Details 7 series User manual

Installation Instructions 005255D Rev D

Tools required:

Page 1 of 22

Series 7 - Adjustable Height Tables

Series 7 - Adjustable Height Tables | Installation Instructions

#2 Phillips Bit

with Extension

4mm

Hex Drive Bit

#2

Square Drive Bit

Page 2 of 22

005255D Rev D

When using an electrical furnishing, basic precautions should always be followed, including the following:

Read all instructions before using (this furnishing).

DANGER - To reduce the risk of electric shock:

1. Always unplug this furnishing from the electrical outlet before cleaning.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Unplug from outlet before putting on or taking off parts.

2. Close supervision is necessary when this furnishing is used by, or near children, invalids, or disabled

persons.

3. Use this table only for its intended use as described in these instructions. Do not use attachments not

recommended by the manufacturer.

4. Never operate this table if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water.

5. Keep the cord away from heated surfaces.

6. Never drop or insert any object into any opening.

7. Do not use outdoors.

8. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

9. For loading always put heavier items at the bottom and not near the top in order to help prevent the

possibility of the furnishing tipping over.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

The power socket/outlet shall be installed near the equipment and shall be easily accessible.

www.steelcase.com/details

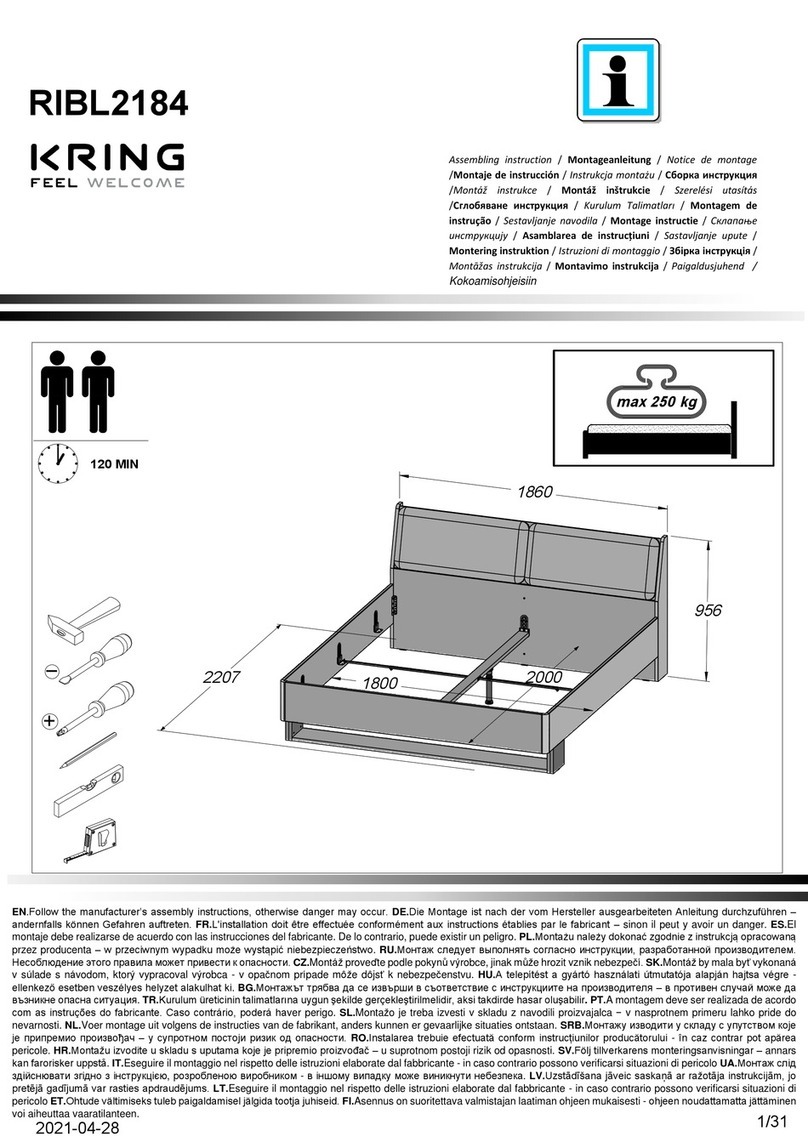

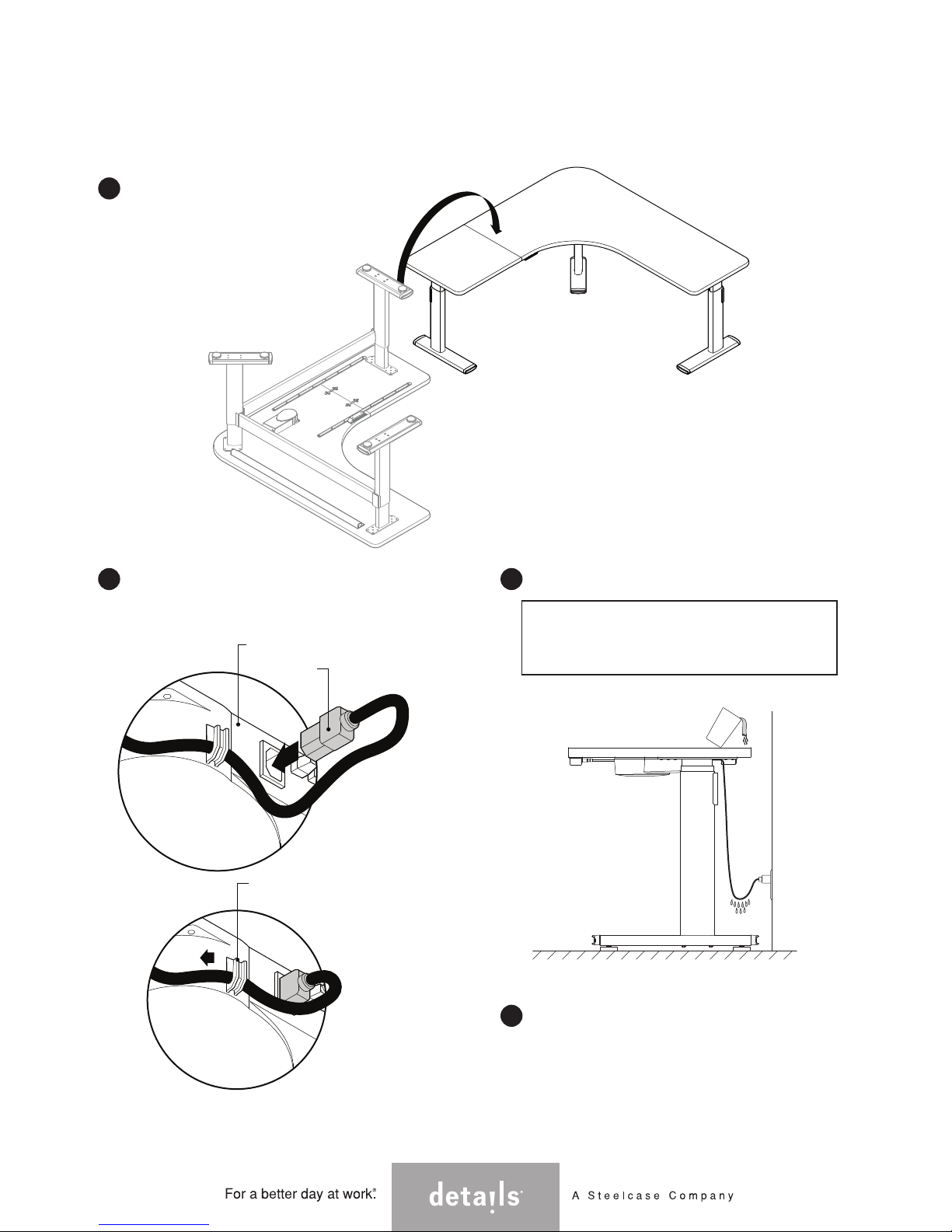

Overview of Assembly Process

1) Determine the table configuration.

2) Assemble 2-piece worksurface (if applicable).

3) Assemble and attach stretchers.

4) Attach legs to worksurface (with worksurface upside-down).

5) Attach control box and wire managers.

6) Connect and route cables.

7) Attach the contoller.

10) Level and clean it up.

11) PLEASE LEAVE THESE INSTRUCTIONS, AND

THE USER GUIDE, IN AN OBVIOUS PLACE

FOR THE END USER AFTER ASSEMBLY.

8) Check for binding and finish leg attachment.

9) Flip table upright and test function.

TABLE OF CONTENTS:

4

5

6 & 7

8 & 9

10 & 11

12 & 13

14 & 15

16

17 & 18

19

20

21 & 22

Lets Get Started!............................................................................................

Attaching Stretchers......................................................................................

Attaching Mounting Plate to Legs..................................................................

Mounting Legs to Worksurface......................................................................

Attaching Control Box & Wire Managers.......................................................

Connecting & Routing Cables........................................................................

Attaching the Controller.................................................................................

Finishing the Leg Installation.........................................................................

Finishing the Table Assembly.........................................................................

Guidelines on Moving the Table.....................................................................

Wiring Guide..................................................................................................

Appendix A: 2-Piece Worksurface Assembly.................................................

PAGE(S):

Page 3 of 22

005255D Rev D

www.steelcase.com/details

1

2

Prepare a large open space to assemble the table.

1

Let's Get Started!

• Sweep the floor! Screws and small parts can damage

the worksurface.

• Put down a CLEAN shipping blanket to protect the worksurface.

Unpack the worksurface and place on the shipping blanket upside-down.

2

• REMEMBER - You're looking at the UNDERSIDE of the worksurface.

Are you sure which side is left or right?

Assembling a 90ocorner table with a 2-piece worksurface?

3

Jump to Appendix 'A' now.

3

Page 4 of 22

005255D Rev D

www.steelcase.com/details

Attaching Stretchers

Page 5 of 22

005255D Rev D

www.steelcase.com/details

Layout the left and right stretcher assembly and the center

connector with the dovetails pointing down. Loosely install the

center connector to the left and right stretcher using two (2)

1/4-20 type F flat head screws with phillips #3 drive...do not

tighten. (Left and right is determined when the table is

standing on the base and is viewed from the front.)

4

Layout the left, right and center lift

columns, place the stretcher into

each dovetail, connect loosely.

5

LH ASSEMBLY

LEFT COLUMN

RIGHT COLUMN

STRETCHER

CENTER COLUMN

RH ASSEMBLY

STRETCHER

COLUMN

TOP VIEW

DOVETAIL

STRETCHER

DOVETAIL

NOTE:

On 90oor 120otables, a 21" foot is

required when the side of the

worksurface is greater than 46". If

the worksurface side is less than

46", a 18" foot is required.

Once each lift column has been

engaged, lightly tap each

connection point with a rubber

mallet 1/8-1/4 inch at a time,

until completely seated. Do not

completely install one lift

column at a time...they must be

installed incrementally.

6

NOTE:

A clean, abrasion free

surface will be necessary

for table assembly.

PHILLIPS

SCREW

DRIVE

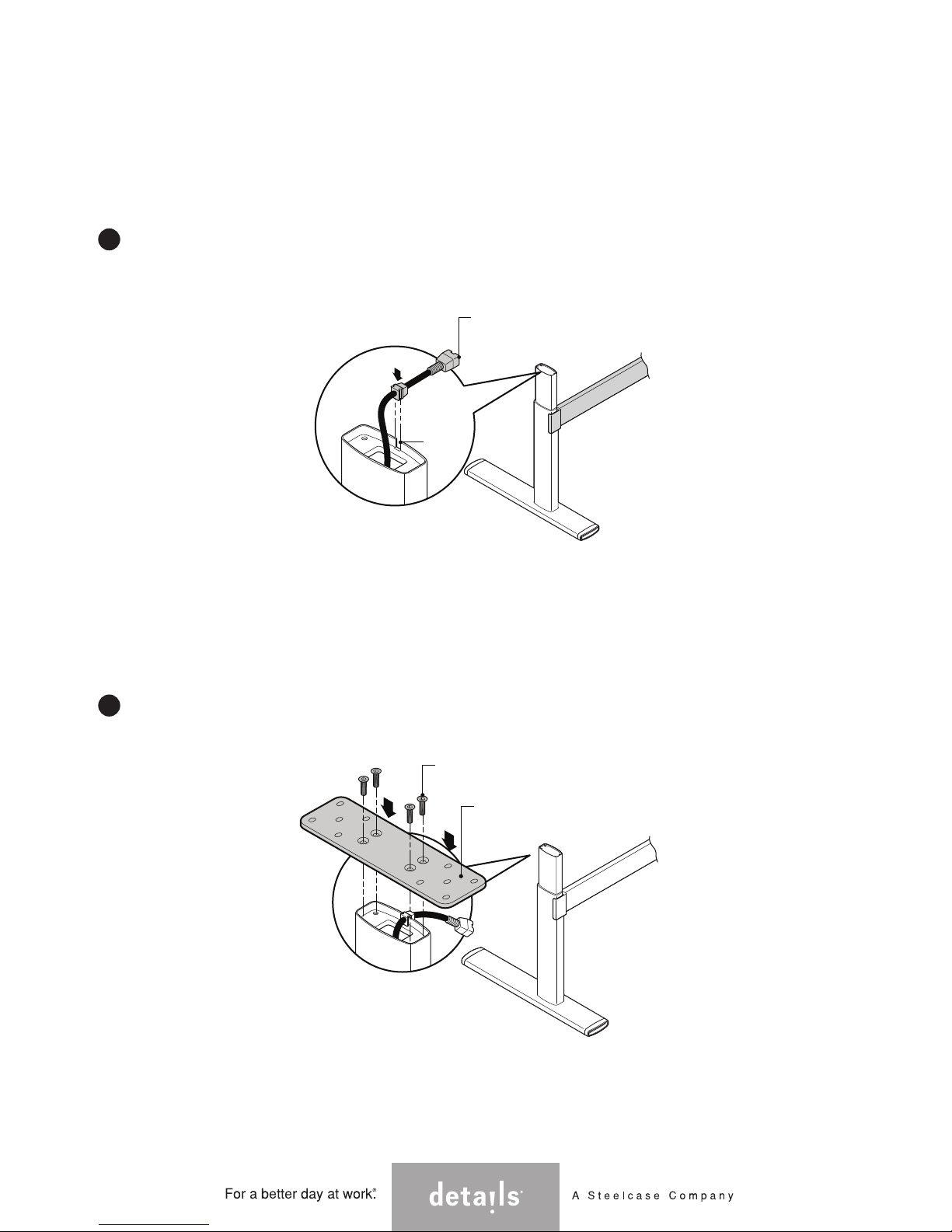

Attaching Mounting Plate to Legs

For 2-Leg Tables:

Page 6 of 22

005255D Rev D

www.steelcase.com/details

Locate and install each mounting plate using 4mm hex head

fasteners provided. Tighten securely.

8

MOUNTING PLATE

4mm HEX HEAD FASTENERS

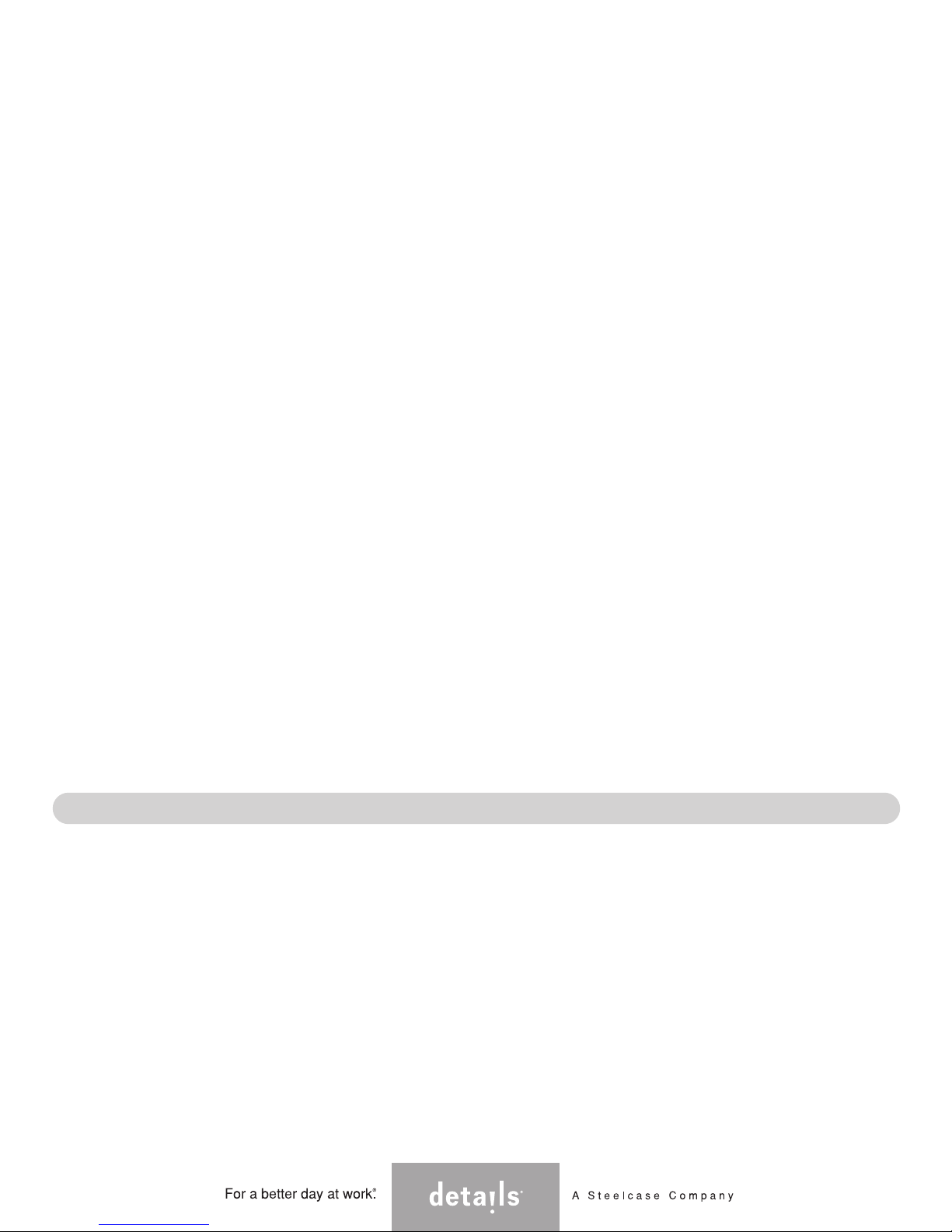

For each lift column, fold the electrical 'pig-tail' towards

the center of the surface. Secure in the notch provided in

each lift column.

7

ELECTRICAL

PIGTAIL

NOTCH

Attaching Mounting Plate to Legs

For 3-Leg Tables:

Page 7 of 22

005255D Rev D

www.steelcase.com/details

Locate and install each mounting plate using 4mm hex head

fasteners provided. Tighten securely.

8

7

For the left and right lift columns, fold the electrical 'pig-tail'

towards the center lift column using the notch provided in

each lift column to secure. The center lift column 'pig-tail'

can be folded in either direction.

CENTER

COLUMN

ELECTRICAL

PIGTAIL

NOTE: The center lift

column ‘pig-tail’ can be

folded in either direction.

MOUNTING PLATE

CENTER

COLUMN

4mm HEX HEAD FASTENERS

(cont.)

Mounting Legs to Worksurfaces

Mounting Plate

Worksurface

Pilot Holes

= PILOT HOLE

= NO PILOT HOLE PROVIDED

For 2-Leg Tables:

With the top still upside down on the

floor, turn the base over (flipping is a 2

person job), and align the attachment

plates to the pre-drilled holes in the top.

Loosely install one fastener in each of

the pre-drilled pilot holes.

Don't install all fasteners until the unit

has been operated through one cycle

(Step 15).

9

Page 8 of 22

005255D Rev D

www.steelcase.com/details

PHILLIPS

HEAD

SCREW

Center Leg

Mounting Plate

Worksurface

Pilot Holes

TOWARD CENTER

OF WORKSURFACE

For 3-Leg Tables:

With the top still upside down on the floor, turn the base over (flipping is a 2 person

job), and align the attachment plates to the pre-drilled holes in the top.

Align the center lifting column first.

Center each pre-drilled hole in the top to the slot in the attachment plate. Loosely

install one fastener in each of the pre-drilled pilot holes.

Once the center lifting column is secured, align the left and right lifting columns in a

similar fashion by moving the plate so that all pre-drilled holes are visible.

Don't install all fasteners until the unit has been operated through one cycle (Step 15).

NOTE: Do not force the left or right lifting columns to perfectly fit the attachment

mounting holes. This can cause binding during articulation.

9

Mounting Legs to Worksurfaces (cont.)

Page 9 of 22

005255D Rev D

www.steelcase.com/details

SQUARE

SCREW

DRIVE

www.steelcase.com/details

Install control box in the

predetermined location,

using pre-drilled holes.

10

Install the wire

management cableway

on the underside of the

worksurface at the rear.

11

Attaching Control Box & Wire Managers

Page 10 of 22

005255D Rev D

CONTROL BOX

2” MINIMUM

2-1/2” MAXIMUM

WIRE MANAGER

WIRE MANAGER

www.steelcase.com/details

Attaching Control Box & Wire Managers (cont.)

Page 11 of 22

005255D Rev D

Install the wire management

cableways onto the underside

of the worksurface as shown.

11

2” MINIMUM

2-1/2” MAXIMUM

WIRE MANAGER

WIRE MANAGER

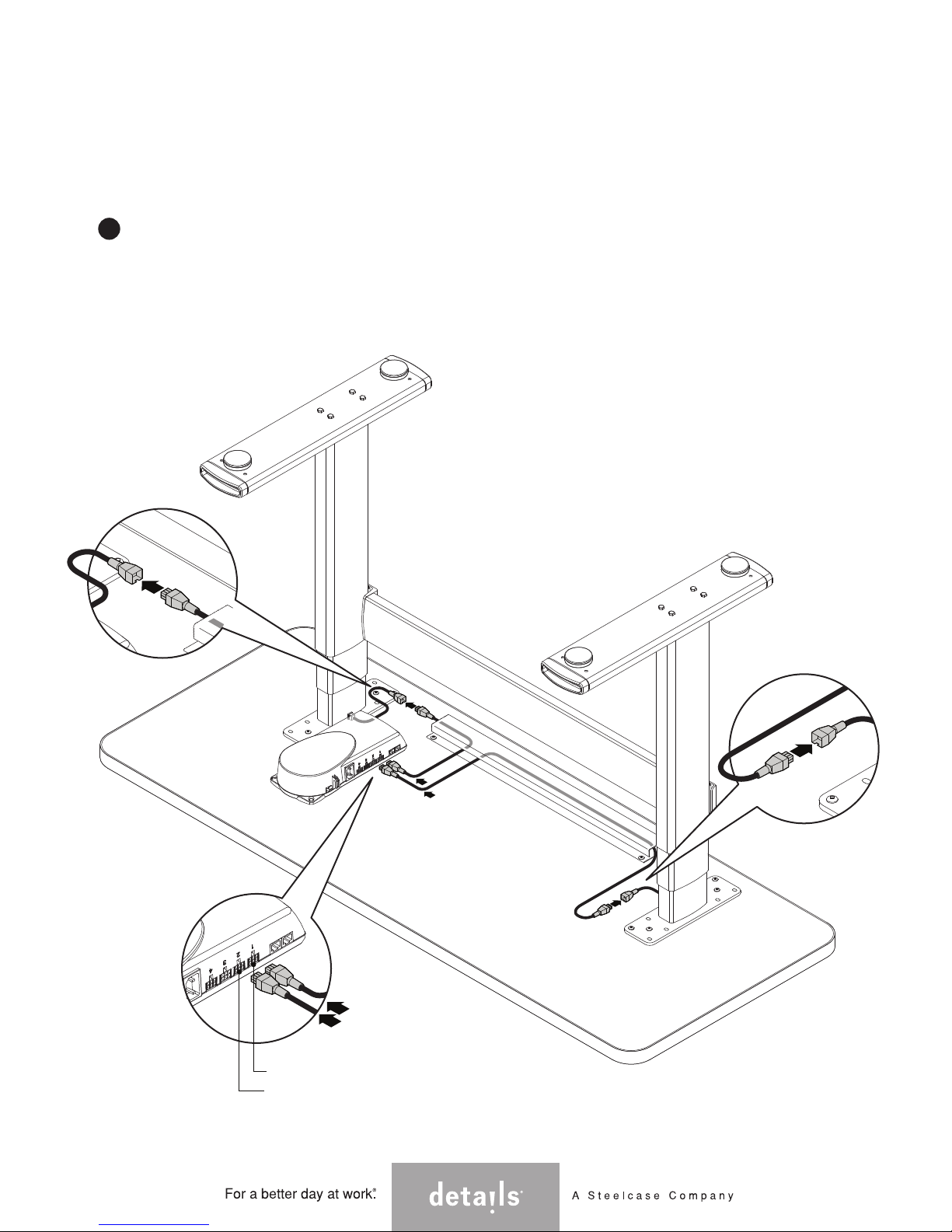

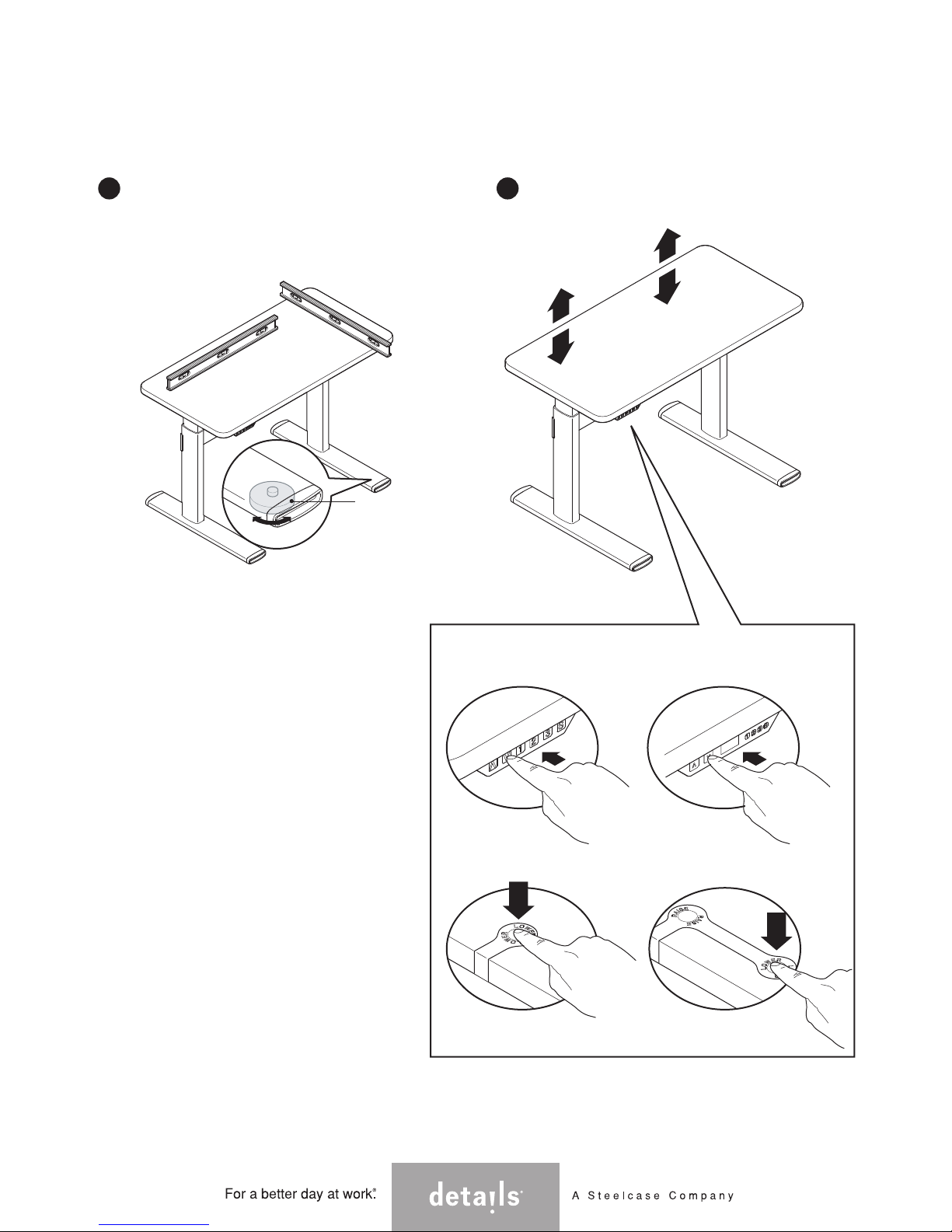

For 2-Leg Tables:

12

Connect the cables to each lifting column and connect the

terminal end to the control box. Route these cables in the

wire management cableway provided. Refer to the Wiring

Guide for more information on page 20.

For optimal wire management, connect lifting columns to the

closest port on the control box.

Connecting & Routing Cables

www.steelcase.com/details

Page 12 of 22

005255D Rev D

PORT #1

PORT #2

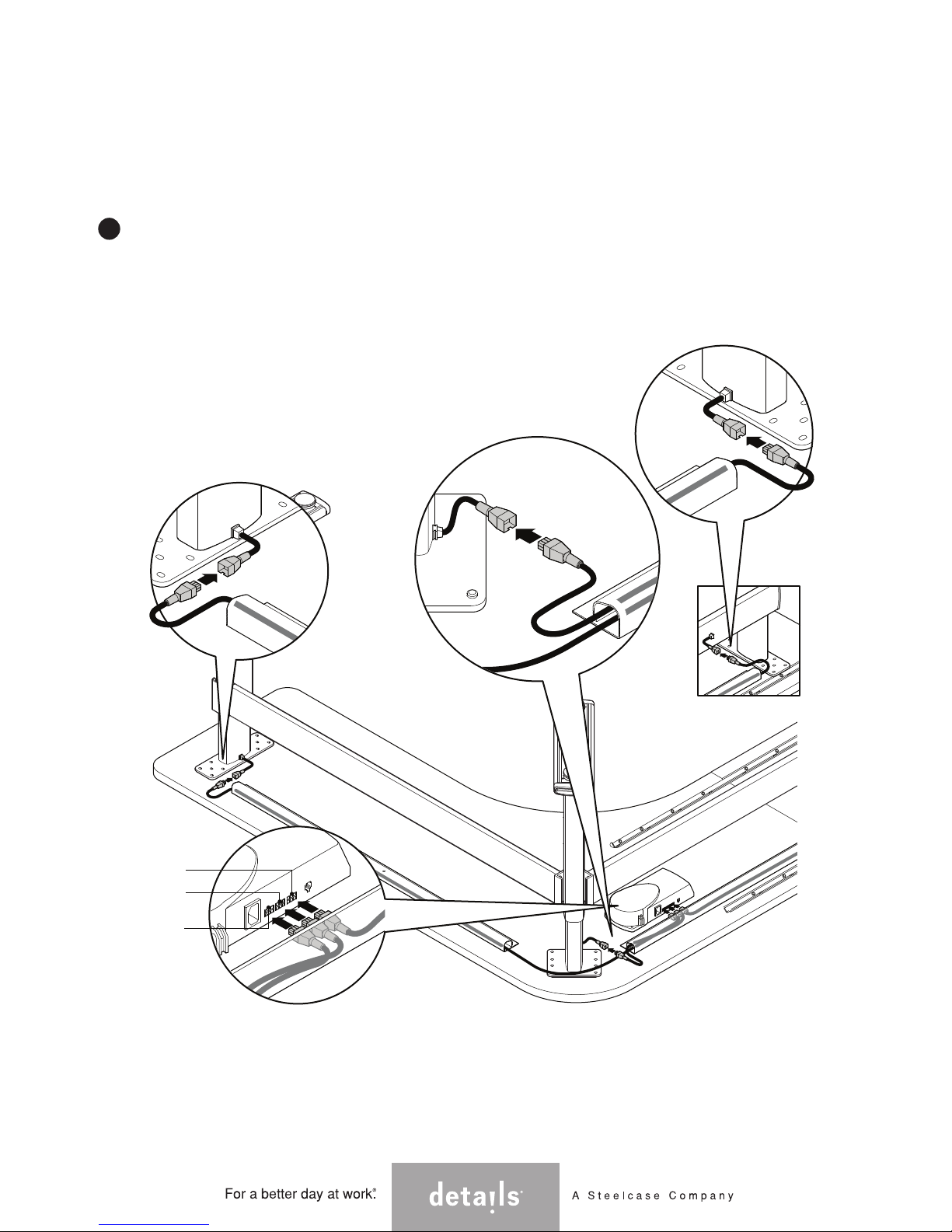

For 3-Leg Tables:

12

PORT #1

PORT #2

Connecting & Routing Cables (cont.)

www.steelcase.com/details

Page 13 of 22

005255D Rev D

Connect the cables to each of the three lifting

columns and connect the terminal end to the

control box. Route these cables in the wire

management cableway provided.

(2000mm cables to the left and right lifting

columns & 1000mm cable to the center lift

column.) Refer to the Wiring Guide on

page 20 for more information.

For best wire management, connect lifting

columns to the closest port on the control box.

PORT #3

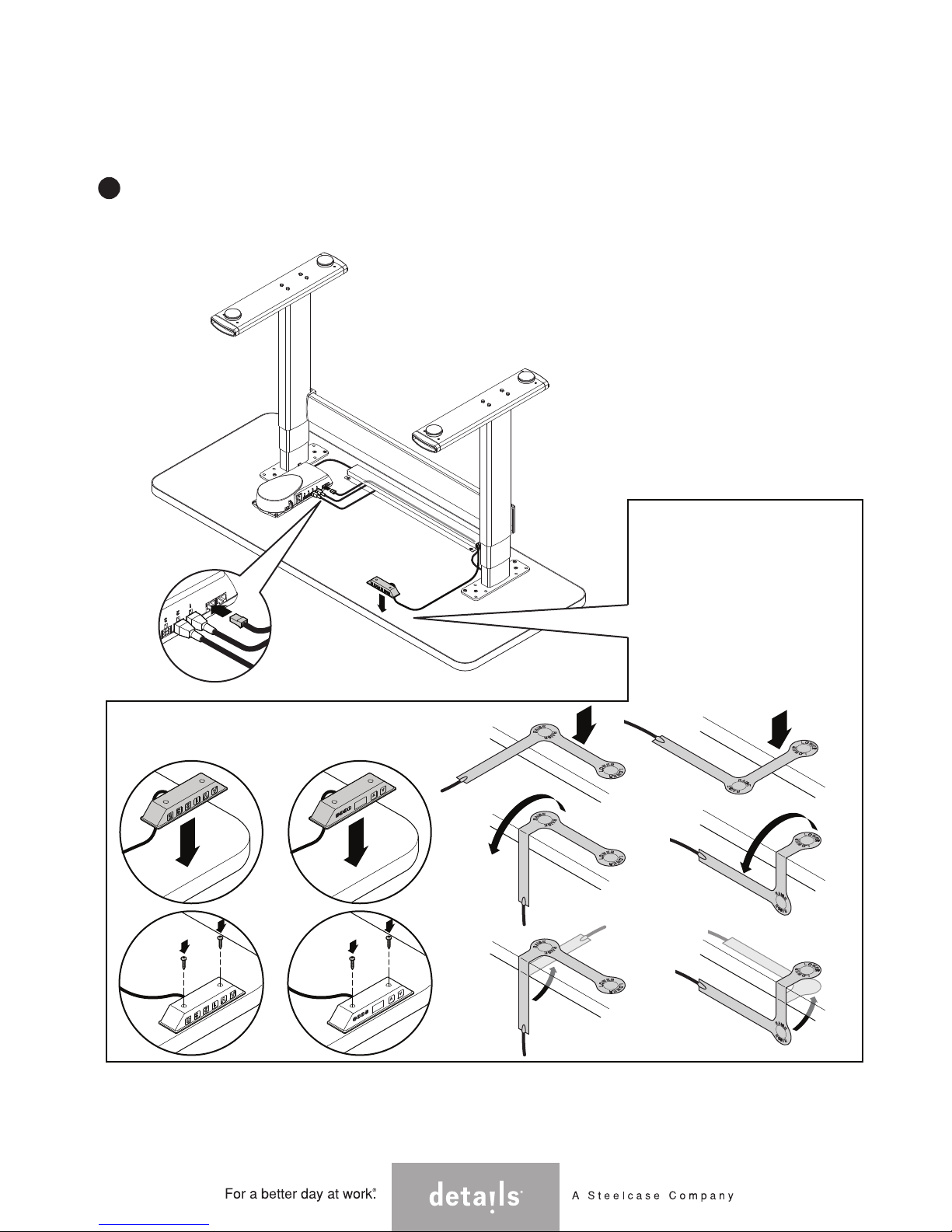

Attaching the Controller

13

NOTE: Push button stick-on controller

installation is shown here. However, the

controller cannot be installed until the

worksurface is flipped over. Once step 18 is

performed, the controller may then be

installed.

NOTE: Remove paper backing from contoller

before installation.

Digital Desk

Panel Controller

Standard

Controller

Install the controller to the underside of the worksurface on

the side preferred by the user. (We recommend it be placed

toward the outside of the table to avoid interference in the

workspace.)

Push Button Stick-On

Controller

www.steelcase.com/details

Page 14 of 22

005255D Rev D

Attaching the Controller (cont.)

14

Install the wire keepers for the control wire. Peel off paper

backing and stick to worksurface. Place wire into each wire

keeper.

www.steelcase.com/details

Page 15 of 22

005255D Rev D

PAPER BACKING

WIRE KEEPER

CONTROL

WIRE

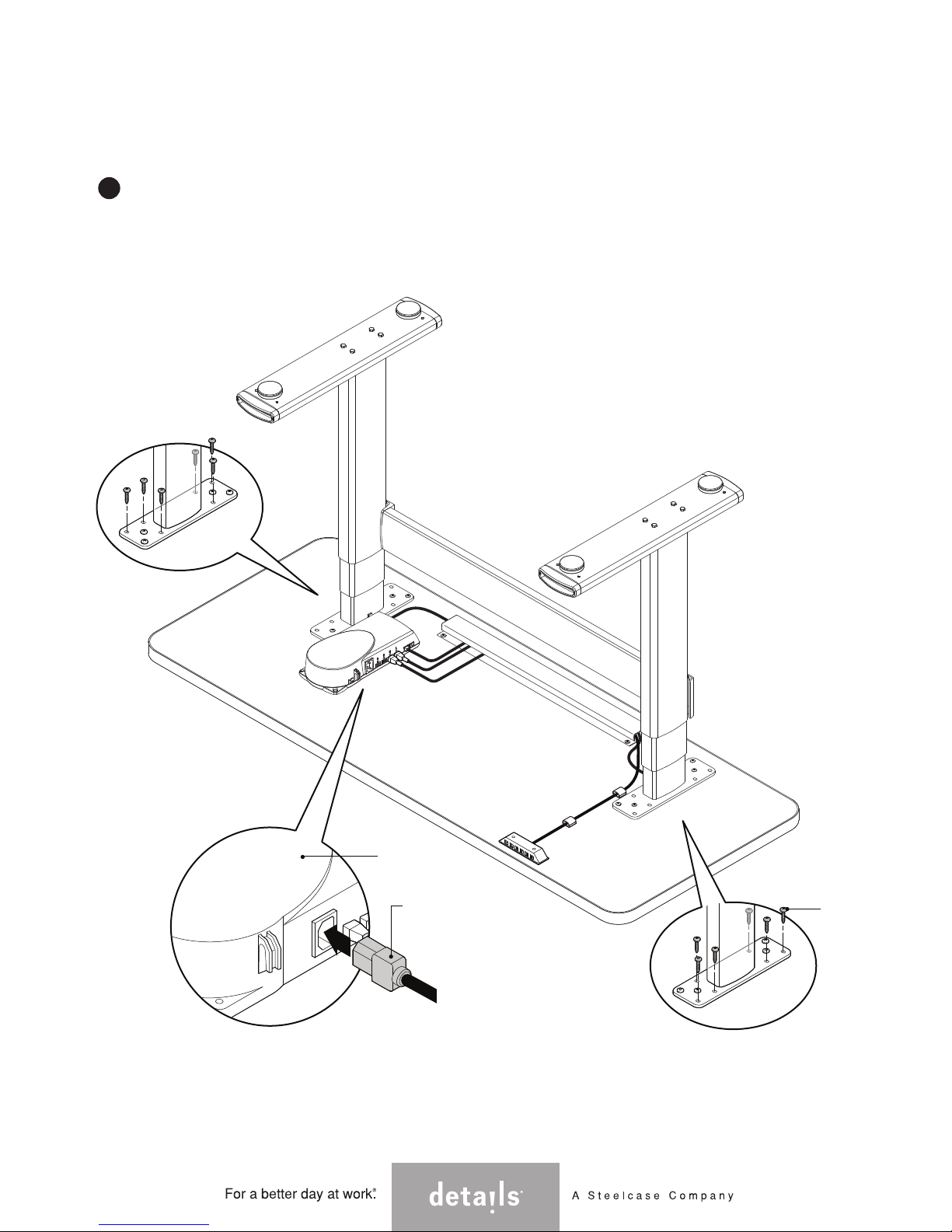

15

Plug unit in and check for binding, by running the table base all

the way through its range of motion and back again, then lower

to bottom and unplug unit. Install the remaining fasteners in

each of the remaining holes and tighten ALL screws securely.

Do not over tighten.

Finishing the Leg Installation

www.steelcase.com/details

Page 16 of 22

005255D Rev D

PHILLIPS

HEAD

SCREW

CONTROL

BOX

PLUG

16

Carefully turn the table over (2 person

operation).

NOTE: Do NOT use either lifting column as a

brace when turning the table over, as this

may cause binding. The top must be lifted

free, rotated, and set down carefully.

After the table is in place, install the 120v

plug into the control box. Secure the cord

to the control box using the molded-in clip.

Plug the cord into an outlet.

CONTROL

BOX

PLUG

MOLDED CLIP

17

Route all cables through wire managers.

19

Keep all cables clear of moving parts!

CAUTION: Be sure to create a 'drip loop' in the

power cord before making the connection to a

live wall socket, to prevent electric shock if

liquids spill on power cord.

Connect power cord to power supply.

18

Finishing the Table Assembly

www.steelcase.com/details

Page 17 of 22

005255D Rev D

Synchronizing the Lifting Columns

Prior to initial use of the height adjustment function you must

"synchronize the system".

•Press the Down arrow until the worksurface comes to a stop at the

lowest position.

•Release the Down arrow.

•Press and hold the down arrow for approximately 5 seconds while

the table synchronizes itself. The surface will quickly lower itself

approximately 5mm, then rise approximately 5mm and finally settle

back to its lowest position.

After performing this function, the movement of all lifting columns

is synchronized by software inside the control box.

In the unlikely event that an error occurs, reset the control unit by

pressing the Up and Down buttons at the same time for 5

seconds. Then repeat the synchronizing sequence as previously

outlined above.

NOTE: Mounting of CPU and

CPU holders: Maximum height

for the 2 units cannot exceed

20-1/2".

Before use, the table must be completely leveled, front-to-back and

side-to-side using the height adjustable glides. Failure to do this

could cause the lifting columns to bind.

Before articulation, you must synchronize the lifting columns as

outlined below.

Digital Desk

Panel Controller

Standard

Controller

Push Button Stick-On

Controller

20 21

Finishing the Table Assembly (cont.)

www.steelcase.com/details

Page 18 of 22

005255D Rev D

GLIDE

Guidelines on Moving the Table

When possible, the table should be moved in a horizontal (flat) position.

If the table must be moved vertically (i.e. standing on a pallet), care must be taken to ensure no side

pressure is placed on any of the lifting columns as it is tipped into position, during transport, and when

tipped off the pallet at the new location.

Before in use in the location, the table must again be completely leveled side-to-side and front-to-back.

Failure to do so may cause binding of the lifting columns and failure to operate properly.

After moving, the lifting columns must be re-synchronized by holding 'down' arrow on the Controller

while the lifting columns seek to level themselves.

1

2

3

4

www.steelcase.com/details

Page 19 of 22

005255D Rev D

V-BRACKETS

WIRE MANAGEMENT

CABLEWAY

CONTROLLER

(can be positioned

on left or right side)

WORKSURFACE TOP

DRAW

BOLTS

LEFT

STRETCHER

LEFT LIFT

COLUMN

RIGHT

STRETCHER

RIGHT LIFT

COLUMN

CENTER LIFT

COLUMN

When connecting cables as stated in Step 12, use this guide as a reference.

Connect the cables from the Lifting Columns to the cables provided. The other end should be connected

to the Control Box. Repeat this for each leg.

Connect the end of the Controller cable into the Control Box.

Follow Steps 13 - 15 to complete the wiring installation.

Once you have completed the wiring, use the Wire Managers to hold all the cables and minimize possible

entanglements.

NOTE: Vertical wire management solutions are also available from Details. Contact your local dealer or

Steelcase.com for more information.

Wiring Guide

3

4

5

2

1

www.steelcase.com/details

Page 20 of 22

005255D Rev D

legs or stretcher in any way.

• Never attach wires to the

CONTROLLER

ATTACHMENT

PLATE

FOOT

GLIDE

LEFT LIFTING

COLUMN

RIGHT LIFTING

COLUMN

CONTROL

BOX

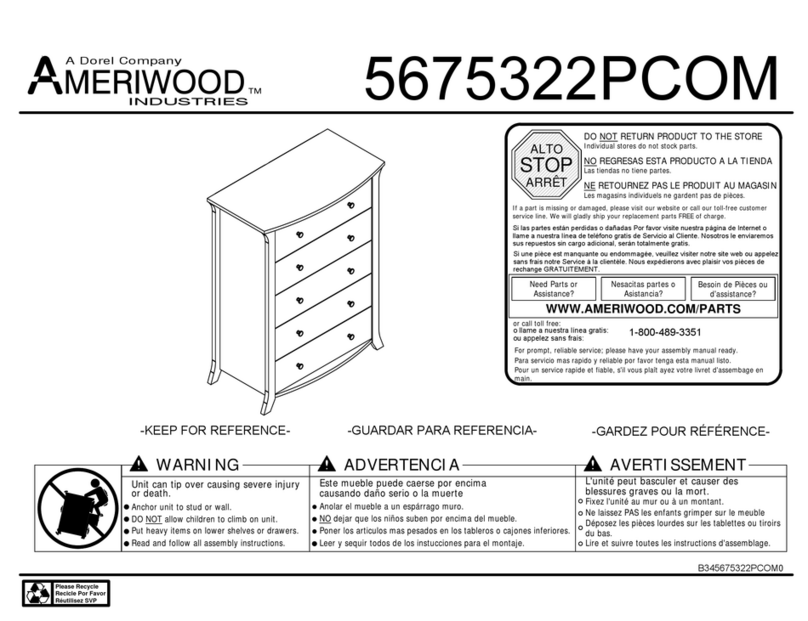

Table of contents

Popular Indoor Furnishing manuals by other brands

Furniture 2 Go

Furniture 2 Go 1022501 Assembly instructions

Dorel

Dorel AMERIWOOD 5675322PCOM manual

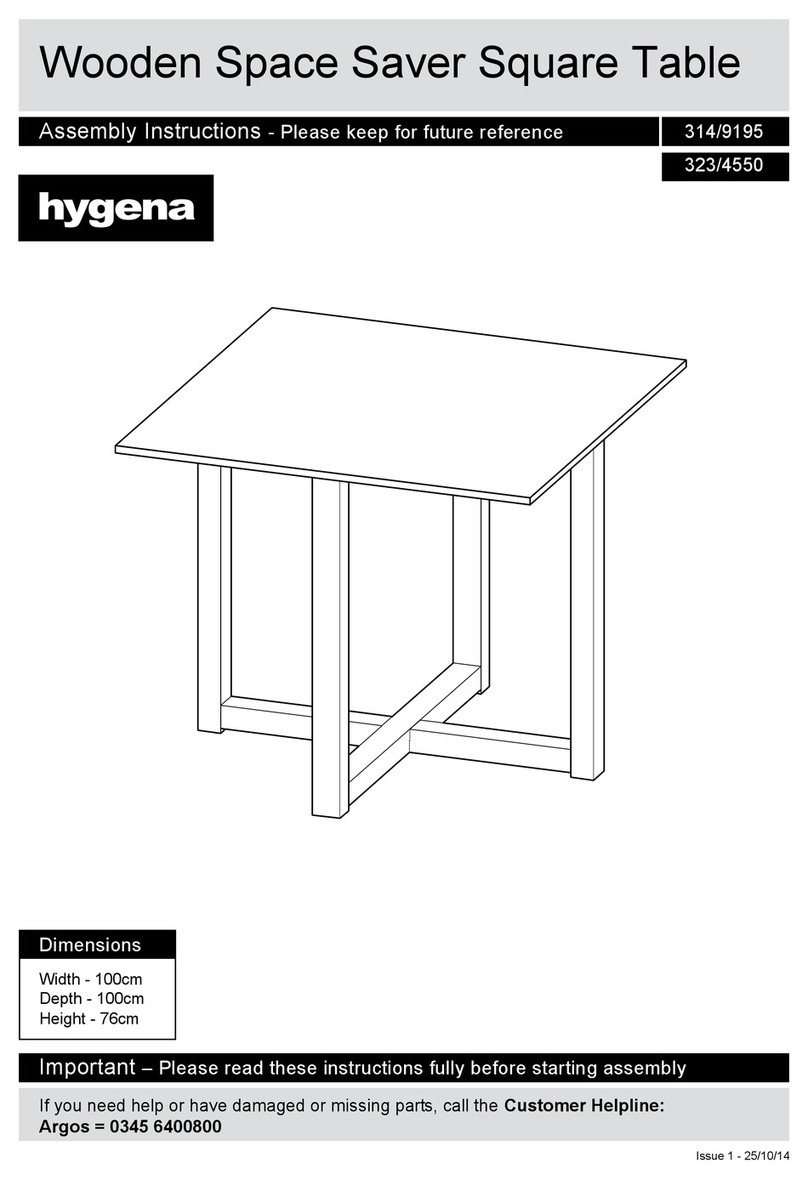

hygena

hygena 314/9195 Assembly instructions

Invacare

Invacare Solace Mattress Assembly, installation and operating instructions

Ronbow

Ronbow Signature Series Installation and care guide

rst brands

rst brands ASTER SL-OFFCE-4-A Assembly instructions

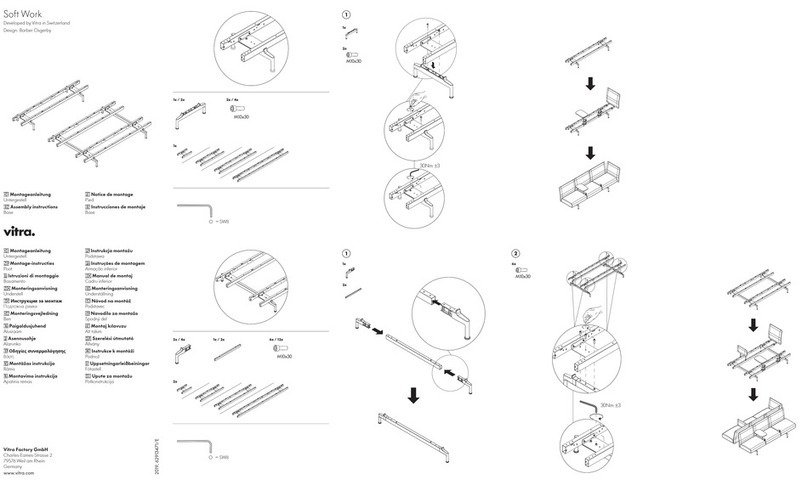

VITRA

VITRA Soft Work Assembly instructions

Lumex

Lumex FR601P Series Assembly and operating instructions

FREEWAY

FREEWAY Agile installation guide

Unfinished Furniture of Wilmington

Unfinished Furniture of Wilmington CANYON XX S-472 Assembly instructions

Garden Oasis

Garden Oasis Adirondack Chair Use and care guide

Furinno

Furinno 18053 Assembly instruction