DGM Optics OA-Series User manual

Last Updated 8August 2000 Page 1of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

OA-Series Telescopes Use and Care Manual

Click here for a printable version (Requires Acrobat® Reader)

DGM OpticsOA-Seriesinstruments offer some of the finest optics and

innovative mechanical design utilized by any telescope available to the amateur

astronomer today. Outlined here are basic procedures to help you attain optimal

performance from your OA-Seriestelescope.

After your Scope Arrives

Once you have received your OA-Seriestelescope carefully unpack all

components and inspect for any damage that may have occurred during

shipping. Although it is rare for damage to have occurred during shipping, it is

very important to contact DGM Opticsso a claim can be filed as soon as

possible with the shipping company.

The Basics: Pre-Alignment

Depending on your model, all the OA-Seriestelescopes require some assembly.

The OA-4.0 is easiest of all the OA-Seriestelescopes as far as assembly and

requires only that the primary mirror is installed in the tube assembly and the

split yoke is secured around the circumference of the tube assembly. To install

the primary mirror, carefully unpack the primary mirror and remove the (3)

machine screws that are attached to the large platter. Then, with the small

orientation hole in the large platter aligned with the focuser, gently slide the

entire assembly into the tube and, using the predrilled holes in the tube attach

the mirror cell and primary to the tube assembly. Next set the tube assembly in

the “Split Yoke”. Placing the split yoke assembly around the tube assembly and

securing it by clamping the adjustable draw latch on the split yoke does this.

Caution: Adjust the draw latch only as tight as is needed to hold the tube

Last Updated 8August 2000 Page 2of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

assembly securely. Then place the split yoke and tube assembly onto the mount

struts. You can now proceed to the alignment step.

If you have purchased the OA-5.1 ATS,the OA-5.5, the OA-6.5 ATS,or

the OA-7.0, you will need to attach the large base plate to the small base

plate and strut assembly. To do this, find the (2) 3/8” nuts and 3/8” fender

washer attached to the 3/8 machine screw and bushing assembly. Then, remove

the 3/8” nuts and 3/8" fender washer attached to the machine screw. Next,

carefully insert the bearing/machine screw assembly on the bottom of the small

base plate and strut assembly into the bushing on the large base plate assembly.

Now, place the fender washer through the 3/8” machine screw and thread the

(2) 3/8” nuts onto the machine screw. Tighten the first 3/8” nut “finger tight”

against fender washer, then with an adjustable wrench hold the first 3/8” nut in

place and tighten the second 3/8” nut down to “lock” the assembly in position. If

you find that the mount has excessive play, repeat the procedure described

above to attain the desired motion and “free play” in the bushing/bearing

assembly. Also, note that this procedure may have to be repeated several times

until your mount has been “broken in”, or with seasonal changes in relative

humidity and temperature. You can now follow the basic primary mirror

installation as described for the OA-4.0 and proceed to the align step.

Because of the size and shipping weight of the OA-9.0 the scope and mount

are shipped in a disassembled state. All necessary hardware is included for

assembly of the mount, and all wood screw holes are predrilled for easy

assembly. Also, the fiberglass tube for the OA-9.0 is a “cut tube” which can be

disassembled for transport. Once you have assembled the mount and tube

assembly you can continue on to the alignment step.

Alignment Part A: The Secondary

Last Updated 8August 2000 Page 3of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

The OA-Seriestelescopes secondary mirrors are permanently mounted and

aligned prior to shipment and rarely require anything more than to be checked

prior to aligning the primary. Here is the procedure. First, you will notice that a

small indelible ink mark has been placed in the center of the primary mirror. This

mark provides a visual reference to the center of the primary when aligning the

secondary mirror. Using an empty film can, with a ¼ inch hole drilled in the

center and placed in the barrel of the focuser, the mark on the primary mirror

should be centered when viewed with your eye on top of the film can. Next

remove the film can and with your eye remaining centered over the barrel of the

focuser move your eye back to approximately 6 inches away. Repeat this step at

distances of 12, then 18, then 24 inches. At each step the secondary should

appear concentric and centered with regard to the barrel of the focuser with your

eye remaining centered on the optical axis as you move farther from the focuser

barrel. If it appears that the secondary is not in correct alignment you can

manipulate the secondary by carefully bending the secondary on the brass rod

that attaches the secondary to the “L” stalk the supports the whole assembly to

the interior of the tube. If you cannot achieve a satisfactory alignment contact

DGM Opticsand I will be happy to assist you. If your secondary mirror appears

to be in correct alignment you can proceed to “part B” of the alignment.

Alignment Part B: The Primary

Next comes the easy part: the primary. To provide a constant reference, the

primary mirror alignment should be done with the scope pointing on the

horizontal looking at a white background. Looking into barrel of the focuser, with

no eyepiece, and your eye centered over the barrel of the focuser, you should

see only the primary with no image of the secondary visible. Next, if you have a

standard OA-Seriesscope (OA-4.0, OA-5.5, or OA-7.0), move your eye

slightly towards the rear of the scope, (the six o’clock position if the front of your

scope is twelve o’clock). If the instrument is correct in alignment you should see

a small “sliver” of the secondary mirror at the twelve o’clock position on the

primary mirror. The key to aligning an off-axis Newtonian telescope is in the fact

that primary is actually a segment taken from a larger “parent mirror” and it is

beneficial to think of it in that way. When looking into the focuser barrel, think of

an imaginary “center line” running through the primary from twelve o’clock to

the six o’clock position on the primary. This imaginary line runs from the thickest

to the thinnest part of the primary and it also points back to the center (apex) of

the old “parent mirror”. If the alignment appears incorrect, use any needed

combination of the primary mirror cell adjusters to bring the image of the

secondary mirror to the correct position on the “center line”. The procedure for

the ATS scopes (OA-5.1 ATS, OA-6.5 ATS, and OA-9.0) is different only

in that the “sliver” of the secondary will be at the six o’clock position, instead of

the twelve o’clock position. Other than that the procedure is the same.

Last Updated 8August 2000 Page 4of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

Alignment Part C: Star Testing

The star test is the final confirmation of the correct alignment of your OA-

Seriestelescope. The test consists of centering a bright star, beginning at low

power, and observing the in and out of focus star images, then repeating the

test with progressively higher power eyepieces. In all cases, with the star

centered in the field of view, the image should be round and concentric with no

trace of astigmatism or coma, (elongation of the star image), both inside and

outside of focus. If you find that the image is not concentric when centered in

the field of view it is usually only a matter of using the "center line" adjuster on

the primary mirror cell and moving the image to the center of the field of view

until it is correct. The "center line" adjuster is the adjuster that is marked with

the small hole in the large plate of the primary mirror cell. Once you have

established the correct alignment by star testing you can note the visual position

of the secondary "sliver" and quickly perform accurate alignments. Also, be sure

that your scope has reached complete thermal equalization before performing

the star test(s). If you are confident that all alignment steps have been

completed correctly and still are not sure if the alignment is optimal please feel

free to contact DGM Opticsfor technical support.

Routine Maintenance: Cleaning the Optics

Cleaning the optics should be performed whenever the primary or secondary

mirrors have an excessive amount of foreign material on the optics, or when the

optical performance is obviously degraded due to surface contaminates. DGM

Optics uses the technique described, but other methods may be used if

preferred.

The Primary

Start by removing the primary mirror and cell from the tube assembly. Do not

remove the primary itself from the mirror cell as the method described can be

done with the mirror in place. The (3) machine screws used to secure the mirror

cell in the tube can be removed during the cleaning process.

1. Prepare a solution consisting of 20 parts distilled water and 1 part mild

dish washing soap.

2. Using, unscented, plain white, bathroom tissue, take 10-12 two-ply

sheets and fold into a square pad, then fold the square pad in half and

set on a clean oil-free surface.

3. Then, set aside 6-8 cotton balls on a clean oil-free surface.

Last Updated 8August 2000 Page 5of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

4. Next, with the mirror facing up, place the mirror cell assembly under

running, room temperature water for about (1) minute.

5. Turn the water off and pour a generous amount of the premixed

distilled water solution over the surface of the primary mirror.

6. Then take the cotton balls and saturate them with the premixed distilled

water solution and lightly swirl them on the surface of the mirror. You

don’t have to swirl the mixture so as to create a lot of bubbles on the

surface, agitate it only enough to see a hint of the soap in the solution.

That will usually be sufficient to remove most stubborn dirt or stains on

the surface.

7. Next, with the mirror facing up, place the mirror cell assembly under

running, room temperature water for (1) minute, except after one

minute turn off the water and quickly flush the surface with a generous

amount of distilled water.

8. After the surface has been flushed with distilled water quickly turn the

mirror cell assembly on its side to drain off excess water. Then take the

bathroom tissue pad and lightly and gently blot the remaining water

from the surface.

9. Next, using a paper towel, carefully wipe up the water on the large and

small platters of the primary mirror cell. Avoid turning the assembly

upside down, and also, avoid touching the freshly cleaned mirror

surface. Inspect and repeat procedure if necessary. Reinstall mirror cell

assembly in tube assembly.

The Secondary

Because of the crucial nature of the secondary mirror alignment, it is advisable to

remove and/or clean it only if there is an excessive amount of contaminants on

the surface. To remove the secondary, loosen the hex nut/threaded rod

assembly that secures the mirror itself to the "L" shaped stalk. If you need

remove the secondary for cleaning be sure to measure the exact distance that

the second hex nut is threaded into the brass rod. That will mark the position

when the secondary is reinstalled. If possible, use cleaning methods that allow

the secondary mirror to remain in place. Try blowing the surface off with low

pressure air or wiping the surface with a soft camel hair brush and then gently

rake the surface with a bathroom tissue pad dampened with a small quantity of

alcohol or methanol. And as always, DGM Opticswill be glad to give technical

support if needed.

Last Updated 8August 2000 Page 6of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

Routine Maintenance: The Mount

DGM OpticsOA-SeriesDobsonian style mount offer some of the smoothest

tracking and most comfortable viewing possible with a Dobsonian mounted

telescope. The optical tube assembly is set in DGM OpticsSplit Yoke. The

Split Yokeallows the tube to be balanced and rotated for comfortable viewing

of any portion of the sky.

All bushing, bearing and trunion parts are custom made using Teflon (TFE) and

Ultra-High Molecular Weight Polyethylene (UHMW). These materials feature

excellent friction coefficients with high chemical and temperature resistance. The

wood is a beautiful, high grade, Atlantic Birch triple coated with a clear

polyurethane finish that will last for years. The finish can be cleaned and

polished with any commercial wood preserving products any time you want to

bring back the "new finish" shine.

As for Teflon (TFE) and Ultra-High Molecular Weight Polyethylene (UHMW)

components, they need only to be kept free of abrasive materials, which may

inhibit the Alt-Azimuth motion(s) of the mount. Cleaning these components by

wiping the surfaces with a clean cloth that has been lightly dampened with

acetone or alcohol. Note: It is recommended that chemical resistant gloves be

worn when using such solvents. Also, the vertical bushing/bearing assembly

should be periodically treated with machine oil such as WD-40, or similar

products, to inhibit corrosion of the machine screw and double nut locking

assembly.

The OA-Seriesmount utilizes a black anti-static Ultra-High Molecular Weight

Polyethylene (UHMW) disc on the large base plate with the small base plate/strut

assembly riding on Teflon (TFE) pads. Periodically the base plates can be

disassembled and cleaned of any debris, and then treated with WD-40 to

increase the smoothness of azimuth motion. The OA-4.0 mount features,

believe it or not, vinyl LP records as the surface the Teflon pads ride on.

The OA-4.0 is now offered with a "Teflon strap clutch". This simple,

inexpensive, device is built in to one of the struts and applies controlled friction

to the trunion bearing and prevents the tube assembly from "falling down" when

various eyepieces are used. This device requires no special maintenance.

However, a thin coat of WD-40, or machine oil, can be applied to the assembly

where the components contact, the trunion bearing, and the Teflon strap. When

additional clamping is applied, the smoothness of the altitude motion is

enhanced. Also, the "Teflon strap clutch" is available with any of the OA-Series

telescopes, and can be easily retrofitted to your scope if you need more friction

with the altitude bearing motion. Contact DGM Opticsfor more details.

Last Updated 8August 2000 Page 7of 7

C:\WINDOWS\Desktop\My Documents -Carol\webpage stuff dgm\Use and Care Manual.htm

A Few No-No's

1. Do not loosen the "split yoke" draw latch with tube pointing up. Doing

this can result in the tube sliding down on the small mount platter and

damaging the tube assembly or the mount.

2. Do not store the Standard OA-4.0 for long periods (2+ hours) at

temperatures greater than 140 degrees Fahrenheit. The Standard OA-

4.0 uses PVC (Polyvinyl Chloride) tubing for the optical tube assembly

and is rated for that temperature.

3. If possible try to bring your OA-Seriestelescope into an intermediate

temperature area after observing in cold weather. This will help inhibit

"sweating" on the optics that can be harmful to thin film mirror coating.

4. And, Finally, Do Not Look Directly at the Sun with your OA-

Series, or ANY Telescope. DOING SO WILL RESULT IN

INSTANT BLINDNESS.

Clear Skies!

This manual suits for next models

6

Table of contents

Popular Telescope manuals by other brands

Discovery Telecom

Discovery Telecom Spark Travel 50 user manual

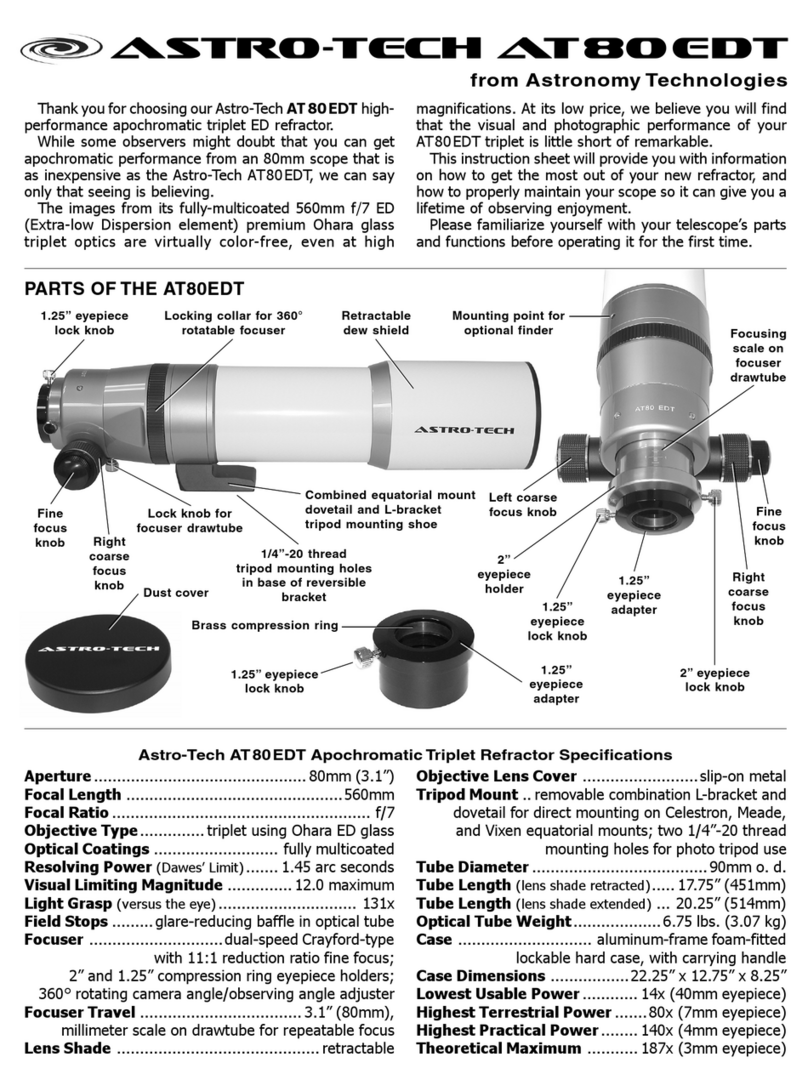

Celestron

Celestron Ultima 60SV 52256 Specifications

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS Observer 60mm EQ instruction manual

König Electronic

König Electronic KN-SCOPE40 manual

Celestron

Celestron CPC 925 user guide

Galileo

Galileo G-545 instructions

Hikmicro

Hikmicro Falcon Series quick start guide

Celestron

Celestron SPC-80 instructions

Omegon

Omegon Advanced X 152 DOB instruction manual

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS AstroView 6 EQ instruction manual

Celestron

Celestron PowerSeeker Square 60 instruction manual

iOptron

iOptron 6001 instruction manual