Digga SG26 Product manual

PM-000033

4 Octal Street, Yatala QLD 4207 Australia

Ph: (07) 3807 3330 - Fax: (07) 3807 1499

Email: [email protected]

OPERATOR’S AND PARTS

MANUAL

SG26 & SG30

STUMP GRINDER

UNIVERSAL SKID STEER

APPLICATIONS

TABLE OF CONTENTS

TO THE OWNER........................................................................................................ A

SAFETY PRECAUTIONS............................................................................................B

General Information

To The Operator

Before You Start

Working With The Stump Grinder

Transporting The Stump Grinder

Maintenance

INTERNATIONAL SYMBOLS......................................................................................C

PREOPERATION........................................................................................................D

Before Operation

Skid Steer

Nomenclature

STUMP GRINDER ASSEMBLIES.............................................................................. E

Stump Grinder Assembly #100318

Rear Guard Assembly #101742

Wheel Assemblies

Hydraulic Valve Assembly #100982

Control Valve Replacement Parts

Standard Flow Drive Assembly #100415

High Flow Drive Assembly #100417

Power and Return Circuit

Cylinder Assembly #100324

Cylinder Assembly #101245

Electrical Schematics - Control Handles (#104367 - Direct & #104368 - use with #101096)

Electrical Schematics - Wiring Harness’s (#101096 - 14 Pin, #108035 - 8 Pin & #108036 - 14 Pin JD)

INSTALLATION INSTRUCTIONS................................................................................F

OPERATING INSTRUCTIONS...................................................................................G

LUBRICATION.............................................................................................................H

MAINTENANCE...........................................................................................................L

Daily / Every 40 Hours

Replacing Teeth

Replacing Hydraulic Motor

Replacing Gearbox / Motor Coupler

Replacing Gearbox

Cylinder Seal Replacement

STORAGE AND TRANSPORTING.............................................................................M

TROUBLESHOOTING................................................................................................N

BOLT TORQUE SPECIFICATION...............................................................................O

SPECIFICATIONS...................................................................................................... P

DECALS......................................................................................................................Q

PREDELIVERY CHECKLIST.......................................................................................R

LIMITED WARRANTY..................................................................................... ............S

TO THE OWNER

8915

3-5-03

A A

GENERAL COMMENTS

Congratulations on the purchase of your new DIGGA product! This

product was carefully designed and manufactured to give you years of dependable

service. Only minor maintenance (such as cleaning and lubricating) is required to

keep it in top working condition. Be sure to observe all safety precautions and

maintenance procedures, as described in this manual.

ABOUT THIS MANUAL

This manual has been designed to help you do a better, safer job. Read this

manual carefully and become familiar with its contents. Remember, never let

anyone operate this unit without reading the “Safety Precautions” and

“Operating Instructions” sections of this manual. (See Sections B and G

respectively.)

Unless noted otherwise, right and left sides are determined from the position

of the operator when behind the product facing forward.

SAFETY ALERT SYMBOL

This is the “Safety Alert Symbol” used by this industry. This symbol is

used to warn of possible injury. Be sure to read all warnings carefully.

They are included for your safety and for the safety of others working

with you.

SERVICE

When servicing your product, remember to use only manufacturer replacement

parts. Substitute parts may not meet the standards required for safe, dependable

operation.

To facilitate parts ordering, record the model and serial number of your unit in

the space provided on this page. This information may be obtained from the identication

plate located on the product.

MODEL____________________________________

SERIAL NUMBER___________________________

DATE PURCHASED_________________________

The parts department needs this information to insure that you receive the

correct parts for your specic model.

SAFETY PRECAUTIONS

6621

5-18-95

B B

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL

IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PER-

SONAL SAFETY OR OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS: Note the use of signal words DANGER, WARNING, and

CAUTION with the safety messages. The appropriate signal word for each has

been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation, which if not avoided,

will result in death or serious injury. This signal word is to be limited

to the most extreme situations, typically for machine components

which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation, which if not avoided,

could result in death or serious injury, and includes hazards that

are exposed when guards are removed. It may also be used to

alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation, which if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

SAFETY PRECAUTIONS

9714

6-28-04

B B

GENERAL INFORMATION

This section is composed of various warnings and safety tips. Read and

learn all the information in this section before you attempt to use your DIGGA

STUMP GRINDER. Also read your vehicle owner’s manual before using your

equipment. This knowledge will help you operate your unit safely. Do not take

this information lightly, it is presented for your benet and for the benet of others

working around you.

The “Safety Alert Symbol” (as described in Section A and at the beginning

of Section B) will be used throughout this manual. It will appear with the word

DANGER, WARNING, or CAUTION above it, and a safety message pertaining to

the specic topic being covered. Take the time to read these messages as you

come across them.

TO THE OPERATOR

The primary responsibility for safety with the equipment falls to the operator.

Make sure that the equipment is operated only by responsible & competent

individuals with the proper instruction. It is the skill, care, common sense, and

good judgement of the operator that will determine how efciently and safely the

job is performed. Know your equipment before you start. Know its capabilities

dimensions, and how to operate all the controls. Visually inspect your equipment

before you start and never operate equipment that is not in proper working order.

BEFORE YOU START

1. Read the entire loader and Stump Grinder manual. This knowledge is necessary

for safe operation.

2. Do NOT operate the standard ow stump grinder on high ow hydraulic

systems. Severe injury could occur due to the increased RPM.

3. Always wear safety goggles and hearing protection during operation, and

make sure ALL safety shields are properly installed.

4. Follow all safety decals. Keep them clean and replace them if they become

worn, damaged or illegible.

5. Do not paint over, remove or deface any safety signs or warning decals on

your equipment.

6. Know your equipment inside and out. Know how to operate all controls

and know emergency shut down procedures.

7. Keep all stepping surfaces, pedals, and controls free from dirt, grease and

oil. Keep equipment clean to help avoid injury from a fall when getting on

or off equipment.

8. Use handholds and step plates when getting on/off . Failure to do so could

cause a fall.

DIGGA STUMP GRINDER

SAFETY PRECAUTIONS

9715

6-28-04

B B

DIGGA STUMP GRINDER

9. Never operate the unit near bystanders, trafc, pets, livestock or buildings.

Be sure others know when and where you will be working. Never

direct discharge towards people, animals or property. Never allow anyone

to approach the stump grinder when in operation.

10. Never take passengers on your equipment. There is no safe place for a

passenger.

11. Never try to board equipment while it is running.

12. Turn off engine, remove the key and disconnect hydraulic couplers

before performing maintenance. If unit must be left raised for maintenance

or any other reason, block the unit securely to prevent accidental

release of the lifting mechanism. Serious damage or personal injury

could result.

13. Never leave the unit unattended when in a raised position. Always make

sure the attachment is on the ground and keys removed before leaving

the unit unattended.

14. Test all controls before you begin.

15. Do not smoke when refueling. Allow room in the gas tank for expansion.

Wipe up any spilt fuel. Secure cap tightly when done.

WORKING WITH THE STUMP GRINDER

1. Never operate the unit without rst reading and understanding the

operator’s manual.

2. Operate the unit only in daylight or sufcient articial light.

3. Do not carry load with arms in the raised position. Always carry loads

as close as possible to the ground.

4. Check your work area and know where all utility lines are. Avoid hitting

underground electrical wires, cables, pipes, fence posts, gas lines,

uneven sidewalk edges, large rocks, etc.

5. Never operate equipment while under the inuence of alcohol, prescription

drugs, nonprescription drugs, or illegal drugs which could inhibit

physical and/or mental capacity.

6. Do not exceed rated operating capacity, as machine may become unstable

which may result in loss of control.

7. Do not operate the unit without covers installed.

8. Keep hands, feet, hair and clothing away from equipment with engine

running. Stay clear of all moving parts.

9. Do not raise the attachment when the grinding wheel is rotating.

10. ALWAYS LOWER THE LOADER ARMS TO THE GROUND, SHUT OFF

THE ENGINE AND REMOVE THE KEY BEFORE GETTING OFF THE UNIT.

SAFETY PRECAUTIONS

9716

6-28-04

B B

DIGGA STUMP GRINDER

TRANSPORTING THE STUMP GRINDER

1. Follow all federal, state and local regulations when transporting the unit on

public roads.

2. Use extra care when loading or unloading the machine onto a truck or

trailer. Disconnect hydraulic couplers during transportation.

MAINTENANCE

1. Never work on equipment while it is running. Always lower the loader arms

to the ground, shut off the engine, remove the key and disconnect

hydraulic couplers before performing maintenance on the unit.

2. Never make hydraulic repairs while the system is under pressure. Injury or

death could result.

3. Observe proper maintenance schedules and repairs to keep the unit in safe

working order.

4 Always wear safety goggles or glasses when working on equipment.

5. Use only manufacturer recommended replacement parts. Other parts may be

substandard in t and quality.

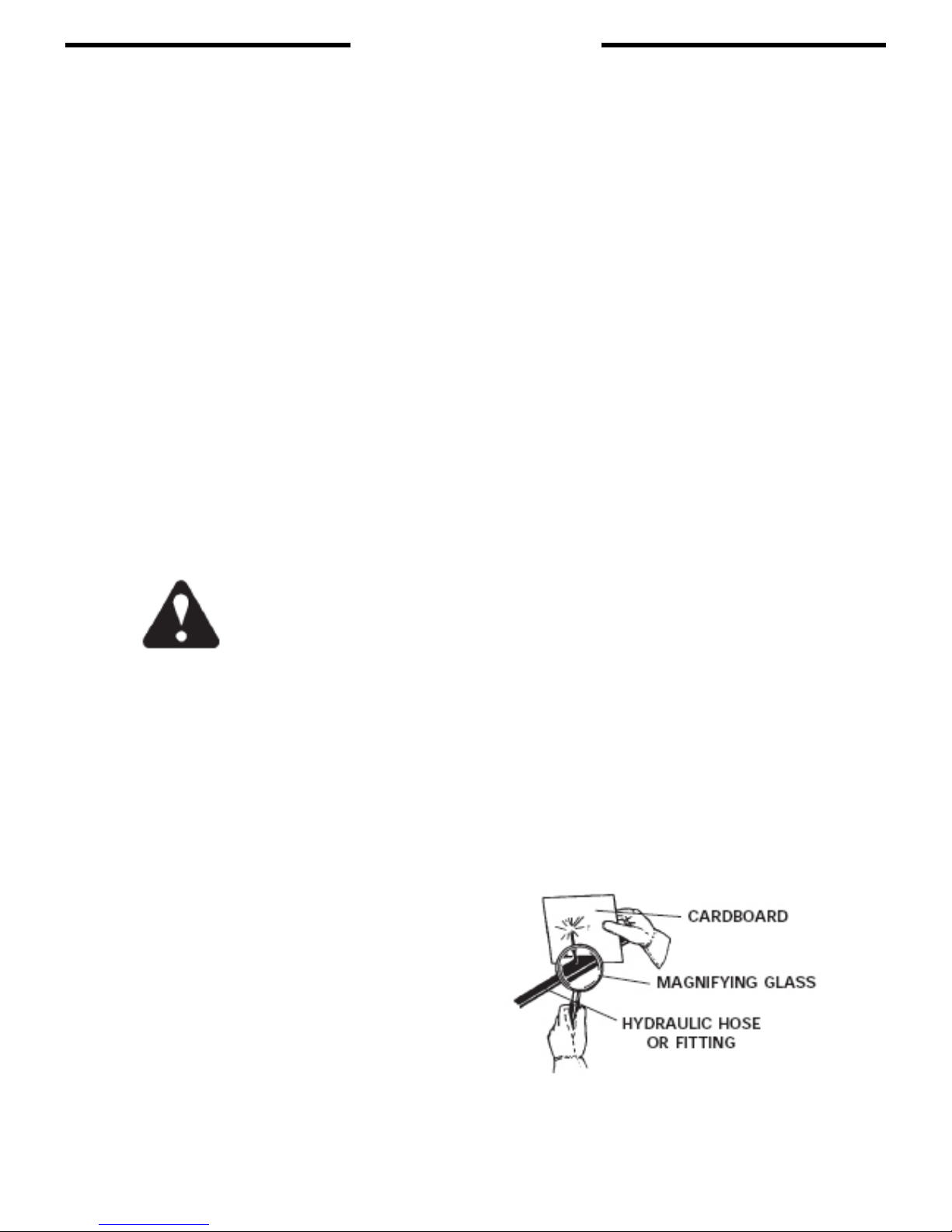

WARNING! Escaping uid under pressure can have sufcient force to penetrate

the skin causing serious personal injury. Fluid escaping from a very

small hole can be almost invisible. Use a piece of cardboard or

wood, rather that hands to search for suspected leaks.

Keep unprotected body parts, such as face, eyes, and arms as far

away as possible from a suspected leak. Flesh injected with hydraulic

uid may develop gangrene or other permanent disabilities.

If injured by injected uid, see a doctor at once. If your doctor is

not familiar with this type of injury, ask him to research it immediately

to determine proper treatment.

INTERNATIONAL SYMBOLS

3869

4-14-94-2

C C

As a guide to the operation of your equipment, various international symbols have

been utilized on the instruments and controls. The symbols are shown below with an indi-

cation of their meaning.

PREOPERATION

9762

8-6-04

D D

DIGGA STUMP GRINDER

GENERAL INFORMATION

The DIGGA Stump Grinders were designed to be easy to use and

maintain. They are operated by the skid-steer auxiliary hydraulics and mount to

the quick attach mechanism for easy operator hook-up. There are two models of

DIGGA stump grinders available, standard ow and high ow. These will allow

mounting the stump grinder to most skid-steer loaders.

Unless noted otherwise, right and left are determined from the position of

the skid-steer operator sitting in the operator’s seat facing forward.

Remember to read the “Safety Precautions” and “Operating Instructions”

sections of the manual BEFORE you attempt to install or use the Stump Grinder

.

NOTE: Illustrations and data used in this manual were current (according to

the information available to us) at the time of printing, however, we reserve

the right to redesign and change the grinders as may be necessary without

notication.

BEFORE OPERATION

The primary responsibility for safety with this equipment falls to the operator.

Make sure that the equipment is operated only by trained individuals that

have read and understand this manual. Don’t hurry the learning process or take

the unit for granted. Practice the operation of your new equipment and become

familiar with the controls and the way it handles on your machine.

If there is any portion of this manual or function you do not understand,

contact your local authorized dealer or manufacturer.

SKID-STEER

Your skid-steer must be equipped with auxiliary hydraulic and an electric

control kit (or the optional electric control handle must be ordered from your

DIGGA dealer).

There are two models of DIGGA stump grinders available, standard

ow and high ow. Be sure the stump grinder you have purchased matches the

hydraulic ow of your skid-steer.

The standard ow unit requires 15-22 GPM and the high ow requires 25-

42 GPM. Operating the high ow stump grinder on a standard ow skid-steer will

result in poor performance.

WARNING! OPERATING THE STANDARD FLOW STUMP GRINDER ON A

HIGH FLOW HYDRAULIC SYSTEM MAY CAUSE SEVERE INJURY

OR DEATH TO THE OPERATOR OR BYSTANDERS DUE

TO THE INCREASED RPM.

PREOPERATION

9763

8-6-04

D D

DIGGA STUMP GRINDER

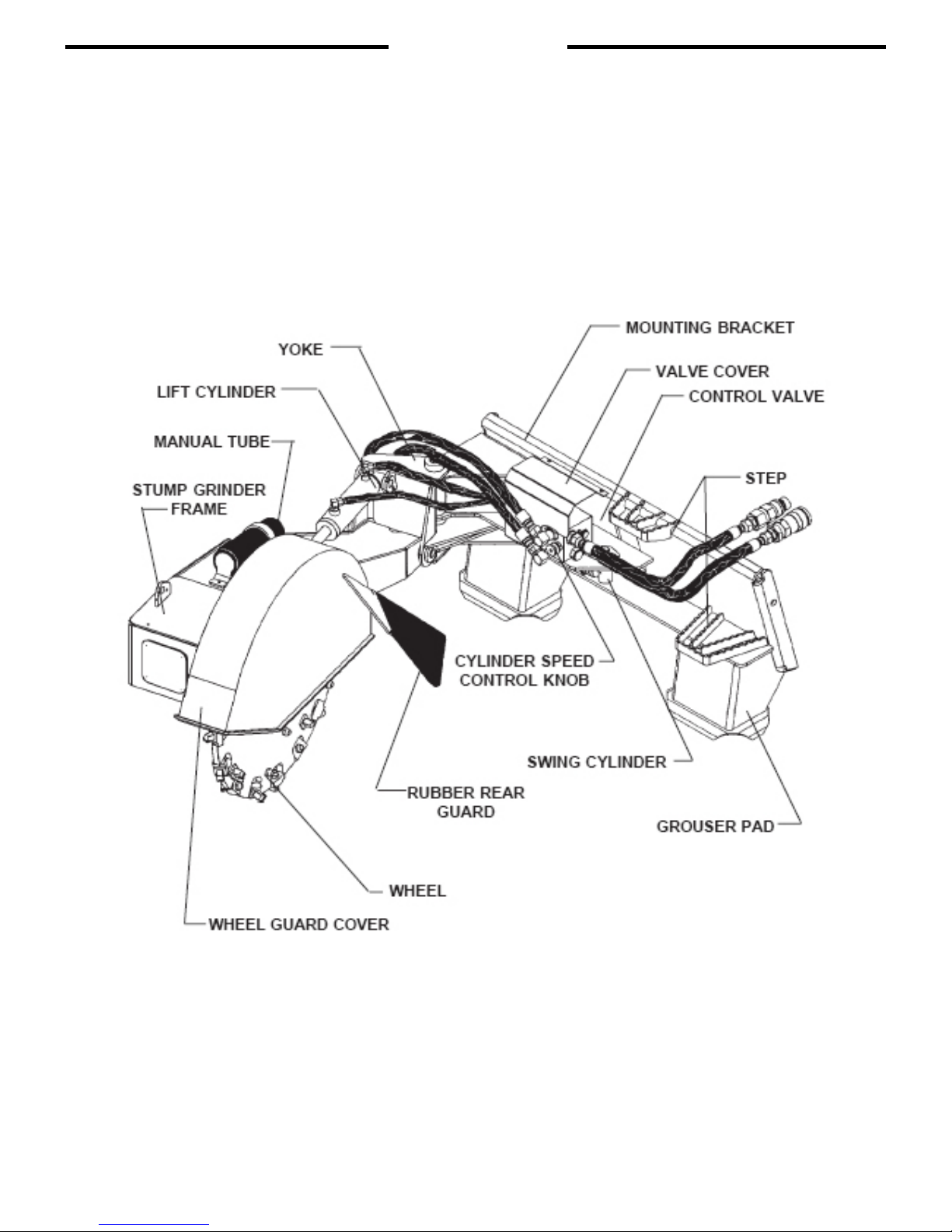

NOMENCLATURE

Throughout this manual, reference is made to various stump grinder

components. The purpose of this page is to acquaint you with the various names

of these components. This knowledge will be helpful when reading through this

manual or when ordering service parts.

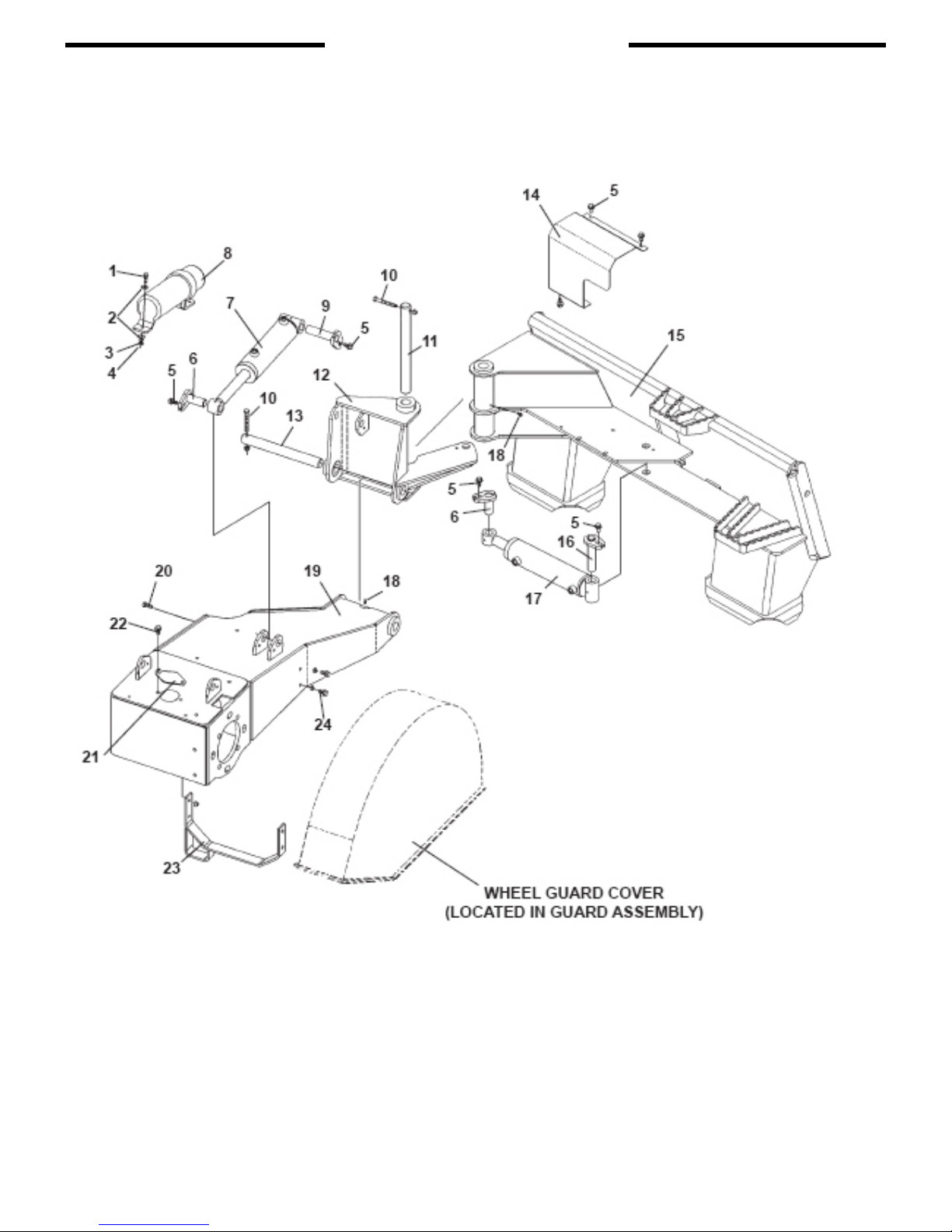

STUMP GRINDER ASSEMBLY

9693

1-30-07-2

E E

ASSEMBLY #100318

STUMP GRINDER ASSEMBLY

9383

1-31-07-2

E E

ASSEMBLY #100318

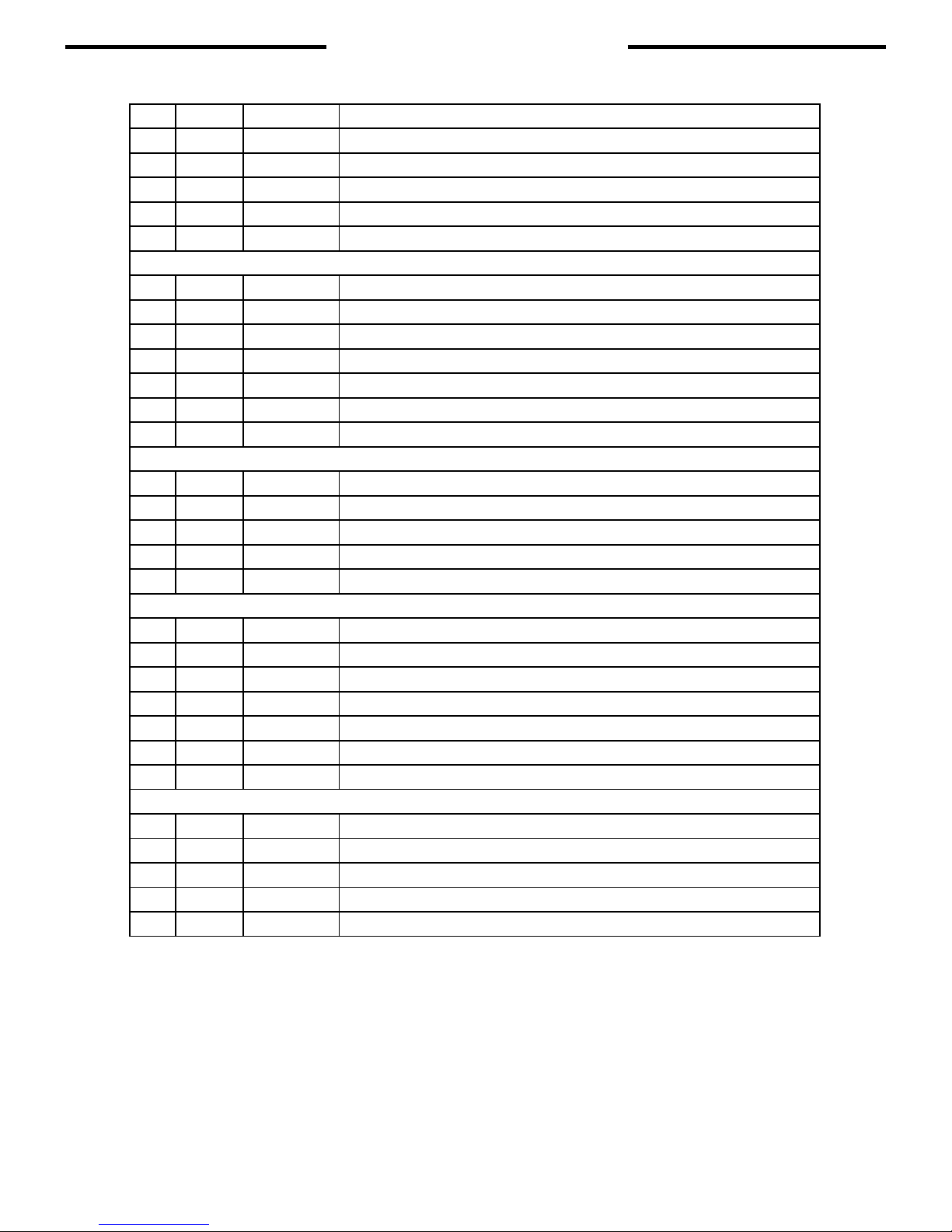

NO REQ’D PART NO. DESCRIPTION

1 2 1022 .31” UNC X 1.00” Hex Capscrew

2 4 1513 .31” Flat Washer

3 2 1502 .31” Lock Washer

4 2 1225 .31” UNC Hex Nut

5 7 1953 .38” UNC X .75” Flange Head Capscrew

6 2 100769 Pin - 1.00” X 2.50”

7 1 101245 Cylinder Assembly - Lift

- 45617 Replacement Seal Kit

8 1 25453 Manual Tube

9 1 100770 Pin - 1.00” X 4.00”

10 2 1051 .38” UNC X 3.00” Hex Capscrew

2 1837 .38” UNC Deformed Lock Nut

11 1 100379 Pin - 1.25” X 13.50”

12 1 100322 Yoke

13 1 100378 Pin - 1.25” X 11.38”

14 1 100420 Valve Cover

15 1 100321 Mounting Bracket

16 1 31990 Pin - 1.00” X 4.50”

17 1 100324 Cylinder Assembly - Swing

- 45617 Replacement Seal Kit

18 2 6616 Grease Fitting

19 1 100323 Stump Grinder Frame

20 2 1043 .38” UNC X 1.00” Hex Capscrew

2 1837 . 38” UNC Deformed Lock Nut

21 1 105762 Access Cover

22 2 1939 .25” UNC X .75” Flangehead Hex Capscrew

23 1 101802 Brace Stand

24 2 1044 .38” UNC X 1.25” Hex Capscrew

2 1837 .38” UNC Deformed Lock Nut

REAR GUARD ASSEMBLY

9765

1-30-07-2

E E

ASSEMBLY #101742

REAR GUARD ASSEMBLY

9383

1-31-07-2

E E

ASSEMBLY #101742

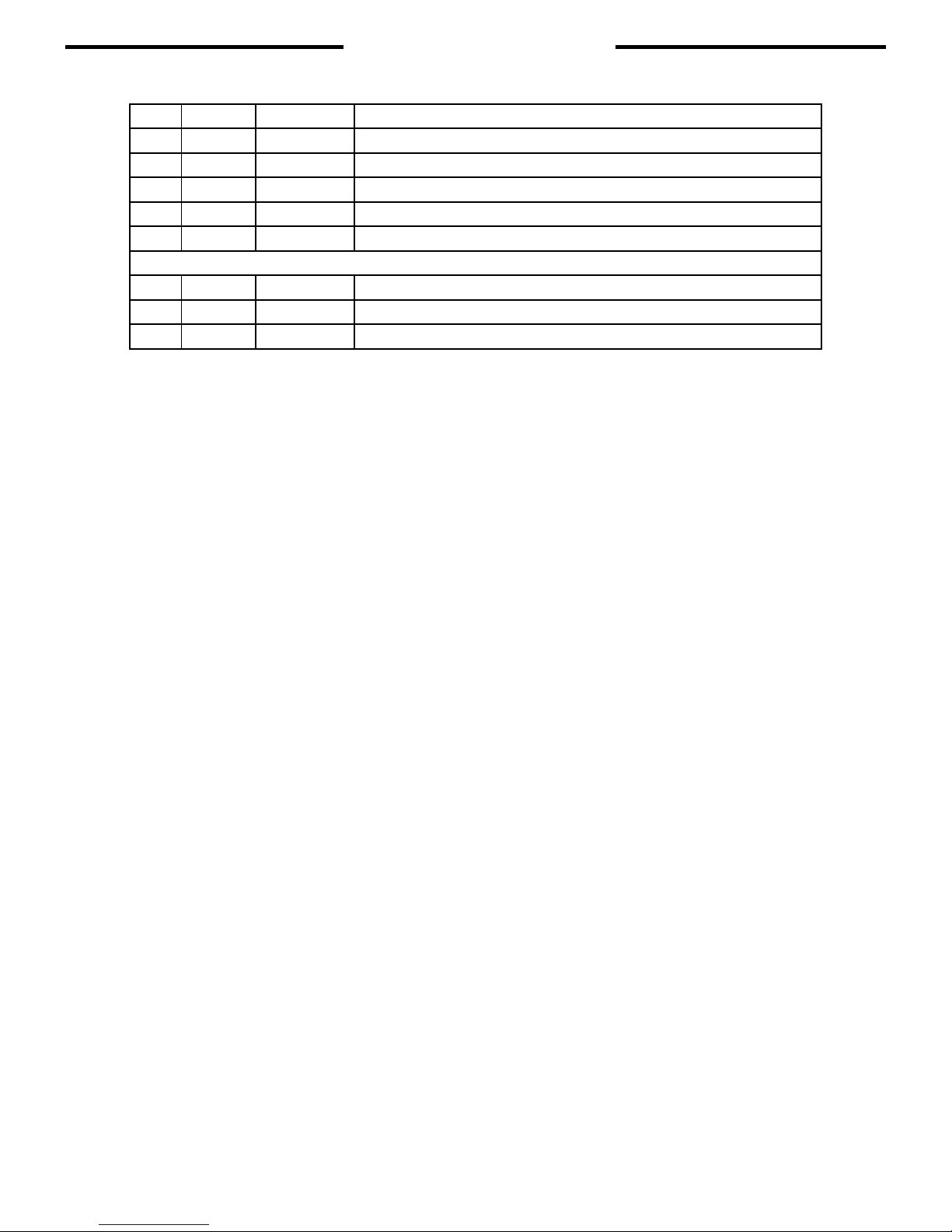

NO REQ’D PART NO. DESCRIPTION

1 1 102061 Wheel Guard Cover

2 4 1043 .38” UNC X 1.00” Hex Capscrew

3 10 1837 .38” UNC Deformed Oval Lock Nut

4 1 102062 Rear Rubber Guard Bracket

5 1 100802 Rubber Guard

6 2 1049 .38” UNC X 2.50” Hex Capscrew

7 20 1514 .38” Flat Washer

8 8 1044 .38” UNC X 1.25” Hex Capscrew

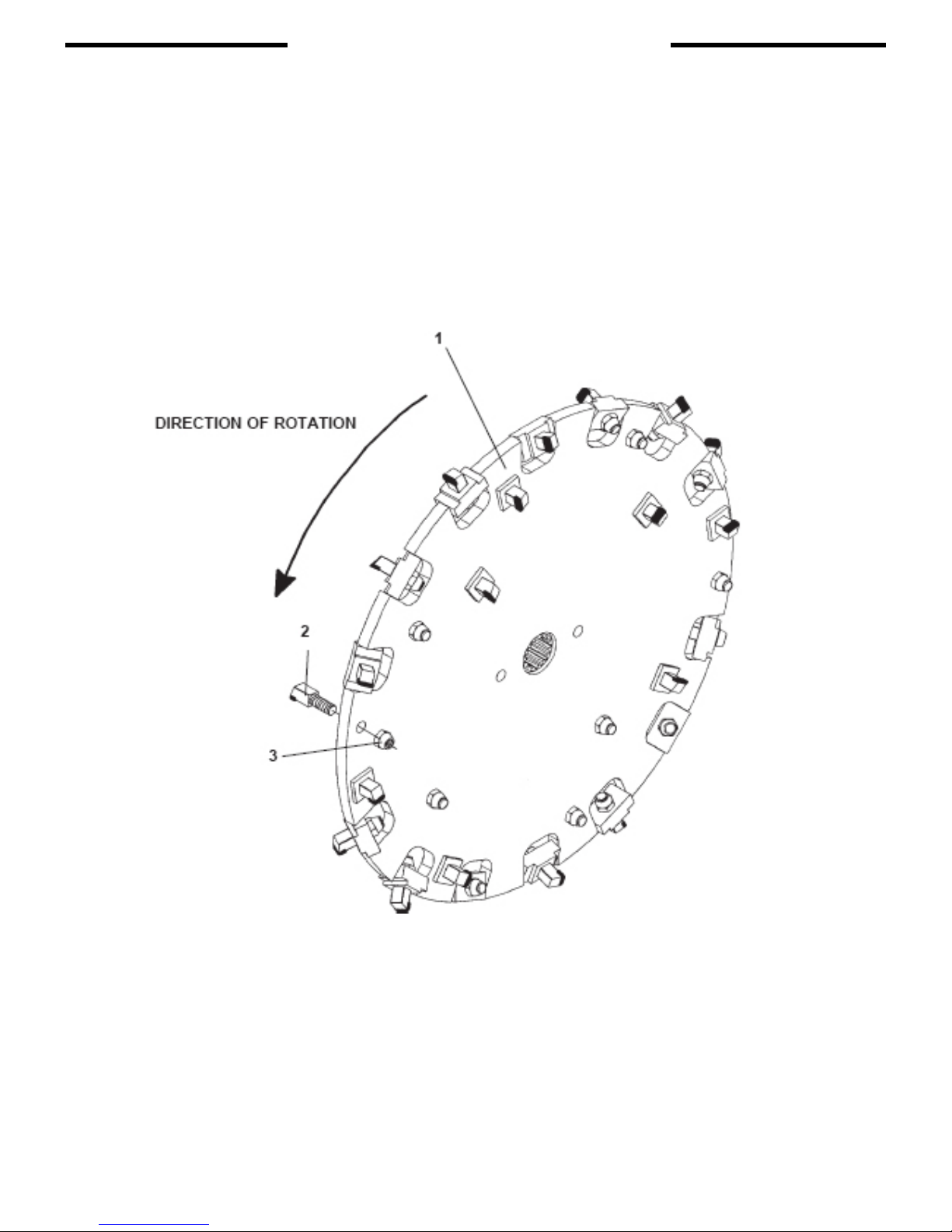

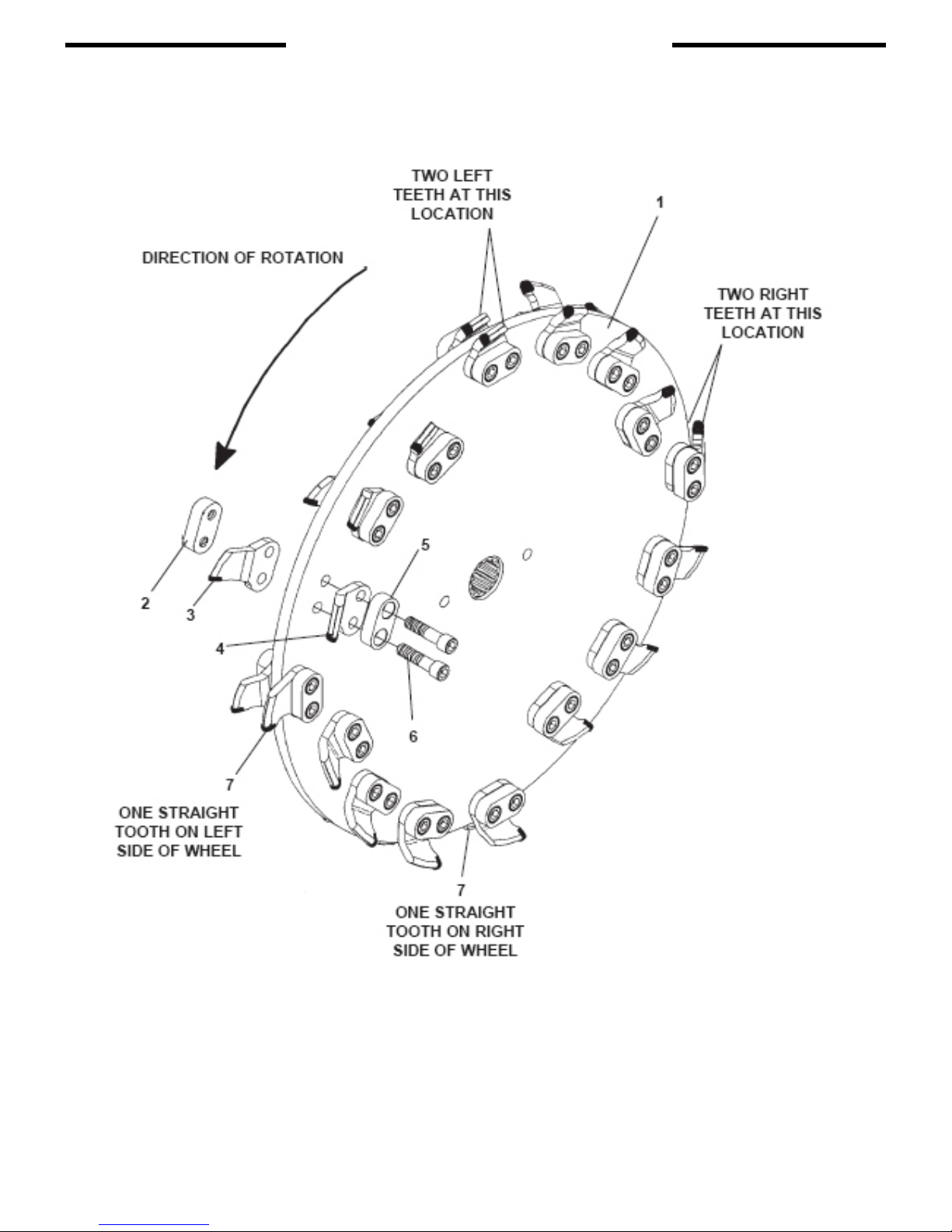

SQUARE TOOTH WHEEL ASSEMBLY

9766

8-9-04

E E

26” STANDARD FLOW WHEEL ASSEMBLY #101234

30” HIGH FLOW WHEEL ASSEMBLY #100418

SQUARE TOOTH WHEEL ASSEMBLY

9767

8-9-04

E E

26” STANDARD FLOW WHEEL ASSEMBLY #101234

30” HIGH FLOW WHEEL ASSEMBLY #100418

NO REQ’D PART NO. DESCRIPTION

1 1 101235 26” Wheel - Standard Flow

1 19911 30” Wheel - High Flow

2 28 19917 Square Tooth - Threaded

3 28 1810 .62” UNF Deformed Lock Nut

REPLACEMENT TOOTH KIT #102075

28 19917 Square Tooth - Threaded

28 1810 .62” UNF Deformed Lock Nut

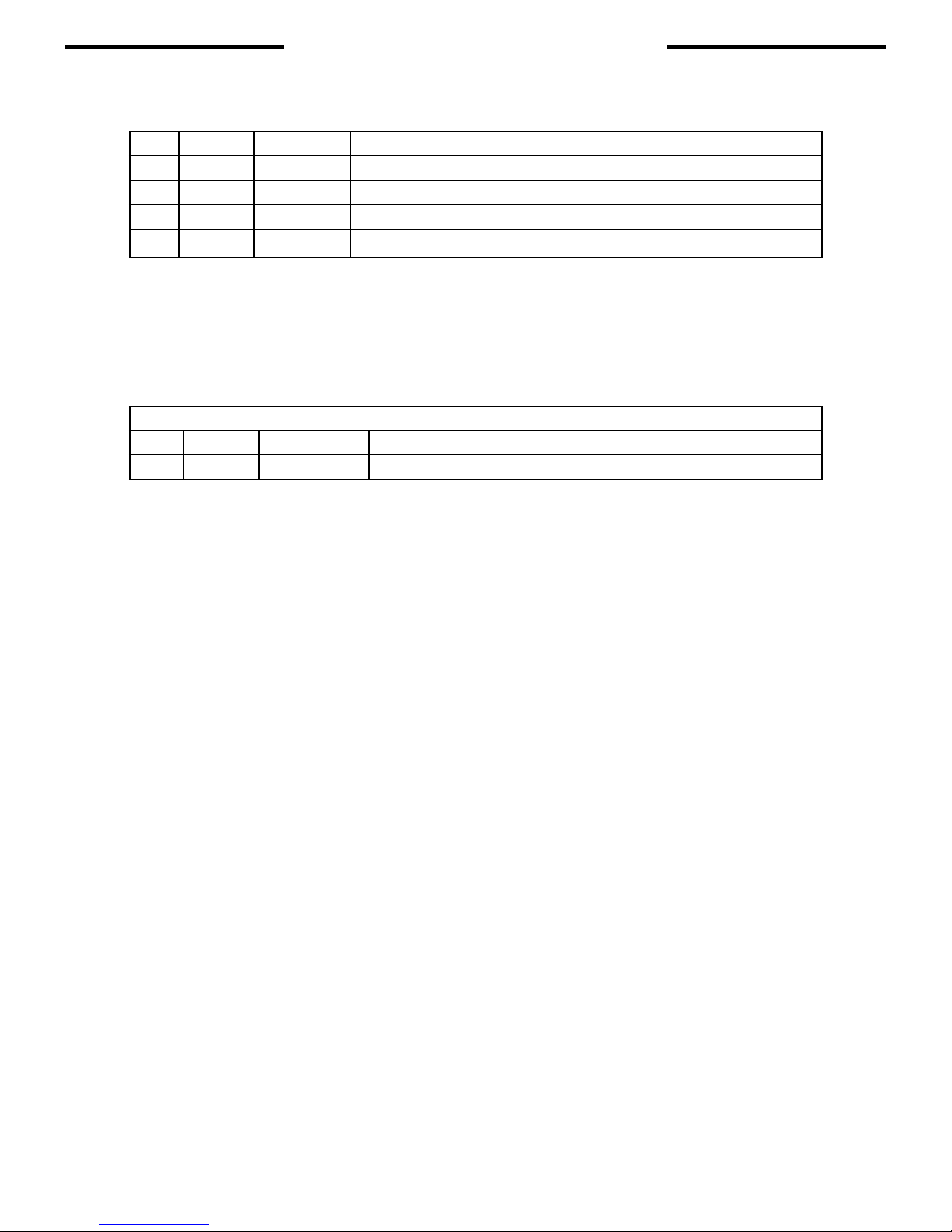

BOLT-ON TOOTH WHEEL ASSEMBLY

9768

8-9-04

E E

26” STANDARD FLOW WHEEL ASSEMBLY #101234

30” HIGH FLOW WHEEL ASSEMBLY #100418

This manual suits for next models

1

Table of contents