ATD-2131 - 2 - Rev. 3/19/09

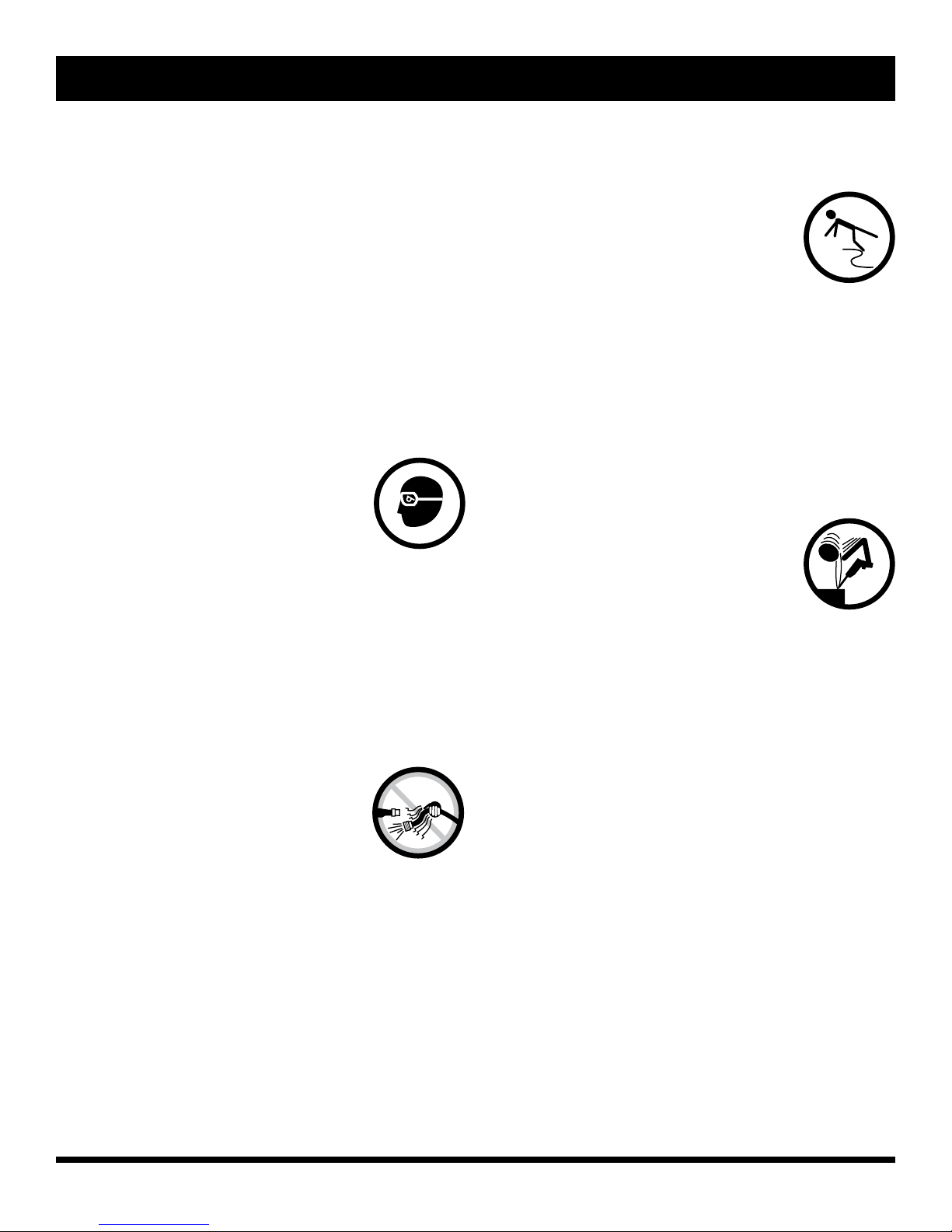

• Slipping,trippingand/orfallingwhile

operating air tools can be a major

cause of serious injury or death. Be

awareofexcesshoseleftonthe

walkingorworksurface.

• Keepbodyworkingstancebalancedandfirm.Donot

overreachwhenoperatingthetool.

• Anticipateandbealertforsuddenchangesinmotion

duringstartupandoperationofanypowertool.

• Donotcarrytoolbythehose.Protectthehosefrom

sharp objects and heat.

• Toolshaftmaycontinuetorotatebrieflyafter

throttleisreleased.Avoiddirectcontactwith

accessoriesduringandafteruse.Gloveswillreduce

theriskofcutsorburns.

• Keepawayfromrotatingendoftool.

Donotwearjewelryorlooseclothing.

Secure long hair. Scalping can occur

ifhairisnotkeptawayfromtooland

accessories.Chokingcanoccurif

neckwearisnotkeptawayfromtool

and accessories.

• Wearglovesandprotectiveclothingtoavoidinjuries

caused by chips or pieces, malfunctioning

accessories,orimproperlyclampedwork.

• Whenpossible,secureworkwithclampsorviseso

both hands are free to operate tool.

• Correctgrindingwheelmountingisnecessaryto

preventinjuryfrombrokenwheels.Donotuse

chippedorcrackedgrindingwheels.Grindingwheels

should be a free fit on the spindle to prevent stress

atthehole.Useonlywheelcollarswhatcomewith

thegrinderformountingthegrindingwheel.Flat

washersorotheradaptersmayoverstressthewheel.

Alwaysuseheavypaperblotterdiscsbetweenthe

wheelcollarsandthegrindingwheel.Tightenthe

wheelonthespindletopreventspinoffwhenthe

air grinder is turned off.

• Donotlubricatetoolswithflammableorvolatile

liquidssuchaskerosene,dieselorjetfuel.

• Don’tforcetoolbeyonditsratedcapacity.

• Donotremoveanylabels.Replaceanydamaged

labels.

• UseaccessoriesrecommendedbyATDTools.

THIS INSTRUCTION MANUAL CONTAINS IMPORTANT

SAFETY INFORMATION.

READ THIS INSTRUCTION MANUAL CAREFULLY AND

UNDERSTAND ALL INFORMATION BEFORE OPERATING

THIS TOOL.

• Alwaysoperate,inspectandmaintainthistoolin

accordancewithAmericanNationalStandards

Institute Safety Code of Portable Air Tools (ANSI

B186.1) and any other applicable safety codes and

regulations.

• Forsafety,topperformanceandmaximumdurabilityof

parts,operatethistoolat90psig6.2barmaxair

pressurewith3/8"diameterairsupplyhose.

• Alwayswearimpact-resistanteyeand

faceprotectionwhenoperatingor

performing maintenance on this tool.

Alwayswearhearingprotectionwhen

using this tool.

• Highsoundlevelscancausepermanenthearingloss.

Use hearing protection as recommended by your

employer or OSHA regulation.

• Keepthetoolinefficientoperating

condition.

• Operatorsandmaintenancepersonnelmustbe

physicallyabletohandlethebulk,weightand

powerofthistool.

• Airunderpressurecancausesevereinjury.Never

directairatyourselforothers.Always

turn off the air supply, drain hose of

air pressure and detach tool from air

supply before installing, removing or

adjusting any accessory on this tool,

or before performing any maintenance

on this tool. Failure to do so could

result in injury. Whip hoses can cause serious injury.

Alwayscheckfordamaged,frayedorloosehosesand

fittings,andreplaceimmediately.Donotusequick

detach couplings at tool. See instructions for correct

set-up.

• Airpoweredtoolscanvibrateinuse.Vibration,

repetitive motions or uncomfortable positions

overextendedperiodsoftimemaybeharmful

to your hands and arms. Discontinue use of tool

if discomfort, tingling feeling or pain occurs.

Seekmedicaladvicebeforeresuminguse.

• Placethetoolontheworkbeforestartingthetool.

Donotpointorindulgeinanyhorseplaywiththis

tool.

▲

!

WARNING!

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT IN INJURY.