DI-BOX FLOWBOX User manual

Flow meter:

ULTRASONICFLOW METER

FLOWBOX

Rising element:

PALMER-BOWLUSFLUME

ZPB160

User’smanual

Wroc aw2020

FLOWBOX

TRANSMITTER

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

1

Thankyoufor choosing productofourfirm.

TheDI-BOXcompanyguarantees thebig quality

ofthepurchased deviceand its proper operation.

The guarantee period for thepurchased apparatus covers: 18months.

Thepresent deviceismanufacturedinconformitywiththestandards

requiredfordigitaltools Bclass.

Thismanual wasissuedonlyinorderforinformation purposes.All information

includedcanbechanged.The DI-BOX doesnot bearthe responsibility forany direct

and indirectdefects arisen as aresult of using this manual.

HEALTHANDSAFETY.The assembly, starting,service, maintenanceand

repairs canbemadeexclusively bythe qualifiedpersonnel inaccordancewith the

obligatorysafetyprinciples.

Thedeviceissafeand works properly,ifitisproperlytransported, stored,

installed, startedup, servicedand maintained. Theproductshouldbeused

inaccordancewiththemanual.

HEALTHANDSAFETY. CAUTION:Theimproperservicemaycause

gettinghurtorseriousdevicedamage.

Zak adAparaturyKontrolno-Pomiaroweji Automatyki Przemys owej

ul.Szczeci ska11a 54-517 Wrocław

tel.071 353 86 55, 602 4844 77 fax. 071 353 86 54

info@di-box.com.pl www.di-box.com.pl

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

2

TABLEOFCONTENTS

1.INITIAL INFORMATION..............................................................................

3

2.TECHNICAL DATA...................................................................................... 3

2.1.Flowmeasuring transmitter M1600.................................................. 3

2.2.Ultrasound level sensor SPA380-4.................................................... 4

2.3.Palmer Bowlus ZPBflume ................................................................

5

3.INSTALLATIONOFMEASURINGSET ........................................................... 7

3.1.Assembly recommendations ............................................................. 7

3.2.Connecting the wires to the transmitter M1600 ................................. 9

3.3.Scheme of electric connections of the transmitter M1600................... 10

4.DEVICESERVICE......................................................................................11

4.1.Displayof device.............................................................................11

4.2.Devicecalibration ............................................................................12

4.3.Measuring scopeand input electric current set ...................................

14

5.MODBUSINTERFACE................................................................................15

5.1.Technicaldata................................................................................15

5.2.Installation and launchoftheMODBUSinterface...............................

16

5.3.Description of registers of thetransmitter M1600..............................17

6.MAINTENANCERECOMMENDATIONS.........................................................18

6.1.Palmer-Bowlus ZPBflume ultrasonic sensor SPA380-4........................18

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

3

1. INITIALINFORMATION

The measuringset servesasnot foamedliquidintensitymeasureflowin the

gravitationconditionsandtotalamount ofsewageflowingthroughthemeasuring

channel.

Inthe scopeofthisapplication,the FLOWBOXflowmeterdeterminesthe temporary

flowon the basisof liquidaccumulationinthePalmer-Bowlusflume ZPB160,in

accordancewith theguidelinesandrecommendationsofthe ISO4359:1983

standard.

Thebasic conditiontoapplythemethodistoprovidefree,

undisturbedinflow and outflow of liquidfromthemeasuringflume.

Measuring set consists of:

→Flowmeasuring transmitter M1600,

→Ultrasonic level sensor SPA380-4,

→Palmer-Bowlus ZPB160 flume.

2. TECHNICALDATA

2.1.Flowmeasuring transmitter M1600

→MEASURINGSCOPES:

Intensity flowmeasurement: for ZPB160

-in the entities m3/h: 40 m3/h

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

4

-in the entities m3(summary): 0...1.000000

→PROGRAMMING: local, for Palmer-Bowlus ZPB160

→OUTPUTSSIGNALS: (electroplating separation in/out)

Current output: 0/4...20mA, load 500 Ωmax.

Impulseoutput: every0,1m3,type:opencolector

Digitaloutput: RS485/MODBUSRTU

→OTHERDATA:

Power supply: ~230V,50Hz

Power consumption: ≤10 VA

Mass: ~1,5kg

Material: ABS

Protection class: IP65

Worktemperaturescope(without

protective case): -10 do55

o

C

2.2.Ultrasoniclevel sensor SPA 380-4

SPA380 isthe ultrasonicinlet ofdistanceforstandard current signalintendedfor

measuring the liquid level changes.

The basicusageissituatedatmeasuringlevelinindustrialandmunicipalsewage

treatment plants,batchandreserve tanks,wells,sewagewet wells,measuring

instruments in open channels,etc.

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

5

The deviceismadein the formof measuringprobehavingthe microprocessor

measuring instrument and ultrasound sensor.

The casingof the probeismadeof PVCwhatassuresthe widescopeof usagesin

different environmentconditions.

The membrane of ultrasoundsensorissituatedinsidethe casingandcommunicates

with frontalsurfaceof the probebythe acousticcouplerwhatprotectsit againstthe

influenceof environment conditions (humidity, caustic fumes,etc.)

The probehasthe function of automaticcleaningoffrontalsurfaceof radiatorwith

gathering sediments bythe instantincreaseof the ultrasound wave emitted power.

SPECIFICATION

Technicalparameters:

→Accuracy: 0.10%of the scopein the laboratoryconditions

0.25%of the scopein the field conditions

→Resolution: 0,7mm

→Measuring scope: 0,25…4,0m.

→Signalbeam curve: 5-7°with decreaseof the power of 3d

→Temperaturecompensation:automatic

Output:

→Analogue output:: 4…20mA or20…4mA

→Max.load:R=(Uzas.-6)24mA

Feeding: 18to 30VDC max.0.07A

Protectionclass: IP68

Threaddiameter: 2.0" NPT

2.3. Palmer-BowlusZPBflume

Palmer-Bowlusmeasuringflumeisone of the prefabricatedmeasuringflumes

intendedformeasuringthe flowin gravitation wires.Itisrecommendedto gravitation

channels with circular section andpipelines working without pressure.

The channel assuresexactrelation between the level of itsfillingandliquidflow

intensity in the channelor pipeline.

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

6

Thebasic conditiontoapplythemethodistoprovidefree,

undisturbedinflow and outflow of liquidfromthemeasuringflume.

Typ

koryta

DN Q

m/h

B

L

Typ

koryta DN

Q

m/h

B

L

ZPB100

Ø110

12

155

800

ZPB400 Ø400

450

450

1500

ZPB160

Ø160

40

210

800

ZPB500 Ø500

730

550

1700

ZPB200

Ø200

70

250

1190

ZPB600 Ø630

980

685

2000

ZPB250

Ø250

130

305

1190

ZPB800 Ø800

1700

860

2600

ZPB300

Ø315

220

368

1400

ZPB1000

Ø1000

4380

1050

3500

Inordertoobtaintheproperflowintensity,theflume mustbe

installedhorizontallywithoutfall.

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

7

3. INSTALLATION OFMEASURING SET

3.1. Assemblyrecommendations

PALMER-BOWLUSFLUMEZPB

→Install the flume on thepipelinebymeansof insertingchannelin pipeline

goblet ortypicalhydraulicmuff inthe wayof assuringthe durability and

tightness of the connection,rememberingabout the properflume

orientation (the indicatorin the channel shows the flowdirection).

→Install theflumeinthehorizontalpositionwithout drops.

→Performsupportof the flumeassuring its immobilization

→Handle mustscrewedto the channel in the given placesbymeansof eight

M5 screws

INLETANDOUTLETCHANNELS

→Providefree, undisturbed inflowand outflowof liquid from the measuring

flume bymeans of ensuring long enoughstraight inlet and outlet channel

parts.

ULTRASONICLEVEL SENSOR SPA 380-4

→SPA380-4sensorshouldbeinstalledinthedurable andsafe wayin the

given measuringhandle. The handle screwedto the reducerbymeansof

2x4M5 shouldguaranteedsolidandsafe placement of the sensorduring

work.

→Put the measuring sensorin thehandle in accordancewith thedrawing.Use

the washers.Screwthe nuts 2,0".

→The wayof ultrasonic signalshould befree of any disturbances.

→The surfaceof the assembly should befree of vibrations.

→The surrounding temperatureshould bebetween -20˚C....+70˚C

→Thereshouldnot betheelectricpowercablesorelectricpowerconverters

nearby.

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

8

Incaseof sensorinstallationoutsideyou shouldcoverit againstthe

sunbeams and environment conditions.

Thedeliveredsensor380-4SPA iscalibratedforthedetermined

typeofflumeand doesnotrequireanysettingsbytheuser.Thechangeof

factorysettings will causeerrorofmeasuringtransmitterM1600.

MEASURINGTRANSMITTERM1600

→Itis recommendedtousethe roofing ofthetransmitter protectingitagainst

directinfluenceof the atmosphericfactors (forinstance:rain, snow) or

installation in safetycase.

→HEALTHANDSAFETY.Inorderto assurethe safety of service(for

instance:duringthe startingup,maintenanceandcleaning)the transmitter

should bemounted in the easyavailable place.

→All connectionsofelectricwiresshouldbeplacedastopreventfrom their

mechanicaldamage.

→The installation of the devicemustmeetswith electromagnetic

compatibility rules.

→The influenceof the disturbancesof the otherdeviceson the flowmeter

work mustbestrictlyeliminated!

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

9

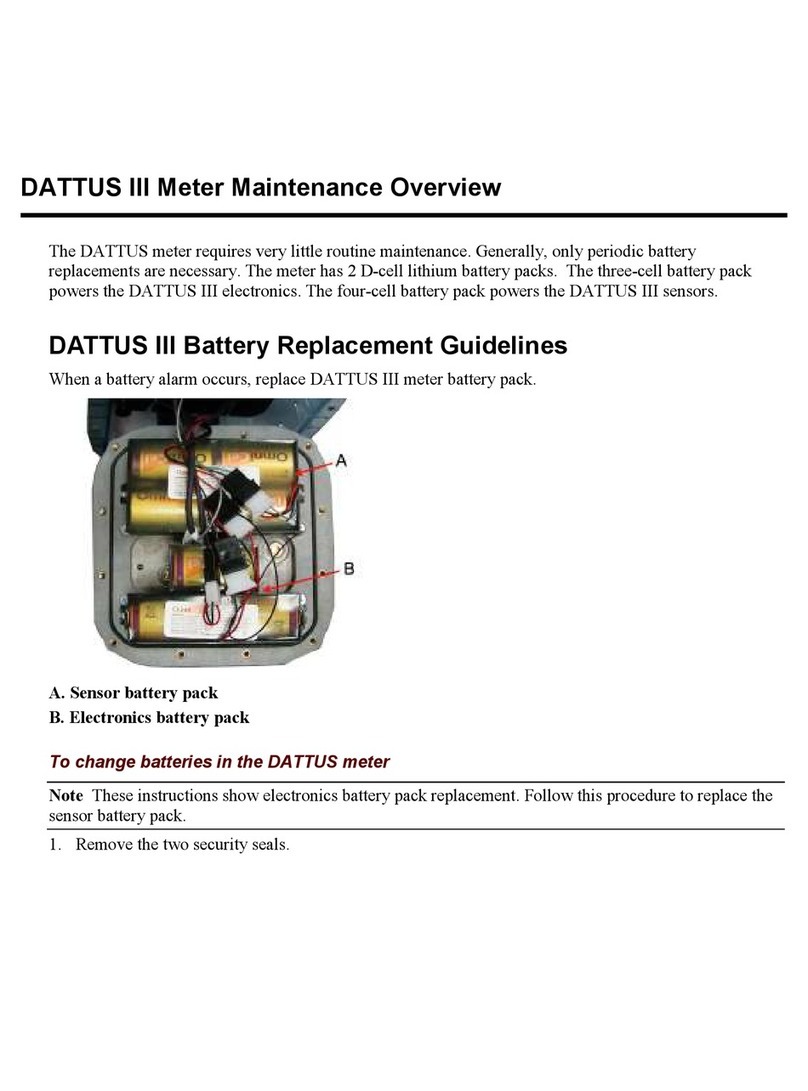

Rys.Dimensions of M1600transmitter and spanof holes for mounting bolts

NOTESREFERRINGTO SETFUNCTIONING:

Inorderto assurethe properfunctioningofthe measuringset, pleaseto workin

accordancewith the manual.

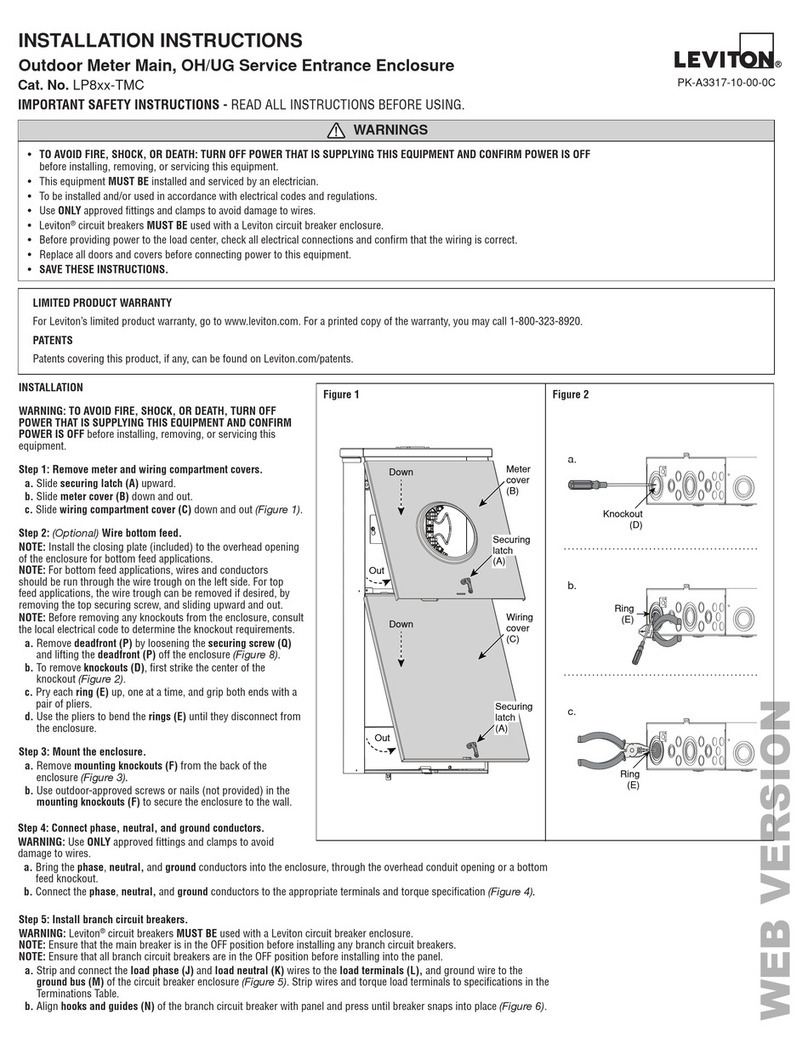

3.2.Connecting thewires to thetransmitter M1600

Inorderto connectthe signal, output andpowersupply wiresto the transmitterstrip

terminal in accordanceelectric scheme (chapter 3.3),you should:

→Unscrewtwoscrewsvisible on thefrontalboard,

→Insertsignal, power supply and output wires into the proper throttles,

→Connectthewiresto theterminalstripandimmobilizethem screwingthe

throttles to the end.

HEALTHAND SAFETY:All

electric connectionsshouldbemade

during switchedoff powersupplyof

themeasuring transmitterM1600.

Do not touchthe stripjointswhile making

the connectionof the wiresto theterminal

strips (usethe screwdriverswith the

isolations,hang the wires on isolation).

Unscrewand take off acover

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

10

3.3.Scheme ofelectricconnections ofthetransmitterM1600

PLC connection to impulseoutput.

Resistor should limit acurrent to max 150mA.

For PLC R=~2-3kΩ.

Installation ofthe devicemustmeets the electromagnetic compatibility rules.

Theinfluenceofthedisturbancesoftheotherdevicesonthe

flowmeterworkmustbestrictly eliminated!

POWER

SUPPLY

-

+

230VAC

N L

Power supply

: 230VA

C,50Hz

CURRENT

OUTPUT

DIGITAL

OUTPUT

Rs485

A

B

COM

SPA-380 SENSOR

SIGNAL INPUT IMPULSE

OUTPUT

SPA-380

We

-

+

Ch V

Count V

I

-

I+

Kabelczujnika SPA

-

380 : LiYCY 2x0,35mm ekr.

BRĄZOWYBIAŁYCZARNY

Ch V

ImA

PLC TransmitterM1600

Impulse output

I+

I

-

24V

DI

0V

R

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

11

4. DEVICE SERVICE

The measuringsetwasconfiguredto measurementtheintensityandamount

of sewagesbyusingthe measuringchannel Plamer-BowlusZPB160andlevel sensor

SPA380-4.The characteristics of measuringchannel andpropermeasuringformula

wasimplementedtothe M1600transmittermemory.Theusershouldonly setthe

parameter h0in accordancewith the point. 4.2.

Inthe event of changethe sensorormeasuringflume the M1600transmitter should

beprogrammedinthecompanyDI-BOX.

4.1.Displayofdevice

The four-buttons keyboard and liquid-crystalunit areto communicatewith the user.

Afterconnectingthe measuringset in accordancewith the electricscheme (point.

3.2.),to the factorof the transmittertherewill beprojectedthefollowingissues:

indicationsof liquidflowintensityin m

3

/h, summaryamount flowingthroughthe

measuring flume and actualvalueof the liquid level in the flume.

By pressingthe button ∧or ∨you may switchamain displayforaninformation of

unit time duration and power stoppage.

Flow intensity

Summary liquidamount

Valueof theliquid levelin

theflume[cm]

V =21.4m3/h9.0

Q =20m3

V =21.4m3/h9.0

Q=20 m3

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

12

Projecting the announcement:

→means incorrectconnection ofultrasonic sensor with aM1600transmitter.

Projecting the announcement:

→means exceeding aflume’s flowrange.

When the #or*characters appearin the display,it indicatesaconnection tothe

Modbus network:

#The M1600transmitter is connected to the Modbus network.

*The M1600 transmitterisconnectedto the Modbusnetwork,the M1600andMaster

areproperly configured.

** The M1600transmitterisconnectedto the Modbusnetwork, the M1600andthe

Masterarecorrectly configured.InquirywasreceivedfromMasterandresponse

was obtained from M1600 transmitter.

4.2.Devicecalibration

Afterproperinstallation of measuringset you shouldmake the measurement ofthe

settingof ultrasoundsensorSPA380-4with relation to the measuringfeet of ZPB160

flume and enter into the memoryof the M1600transmitter.

Timeduration

Number ofpower stoppage

V =! !! 20.0

Q =20m3

duration stopp

1:2511

SENSOR?h0.0

Q =20m3

V =21.4m3/h9.0

Q =20 m3**

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

13

Itis the mosteffectivewayto dothis:

→Plug the input partof measuring channel,

→Fill the inputpartwith waterasto overflowthe waterthroughthe

measuring feet and water level levels to the measuring feet,

→Checkthe value of the fillingindicatedbythetransmitterM1600on

the displayatfactorysettings:

Ifthe fillingvalue hon the displayis anotherthan"0" (on the drawing h=-0.1) in

theseconditions (the lackof flow) you should:

→Press the button CAL throughabout 20-30seconds until the announcement

displays:

Itmeansthatthe ultrasoundsensorSPA380-4front -inaccordancewith factorysettings

-is 52.4cmfrom the surfaceof ZPBflume’s measuring feet.

→Buttons ∨(or^dependson situation)decrease(orincrease)the value H0

with sizehdisplayedbythe transmitterM1600 (in the describedexample

the value hwas -0.1cmsoyou need to increasethis valueh0,sotheproper

value h0is 52.4+0.1=52.5cm)

→press button SAVE

Aftermakingtheseactivitiesthereshouldbedisplayedthe actualvalue, filling(level)

of the liquid.

Ifthereisnot possible to performthe above-mentionedprocedureforsome reasons,

applyingthe solution with lowerexactness -physically measurethe distancefront

sensorfrom measuringfeet. Inorderto changethesettingthe followingshouldbe

performed:

V =0.0m3/h-0.1

Q =20 m3

h0 =52.4cm?

ZERO LEVEL

V =0.0m3/h0.0

Q =20 m3

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

14

→Press the button CAL throughabout 20-30seconds until the announcement

displays:

→Buttons ∨or^set the new,with referenceto factorysettings,proper

distance-forthe channel ZPB, inaccordancewith the belowmentioned

drawing:

h0

→After measuring and setting theproper distance h0 you should press button

SAVE,whatwill beconfirmed by OK.

4.3.Measuring scopeand inputelectriccurrentset

Wanting to read outor set the measuring scopeor outflowcurrent, one should:

→Press the button SAVE throughabout 5seconds until the announcement

displays:

h0 =56.3cm?

ZERO LEVEL

0.0-40.04mA

measuringscope

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

15

Itmeansthatthe flowintensity measuringscopewithin the scope 0-40m3/h for

the current scope 4-20mA wasmanufacturedset. Ifthereisanecessity to change

it, you should press button CAL and then choseone of the scopebybuttons ∨or ^.

0

-

1

0

m

3

/h

0

-

20mA

0

-

2

0

m

3

/h

0

-

20mA

0

-

3

0

m

3

/h

0

-

20mA

0

-

4

0

m

3

/h

0

-

20mA

0

-

1

0

m

3

/h

4

-

20mA

0

-

2

0

m

3

/h

4

-

20mA

0

-

3

0

m

3

/h

4

-

20mA

0

-

4

0

m

3

/h

4

-

20mA

You should press SAVE whatwill beconfirmed by OK.

5. MODBUS INTERFACE

MODBUSinterfaceallowsforthe connection of oneormoremeasuringtransmitters

to acommon transmissionline ofthe RS-485 standard with the useof Modicon-

MODBUSprotocol. MODBUSinterfaceis characterized bythe following capabilities:

→reading the current measurementresults,

→reading the previously entered parameters,

→writing newparameters,

→examining the devicestatus.

5.1.Technical data

1.Transmission line:in accordancewith specification of the (EIA)RS-485standard.

2.Communication protocol:in accordancewith specificationof the Modicon-MODBUS

standard.

3.Maximum line length:1200m.

4.Galvanic barrier:for eachtransmitter.

5.Maximum number of logicalunits:247.

6.Maximum number of physicalunits connected to the line withoutarepeater:32.

7.Maximum access time to asingle station:below300ms.

8.Format of transmission for asingle character (asynchronous transmission):

→rate:9600bauds,

→number of bits:8(RTU),

→number of stop bits:1,

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

16

→error control:no parity control (NONE PARITY).

9.Resistanceto interference:in accordancewith specification of the (EIA)RS-485

standard.

5.2.Installationand launchoftheMODBUSinterface

Connectionoftransmitters:

Transmitters mustbeconnectedto the existingline in accordancewith the figure

presented below:

PLC Data+(A)

R

R

A

B

Data-(B)

Mxxxx

Rs485

COM

A

B

COM

Rs485

ConnectionofM1600 transmittertotheMODBUSnetwork

R=100 –150

1W, depending onthe wave impedanceof the used cable.

Resistors can’tbeused in the caseof shortconnections.

ConfigurationoftheM1600transmitter:

Eachtransmitteroperatingin the networkmustbeproperly configuredwith the use

of keyboard throughassignmentofaunique identification number.

Determinationof thenumberidentifyingtransmitterinthenetwork:

→press andholdSAVEkey forapprox.15s-afterthistime, the message

MODBUSNUMBER will appearinthe bottom partof thedisplayandthe

current devicenumber will bedisplayed in the upper part,

→exit from the procedureoccurs after pressing SAVE key again,

→in orderto changethe current devicenumber,press CAL key andthen use

arrowkeys to set the desired devicenumber,and press SAVE key,

→pressing CAL key again beforepressing SAVE key will result in cancelling

the carriedout settings andreturnto the displayof thecurrentdevice

number.

R

www.di-box.com.pl – User’s manual

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

17

5.3.Descriptionofregistersofthetransmitter M1600

Readingof the measurement resultsandsettingoftransmitterparameters occurs

through16-bit registers available viastandard functions of the MODBUSprotocol.

The followingreadingandwritingregisters aredistinguished FOR MEASURING

TRANSMITTERS:

→read with the useof function3(Read Holding Registers),

→written with the useof function 6(Write single register)

→address range0-65535

Types of variables:

UNSIGNED -16-bit unsigned integer,represented byone register.

FLOAT -32-bit floatingpoint value accordingto the IEEEstandard,representedby

tworegisters (32bits).

LONGINTEGER –32-bit totalvalue accordingto the IEEE standard,representedby

tworegisters (32bits).

ReadHolding Registers

1.Address:0,Format:FLOAT

LEVELin [m]-for the flowtransmitter,

2.Address:0,Format:FLOAT

FLOW in [m³/h]-for the flowtransmitter,

3.Address:0,Format:FLOAT

SUMMARYin [m³]-for the flowtransmitter,

4.Address:0,Format:FLOAT

ZEROLEVEL[m]-for the flowtransmitter,

Handling oferrors

Inthe Exception Response, the devicereturns error codes:

1–illegalfunction,

2–illegaladdress of registers,

3–illegalvalue of registers.

Handling oferrorsintheM1600transmitter

The following messages areshownon the transmitter display:

#-transmitters is connected to theModbus network,

www.di-box.com.pl - Instrukcjaobs ugi

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Copyright © DI-BOX2020, www.di-box.com.pl,info@di-box.com.pl

18

*-transmitterisconnectedto the Modbusnetwork, transmitterandMasterare

correctly configured,

*1 -illegalfunction,

*2 -illegaladdress of registers,

*3 -illegalvalue of registers,

*4 -CRCchecksum error.

6. MAINTENANCE RECOMMENDATIONS

5.1. Palmer BowlusZPB flume and ultrasonicsensor SPA 380-4

Checkthe permeability andclearness of the liquidpilingupelements(measuring

flume)dependingon needs.The maintenanceof the sensorSPA380-4refers to the

occasionalcheckof sensorsurfaceclearness andpossible wipingthe sensorfrontal

surfacewith the soft cloth.

This manual suits for next models

1

Table of contents