3

Kielder WT Ltd KWT-013-IMH22

Noise & Vibration Data

Acoustic Pressure: <84 dB(A) K=3dB

Acoustic Power: <95 dB(A) K=3dB

Maximum Vibration (surface grinding): 7.0m/s2

/ K = 1.5m/s2

Sound emission values determined according

to EN60745-2-3. The declared vibration total

value has been measured in accordance with a

standard test method used to compare one tool

with another and according to EN60745. Both

sound and vibration values have an uncertainty

factor of K. The declared total values may be used

in a preliminary assessment of exposure.

WARNING!

The vibration emission during

actual use of the power tool can

dier from the declared total

value depending on the ways in which the tool is

used. The need to identify safety measures and to

protect the operator are based on an estimation

of exposure in the actual conditions of use (taking

account of all parts of the operating cycle, such

as the times the tool is switched o, when it is

running idle, in addition to trigger time). Identify

additional safety measures to protect the operator

such as proper maintenance of the tool, keeping

hands warm and organisation of work patterns.

CONTENTS

Safety Rules & Instruction 4

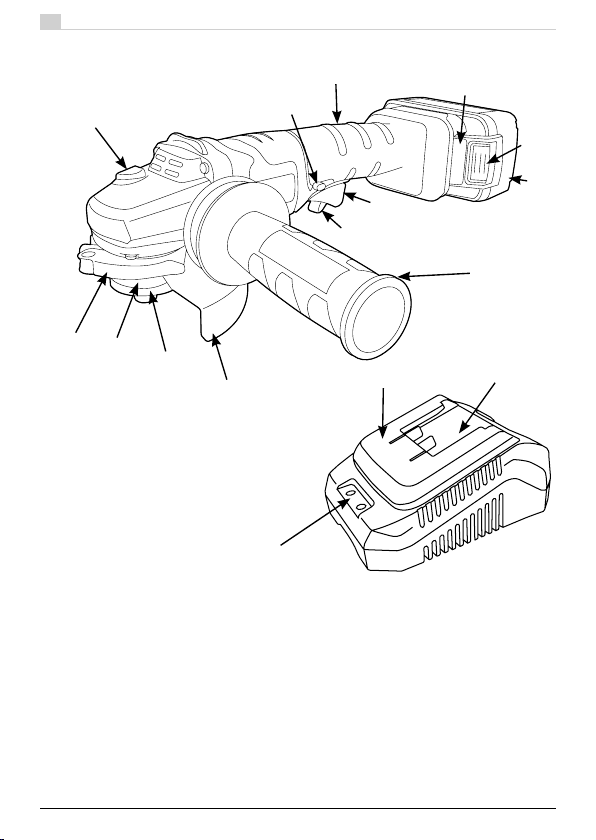

Product Overview Diagram 10

Specication Table 11

Usage

Angle Grinder 12

Battery 16

Charger 18

Warranty & Support 20

EC - Declaration Of

Conformity

We declare that under our responsibility the

product under part number:

KWT-013 18V Cordless Angle Grinder complies

with the applicable EU directives:

2011/65/EU, 2014/30/EU, 2006/42/EC

including the amendments and are manufactured

in accordance following standards or

standardised documents:

EN 60745-1

EN 60745-2-3

All documentation is held in KWT-013 Technical

File and is available, on request for review.

Authorised Signatory:

Steven Bulloss

Director

Dated: 10/05/22

Kielder WT Ltd, Unit 14 Carlisle Business Park,

40 Chambers Lane, Sheeld S4 8DA

IMPORTANT!

Please read these operating and

safety instructions carefully and

completely. For your own safety,

before using this equipment check that all

external parts are rmly secured and the machine

in tact. If you are uncertain about any aspect of

using this equipment, or require support please

contact Kielder WT customer services and we’ll

be happy to help:

Tel: 0114 242 3794 Email: tools@kielder.co

Plug Type

• The appliance is supplied with a moulded three

pin mains plug for your safety and convenience.

• Only use this plug in the socket it is intended.

• A 3 amp fuse is tted in this plug. Should

the fuse need to be replaced please ensure that

the replacement fuse has a 3 amp rating and it is

approved by ASTA or BSI to BS1362.

• Check for the ASTA mark or the BSI mark on the

fuse.

• If the plug contains a removable fuse cover, you

must ensure that it is retted when the fuse

is replaced.

• If you lose the fuse cover the plug must not be

used until a replacement cover is obtained.

Intended Use

With the appropriate disc tted, this tool is

intended for surface preparation and nishing.

DANGER!

This tool has a rotating disc,

which is capable of cutting

you and causing serious injury

or death, if not used correctly. Please read this

manual and the cautionary markings on the tool

and obey the safety instructions to avoid injury.

If you allow someone else to use the tool please

ensure that they have read this manual or have

been fully trained in its proper and safe use.