Diesel WARTSILA F 240 User manual

Manual

ECopyright 2004 by Wärtsilä Nederland B.V.

All rights reserved. No part of thisbooklet may be reproduced or copied in anyform

or by any means (electronic, mechanical, graphic, photocopying, recording, taping

or other information retrieval systems) without the prior written permission of the

copyright owner.

THISPUBLICATIONISDESIGNEDTOPROVIDEASACCURATEANDAUTHORITATIVEINFORMATION

IN REGARD TO THE SUBJECT---MATTER COVERED AS WAS AVAILABLE AT THE TIME OF WRITING.

HOWEVER, THE PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY

FOR SPECIALISTS IN THE AREA, AND THE DESIGN OF THE SUBJECT---PRODUCTS IS SUBJECT TO

REGULAR IMPROVEMENTS, MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER

AND COPYRIGHT OWNER OF THIS PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIA-

BILITY FOR ANY EVENTUAL ERRORS OR OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES

ARISING FROM THE FEATURES OF ANY ACTUAL ITEM IN THE RESPECTIVE PRODUCT BEING DIF-

FERENT FROM THOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER AND COPYRIGHT HOLDER

SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL OR OTHER LOSS, OR

ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY PARTY MAKING USE OF THIS PUBLICATION

OR THE INFORMATION CONTAINED HEREIN.

--

Date of issue November 2004

ENGINE TYPE F 240 --engine

Author SERVICE

Approved

AUTHORIZATION Management WNL

DOCUMENT

13128

Distribution

Status

Number

Manual

Manual

F 240 COMMUNICATION

Ver. 01 xx -- 3

In order to maintain the operational safety of your engine, a simple, and a fast contact

between you and Stork--Wärtsilä Diesel B.V can be of essential importance.

Stork--Wärtsilä Diesel B.V.

Postbus 10608

8000 GB ZWOLLE

Telefoon 038--4253253

Telex 42116

FAX 038-- 4223564

From Monday to Friday Stork--Wärtsilä Diesel B.V can be contacted on telephone

number 038--4253 253 during working hours from 08.00 -- 16.30 hours; ask for

departments:

-- SERVICE-- PARTS:

For information about inquiries, information about service, ordering spare parts

or tools

-- SERVICE --INSPECTION:

For all technical support.

During non--working hours one of our staff members will always be available on the

above number. He will have one of our experts to call you back as soon as possible.

Furthermore youcan contact one ofour Service Departments inThe Netherlands dur-

ing working hours as mentioned below:

SCHIEDAM (ROTTERDAM)

DEN HELDER

STELLENDAM

URK (only on Saturday)

IJMUIDEN

For information on Service Departments throughout the world, please contact Stork--

Wärtsilä Diesel B.V. headquaters, Zwolle.

-- o -- o -- o -- o -- o --

Introduction

Headquarters

in The

Netherlands

Service

departments in

the Netherlands

Service depart-

ments through-

out the world

Hanzelaan 95

8017 JE ZWOLLE

Tel.: 010 -- 4 277 100

Adres: Havenstraat 24

Fax: 010 -- 4 264 571

Tel.: 0223 -- 33 59 88

Adres:Het NieuweWerk102

Fax: 0223 -- 333890

Tel: 0187 -- 491956

Adres: Deltahaven 7

Fax: 0187 -- 493428

Tel: 0527 -- 682053

Adres: Industrierondweg 6D

Tel.: 0255 -- 511678

Adres: Trawlerkade 46

Fax: 0255 -- 536724

Manual

F 240 COMMUNICATION

Ver. 01 xx -- 4

Manual

F 240 CONTENTS

xx -- 5

Ver. 01

CHAPTER 0: GENERAL

0A PURPOSE 0--1..............................................................

0B DOCUMENTATION OVERVIEW 0--2...........................................

0C MANUAL SETUP/PAGE SETUP 0--3..........................................

1. Manual setup 0--3........................................................

2. Page setup 0--3..........................................................

0D DESCRIPTION OF THE ENGINE 0--5.........................................

1. Crankshaft and bedplate 0--5.........................................

2. Cylinder block 0--5...................................................

3. Cylinder liner 0--5....................................................

4. Piston with connecting rod 0--5.......................................

5. Cylinder head 0--5...................................................

6. Camshaft and valve mechanism 0--5..................................

7. Injection equipment 0--6..............................................

8. Exhaust manifold 0--6................................................

9. Turbocharging and charge air cooling 0--6.............................

10.Definitions 0--6......................................................

CHAPTER 1: OPERATION

1A GENERAL 1--1.............................................................

1. Commissioning 1--1....................................................

2. General 1--1...........................................................

3. Starting and stopping of the engine 1--1.................................

4. Operation 1--1.........................................................

5. Running--in 1--1........................................................

6. During operation 1--1...................................................

7. After stopping 1--2.....................................................

8. Long shut--downs 1--2..................................................

CHAPTER 2: BACKGROUND INFORMATION

2A SAFETY ASPECTS 2--1.....................................................

1. Safety aspects 2--1.....................................................

Risk of crankcase explosion 2--1..........................................

2. Maintenance instructions 2--1...........................................

General 2--1............................................................

Removal 2--2...........................................................

Fuel injector 2--2........................................................

Mounting 2--2...........................................................

Last check 2--2.........................................................

2B CRANK DEGREES NINE CYLINDER ENGINE 2--3.................................

1. General 2--3...........................................................

2. Reading crank position 2--3.............................................

2C ENGINE TOOLS 2--4............................................................

1. General 2--4...........................................................

2. Tool 9612 F 927 2--4....................................................

2D INDEX OF SYMBOLS 2--5.......................................................

Manual

F 240 CONTENTS

xx -- 6

Ver. 01

CHAPTER 3: TECHNICAL DATA

3A MAIN DATA 3--1............................................................

1. Engine specifications 3--1..............................................

2. Weights in kg. 3--1.....................................................

3. Oil contents in liters 3--1................................................

4. Cooling water in liters 3--1.............................................

5. Cylinder numbers 3--2..................................................

6. Combustion sequence 3--2.............................................

7. Standard valve timing 3--2..............................................

8. Valve clearance 3--2....................................................

9. Pressures 3--3.........................................................

10. Temperatures 3--3......................................................

11. Pump data 3--3.........................................................

3B TIGHTENING TORQUES 3--4.................................................

1. Cylinder head 3--4......................................................

2. Cylinder block 3--4.....................................................

3. Fuel 3--4...............................................................

4. Camshaft 3--5..........................................................

5. Connecting rod 3--5....................................................

6. Main bearings 3--5.....................................................

7. Crankshaft 3--5........................................................

8. Engine/generator on foundation 3--5....................................

9. Assembly tie rods 3--6..................................................

3C NO GO CRITERIA 3--8......................................................

1. Piston (2--parts conf.) 3--8..............................................

2. Connecting rod 3--8....................................................

3. Main bearing (with mounted cylinder block) 3--8.........................

4. Axial bearing 3--8......................................................

5. Camshaft 3--9..........................................................

6. Camshaft drive 3--9....................................................

7. Valves (inlet and exhaust) 3--9..........................................

8. Lubricating oil pump 3--9...............................................

CHAPTER 4: INJECTION AND MAINTENANCE

4A GENERAL 4--1..............................................................

1. General 4--1...........................................................

2. Daily check 4--1........................................................

3. Weekly check 4--2......................................................

4. Observation list 4--3....................................................

4B INSPECTION AND MAINTENANCE PROCEDURES 4--4........................

1. Maintenance interval/effective life 4--4...................................

2. Inspection 4--4.........................................................

3. Daily maintenance 4--5.................................................

4. Weekly maintenance 4--6...............................................

5. 750--hours overhaul 4--7................................................

6. 1500--hours overhaul 4--8...............................................

7. 3000--hours overhaul 4--9...............................................

8. 6000--hours overhaul 4--10...............................................

9. 12000--hours overhaul 4--12..............................................

10. 24000--hours overhaul 4--14..............................................

11. 36000--hours overhaul 4--16..............................................

4C TEST RUNNING 4--18........................................................

1. Test running 4--18.......................................................

2. Running--in 4--18........................................................

3. Functional test 4--20.....................................................

Manual

F 240 CONTENTS

xx -- 7

Ver. 01

CHAPTER 5: FUEL SYSTEM

5A INTRODUCTION 5--1........................................................

1. General 5--1...........................................................

2. Description of engine parts 5--1.........................................

Fuel feed pump (1.1) 5--1................................................

Fine fuel filter (1.2) 5--1..................................................

High pressure fuel pumps (1.3) 5--1........................................

Fuel injector (1.5) 5--2...................................................

Pressure regulating valve (1.6) 5--2........................................

Leak--off fuel (2.1, 2.2 and 2.3) 5--2........................................

5B FUEL REQUIREMENTS 5--3.................................................

Bunker requirements 5--3................................................

Engine fuel requirements 5--3.............................................

5C FUEL FILTER ELEMENT 5--4.................................................

1. General 5--4...........................................................

2. Removal 5--4...........................................................

3. Fitting 5--5.............................................................

5D INSPECTIONS, MOMENT OF INJECTION 5--6.................................

1. Training tools 5--6......................................................

2. Fuel control system 5--7................................................

3. Verification of moment of injection 5--8..................................

4. Checking pre--lifting 5--9................................................

5E CONSTANT PRESSURE VALVE 5--10..........................................

1. Tool 5--10...............................................................

Tool A 5--10.............................................................

Tool B 5--10.............................................................

2. Testing 5--10............................................................

5F GENERAL DIAGRAM 5--11....................................................

CHAPTER 6: LUBRICATING OIL SYSTEM

6A INTRODUCTION 6--1........................................................

1. General 6--1...........................................................

2. Description of engine parts 6--1.........................................

Lubricating oil pump (1.0) 6--1............................................

Thermostatic three--way valve (1.2) 6--1....................................

Safety overflow valve (1.3) 6--1...........................................

Pressure regulating valve (1.6) 6--1........................................

Main lubricating oil manifold (1.7) 6--2......................................

Pre--lubricating pump (4.0) 6--2...........................................

Needle valve (5.6) 6--2...................................................

Crankcase venting (A) 6--2...............................................

6B LUBRICATING OIL REQUIREMENTS 6--3.....................................

1. General 6--3...........................................................

2. Engine lubricating oil 6--3..............................................

3. Sub--suppliers manuals 6--3............................................

4. Testing engine lubricating oil 6--4.......................................

5. No go criteria for engine lubricating oil 6--4..............................

6C LUBRICATING OIL FILTER 6--5..............................................

1. General 6--5...........................................................

2. Removing 6--6.........................................................

3. Assembly 6--6.........................................................

6D CENTRIFUGAL FILTER 6--7..................................................

1. General 6--7...........................................................

2. Disassembly 6--7.......................................................

3. Replacement 6--7......................................................

6E LUBRICATION OF INLET VALVE SEATS 6--9..................................

1. General 6--9...........................................................

2. Checking 6--9..........................................................

Manual

F 240 CONTENTS

xx -- 8

Ver. 01

6F BARRIER OIL SYSTEM HIGH PRESSURE FUEL PUMPS 6--10...................

1. General 6--10...........................................................

2. Checking the barrier oil system HP fuel pumps 6--10......................

6G INSPECTIONS 6--11..........................................................

1. Lubricating oil overflow valves 6--11......................................

6H LUBRICATING OIL THERMOSTATS 6--12......................................

1. General 6--12...........................................................

2. Inspection of the thermostatic wax elements 6--12........................

6J GENERAL DIAGRAM 6--13....................................................

CHAPTER 7: COOLING WATER SYSTEM

7A INTRODUCTION 7--1........................................................

1. General 7--1...........................................................

2. Description of engine parts HT--circuit 7--1...............................

Cooling water pump (1.0) 7--1.............................................

De--aeration points (1.3) 7--1..............................................

Thermostatic 3--way valve (1.4) 7--1.......................................

Water cooler (1.5) 7--1...................................................

Cooling water expansion tank (1.7) 7--1....................................

Emergency cooling (E) 7--1...............................................

3. Description engine parts LT--circuit 7--2.................................

Cooling water pump (2.0) 7--2.............................................

Charge air cooler (2.3) 7--2...............................................

Lube oil cooler (2.4) and water cooler (1.5) 7--2.............................

Emergency cooling LT--circuit 7--2.........................................

7B REQUIREMENTS 7--3.......................................................

1. Cooling water specifications 7--3........................................

2. Cooling water treatments 7--4...........................................

3. Checking of cooling water quality 7--5...................................

7C COOLING WATER DE--AERATION 7--6........................................

General 7--6............................................................

Checking and inspection 7--6.............................................

7D COOLERS 7--7.............................................................

1. Heat exchangers 7--7...................................................

2. Air cooler 7--7..........................................................

Insufficient cooling 7--7...................................................

7E COOLING WATER THERMOSTATS 7--8.......................................

7F COOLING WATER PUMP 7--9................................................

1. Disassembly 7--9.......................................................

2. Assembly 7--10.........................................................

7G INSPECTION COOLING WATER SPACE 7--11..................................

7H GENERAL DIAGRAM 7--12....................................................

CHAPTER 8: AIR INLET AND EXHAUST SYSTEM

8A INTRODUCTION 8--1........................................................

1. General 8--1...........................................................

2. Description of engine parts 8--1.........................................

Inlet air filter (1.1) 8--1...................................................

Turbocharger (1.2) 8--1..................................................

Air cooler (1.4) 8--2......................................................

Exhaust manifold (2.1) 8--2...............................................

8B COMBUSTION AIR REQUIREMENTS 8--3.....................................

1. Specification 8--3......................................................

Reference conditions 8--3................................................

2. Receiver pressure and exhaust gas temnperature 8--3....................

8C CHARGE AIR CONDENSATION 8--4..........................................

1. Checking discharge opening 8--4.......................................

2. Inspection discharge 8--4...............................................

Manual

F 240 CONTENTS

xx -- 9

Ver. 01

8D TURBOCHARGER 8--5......................................................

1. General 8--5...........................................................

2. Cleaning compressor side 8--5..........................................

3. Cleaning of the air filter 8--6............................................

8E EXHAUST COMPENSATORS 8--7............................................

1. Necessary tools 8--7....................................................

2. Fitting of the compensator 8--7..........................................

8F GENERAL DIAGRAM 8--8....................................................

CHAPTER 9: STARTING AND STOPPING SYSTEM

9A INTRODUCTION 9--1........................................................

1. General 9--1...........................................................

2. Description of engine parts 9--1.........................................

Starting device (1.--) 9--1.................................................

Stopping device (2.--) 9--1................................................

9B STARTING PROCEDURE 9--2................................................

1. Prior to starting 9--2....................................................

Fuel system 9--2........................................................

Cooling water system 9--2................................................

Start and stop system 9--2................................................

Alarm system 9--2.......................................................

Lubricating oil system 9--2................................................

2. Starting 9--2...........................................................

3. Stopping 9--2..........................................................

9C STARTING AIR DISTRIBUTOR 9--3...........................................

1. Replacing the driver 9--3................................................

2. Checking the setting 9--3...............................................

3. Setting the distributor disc 9--4.........................................

9D GENERAL DIAGRAM 9--5....................................................

CHAPTER 10: ALARM AND SAFETY SYSTEM

10A DESCRIPTION 10--1..........................................................

1. General 10--1...........................................................

2. Speed measuring system 10--1...........................................

3. Alarm and protection switches 10--3......................................

4. Alarm and protection unit 10--4..........................................

5. Co--signaling board 10--5................................................

10B TESTING THE SETTINGS 10--6...............................................

1. General 10--6...........................................................

2. Test, checks and calibrations 10--6.......................................

10C DIAGRAM RPM MEASURING SYSTEM 10--8...................................

10D DIAGRAM ALARM AND SAFETY 10--10.........................................

CHAPTER 11: MAIN BEARINGS

11A NECESSARY TOOLS 11--1....................................................

Tool A 11--1.............................................................

Tool B 11--2.............................................................

Tool C 11--3.............................................................

11B REMOVAL 11--4..............................................................

11C REPLACEMENT 11--5........................................................

CHAPTER 13: CYLINDER BLOCK

13A INTERNAL INSPECTION 13--1................................................

1. Crankshaft space 13--1..................................................

2. Cooling water spaces 13--1..............................................

Manual

F 240 CONTENTS

xx -- 10

Ver. 01

CHAPTER 14: EXPLOSION VALVE

14A CHECKING 14--1.............................................................

CHAPTER 15: CYLINDER LINER

15A NECESSARY TOOLS 15--1....................................................

Tool A 15--1.............................................................

15B INSPECTION 15--2...........................................................

1. Endoscope inspection 15--2.............................................

2. Inspection points 15--2..................................................

15C REMOVAL 15--3..............................................................

Tool A 15--3.............................................................

15D FITTING 15--4................................................................

CHAPTER 16: PISTON AND CONNECTING ROD

16A GENERAL DESCRIPTION 16--1...............................................

1. Piston 16--1.............................................................

2. Connecting rod 16--1....................................................

16B NECESSARY TOOLS 16--2....................................................

Tool A 16--2.............................................................

Item 1 16--2.............................................................

Item 2 16--3.............................................................

Item 3 16--3.............................................................

Item 4 16--3.............................................................

Item 5 16--3.............................................................

Item 6 16--4.............................................................

Item 7 16--4.............................................................

Item 8 16--4.............................................................

Tool B 16--5.............................................................

Tool C 16--6.............................................................

16C REMOVAL BIG END BEARING 16--7...........................................

Tool A 16--7.............................................................

Tool A+B 16--7...........................................................

16D FITTING BIG END BEARING 16--9.............................................

Tool A 16--9.............................................................

Tool B 16--9.............................................................

16E REMOVING 16--11............................................................

Tool A 16--11.............................................................

Tool A 16--11.............................................................

16F REMOVAL OF GUDGEON PIN 16--12...........................................

16G FITTING OF GUDGEON PIN 16--13.............................................

16H REMOVAL OF PISTON RINGS 16--14...........................................

Tool C 16--14.............................................................

16J FITTING OF PISTON RINGS 16--15.............................................

Tool C 16--15.............................................................

16K FITTING PISTON AND CONNECTING ROD 16--16................................

Tool A 16--16.............................................................

Tool A 16--17.............................................................

Manual

F 240 CONTENTS

xx -- 11

Ver. 01

CHAPTER 17: FUEL INJECTOR

17A NECESSARY TOOLS 17--1....................................................

Tool A 17--1.............................................................

Tool B 17--2.............................................................

Tool C 17--3.............................................................

Tool D 17--4.............................................................

Tool E 17--5.............................................................

17B REMOVAL 17--6..............................................................

Fuel injector 17--6........................................................

Removal procedure when injector sticks 17--7................................

17C CHECKING 17--8.............................................................

1. Connecting 17--8........................................................

2. Checking of the opening pressure 17--8..................................

3. Checking of the needle seal 17--8........................................

4. Checking fuel jet 17--8...................................................

5. Test results 17--9........................................................

17D DISASSEMBLY AND TESTING OF NOZZLE 17--10...............................

1. Disassembly 17--10.......................................................

2. Nozzle inspection 17--10..................................................

3. Sliding test 17--10........................................................

4. Inspection of nozzle holder 17--10.........................................

17E ASSEMBLY OF NOZZLE 17--11................................................

17F SETTING OPENING PRESSURE 17--12.........................................

17G REFITTING 17--13.............................................................

Fitting of injector in cylinder head 17--13......................................

CHAPTER 18: CYLINDER HEAD

18A NECESSARY TOOLS 18--1....................................................

Tool A 18--1.............................................................

Tool B 18--2.............................................................

Tool C 18--3.............................................................

18B REMOVAL 18--4..............................................................

Tool A 18--4.............................................................

Tool B 18--4.............................................................

18C FITTING 18--5................................................................

18D VALVES 18--6................................................................

1. Removal 18--6...........................................................

2. Inspection 18--6.........................................................

3. Fitting 18--6.............................................................

18E VALVE SPRINGS 18--7.......................................................

1. Removal 18--7...........................................................

Tool B 18--7.............................................................

2. Inspecting the valve springs 18--7........................................

3. Fitting 18--8.............................................................

18F ADJUSTMENT OF VALVE CLEARANCE 18--9..................................

1. General 18--9...........................................................

2. Adjustment procedure 18--9..............................................

18G CYLINDER HEAD SAFETY VALVE 18--11........................................

1. Inspection 18--11.........................................................

18H STARTING AIR VALVE 18--12..................................................

1. Removal 18--12...........................................................

2. Fitting 18--12.............................................................

Manual

F 240 CONTENTS

xx -- 12

Ver. 01

CHAPTER 19: CAMSHAFT

19A CHECKING VALVE TIMING 19--1..............................................

Exhaust valve 19--1......................................................

Inlet valve 19--2..........................................................

CHAPTER 20: GOVERNOR

20A GOVERNOR DRIVE INSPECTION 20--1........................................

20B GOVERNOR ADJUSTMENT 20--2..............................................

1. Compensation 20--2.....................................................

2. Compensation needle valve 20--2.........................................

3. Adjustment of the governor after overhaul 20--2...........................

4. Speed droop 20--2.......................................................

20C INTERNAL CLEANING 20--3..................................................

CHAPTER 22: VIBRATION DAMPER

22A SAMPLING OF VISCOUS LIQUID 22--1........................................

1. General 22--1...........................................................

2. Liquid sampling 22--1...................................................

CHAPTER 23: ENGINE ALIGNMENT

23A VERIFICATION 23--1.........................................................

1. General 23--1...........................................................

2. Verification of engine alignment 23--1....................................

3. Foundation bolts 23--2..................................................

4. Flexible foundation elements (if fitted) 23--2...............................

5. Verification in height 23--2...............................................

23B CRANKWEB DEFLECTION 23--3..............................................

1. Crankweb deflection 23--3...............................................

Measurement 23--4.......................................................

Evaluation 23--4..........................................................

2. Axial bearings 23--4.....................................................

Manual

F 240

0A PURPOSE

GENERAL

Ver. 01 0--1

The purpose of this manual is to give the user a guide for working on and with the en-

gine. This manual has been prepared using the manufacturer’s best knowledge and

experience and is a part of the documentation supplied with the engine.

It is only a manualand therefore concise. It is very well imaginable that beforestarting

or when performing particular jobs you have questions to which the manual gives no

answer. In that case, do not take any unnecessary risk, and contact the Service In-

spection department of Stork--Wärtsilä Diesel B.V.

Stork--Wärtsilä Diesel reserves the right to minor alterations and improvements due

to engine development without being obliged to enter the corresponding changes in

this manual.

The operationand/or maintenancework described in thismanual must only be carried

out by trained technicians specialised in diesel engines.

Ensure that everyone concerned with the maintenance of the engine has this manual

available, reads it carefully and understands it, before undertaking maintenance work

on the engine.

Ensure that all equipment and tools for maintenance are in good

condition.

To ensure the best efficiency, reliability and lifetime of the engine and its components,

only genuine spare parts should be used.

Modifications as to the settings may only be made after written approval from Stork--

Wärtsilä Diesel B.V.

The customer will be solely responsible in the following cases, among other things:

-- for failure caused by neglecting to consult the engine documentation, which may

result in malfunction of the engine, short life time of components, personal injury

or damage to property or environment

-- for faulty treatment or maloperation, also when the circumstances are not de-

scribed in the engine documentation

-- for any consequence resulting from incorrect translation or interpretation of the

original engine documentation supplied with the engine.

-- o -- o -- o -- o -- o --

0B DOCUMENTATION OVERVIEW

Manual

F 240

0B DOCUMENTATION OVERVIEW

GENERAL

Ver. 01 0--2

The engine documentation that has been delivered with your engine consists of three

parts:

1. MANUAL

The manual describes the operation and maintenance of the engine.

2. PARTS CATALOGUE.

This catalogue contains :

-- test report

-- pipe arrangement / internal system diagrams. specific for this engine

-- electrical documentation

-- parts lists with in most cases, additional assembly drawings

Use the manual during maintenance work together with the parts catalogue

3. SUB--SUPPLIERS MANUALS.

This is a collection of the information supplied by sub--suppliers.

-- o -- o -- o -- o -- o --

0C MANUAL SETUP / PAGE SETUP

Manual

F 240

0C MANUAL SETUP / PAGE SETUP

INTRODUCTION

1. MANUAL SETUP

Manual

F 240

0C MANUAL SETUP / PAGE SETUP

GENERAL

Ver. 01 0--3

Each manual starts with a table of contents and each chapter starts with a chapter

overview.

Each page consists of a header, (the text above the upper horizontal line), the main

text and the footer, (the part beneath the lower horizontal line).

-- Header:

The header consists of:

TYPE OF MANUAL:

-- MANUAL ;

-- PARTS CATALOGUE.

-- SUB--SUPPLIERS MANUALS.

ENGINE TYPE:

-- engine number in the case of engine specific data.

ENGINE CONFIGURATION:

This is indicated by a letter following the engine type on every page concerned:

-- HFO = Heavy Fuel Oil ;

-- L = L--engine ;

-- MDO = Marine Diesel Oil, (light fuel oil) ;

-- P = Propulsion ;

-- S = Stationary / Auxiliary ;

-- V = V--engine ;

CHAPTER TITLE /SECTION TITLE:

The section title is preceded by the chapter number and a letter for reference

purpose.

SUB--SECTION

(This is not a part of the header).

1. Manual setup

Page setup

0--1

Ver. 01

-- o -- o -- o -- o -- o --

Manual

F 240

0C MANUAL SETUP / PAGE SETUP

GENERAL

Ver. 01 0--4

-- TEXT PART:

The text part of a paragraph is divided into two columns:

-- margin column: for sub dividing of the sections and for indicating the tools ;

-- text column: for the text of the paragraph.

-- FOOTER:

VERSION NUMBER

In case of a relevant modification.

MANUFACTURER’S NAME.

PAGE NUMBERING:

Thepagenumber consistsofthe chapter numberfollowed by thepage number.

The page number for each chapter starts with 1.

END--SIGN:

Each section ends with the end--sign.

-- o -- o -- o -- o -- o --

0D DESCRIPTION OF THE ENGINE

Manual

F 240

0D DESCRIPTION OF THE ENGINE

GENERAL

Ver. 01 0--5

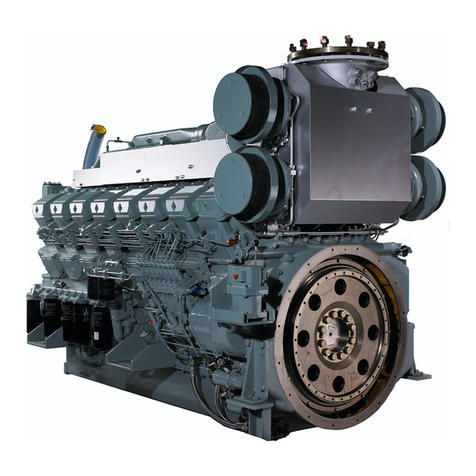

The crankshaft is made from a one piece alloy steel forging. The dimensions of the

crankpins are identical throughout the range of engines, as are the dimensions of the

main bearing journals in order to optimize standardisation between engine

components of different cylinder configurations. A combined main/axial bearing is lo-

cated atflywheel end. Fullrotational balanceis achieved by mounting counterbalance

weights. A torsional vibration damper is fitted at the opposite side of the flywheel end.

Full power can be taken either from the flywheel end or from the vibration end of the

engine.

The crankshaft gear wheel is fixed to the crankshaft by means of clamping rings.

The crankshaft is mounted in the bedplate

The main bearings are of tri--metal design with steel back, lead bronze inter layer and

a lead--tin running layer.

The cylinder block, made of nodular cast iron, is cast in one piece for each cylinder

configuration. It incorporates the cooling water manifold and the camshaft bearings.

Whendimensioning,theaimhas beento providelowstresslevelsandgoodtotalrigid-

ity. The crankcase covers are fitted to the cylinder block by studbolts and sealed by

a gasket. A number of crankcase covers are equipped with explosion valves for safe

pressure relief in case of high crankcase pressure.

The cylinder liners are centrifugally cast of special cast iron. At the bottom the cooling

water space between cylinder block and liner is sealed by three O--rings. The cylinder

liner is above the turning point of the piston provided with special grooves for an

optimal running habit of the piston with the liner.

The piston is of the composite type with steel crown and aluminium skirt. The piston

crown is cooled by means of the “cocktail shaker effect” with lubricating oil supplied

through the connecting rod bore, which also lubricates the gudgeon pin bearing. The

piston ring grooves in the steel crown are hardened.

The piston ring set is chrome--plated and consists of three compression rings and one

springloaded, oil scraper ring.

The connecting rod is forged of alloy steel and fully machined. The gudgeon pin

bearings and the connecting rod bearings are of trimetal designwith steel back, a lead

bronzeinter layer andalead--tinrunninglayer.Thecamshaftbearings are ofthesame

composition.

The cylinder head is made of alloyed cast iron. The flame plate is relatively thin and

is efficiently cooled by cooling water. The mechanical load is absorbed by a strong

intermediate deck and top deck. The cylinder head is mounted on the cylinder block

with six cylinder head studs. All valve seats are changeable.

The cams are individually mounted on the camshaft by means of a hydraulic shrink

fit. This allows the cams to be adjusted when necessary. The camfollowers are

mounted per cylinder in a guide block.

The camshaft bearings are of the same composition as the connecting rod berarings.

The camshaft is driven by the crankshaft through a gear train.

1. Crankshaft and

bedplate

2. Cylinder block

3. Cylinder liner

4. Piston with

connecting rod

5. Cylinder head

6. Camshaft and

valve

mechanism

Manual

F 240

0D DESCRIPTION OF THE ENGINE

GENERAL

Ver. 01 0--6

The injection equipment is made by Bosch. The high pressure fuel pumps are of the

single--cylinderandflow--throughtype.Thefuelinjectoriscentrallylocatedinthecylin-

der head. The fuel supply is through a high pressure fuel line between the high

pressure fuel pump and the injector. The injection equipment is fully separated from

the lubricating oil system.

Betweenexhaust pipesectionsexpansioncompensatorsarefitted.Exhaust pipesare

insulated by mineral wool and shielded by a sheet metal cover.

The turbochargers are made by Asea Brown Boveri with axial turbines, and roller

bearings or plain bearings depending on the type. The turbochargers are arranged at

the flywheel end of the engine. For cleaning the air side of the turbocharger during

operation there is a water washing device. The air cooler is fitted on to the air inlet

manifold. The water side is accessible by removing the end covers of the cooler.

The cylinders are numbered in ascending order in the direction of the flywheel.

The standard direction of rotation of the engine is ”clockwise” facing the flywheel.

7. Injection equip-

ment

8. Exhaust manifold

9. Turbocharging

and charge air

cooling

10. Definitions

operating side

flywheel end

direction of

rotation clockwise

counter

clockwise

exhaust side 1

2

3

4

5

6

1000 F 910

Cross section F240

Manual

F 240

0D DESCRIPTION OF THE ENGINE

GENERAL

Ver. 01 0--7

-- o -- o -- o -- o -- o --

Manual

F 240

0D DESCRIPTION OF THE ENGINE

GENERAL

Ver. 01 0--8

Table of contents