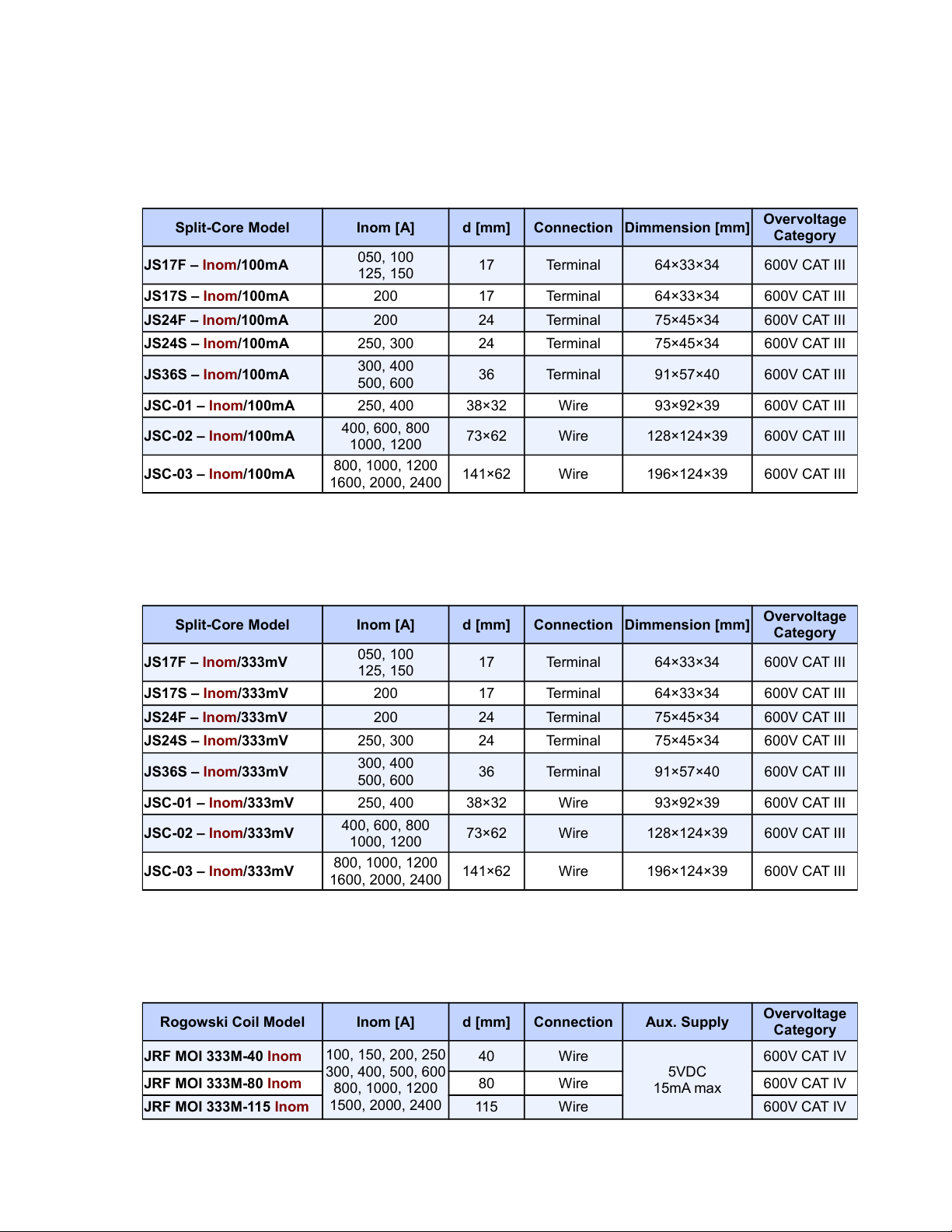

X/5A current input option The current signals from 5A or 1A instrument current transformers must be

connected to the terminal pairs I1k, I1l, I2k, I2l, I3k, I3l (No. 1

ö

6). A connection cable maximum cross section

area is 2.5mm2.

X/100mA current input option The supplied current transformers (which are standard accessory) must

be clamped on measured wires and interconnected with corresponding terminal pairs I1k, I1l, I2k, I2l, I3k, I3l

(no. 41

ö

46) using a twisted-pair cable of maximum length of 3 m.

Warning !: Connection of other current to an instrument is strictly forbidden !!! The instru-

ment can be seriously damaged by using unsupported 3rd party CTs!

The secondary winding of the split-core transformers is led to the screw terminals. The ”K“/”L“ and ”k“/”l“

orientation is marked on the CT guide groove. A connection cable maximum cross section area is 1.5mm2.

X/333 mV current input option (333mV CT or RCT only) these instruments are supplied with separate

terminal connector for each current input. The current transformers with nominal output voltage 333 mV must

be clamped on measured wires and interconnected with corresponding terminal pairs using a twisted-pair cable

of maximum length of 3 m. Again, proper current signal polarity (k and l terminals) must be observed.

Connection of the current inputs with X/333mV option is shown in fig. 5: terminals SI1, SI2 and SI3 (nr. 62,

65 and 68) are input signals corresponding to currents I1, I2 and I3 (terminal “k” of the measuring CT or white

wire of the RCT). SG terminals (nr. 63, 66 and 69) are a common pole for signals I1, I2 and I3 (terminal “l”

of the measuring CT or black wire of the RCT) and also a negative pole of the internal 5V auxiliary voltage

supply. These terminals are internally interconnected. SP terminals (nr. 61, 64 and 67) are the positive pole of

the internal 5V auxiliary voltage supply for the connected RCT sensors.

Warning !: Connection of unsupported type of current transformer such as the common type

with 5A or 1A secondary to an 333mV option instrument is strictly forbidden! The instrument

can be seriously damaged!

Warning !: Do not connect the current input signals of the 333mV option with neither ground

nor other potential ! Otherwise, measurement accuracy can be affected or the instrument can be

damaged!

The flexible current sensors with embedded integrator usually require a power supply. For such purpose the

instruments are equipped with auxiliary power supply 5V. Maximum load of each sensor connected is 20 mA.

2.2.4 Communication peripherals

USB communication port for USB slave is located on the front panel in its bottom-right corner. This

communication port is intended for easy local configuration and fast download of archived data to the local

PC. Use the supplied USB cable only. SMY 133 is a USB slave device. For correct operation it needs a driver

installed in your operating system (see the ENVIS user guide for more info).

Ethernet interface (optional) 10Base-T Ethernet interface with RJ-45 connector described ETH is situated

on a back side (terminal panel) of the device. Ethernet interface can be used as substitution for the primary

RS-485 for connection of the device to LAN and for easy connection of remote control PC.

RS-485 Serial Line serves usually as a remote communication for reading of actual data, archive downloading

and device configuration. Serial RS-485 line uses terminals A, B and GND (no. 28, 29 and 30 on fig. 3a and 8).

The final points of the communication line must be properly terminated with resistance.

7