Contents

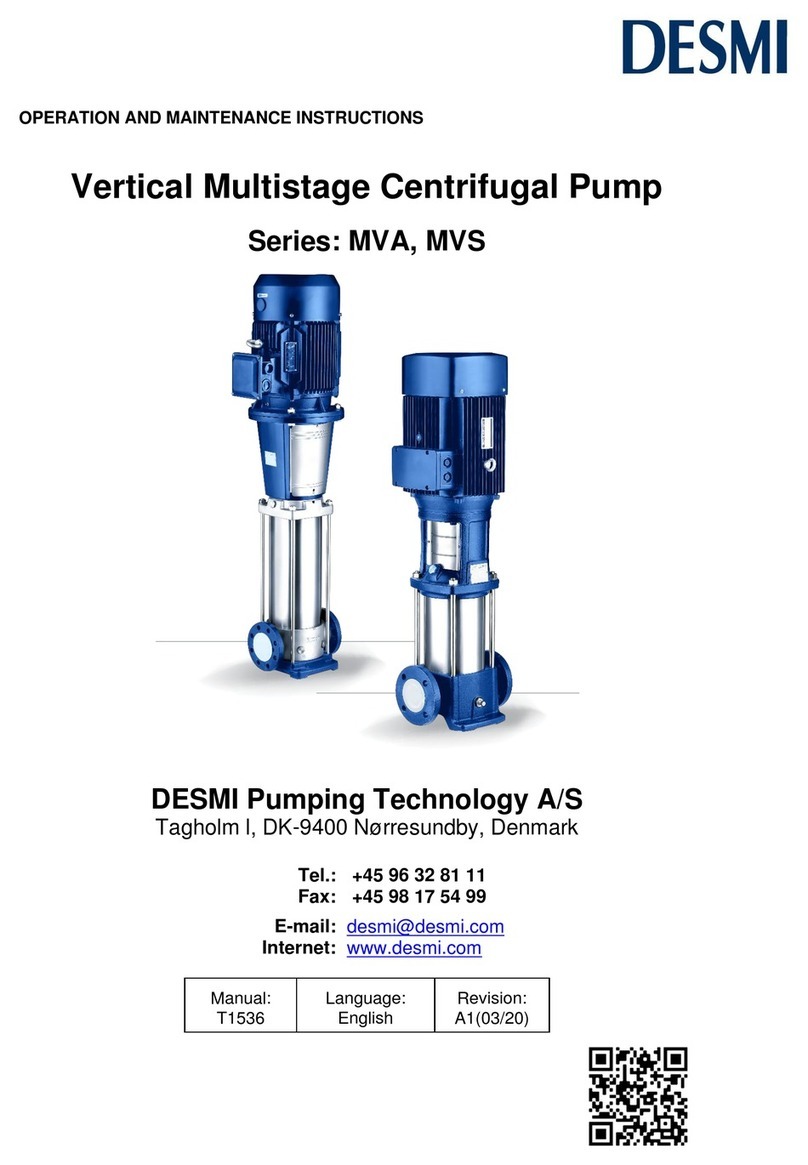

1. PRODUCT DESCRIPTION................................................................................................................................... 4

1.1 DELIVERY ............................................................................................................................................................... 4

2. TECHNICAL DATA ............................................................................................................................................... 4

2.1 ACCESSORIES ...................................................................................................................................................... 4

2.2 SPACE AROUND THE PUMP.............................................................................................................................. 4

2.3 EXPLANATION OF THE TYPE NUMBER........................................................................................................... 5

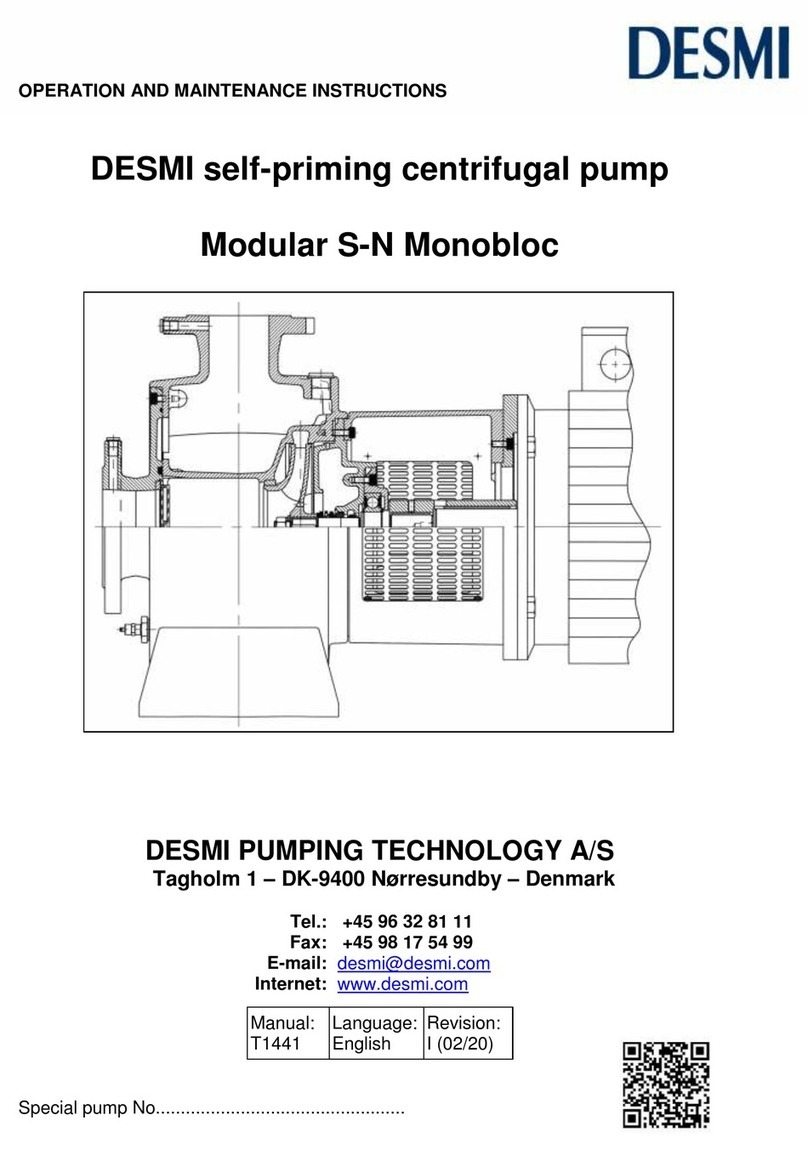

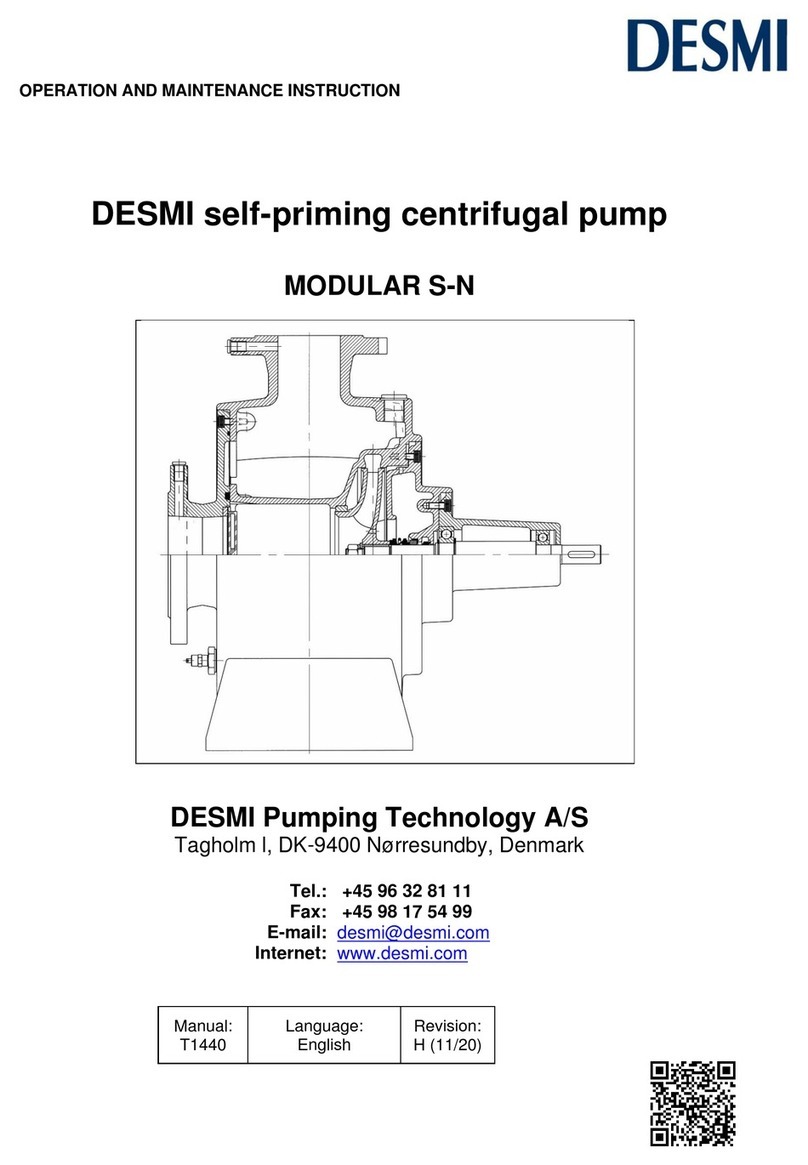

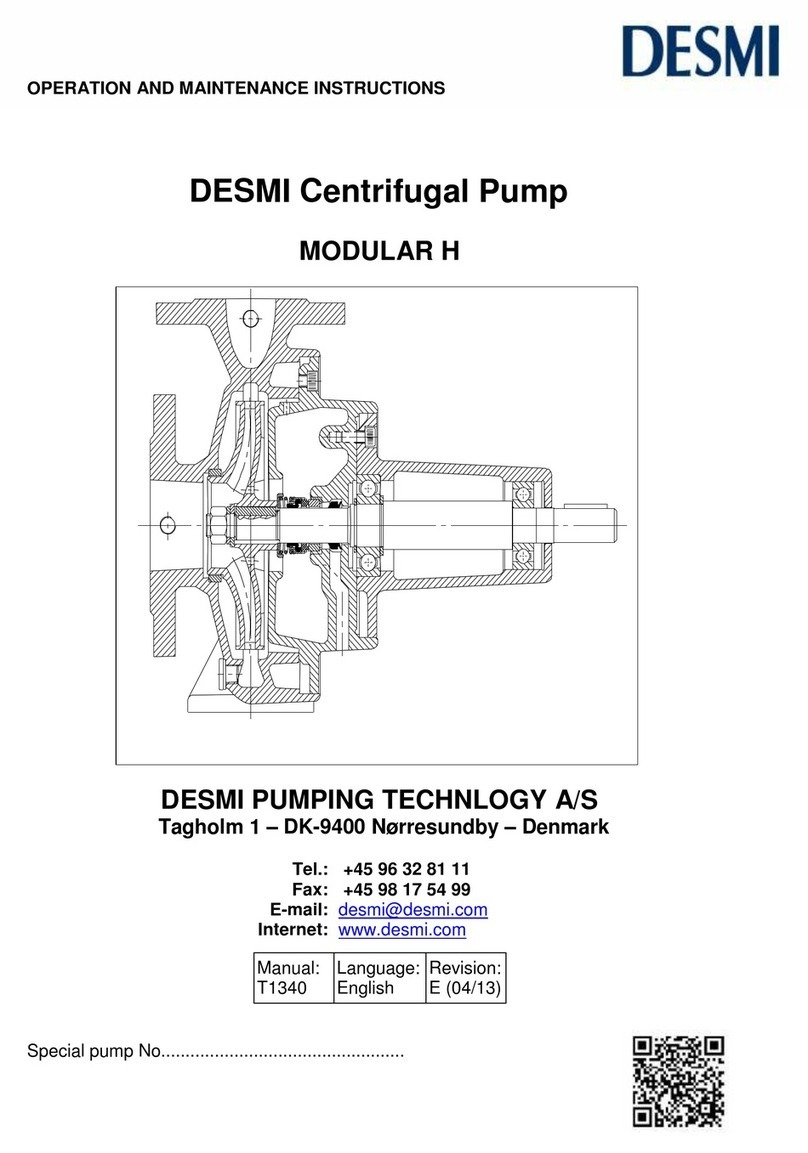

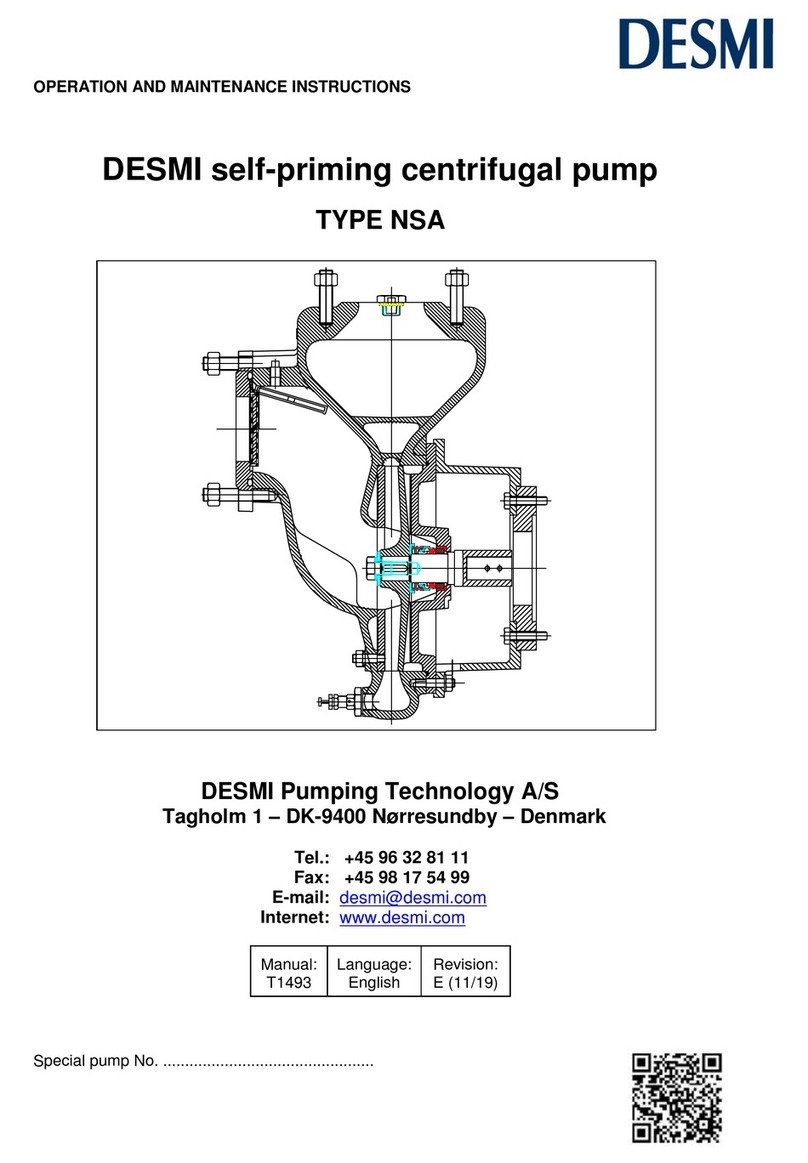

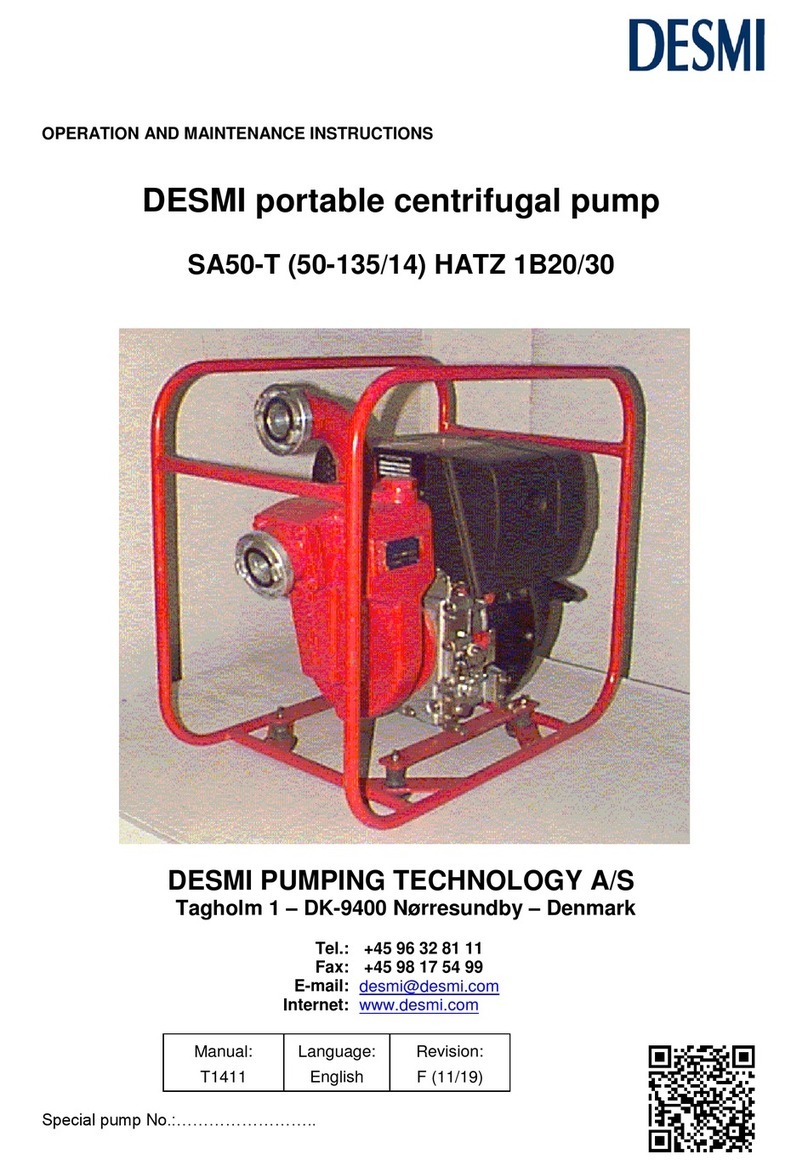

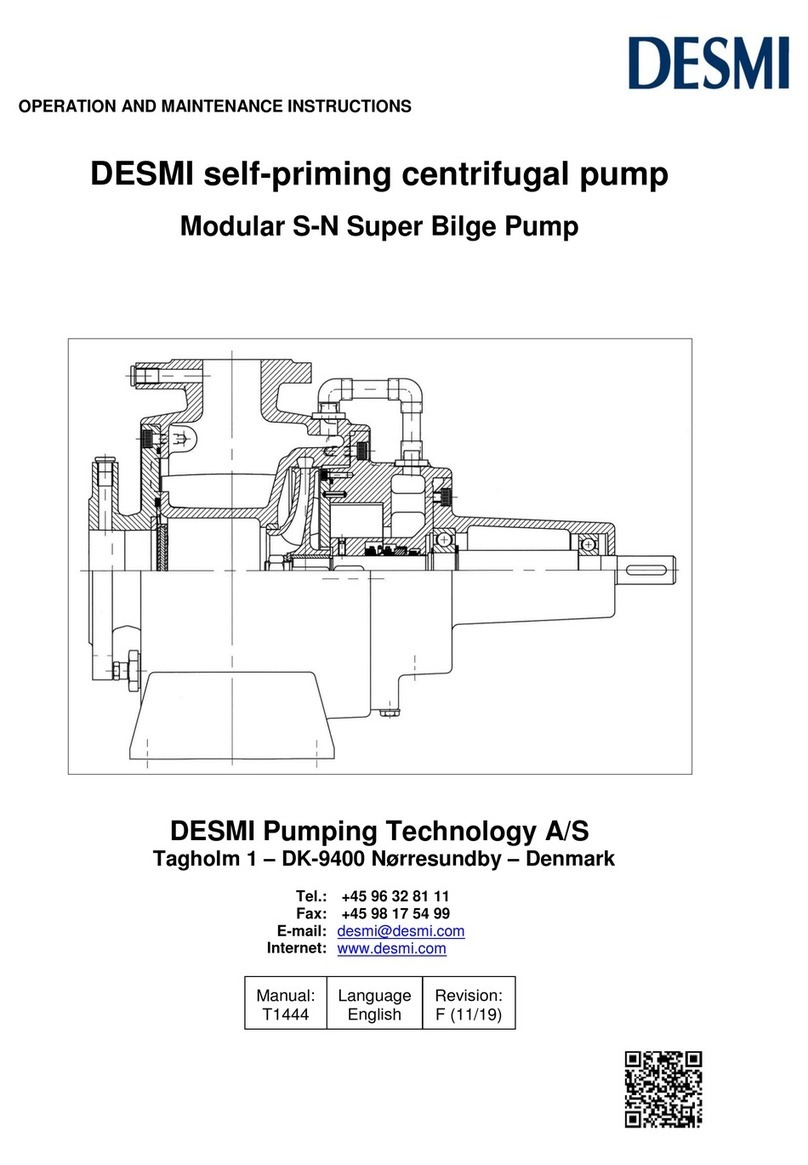

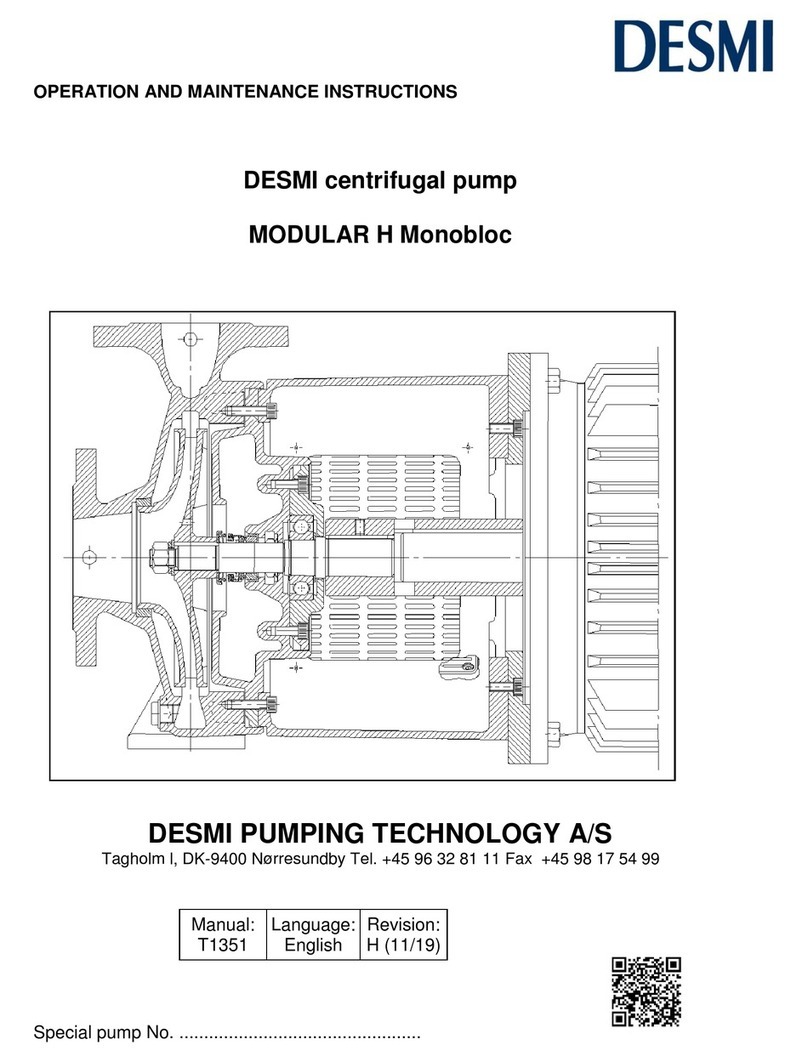

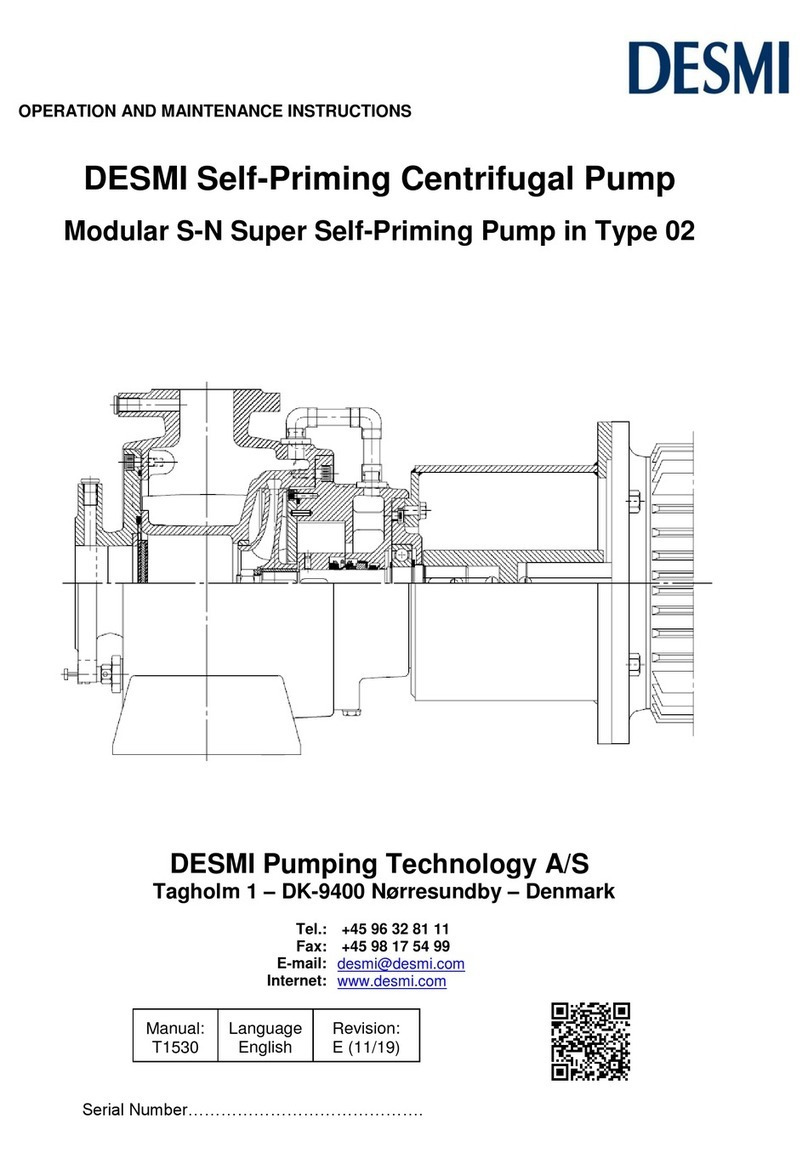

2.4 TECHNICAL DESCRIPTION ................................................................................................................................ 6

3. INSTALLATION..................................................................................................................................................... 7

3.1 MOUNTING/FASTENING...................................................................................................................................... 7

3.2WIRING.................................................................................................................................................................... 8

4. TRANSPORT/STORAGE ..................................................................................................................................... 8

5. DISMANTLING....................................................................................................................................................... 8

5.1 DISMANTLING MOTOR AND BRACKET........................................................................................................... 8

5.2 DISMANTLING COUPLING ................................................................................................................................. 8

5.3 DISMANTLING TOP BEARING AND SHAFT SEAL......................................................................................... 8

5.4 DISMANTLING BOTTOM BEARING .................................................................................................................. 9

5.5 DISMANTLING BOTTOM SHAFT SEAL............................................................................................................. 9

5.6 DISMANTLING REAR COVER WITH SHAFT AND IMPELLER...................................................................... 9

6. ASSEMBLING.......................................................................................................................................................10

6.1 FITTING SEALING RING AND IMPELLER....................................................................................................... 10

6.2 FITTING TOP BEARING AND SHAFT SEAL.................................................................................................... 10

6.3 FITTING REAR COVER WITH SHAFT AND IMPELLER................................................................................ 10

6.4 FITTING BOTTOM SHAFT SEAL....................................................................................................................... 10

6.5 FITTING BOTTOM BEARING............................................................................................................................. 11

6.6 FITTING COUPLING............................................................................................................................................ 11

6.7 COUPLING GUARD............................................................................................................................................. 12

7. FROST PROTECTION.........................................................................................................................................12

8. DISMANTLING......................................................................................................................................................12

9. START-UP.............................................................................................................................................................12

9.1 STARTING............................................................................................................................................................. 13

10. SYSTEM BALANCING ......................................................................................................................................13

10.1 FAULT-FINDING CHART.................................................................................................................................. 14

11. INSPECTION AND MAINTENANCE ................................................................................................................16

11.1 INSPECTION DURING OPERATION.............................................................................................................. 16

11.2 DRAINING THE PUMP...................................................................................................................................... 16

11.3 INSPECTION ...................................................................................................................................................... 16

11.4 LUBRICATING BEARINGS............................................................................................................................... 16

12. REPAIRS.............................................................................................................................................................18

12.1 ORDERING SPARE PARTS............................................................................................................................. 18

13. OPERATING DATA............................................................................................................................................19

14. EU DECLARATION OF CONFORMITY...........................................................................................................20