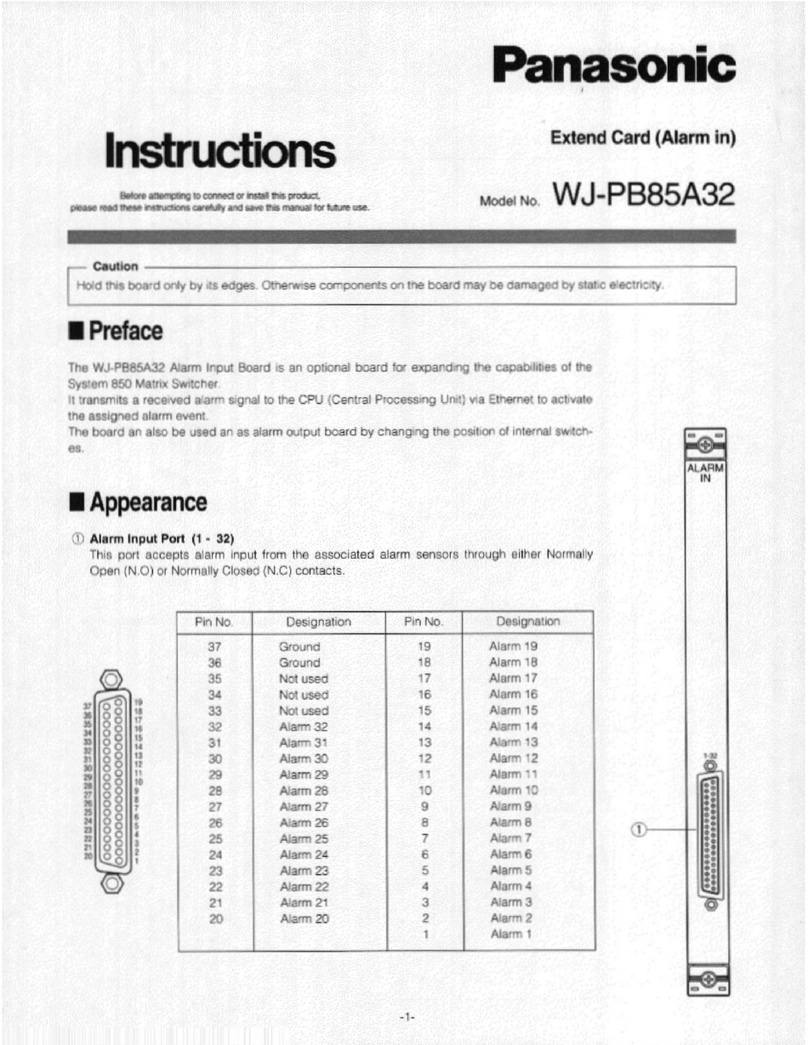

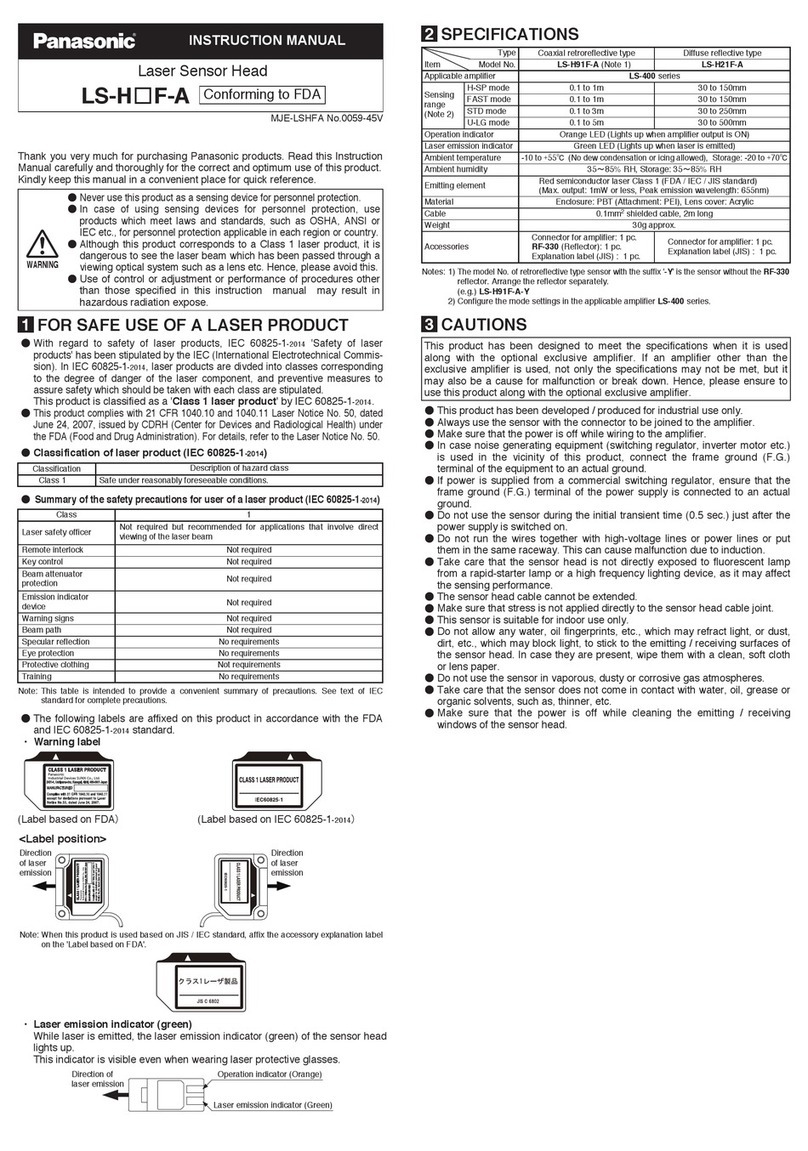

6SPECIFICATIONS

Type General purpose High precision

Model No.

(Note 2)

HG-S1010-AC HG-S1110-AC

With no seal cap

mounted

With no seal cap

mounted

Position detection method Optical absolute linear encoder method

Measurement range 10mm (Note 3)

Stroke 10.5mm or more (Note 3)

Measuring

force

(Note 4)

Downward mount (Note 5) (Note 5) (Note 5) (Note 5)

Upward mount (Note 5) (Note 5) (Note 5) (Note 5)

Side mount (Note 5) (Note 5) (Note 5) (Note 5)

Resolution 0.5μm0.1μm

Sampling cycle 1ms

Indication

accuracy

(P-P)

Full range ȝPRUOHVV ȝPRUOHVV

Limited range ȝPRUOHVVDQ\ȝP ȝPRUOHVVDQ\ȝP

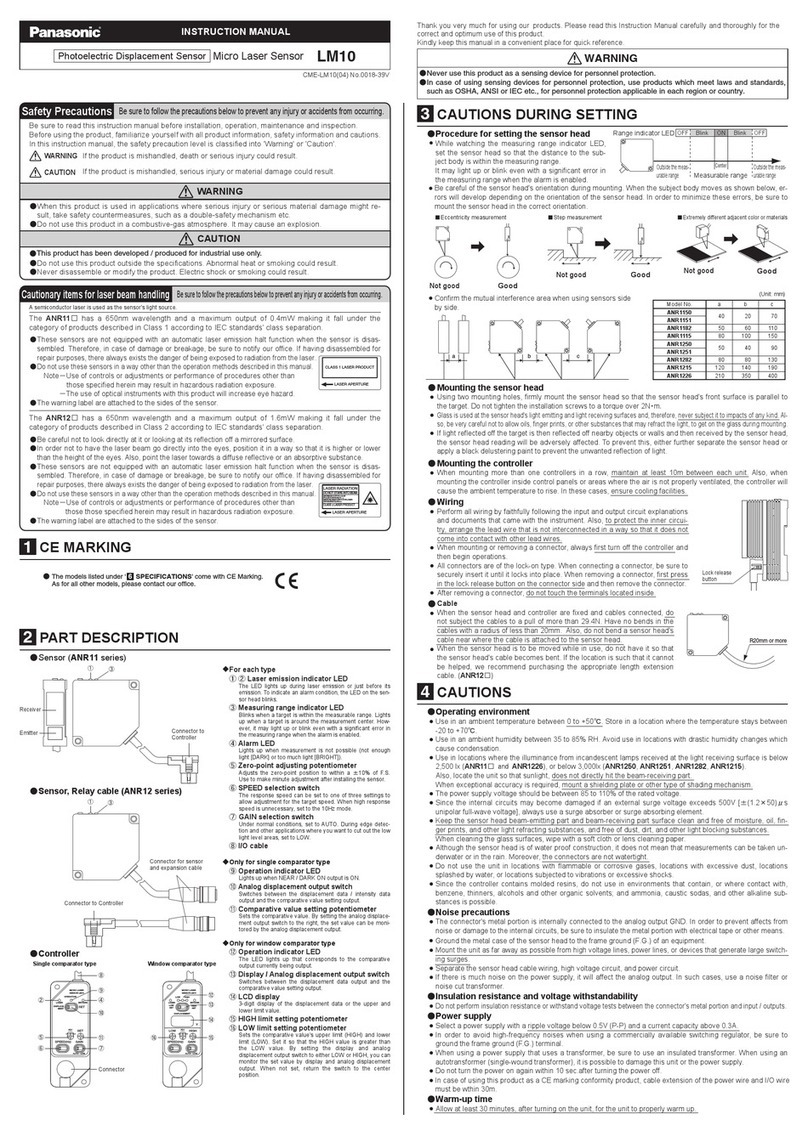

Operation indicator Equipped (2-color LED: Orange, green)

Working pressure range 0.14 to 0.16MPa 0.035 to

0.045MPa 0.14 to 0.16MPa 0.035 to

0.045MPa

Capacity to resist pressure 0.2MPa

8VDEOHÀXLG Dry air (Dew point temperature: -10°C or lower)

Applicable tube Outside diameter: 4mm / Inside diameter: 2.5mm

Protective structure (Note 6) IP67(IEC) ņIP67(IEC) ņ

Contamination level 2

Elevation 2,000m or lower (Note 8)

Mechanical life (Note 7) 30 million times or more (typical value)

Tip deviation amount ȝPW\SLFDOYDOXH

Grounding method Capacitor grounding

Insulation resistance 0ȍRUPRUHDW9'&

Hot swap function Incorporated

Ambient temperature -10 to +55°C (No dew condensation or icing allowed), Storage: -20 to +60°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Material Body: Zinc, Holder: Stainless steel, Spindle: Tool steel, Probe: Ceramic (Note 9)

Weight (main unit only) Approx. 80g

1RWHV0HDVXUHGDWDQDPELHQWWHPSHUDWXUHRI&XQOHVVRWKHUZLVHVSHFL¿HG

2) Connect an

HG-S series controller (manufactured in or after February 2019).

3) The position that represents "0" as an absolute value is a position where the spindle is pushed further down

from the bottom dead point by 0.1mm or more. The term "stroke" indicates the total stroke length from the

bottom dead point to the top dead point.

4) Measuring force changes with the air pressure used. Removing the seal cap enables the product to be used

as the low measuring force type. For details on how to remove the seal cap, refer to " 8MAINTENANCE".

5) For the relationship between supplied air pressure and measuring force or between measuring force and

SXVKHGVSLQGOHSRVLWLRQVHHWKH¿JXUHVEHORZ)RUXSZDUGPRXQWZLWKRXWDVHDOFDSVXEWUDFW1IURPWKH

PHDVXULQJIRUFH)RUVLGHPRXQWVXEWUDFW1IURPWKHPHDVXULQJIRUFH7KHIROORZLQJ¿JXUHVDUHRQO\W\SL-

FDOH[DPSOHVDQGWKHVHUHODWLRQVKLSVGLႇHUGHSHQGLQJRQWKHDVVHPEO\DFFXUDF\RIWKHSURGXFWRUWKHDEUD-

sion status of sealing materials.

ƔWhen no seal cap is mounted

Pushed spindle position [mm]

Measuring force [N]

<Downward mount (typical example)>

<Side mount (typical example)>

Pushed spindle position [mm]

Measuring force [N]

<Upward mount (typical example)>

Pushed spindle position [mm]

Measuring force [N]

<Downward mount (typical example)>

Measuring force [N]

Pushed spindle position [mm]

6) Protective structure is not applicable when the sealing portions have deteriorated or become damaged. The

protection level is zero when the seal cap is removed.

7) Typical value in a clean environment with no contact with dust or liquids such as water and oil.

The sealing material (O-ring) for the seal cap must be replaced at appropriate intervals. For approximate re-

placement intervals, refer to "How to replace the seal cap" in " 8MAINTENANCE".

8) Do not use or store this product in environments where ambient air is pressurized to an air pressure higher

than the atmospheric pressure at an altitude of 0 m.

9) The probe is also available as an option.

7CAUTIONS

The special sensor head HG-SƑLVGHVLJQHGWREHXVHGZLWKWKHFRQWUROOHU

HG-SCƑ,IXVHGZLWKRWKHUWKDQWKHVSHFLDOVHQVRUFRQWUROOHURSWLRQWKHVSHFL¿FD-

tions will not be met and product malfunctioning or damage may occur.

ƔThis device has been developed / produced for industrial use only.

Ɣ'RQRWXVHWKLVSURGXFWRXWVLGHWKHUDQJHRIWKHVSHFL¿FDWLRQV5LVNRIDQDFFLGHQW

and product damage. There is also a risk of a noticeable reduction of service life.

ƔDeviations may occur in the measured value at the bottom dead point. Do not use

the bottom dead point as a reference. The position where the spindle is pushed

further down from the bottom dead point by 0.1mm or more must be used as the

reference point.

ƔDo not wire in parallel with a high-voltage line or power line, or run through the

same conduit. Risk malfunctioning due to induction.

ƔDo not use the product during the initial transient time after the special controller

HG-SCƑLVWXUQHG21

ƔDo not apply stress such as excessive bending or pulling to the extracted part of a

cable.

ƔWhen attaching the sensor head connection cable to this product, do not apply

force to the product.

ƔOnly one joint (optional) can be installed to one sensor head.

ƔThis product is suitable for indoor use only.

ƔAvoid dust, dirt, and steam.

ƔDo not use this sensor in places where it may come in contact with corrosive gas-

es, ozone, or other harmful gases.

ƔEnsure that the product does not come into contact with organic solvents such as

thinner.

ƔEnsure that the product does not come into contact with strong acid or alkaline.

ƔEnsure that the product does not come into contact with oil or grease.

Ɣ

7KLVSURGXFWFDQQRWEHXVHGLQDQHQYLURQPHQWFRQWDLQLQJÀDPPDEOHRUH[SORVLYHJDVHV

Ɣ3HUIRUPDQFHPD\QRWEHVDWLVIDFWRU\LQDVWURQJHOHFWURPDJQHWLF¿HOG

ƔThis product is a precision device. Do not drop or otherwise subject to shock. Risk

of product damage.

ƔMount the sensor unit perpendicular to the measured surface. Mounting the sen-

VRUXQLWREOLTXHO\ PD\QRWRQO\UHVXOWLQPHDVXUHPHQWHUURUEXW DOVRVLJQL¿FDQWO\

shorten its service life.

ƔDo not allow excessive horizontal force to be applied to the spindle.This may

cause reduced accuracy and durability.

ƔMount a pressure-reducing valve to use the product within the allowable working

pressure range. Excessive pressure may result in failure or damage.

ƔDo not use air containing foreign objects (such as carbon powder or dust), water,

or oil. Doing so may result in electric shock or failure. To prevent such problems,

WDNHDSSURSULDWHPHDVXUHVVXFKDVPRXQWLQJDLU¿OWHUVRUPLVWVHSDUDWRUV

Ɣ %HIRUHSHUIRUPLQJPDLQWHQDQFHLQVSHFWLRQRUFOHDQLQJDOZD\VVKXWRႇDLUVXSSO\

completely and check that the pressure inside the product and piping is zero. Fail-

ure to do so may result in accidents or failures due to air pressure.

ƔWhen the product becomes unusable or unneeded, dispose of the product appro-

priately as industrial waste.

ƔNever attempt to disassemble, repair, or modify the product.

8MAINTENANCE

How to replace the probe

ƔAlways secure the spindle to prevent rotation before replacing the probe. Risk of

product damage if an excessive torque (0.2N·m or more) is applied to the spindle.

ƔIf the seal cap is scratched or damaged during probe replacement, the

VSHFL¿FDWLRQVRIWKHSURWHFWLYHVWUXFWXUHPD\QRWEHVDWLV¿HG

1.

Turn the probe screw in the direction of the arrow and remove the probe from the

spindle. When turning the probe screw, hold the cut face of the spindle with the

provided sensor head fastening wrench to prevent the spindle from turning.

Hold the sensor head fastening wrench in place, and turn only the probe.

Sensor head

fastening wrench

(Accessory)

Probe

Turn

2. Attach the new probe to the spindle. The tightening

torque should be 0.4N·m or less. Make sure that the

probe does not come OFF.

When turning the probe screw, hold the cut face of the

spindle with the provided sensor head fastening wrench

to prevent the spindle from turning.

Hold the sensor head fastening wrench in place, and

turn only the probe. Turn

How to replace the seal cap

Replace the seal cap at appropriate intervals according to the deterioration status of

the sealing material.

Replace the seal cap when the number of sliding operations reaches approximately

¿YHPLOOLRQ

ƔWhen removing or mounting the seal cap, always remove the product from the

housing.

ƔWhen removing or mounting the seal cap, stop supplying air.

ƔTo prevent problems, replace the seal cap before the internal O-ring becomes

worn.

How to remove

1. Remove the probe.

2. While pulling the seal cap, expose the

edge of the O-ring.

3. Loosen the seal cap by rotating it in the

direction indicated by the arrow.

4. After loosening the seal cap completely,

pull it out.

5. Finally, remove the O-ring.

Seal cap

O-ring

How to mount

1. Mount the O-ring in the specified posi-

tion.

2. Slide the seal cap onto the spindle and

move it to a position where it can rotate

at no load.

3. Push in the seal cap while rotating it in

the direction indicated by the arrow.

Note: Check that the O-ring does not protrude.

Seal cap

O-ring

Panasonic Industrial Devices SUNX Co., Ltd.

https://panasonic.net/id/pidsx/global

Please visit our website for inquiries and about our sales network.

PRINTED IN JAPAN © Panasonic Industrial Devices SUNX Co., Ltd. 2020