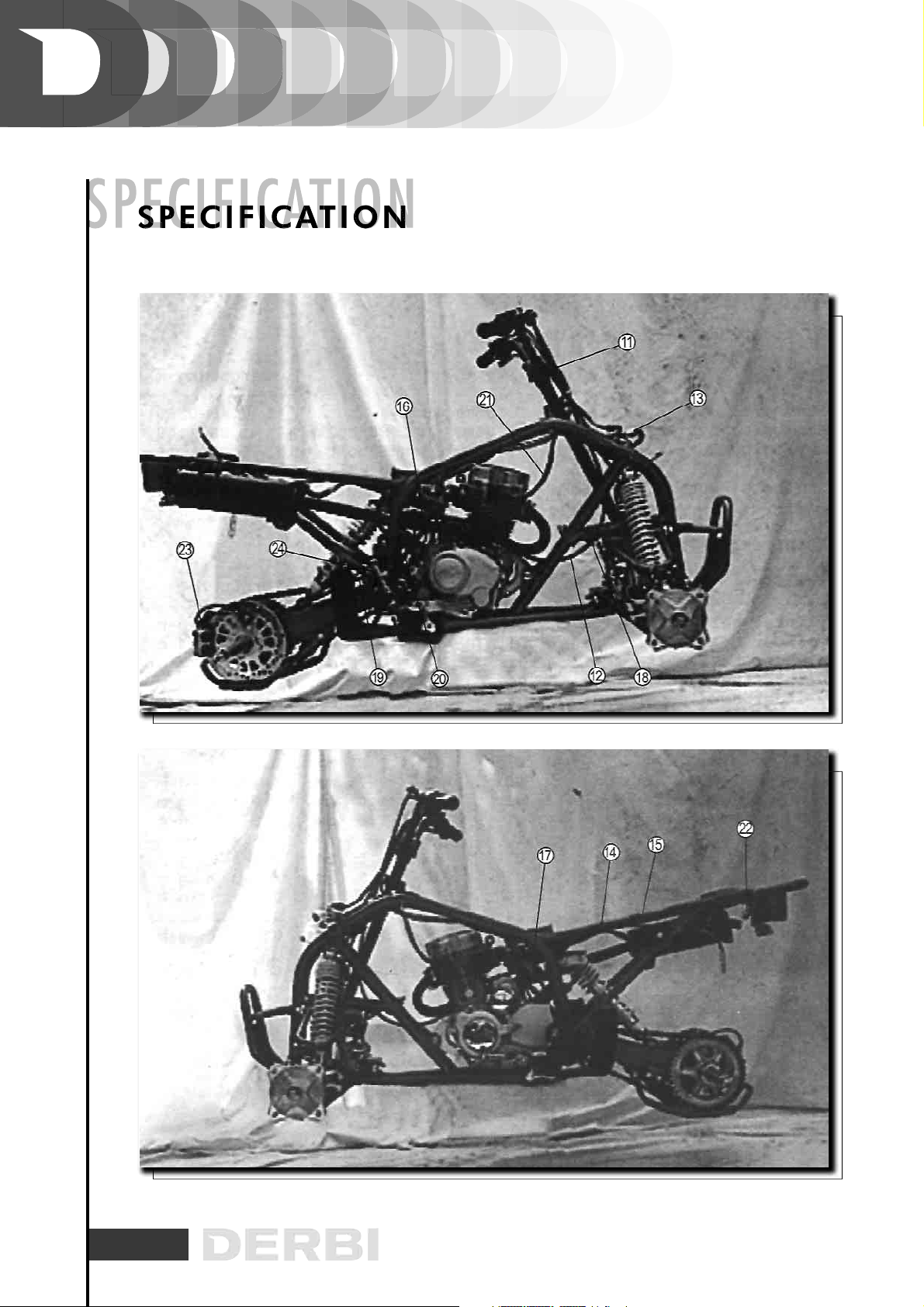

2-2. LOCATION & CABLE ROUTING

01. Clutch cable

02. Parking brake cable

03. Front brake cable

04. Throttle switch lead

05. Throttle cable

06. Handlebar switch

07. Voltage regulator lead

08. Main switch

09. Wire harness

10. Ground lead

11. Front brake cable

12. Clutch cable

13. Main switch lead

14. Wire holder

15. Clamp

16. Carburettor overflow hose

19. Flywheel magneto lead

18. Cable guide

19. Rear brake cable

20. Crankcase ventilation hose

21. Spark plug lead

22. Tail/brake light lead

23. Rear brake fluid reservoir

24. Master cylinder

17

18

19

2-3. TORQUE VALUE

2-3-1. Standard Torque Value

2-3-2. Engine Pares Torque Value

Cylinder head oil-check bolt 01 06 * 1,0 mm 0,8-1,2 Kg.-m

Oil filter lock nut 01 16 * 1,0 mm 4,0-5,0 Kg.-m

Oil Rotor cap nut 03 05 * 0,8 mm 0,4-0,8 Kg.-m

Oil pump bolt 02 06 * 1,0 mm 0,7-1,1 Kg.-m

Carburettor lock bolt 02 06 * 1,0 mm 0,8-1,2 Kg.-m

Exhaust pipe joint lock nut 02 06 * 1,0 mm 0,8-1,2 Kg.-m

Rock arm lock bolt 03 08 * 1,25 mm 1,5-2,0 Kg.-m

Valve adjusting lock nut 02 06 * 0,75 mm 1,4-1,8 Kg.-m

Bearing push bolt 01 06 * 1,0 mm 0,8-1,2 Kg.-m

SPG stopper bolt 01 06 * 1,0 mm 0,8-1,2 Kg.-m

Oil filter screen cap 01 36 * 1,5 mm 1,5-3,0 Kg.-m

Oil bolt 01 12 * 1,5 mm 2,0-3,0 Kg.-m

Crankcase assembly bolt 10 06 * 1,0 mm 0,8-1,5 Kg.-m

L crankcase cover bolt 14 06 * 1,0 mm 0,8-1,2 Kg.-m

R crankcase cover bolt 11 06 * 1,0 mm 0,8-1,2 Kg.-m

ACG bolt 03 05 * 0,8 mm 0,4-0,7 Kg.-m

ACG coil lock bolt 02 05 * 0,8 mm 0,4-0,7 Kg.-m

Perno del generador A.C. 01 10 * 1,25 mm 4,0-5,0 Kg.-m

0,45 - 0,60

0,80 - 1,20

1,80 - 2,00

3,00 - 4,00

5,00 - 6,00

05mm screw

06-nim nut, SH bolt

06mm flange bolt. nut

08mm flange bolt. nut

10mm flange bolt. nut

0,45 - 0,60

1,00 - 1,40

0,70 - 1,10

2,00 - 3,00

3,50 - 4,50

05mm bolt, nut

06mm bolt, nut

08mm bolt, nut

10mm bolt, nut

12mm bolt, nut

TORQUE (KG.-M)

TYPE TORQUE (KG.-M)

TYPE

Q’TY

ITEM TORQUE

THREAD DIA.

02

04

01

04

03

0,8-1,2 Kg.-m

2,8-3,2 Kg.-m

1,8-2,3 Kg.-m

2,3-2,8 Kg.-m

0,8-1,2 Kg.-m

Cylinder bolt

Cylinder head bolt

Cylinder head bolt

Cylinder head nut

Cylinder head cover bolt

06 * 1,0 mm

08 * 1,25 mm

08 * 1,25 mm

08 * 1,25 mm

06 * 1,0 mm

Table of contents

Other Derbi Offroad Vehicle manuals