3.2 FROM THE MECHANIC ENERGY TO THE ELECTRIC

ENERGY................................................................................................ 41

3.2.1 Connection and function of the current machine ..................... 41

3.3 FIRST EXPERIMENTS WITH THE GENERATOR ..................... 42

3.4 ROTATION DIRECTION INDICATOR........................................ 43

3.4.1 The transfer of the circuit......................................................... 43

3.4.2 The technical and the real current direction............................ 46

3.5 MOUNTING THE GENERATOR .................................................. 47

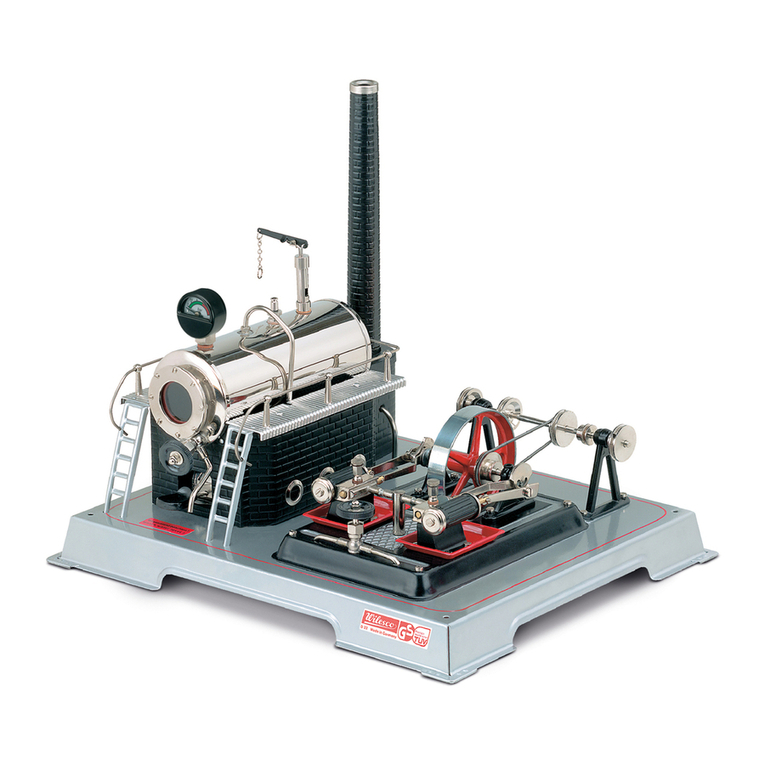

3.5.1 Generator, to connect mechanically with the flywheel of the

steam engine ..................................................................................... 48

3.5.2 Measuring the voltage of the generator ................................... 49

3.5.3 The direction of the rotation of the steam engine and the

generator ........................................................................................... 51

3.6 USING STEAM ENERGY TO GENERATE ELECTRICITY....... 52

3.6.1 Evaluating the power of the steam engine and of the

generator ........................................................................................... 52

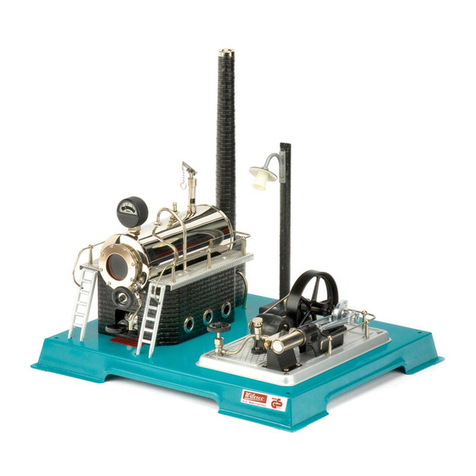

3.7 STEP BY STEP GENERATING BRIGHT LIGHT OUT OF

STEAM .................................................................................................. 55

3.7.1 More light with 2 white LEDs................................................... 58

3.7.2 Light from four LEDs generated throught the steam engine.... 59

3.8 STORAGE OF THE ELECTRIC ENERGY.................................... 61

3.8.1 Charging the capacitor storage through the steam engine...... 61

3.8.2 Diode blocking discharge, Schottkydiode ................................ 64

3.8.3 Charge indicator for the electrolytic........................................ 66

3.8.4 Using stored energy.................................................................. 69

3.8.5 The steam engine as a charging station for the torch .............. 70

4. ANNEX................................................................................................... 73

4.1 COLLECTION OF THE FORMULARIES..................................... 73

4.1.1 Voltage, current and resistance................................................ 73

4.1.2 Parallel circuit of resistors....................................................... 74

4.1.3 Series connection of resistors................................................... 75

4.1.4 Calculation of the power .......................................................... 75

4.2 TROUBLESHOOTING................................................................... 75

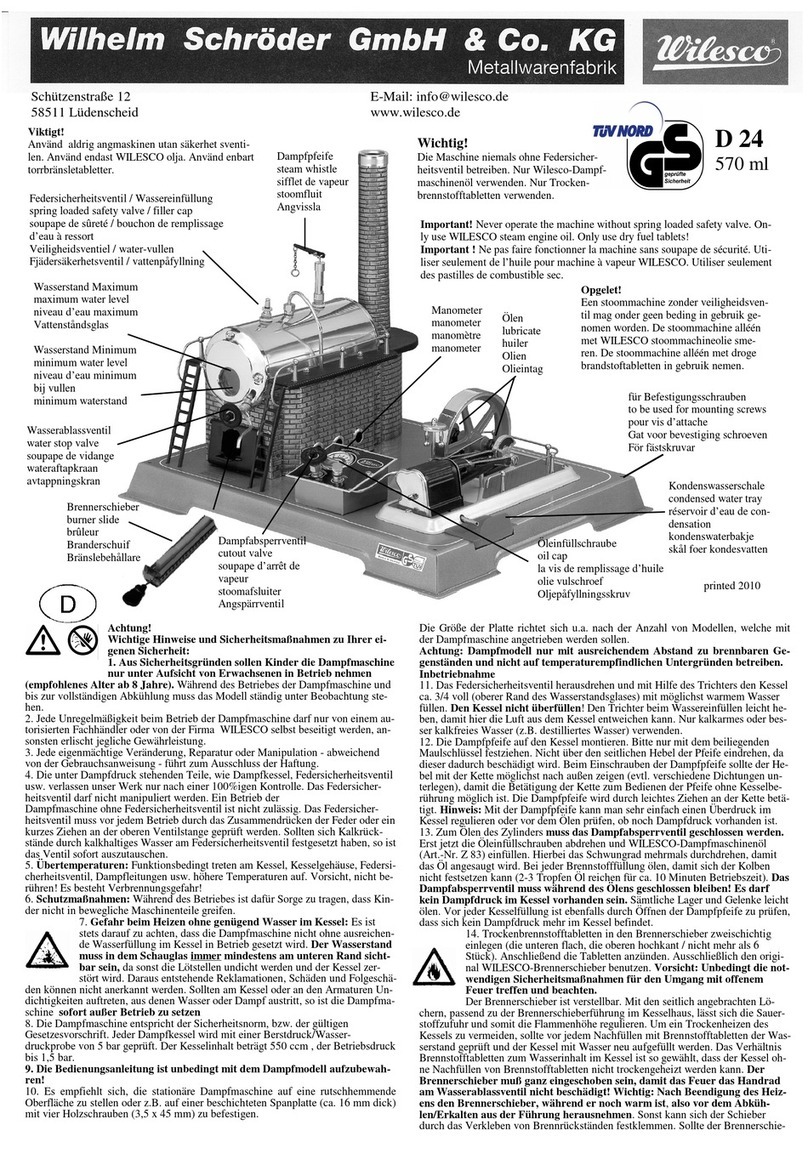

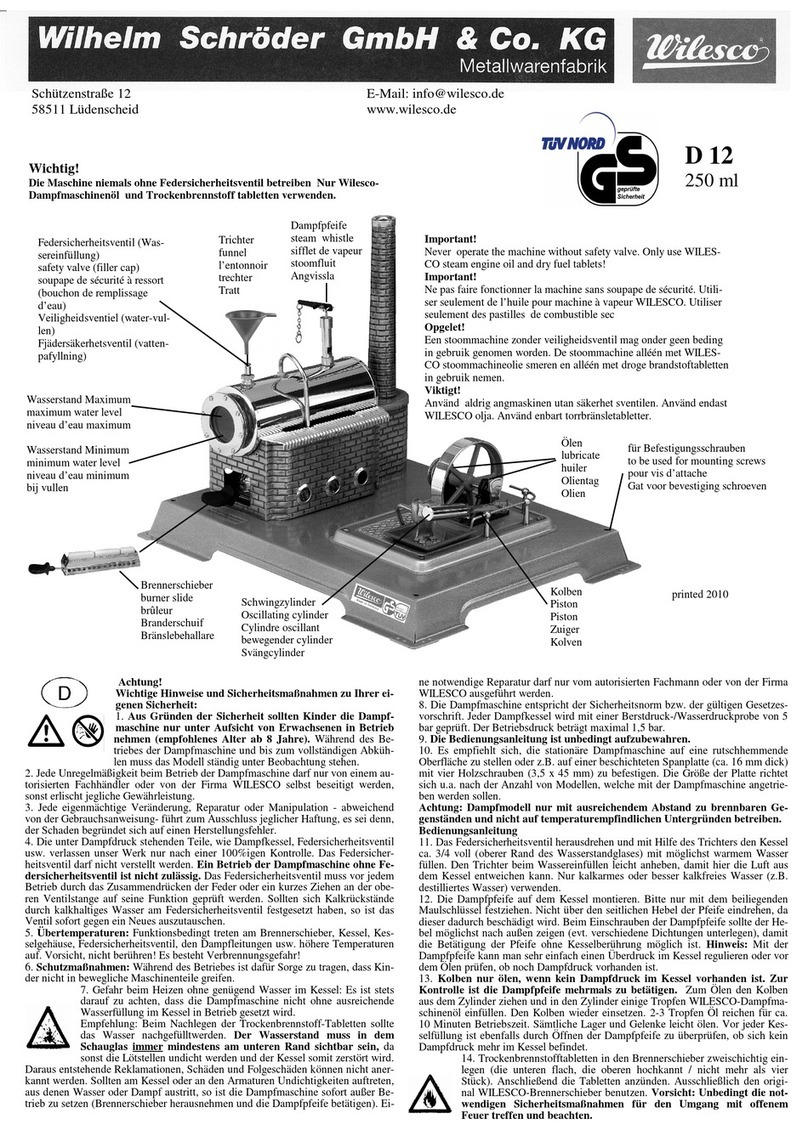

4.2.1 The steam engine ...................................................................... 76

4.2.2 The electronic........................................................................... 76

4.3 SUPPLIER SOURCES FOR SPARE PARTS AND ELECTRONIC

PARTS.................................................................................................... 77

4.3.1 Consumable supplies for steam engines................................... 77

4.4 WARRANTY................................................................................... 78