Digilent Pmod CMPS2 User manual

1300HenleyCourt

Pullman,WA99163

509.334.6306

www.store.digilent.com

PmodCMPS2™ Reference Manual

RevisedJuly19,2017

ThismanualappliestothePmodCMPS2rev.A

DOC#: 410-355

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 1of 12

TableofContents

Table of Contents .................................................................................................................. 1

Overview............................................................................................................................... 2

1Specifications................................................................................................................. 2

1.1 Pinout Table Diagram....................................................................................................... 3

1.2 Physical Dimensions ......................................................................................................... 3

2Functional Description ................................................................................................... 3

2.1 Serial Communication ...................................................................................................... 3

2.2 Register Details................................................................................................................. 3

2.2.1 Data Registers ........................................................................................................... 3

2.2.2 Status Register .......................................................................................................... 4

2.2.3 Internal Control Registers ......................................................................................... 4

2.2.4 Continuous Measurement Mode.............................................................................. 5

2.2.5 Output Resolution Measurement Time.................................................................... 5

2.3 Quick Start........................................................................................................................ 5

2.4 Applications Information.................................................................................................. 7

2.4.1 Calibration................................................................................................................. 7

2.4.2 Data Conversion...................................................................................................... 11

2.5 Timing Diagrams............................................................................................................. 12

Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 2of 12

Overview

The Digilent Pmod CMPS2 is a 3 axis anisotropic magneto-resistive sensor. With Memsic's MMC34160PJ, the local

magnetic field strength in a ±16 Gauss range with a heading accuracy of 1° and up to 0.5 mG of resolution.

1 Specifications

The Pmod CMPS2.

Features include:

Low noise 3-axis Digital Compass

0.5 mG Field Resolution in ±16 Gauss fields

I²C Slave, FAST (≤400 kHz) mode

Optional pull-up resistors for SCL and SDA pins

±1° heading accuracy

Small PCB size for flexible designs 0.8“ × 1.25” (2.0

cm × 3.2 cm)

6-pin Pmod connector with I²C serial interface

Pass-through Pmod host port for daisy chaining

Follows Digilent Pmod Interface Specification 1.1.0

Library and example code in the Pmod

CMPS2 Resource Center

Parameter

Min

Typical

Max

Units

Power Supply Voltage

1.62

1.8

3.6

V

Output Resolution

12

14

16

bits

Alignment Error

-3

±1

+3

Degrees

Parameter

Condition

Value

Units

Total RMS Noise

16 bits at 7.92 ms/S

1.5

mG

Total RMS Noise

16 bits at 4.08 ms/S

2.0

mG

Total RMS Noise

14 bits at 2.16 ms/S

4.0

mG

Total RMS Noise

12 bits at 1.20 ms/S

6.0

mG

Max Output Data Rate

16 bits at 7.92 ms/S

125

Hz

Max Output Data Rate

16 bits at 4.08/S

250

Hz

Max Output Data Rate

14 bits at 2.16 ms/S

450

Hz

Max Output Data Rate

12 bits at 1.20 ms/S

800

Hz

Parameter

Value

Units

Field Range for Each Axis

±16

G

Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 3of 12

1.1 PinoutTableDiagram

Header J1

Header J2

Jumper JP1

Pin

Signal

Description

Pin

Signal

Description

Pin

Status

Description

1

N/C

Not Connected

1

N/C

Not Connected

SCL

Loaded

4.7 kΩ Pullup

to Vcc

2

N/C

Not Connected

2

N/C

Not Connected

SCL

Unloaded

No Pullup to

Vcc

3

SCL

Serial Clock

3

SCL

Serial Clock

SDA

Loaded

4.7 kΩ Pullup

to Vcc

4

SDA

Serial Data

4

SDA

Serial Data

SDA

Unloaded

No Pullup to

Vcc

5

GND

Power Supply

Ground

5

GND

Power Supply

Ground

6

VCC

Power Supply

(3.3V)

6

VCC

Power Supply

(3.3V)

1.2 PhysicalDimensions

The pins on the pin header are spaced 100 mil apart. The PCB is 1.25 inches long on the sides parallel to the pins on

the pin header and 0.8 inches long on the sides perpendicular to the pin header.

2 FunctionalDescription

The Pmod CMPS2 utilizes the MMC34160PJ to collect magnetic field data. While communicating with the host

board via the I²C protocol using an I²C address of 0x0110000/ users can measure the ±16 G field surrounding the

device.

2.1 SerialCommunication

The Pmod CMPS2 communicates with the host board via the I²C protocol. By first sending the 7-bit I²C device

address of 0110000 and then a read/write bit (high/low logic level, respectively), followed by the register address

of interest at a maximum clock frequency of 400 kHz users can both configure and read from the Pmod CMPS2. An

additional set of pins on header J2 is provided so that users may daisy chain the Pmod CMPS2 with other I²C

devices.

2.2 RegisterDetails

2.2.1 DataRegisters

Each Cartesian axis has two registers to store the high and low data bytes for each measurement. The data

registers are arranged in a low byte, high byte arrangement.

Data Registers addresses 0x00 to 0x05

Address

Register Name

0x00

X out LSB

0x01

X out MSB

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 4of 12

Data Registers addresses 0x00 to 0x05

Address

Register Name

0x02

Y out LSB

0x03

Y out MSB

0x04

Z out LSB

0x05

Z out MSB

2.2.2 StatusRegister

Bit Name

Bit Number

Bit Description

Bit Values

Functional Description

RSV

[7]

Reserved

0¹

Reserved Bit

RSV

[6]

Reserved

0¹

Reserved Bit

RSV

[5]

Reserved

0¹

Reserved Bit

RSV

[4]

Reserved

0¹

Reserved Bit

ST_XYZ_OK

[3]

ST_XYZ_OK

0¹

Indicates that the selftest was OK when

this bit is a "1"

Rd_Done

[2]

Rd_Done

0¹

Indicates that chip was successfully able

to read its memory.

Pump On

[1]

Pump On

0¹

This bit indicates the status of the charge

pump.

RSV

[0]

Meas Done

0¹

Indicates that a measurement event is

completed.

2.2.3 InternalControlRegisters

Internal Control 0

Bit Name

Bit Number

Bit Description

Bit Values

Functional Description

Refill Cap

[7]

Refill Cap

0¹

Setting this bit will recharge

the

capacitor at the CAP pin, it is

requested to be issued

before the SET/RESET

command

RST

[6]

Reset Sensor

0¹

Setting this bit will reset the

sensor

SET

[5]

Set Sensor

0¹

Setting this bit will set the

sensor

No Boost

[4]

No boost

0¹

Disable the charge pump

CM Freq1²

[3]

Continuous

Measurement bit 1

0¹

Controls the continuous

measurement rate of the

chip

CM Freq0²

[2]

Continuous

Measurement bit 0

0¹

Controls the continuous

measurement rate of the

chip

Cont Mode On

[1]

Continuous

Measurement

Mode

0¹

Setting this bit enables

Continuous Measurement

Mode

TM

[0]

Take Measurement

0¹

Setting this bit will initiate a

reading

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 5of 12

Internal Control 1

Bit Name

Bit Number

Bit Description

Bit Values

Functional Description

RST

[7]

Software reset bit

0¹

Normal Operation, this bit

self clears

TEMP-tst

[6]

Temp test

0¹

Factory-use register

ST_XYZ

[5]

Selftest check

0¹

Set this bit an execute TM

command, the result can be

read as bit ST-XYZ_OK

Z-inhibit

[4]

Z-inhibit

0¹

Factory-use register

Y-inhibit

[3]

Y-inhibit

0¹

Factory-use register

X-inhibit

[2]

X-inhibit

0¹

Factory-use register

BW1³

[1]

Bandwidth bit

0¹

Controls the output

resolution and

measurement time

BW0³

[0]

Bandwidth bit

0¹

Controls the output

resolution and

measurement time

Notes:

¹ - This is the value on power-up and reset

² - For more details see the Continuous Measurement Mode section

³ - For more details see the Output Resolution and Measurement Time section

2.2.4 ContinuousMeasurementMode

Continuous Measurement Mode Settings

CM Freq1

CM Freq0

Frequency

0

0

1.5 Hz

0

1

13 Hz

1

0

25 Hz

1

1

50 Hz

2.2.5 OutputResolutionMeasurementTime

Bandwidth Output Resolution and Measurement Time

BW1

BW0

Output Resolution

Measurement Time

0

0

16 bits

7.92 mS

0

1

16 bits

4.08 mS

1

0

14 bits

2.16 mS

1

1

12 bits

1.20 mS

2.3 QuickStart

Here is the series of commands to acquire a set of magnetometer data from the Pmod CMPS2 via pseudo I²C code.

1. Power on the Pmod CMPS2 and wait for 10 mS before further operation.

2. Provide a START condition and call the device ID with a write bit

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 6of 12

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

3. Wait to receive an ACK from the Pmod CMPS2.

4. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

5. Wait to receive an ACK from the Pmod CMPS2.

6. Write the command to take a measurement by setting bit 0 high followed by a STOP bit.

I2CWrite(0x01); //0x01 initiates a data acquisition

7. Delay at least 7.92 mS by default to allow the Pmod CMPS2 to finish collecting data.

8. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

9. Wait to receive an ACK from the Pmod CMPS2.

10. Send the Status Register (0x03) as the register to read

I2CWrite(0x03); //indicate you wish to interact with address 0x03

11. Provide a START condition and call the device ID with a read bit

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

12. Wait to receive an ACK from the Pmod CMPS2.

13. Cycle the SCL line to receive the Status Register data on the SDA line. Keep reading the Status Register by

repeating steps 8 through 13 until bit 0 is set to '1', indicating that the data on all 3 axes as available to be

read.

14. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

15. Wait to receive an ACK from the Pmod CMPS2.

16. Send the first register address corresponding to Xout LSB (0x00) as the register to be read.

I2CWrite(0x00); //address 0x00 as the first register to be read

17. Provide a START condition and call the device ID with a read bit

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

18. Wait to receive an ACK from the Pmod CMPS2.

19. Cycle the SCL line to receive the data bits from the X, Y, and Z registers in the SDA line, providing an ACK

between each data byte. The Pmod CMPS2 address pointer automatically moves to each consecutive

byte. End the communication by sending a NACK followed by a STOP command.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 7of 12

I2CReadMultiple(6); //read six bytes, sending an ACK to the slave device betwe

en each byte received and a NACK after the last byte

20. Convert the readings into usable data. More details are available in the Data Conversion section.

21. Wait 1/3 of the acquisition time (by default 2.64 ms) before performing another measurement.

2.4 ApplicationsInformation

The Pmod CMPS2 is an ideal Pmod to use as a compass. Like all compasses, it is recommended that the Pmod

CMPS2 is calibrated before using the module.

2.4.1 Calibration

To calibrate the magnetometer, the offset associated with the magnetic sensors and the environment needs to be

calculated and removed from future measurements.

The internal offset can be calculated and accounted for through the following method:

1. Power on the Pmod CMPS2 and wait for 10 mS before further operation.

2. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

3. Wait to receive an ACK from the Pmod CMPS2.

4. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

5. Wait to receive an ACK from the Pmod CMPS2.

6. Write the command to recharge the capacitor to prepare for the SET action.

I2CWrite(0x80); //0x80 refills the capacitor

7. Wait to receive an ACK from the Pmod CMPS2.

8. Delay at least 50 mS to allow the Pmod CMPS2 to finish preparing.

9. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

10. Wait to receive an ACK from the Pmod CMPS2.

11. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

12. Wait to receive an ACK from the Pmod CMPS2.

13. Write the command to start a SET action.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 8of 12

I2CWrite(0x20); //0x20 starts the SET action

14. Wait to receive an ACK from the Pmod CMPS2.

15. Delay at least 1 mS to allow the Pmod CMPS2 to finish the SET action.

16. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

17. Wait to receive an ACK from the Pmod CMPS2.

18. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

19. Wait to receive an ACK from the Pmod CMPS2.

20. Write the command to take a measurement by setting bit 0 high followed by a STOP bit.

I2CWrite(0x01); //0x01 initiates a data acquisition

21. Delay at least 7.92 mS by default to allow the Pmod CMPS2 to finish collecting data.

22. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

23. Wait to receive an ACK from the Pmod CMPS2.

24. Send the Status Register (0x03) as the register to read

I2CWrite(0x03); //indicate you wish to interact with address 0x03

25. Provide a START condition and call the device ID with a read bit

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

26. Wait to receive an ACK from the Pmod CMPS2.

27. Cycle the SCL line to receive the Status Register data on the SDA line. Keep reading the Status Register by

repeating steps 8 through 13 until bit 0 is set to '1', indicating that the data on all 3 axes as available to be

read.

28. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

29. Wait to receive an ACK from the Pmod CMPS2.

30. Send the first register address corresponding to Xout LSB (0x00) as the register to be read.

I2CWrite(0x00); //address 0x00 as the first register to be read

31. Provide a START condition and call the device ID with a read bit

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 9of 12

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

32. Wait to receive an ACK from the Pmod CMPS2.

33. Cycle the SCL line to receive the data bits from the X, Y, and Z registers in the SDA line, providing an ACK

between each data byte. The Pmod CMPS2 address pointer automatically moves to each consecutive

byte. End the communication by sending a NACK followed by a STOP command.

I2CReadMultiple(6); //read six bytes, sending an ACK to the slave device betwe

en each byte received and a NACK after the last byte

34. Each of the readings will contain the external magnetic field Hin addition to offset associated with the

current put through the coil by the SET action.

𝑂𝑢𝑡𝑝𝑢𝑡1 = +𝐻 +𝑂𝑓𝑓𝑠𝑒𝑡

35. Now a RESET action will be performed to reverse the magnetization for the sensing resistors to get the

inverse offset value.

36. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

37. Wait to receive an ACK from the Pmod CMPS2.

38. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

39. Wait to receive an ACK from the Pmod CMPS2.

40. Write the command to recharge the capacitor to prepare for the RESET action.

I2CWrite(0x80); //0x80 refills the capacitor

41. Wait to receive an ACK from the Pmod CMPS2.

42. Delay at least 50 mS to allow the Pmod CMPS2 to finish preparing.

43. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

44. Wait to receive an ACK from the Pmod CMPS2.

45. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

46. Wait to receive an ACK from the Pmod CMPS2.

47. Write the command to start a RESET action.

I2CWrite(0x40); //0x40 starts the RESET action

48. Wait to receive an ACK from the Pmod CMPS2.

49. Delay at least 1 mS to allow the Pmod CMPS2 to finish the SET action.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 10 of 12

50. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

51. Wait to receive an ACK from the Pmod CMPS2.

52. Send the Internal Control Register 0 (address 0x07) as the register to communicate with

I2CWrite(0x07); //address 0x07 corresponds to Control Register 0

53. Wait to receive an ACK from the Pmod CMPS2.

54. Write the command to take a measurement by setting bit 0 high followed by a STOP bit.

I2CWrite(0x01); //0x01 initiates a data acquisition

55. Delay at least 7.92 mS by default to allow the Pmod CMPS2 to finish collecting data.

56. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

57. Wait to receive an ACK from the Pmod CMPS2.

58. Send the Status Register (0x03) as the register to read

I2CWrite(0x03); //indicate you wish to interact with address 0x03

59. Provide a START condition and call the device ID with a read bit

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

60. Wait to receive an ACK from the Pmod CMPS2.

61. Cycle the SCL line to receive the Status Register data on the SDA line. Keep reading the Status Register by

repeating steps 8 through 13 until bit 0 is set to '1', indicating that the data on all 3 axes as available to be

read.

62. Provide a START condition and call the device ID with a write bit

I2CBegin(0xA0); //device ID 0x30 with a write (0) bit

63. Wait to receive an ACK from the Pmod CMPS2.

64. Send the first register address corresponding to Xout LSB (0x00) as the register to be read.

I2CWrite(0x00); //address 0x00 as the first register to be read

65. Provide a START condition and call the device ID with a read bit

I2CBegin(0xA1); //device ID 0x30 with a read (1) bit

66. Wait to receive an ACK from the Pmod CMPS2.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 11 of 12

67. Cycle the SCL line to receive the data bits from the X, Y, and Z registers in the SDA line, providing an ACK

between each data byte. The Pmod CMPS2 address pointer automatically moves to each consecutive

byte. End the communication by sending a NACK followed by a STOP command.

I2CReadMultiple(6); //read six bytes, sending an ACK to the slave device betwe

en each byte received and a NACK after the last byte

68. Each of the readings will contain the external magnetic field Hin addition to offset associated with the

current put through the coil by the RESET action.

𝑂𝑢𝑡𝑝𝑢𝑡2 = −𝐻 +𝑂𝑓𝑓𝑠𝑒𝑡

69. The offset associated with the device can be calculated and then subtracted from future measurements to

obtain the actual magnetic field.

𝑂𝑓𝑓𝑠𝑒𝑡 = 𝑂𝑢𝑡𝑝𝑢𝑡1+𝑂𝑢𝑡𝑝𝑢𝑡2

2

The other method of calibration is to remove the hard iron bias introduced to the magnetometer by the

surrounding environment by measuring (either continually or for a set time) all of the possible magnetometer

readings in a Cartesian sphere and keep track of the highest and lowest readings for each axis. The offset can then

be calculated in the same fashion as described above with the SET and RESET actions. The advantage of this

method is when the Pmod CMPS2 is continually changing locations or when other external magnetic fields may be

introduced into the test environment.

2.4.2 DataConversion

The Memsic MMC34160PJ provides data for each axis in units of Gauss, but the information is generally more

legible when presented as a compass heading. The method for converting Gauss units to a compass heading is

provided below.

1. Calculate the real Gauss value for the X and Y axes from the amount of LSBs returned where the LSB value

by default is 0.48828125 mG, resulting in 2048 LSBs per Gauss.

𝑥𝐺𝑎𝑢𝑠𝑠𝐷𝑎𝑡𝑎 = 𝑥𝐷𝑎𝑡𝑎𝐿𝑆𝐵 ∗0.48828125𝑚𝐺

𝑥𝐺𝑎𝑢𝑠𝑠𝐷𝑎𝑡𝑎 = 𝑦𝐷𝑎𝑡𝑎𝐿𝑆𝐵 ∗ 0.48828125𝑚𝐺

2. Calculate the direction Dby first checking to see if the X Gauss data is equal to 0 to prevent divide by 0

zero errors in the future calculations. If the X Gauss data is 0, check to see if the Y Gauss data is less than

0. If Y is less than 0 Gauss, the direction D is 90 degrees; if Y is greater than or equal to 0 Gauss, the

direction D is 0 degrees.

3. If the X Gauss data is not zero, calculate the arctangent of the Y Gauss and X Gauss data and convert from

polar coordinates to degrees.

𝐷 = arctan(𝑦𝐺𝑎𝑢𝑠𝑠𝐷𝑎𝑡𝑎

𝑥𝐺𝑎𝑢𝑠𝑠𝐷𝑎𝑡𝑎) ∗180

𝜋

4. If the direction D is greater than 360 degrees, subtract 360 degrees from that value.

5. If the direction D is less than 0 degrees, add 360 degrees to that value.

6. The compass heading can then be determined by the direction value D:

If D is greater than 337.25 degrees or less than 22.5 degrees –North

If D is between 292.5 degrees and 337.25 degrees –North-West

If D is between 247.5 degrees and 292.5 degrees –West

If D is between 202.5 degrees and 247.5 degrees –South-West

If D is between 157.5 degrees and 202.5 degrees –South

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Pmod CMPS2™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 12 of 12

If D is between 112.5 degrees and 157.5 degrees –South-East

If D is between 67.5 degrees and 112.5 degrees –East

If D is between 0 degrees and 67.5 degrees –North-East

2.5 TimingDiagrams

An example timing diagram for reading and writing to the Pmod CMPS2 taken from the Memsic datasheet is

provided below:

When using an external power supply to run the Pmod, be sure to stay within the parameters provided

in Specifications.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Table of contents

Other Digilent Accessories manuals

Popular Accessories manuals by other brands

Vega

Vega VEGAVIB 62 operating instructions

Imetec

Imetec SCALDALETTO Instructions for use

YoSmart

YoSmart DS77-U02W user manual

PCB Piezotronics

PCB Piezotronics 740M04 Installation and operating manual

turck

turck FCS-G1/2A4-NAEX0/L065 manual

CMA Dishmachines

CMA Dishmachines FLOWRATE SENSOR 0387I user guide

UNITED

UNITED B4413 instruction manual

McAfee

McAfee IIP-M65K-ISAA - Network Security Platform... product manual

Tru-Test

Tru-Test WOW2 quick start guide

Heath

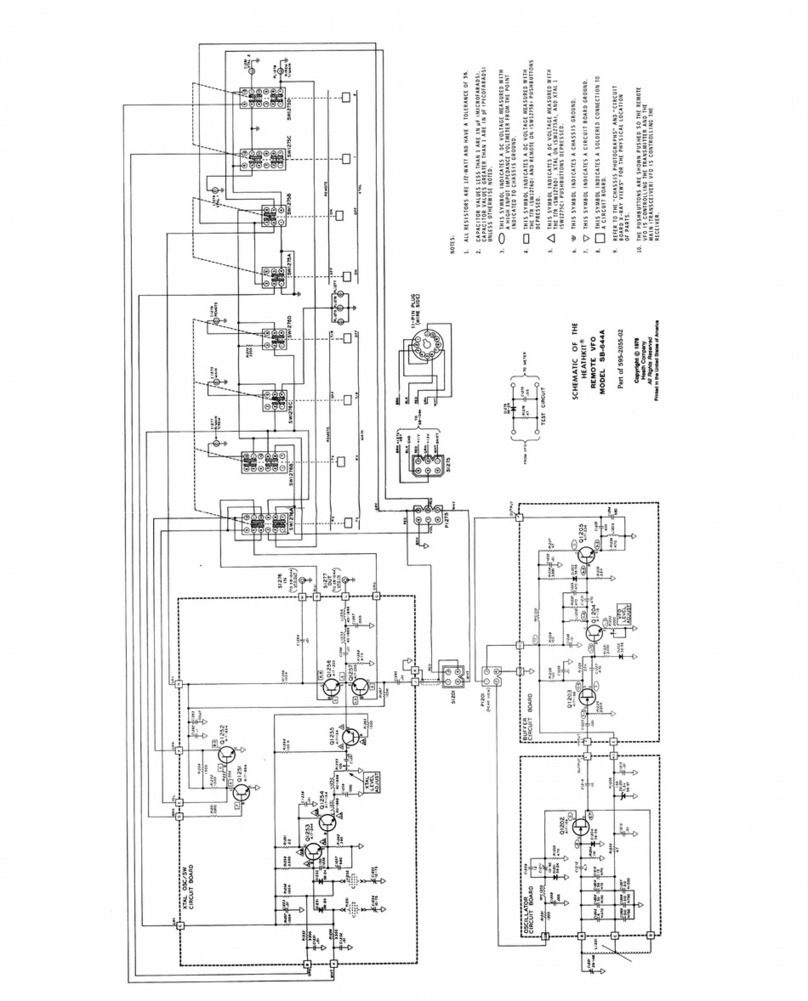

Heath Heathkit SB-644A Schematic diagram

Kobold

Kobold SEN-9601 operating instructions

American Standard

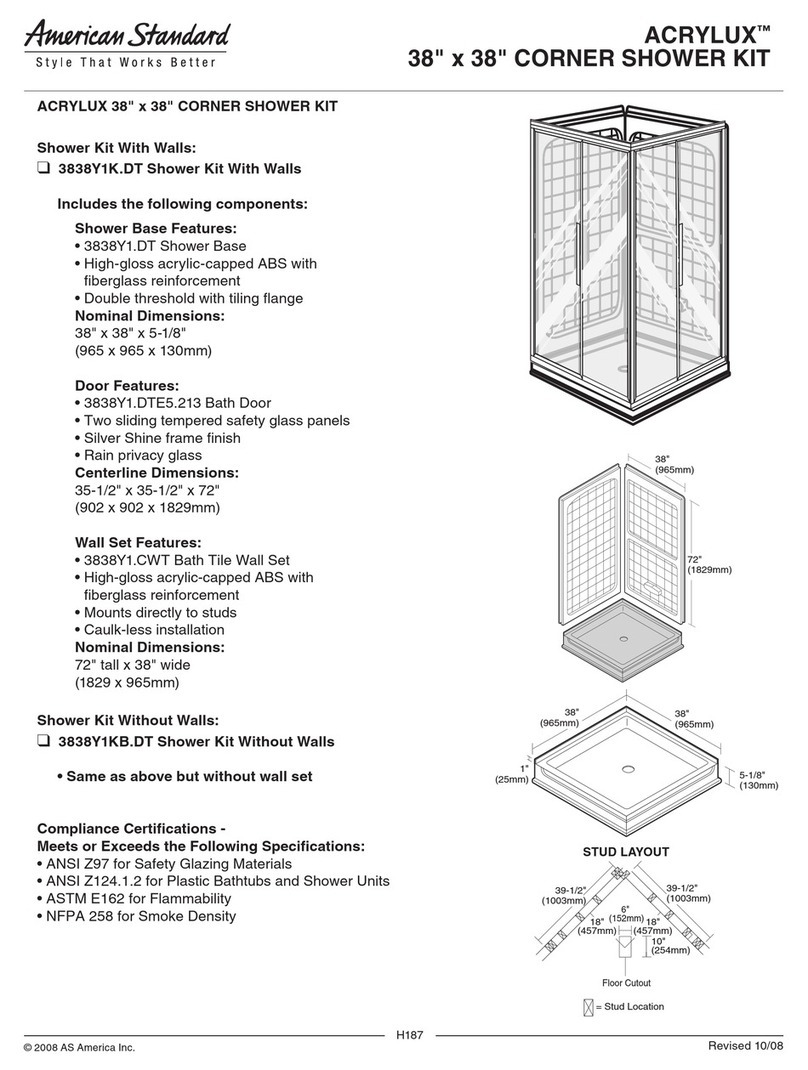

American Standard ACRYLUX 3838Y1K.DT Specifications