Diamond Tech DIAMOND MAX ELITE User manual

DIAMOND TECH

Innovations For Creativity

DIAMOND MAX™ELITE

OPERATIONS MANUAL

TWO-IN-ONE GLASS GRINDER

Contents

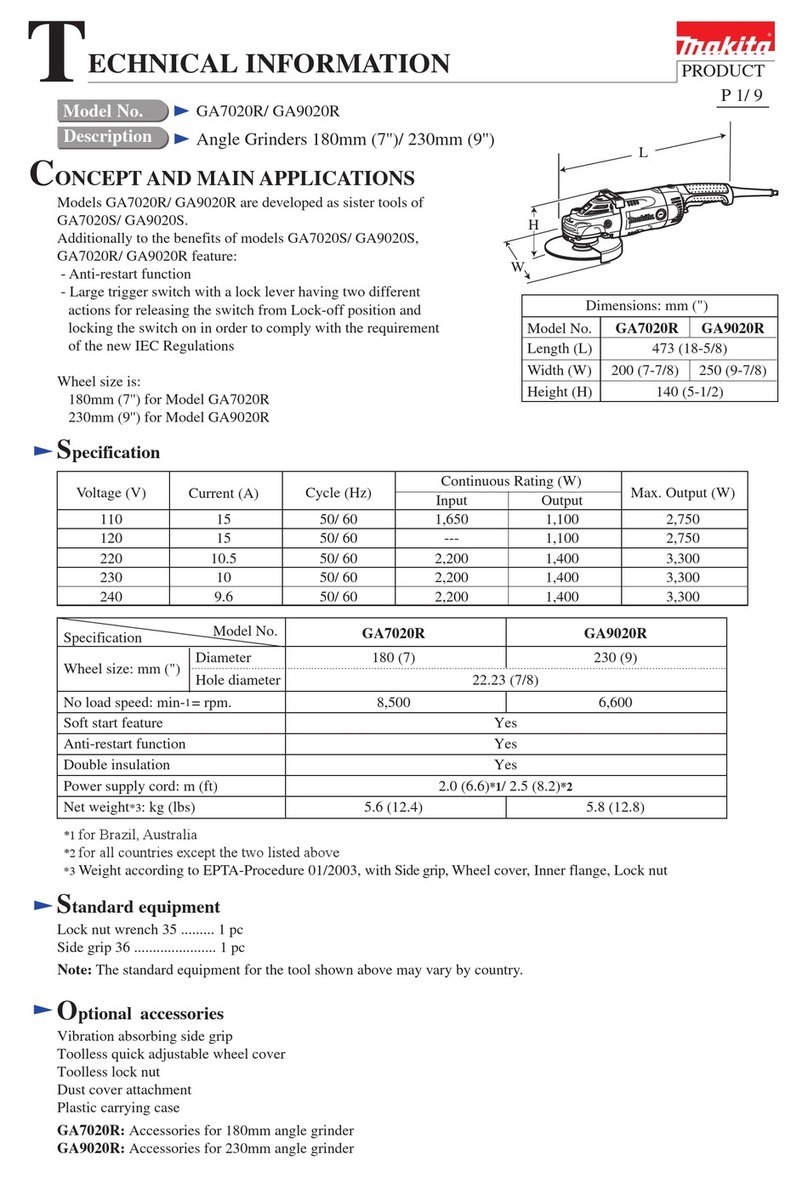

Your Diamond Max Elite Grinder™has been shipped partially assembled. Carefully remove grinder and parts

from the packaging.

1 - Grinder Body with Light

2 - 6” Flat Disk (260 Grit)

3 - 1” Silver Bullet™Bit

4 - Advanced Super Sponge™

5 - Adjusting Hex Wrench

6 - 300/450 Bevel Block

7 - Water Reservoir with Slide Valve

8 - Disk Support Collar and Disk Retaining Nut

9 - Easy Glide Work Surface

10 -Anti-Seize Lubricant

DELUXE MODEL ALSO INCLUDES:

1 - Bit Spacing Collar

2 - 3/4” Silver Bullet™Bit

3 - 1/4” Silver Bullet™Bit

4 - Easy-On™Footswitch

Assembly Instructions

A. Disk Installation

Disk installation is necessary in order to simultaneously use both the bit and disk.

Disk installation also prevents water from dripping into the motor housing.

1. Remove the packing included to protect the grinder during shipment.

2. To install the grinder disk use a hex wrench to loosen and remove grinder

bit (FIG.1).

3. Remove the grid surface, water tray and beveling block.

DIAMOND MAX™ELITE INSTRUCTION MANUAL - PAGE 2

FIG.1

1

2

3

4

5

6

9

7

8

1

23

4

Before You Begin

Read and follow all instructions carefully.

• After unpacking all components, assemble grinder on a rm level surface to prevent grinder from tilting

and rocking.

• Be sure the power switch is in the OFF position before plugging in the grinder.

• Always disconnect grinder from electrical outlet before setting up or servicing.

• Wear proper apparel. Never wear loose tting clothes, neckties, jewelry and gloves that may get caught in

moving parts.

• Always wear safety glasses. Everyday eyeglasses have only impact resistant lenses they are not

safety glasses.

• Never turn on grinder while glass or working materials are touching the bits or disks.

• Never leave grinder running unattended. Turn power OFF when not in use.

• Do not operate while under the inuence of medication or alcohol.

• To ensure top performance keep grinder properly maintained and lubricated.

WARNING: This product contains small parts that may be a choking hazard to small children.

KEEP OUT OF REACH OF CHILDREN.

10

PAGE 3 - DIAMOND MAX™ELITE INSTRUCTION MANUAL

FIG.2

FIG.3

FIG.4

FIG.5

FIG.6

Retaining Nut

Disk Support Collar

Grinder Motor Shaft

Line Hole up with Pin

Flat Side of

Motor Shaft

Remove the disk retaining nut from the disk support collar which is

already installed on the base of the grinder shaft (FIG.2).

4. Using the hex wrench, loosen the screw holding the disk support collar on

the shaft and remove the collar (FIG.3).

5. Lubricate the full length of the grinder motor shaft (FIG.4), as well as the

inside opening of the disk support collar, the disk and the disk retaining nut

threads with a thin coat of anti-seize. Anti-seize lubricant helps prevent the

bit from seizing on the shaft and seals out ground glass particles.

Anti-seize is readily available at any hardware store.

6. Reinstall the disk support collar by aligning the at surface of the shaft with

the collar hex screw.

7. Line up the pin hole on the bottom of the disk with the pin on the disk

support collar and lower the disk into place (FIG.5). Push disk down rmly

to minimize disk vibration and secure by threading the disk retaining nut

onto the collar.

8. Replace the water tray, grid surface, splash guard and beveling

block (optional).

B. Bit Installation

1. Before reinstalling the grinder bit, lubricate the top of the motor shaft and

inside the bit by applying a thin coating of anti-seize lubricant.

2. Slide the bit onto the motor shaft, positioning the set screw over the at

side of the motor shaft (FIG.6). Position the bit on the shaft so at least 1/8”

of the diamond surface is exposed above the grid work surface.

3. Secure the bit to the shaft by turning the set screw clockwise with the

hex wrench.

IMPORTANT: Always secure the bit to the at side of the motor shaft.

Tightening the bit to the rounded side can scar the shaft and prevent bit

removal!

C. Sponge Installation

The technologically advanced Super Sponge™can absorb over 10 times its

weight in water. Its superior wicking ability insures a sufcient water supply to

protect the bit and keep the glass cool.

1. Wet the Super Sponge™by immersing it in water until soft and pliable.

2. Fill the water reservoir (FIG.7) about 3/4 of the way to the top. You may

add special grinding lubricant if desired.

3. When using the grinder bit, keep the slide valve closed (FIG.8).

4. Insert the sponge between the sponge holder on the work surface and

grinder bit so that the bottom of the sponge is in contact with the coolant/

water in the reservoir and the top of the sponge is in contact with the

diamond surface of the bit (sponge may be trimmed to ensure proper t).

5. The wet sponge should remain in contact with the bit while grinding

(FIG.9). Periodically rinse out the sponge to remove grinding residue.

When the sponge becomes worn, replace it.

6. Should your sponge become dry during periods of non-use, simply

immerse in water and reinstall.

FIG.9

FIG.7

FIG.8

FIG.11

FIG.10

Slide Valve Closed

Deluxe Model Only

The Diamond Max Deluxe comes with 3/4” and 1/4” Silver Bullet™Bits for

grinding versatility.

1. To install the 3/4” grinder bit, remove 1” grinder bit.

2. Snap spacing collar into the grid surface to reduce the size of the

opening (FIG.10).

3. Slide the bit onto the motor shaft, positioning the set screw over the at

side of the motor shaft. Position the bit on the shaft so at least 1/8” of the

bit surface is exposed above the grid work surface.

4. Secure the bit to the shaft by turning the set screw clockwise with the

hex wrench.

5. The 1/4” grinder bit is useful for both drilling holes and intricate grinding.

The 1/4” bit is placed directly onto the top of the shaft and tightened with

the hex screw. It can also be installed without removing the 1” or 3/4” bit by

lowering the position of these bits on the shaft and installing the 1/4” bit on

top of the existing bit. You now have two bits to work simultaneously

6. Deluxe models also come with an Easy-On™foot-switch. This switch allows

you to easily turn the grinder on or off with a simple tap of the toe. To use,

plug grinder directly into the foot-switch, then plug foot-switch into any

outlet. Turn grinder to the ON position.

Grinder Use and Maintenance

A. Bit Use

Remember to wear safety glasses or install a protective face shield

when grinding.

1. If you are a rst time user, get the feel of the grinder by turning on the

grinder and grinding a piece of scrap glass. Begin by pushing the glass

into the grinding bit using light pressure and moving the glass back and

forth across the bit (FIG.11).

2. Slowly increase the pressure until you feel comfortable with the grinding

speed and your control. You’ll quickly learn the optimum grinding pressure

for the types of glass you use.

3. Stop periodically and check the sponge placement and water level.

Grinding without water greatly reduces the life of your grinding bits.

4. Over time, a bit may grind less effectively causing your glass to chip this is

a result of wearing away of the bit’s diamond surface. When this happens,

it is time to expose a new portion of the diamond surface. Loosen the set

screw using the hex wrench and move the grinding bit up on the shaft to

expose a new 1/8” section of diamond.

5. Secure the bit back in place making sure to tighten it against the at side of

the motor shaft. Reposition the sponge if needed.

B. Disk Use

1. When ready to start disk grinding, remove the grid work surface, ll the

water reservoir 3/4 full, open the slide valve (FIG.12) and replace the

surface grid. If needed, you can increase water supply to the grinding disk

by slightly enlarging the holes located behind the slide valve using a paper

clip or a ridged metal object. Use caution to prevent over-enlargement of

the holes. Your Diamond Max™comes with a drain opening on the grinder

base to prevent excess water from building up under the disk (FIG.13).

FIG.12

Slide Valve Open

DIAMOND MAX™ELITE INSTRUCTION MANUAL - PAGE 4

Do not plug drain hole. Set your grinder on a collection tray or shallow

pan that will capture the excess water.

2. While grinding, hold glass rmly and move the glass from side to side

over disk. To grind an accurate 900straight edge hold material

against the back of the water reservoir. To grind accurate 300or 450miter

edges, use the reversible bevel block (FIG.14).

3. To avoid unnecessary disk vibration, ensure a secure t between the

disk and lower support collar.

4. Minor chipping may occur with a new disk. Chipping will stop after a

little use.

C. Care Information

1. NEVER GRIND DRY. Always make sure the sponge for the grinder bit

is wet or that water is dripping on the disk while grinding.

2. DO NOT OPERATE WITHOUT DIAMOND DISK INSTALLED. Disk acts

as a cover to keep water from dripping on the motor housing.

3. While using the grinder bit, use only light to medium pressure on the bit. Do not push material against bit

using excessive force. Unnecessary pressure will shorten grinder and grinder bit life.

4. Clean water reservoir and Super Sponge™ after each use. Remove water reservoir and ush out grinding

residue around the sides of the base under the disk. The drain hole in the grinder box allows water to ush

through when cleaning or if using large volumes of water on the disk when grinding.

5. If the grinding bit becomes dry, add water directly to the Super Sponge™.

6. To extend the life of the grinder, clean and lubricate the motor shaft, inside openings of all disks and bits

and all set screws every 25 hours of use.

7. Grinder bits and disks should be removed from the machine if they are not in use for a week or more. This

will keep them from “cementing” to the shaft. It will also provide you with the opportunity (and habit) of

inspecting the motor shaft and bits for proper care and maintenance.

8. Some rust may form on the diamond disk, this will not effect the efciency or life of the disk.

9. DO NOT GRIND METAL. It will make the surface unsuitable for glass in seconds.

Troubleshooting

Problem: Grinder bit, disk or disk collar has become stuck onto the motor shaft.

Solution 1: Loosen set screws and push the bit as far down the shaft as possible. Most often the shaft above

where the bit was mounted crusts with glass debris, coolant, hard water residue, etc. Using a small piece of

ne steel wool or scrubby, polish the end of the shaft all the way down to where the bit rests.

Solution 2: If you can push the bit down as above, but you notice that there is a burr or scar on the round side

of the motor shaft caused by the set screw in the wrong position (it appears as a small ring cut into the shaft),

you will need to polish it out. This can often be done by using the same steel wool mentioned above, but

occasionally it requires stronger abrasives. Be very careful here! You only want to remove the scar, you do not

want to make the shaft smaller. It may be necessary to use very ne grit emery cloth or sandpaper here. But

again, be very careful, the motor shaft can be easily damaged. Once the scar is polished out, remove the bit.

Clean both the bit and shaft and use lubricant. Never tighten the bit to the round side of the motor shaft.

Solution 3: If the bit or disk is still stuck, use a plumbers helper or vice grip to remove the bit. If further

assistance is necessary, call Diamond Tech toll free at (800) 937-9593 for tech service or to obtain a Return

Authorization Number and further instructions to send your machine in for repair.

PAGE 5 - DIAMOND MAX™ELITE INSTRUCTION MANUAL

FIG.14

Drain

FIG.13

Diamond Tech

Diamond Max Series 6 Year Warranty

All Diamond Tech grinders and accessories are manufactured to high quality standards and are serviced by highly

qualied technicians.

Diamond Max Grinders are warranted to the original purchaser for six full years from the original purchase date. During

the six year period, if you feel the Diamond Max Grinder is not performing properly and needs to be serviced, contact

Diamond Tech at 800-937-9593 or email [email protected] for a Return Authorization Number. Equipment will not be

accepted at Diamond Tech without a Return Authorization Number.

If returning your grinder for evaluation or repair, be sure to include your Name, Address, Daytime Phone Number with

Area Code and a letter explaining the specic problem you are encountering. You will be contacted if any necessary parts

or service are not covered under the warranty.

Date of purchase ___ / ___ / ___

Mark the Return Authorization Number clearly on every package! Do not send this product back without such prior

authorization! Return postage and insurance are the responsibility of the consumer. Diamond Tech will return your grinder

postage paid and insured if it is under warranty. Any grinder no longer under warranty will be returned at the owner’s

expense. Diamond Tech reserves the right to repair or replace faulty equipment at its discretion. The Diamond Max

Grinder is warranted against defective materials or workmanship. If the Diamond Max Grinder suffers damage due to

customer modications and/or is used for any application other than that for which it was designed, this warranty is void.

This warranty does not include damage due to: (A) neglect (B) accident (C) unreasonable use (D) improper maintenance

(E) any other causes not attributed to defects in material or workmanship. This warranty specically excludes the Diamond

Max Grinder bits or disks. Any implied or otherwise explicit guarantees made through merchandiser of this product are not

covered in this warranty coverage agreement and are expressly disclaimed.

IMPORTANT NOTE: This machine was designed for certain applications only. Diamond Tech strongly recommends that

this machine NOT be modied and/or used for any application other than that for which it was designed. If you have any

questions relative to its application, please contact us and we will advise as to it proper use.

Additional Parts and Accessories

Item Item Number

WORK SURFACE GRID 289

UNIVERSAL FACE SHIELD 75

STEP-UP WORK SURFACE 72

EASY-ON FOOTSWITCH 42

MAX SPLASH GUARD P203

GRINDER MOTOR 110V/220V P216/P216A

GRINDER CAPACITOR 110V/220V P221/P221A

GRINDER DISK COLLAR WITH RETAINING NUT P218

SLIDE VALVE P201

SUPER SPONGE REPLACEMENTS 66SUPER

1/4” FAST BIT 23

1/4” STANDARD BIT 60

3/4” FAST BIT 36

3/4” STANDARD BIT 35

1” FAST BIT 29

1” STANDARD BIT 41

ANGLED BIT 30

REDUCING BIT 31

180 GRIT DISK 57

260 GRIT DISK 56

360 GRIT DISK 32

10/2018

5600 Airport Blvd, Suite C, Tampa, Florida 33634

(U.S.A., Canada) 813-806-2923

www.DiamondTechCrafts.com

Table of contents

Other Diamond Tech Grinder manuals

Popular Grinder manuals by other brands

Milwaukee

Milwaukee 5192 Operator's manual

EINHELL Expert

EINHELL Expert TE-AG 125 CE Original operating instructions

Kielder

Kielder KWT-013 Original instruction manual

Bosch

Bosch GGS 6 S PROFESSIONAL Original instructions

Waring

Waring WSG30K Instructions for the use

Parkside

Parkside PWS 230 D4 Translation of the original instructions