Digimoba Elektronic 4000 Trackswitch ID Manager User manual

1

Manual Trackswitch ID Manager

2

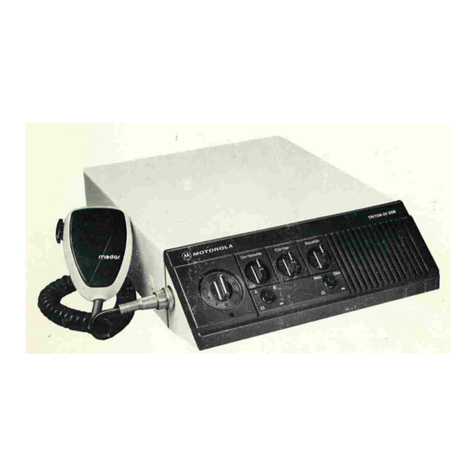

The Trackswitch ID Manager is used to read and write RFID Tags, also called

transponders. These transponders are available in various forms. Transponders in

paper or in foil form are ideally suited as stickers for model railway purpose.

RFID (Radio Frequency Identification) is a technology that enables wireless

identification and communication. The corresponding transponders are able to store

data without their own energy source and, if necessary, transmit it to suitable reading

devices.

In addition, a special protocol ensures that a collision of data from many

transponders, which are simultaneously in the reading or writing area of the antenna

of the ID Manager or other reader, is prevented. This means that only one

transponder can be actively processed at a time.

This makes it possible, for example, to identify or mark model railway vehicles

contactless. The transponders (Tags) in the form of paper stickers or foil stickers can

easily be stuck on the underside or inside model vehicles. The information stored in

these transponders can be read using the ID Manager ore the reader module 4010.

The reader module 4010 can transmit the read information directly to a display

module 9086 (with cable 8030) or via Trackswitch feedback bus (with feedback bus

cable 8015---8019) to the control system Trackswitch or S88 feedback bus (with

adapter cable 8032) to any other control system supporting S88 bus. In both cases,

power is supplied via the bus cables.

Currently supported are four-digit numbers, which are displayed on the four-digit

display module 9086. When the reader module 4010 is directly connected to the

display module 9086, these two devices are powered by a normal USB charger and

connection cable 8031 on the reader module 4010. The display module 9086 has

been developed to fit the Digimoba track control panel. However, it can also integrate

in self-developed track control panels.

Thus, this system is able to identify 10,000 (0000—9999) different vehicles. This is

especially helpful in areas that are difficult or impossible to see on a model railway

layout (incisions, fiddle yards, tunnels, poorly visibly stations etc.) for the necessary

overview of the whereabouts of the vehicles or entire trains. In connection with

corresponding PC control programs, these numbers can also be used to trigger

different routes or other actions. This means that routes for different trains can be

guided differently, sound playback started, functions switched on, platform and other

lightning switched on, speeds changed and much more.

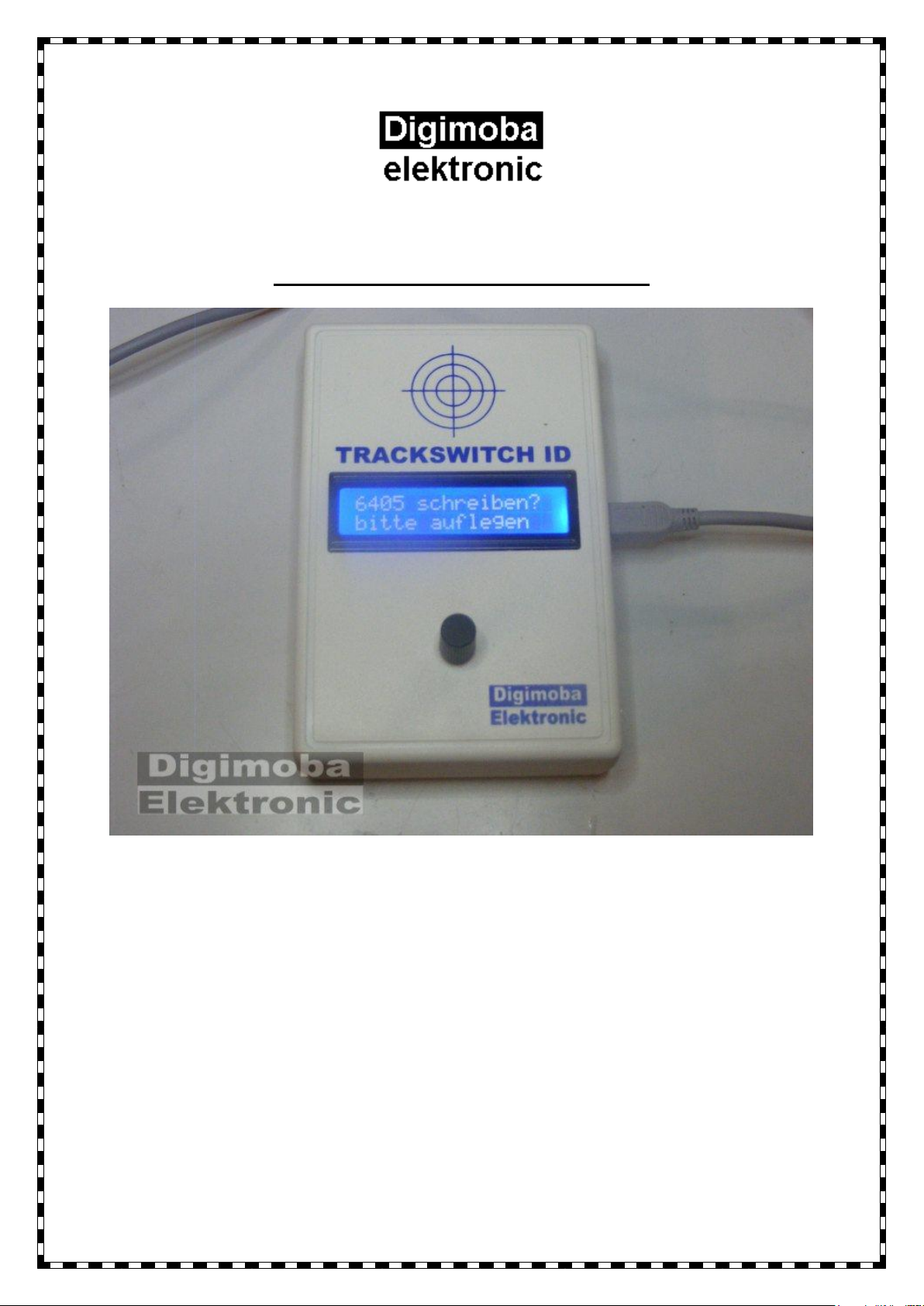

To write a suitable transponder (Tag) with the ID Manager 4000 select the menu

point “Transponder schreiben?” with the rotary encoder. Press the rotary knob briefly

to select the thousands digit. The desired number can be set by turning the rotary

knob. By pressing the rotary encoder, the next lower decimal point is reached to

select the next number until all numbers have been entered completely. Press twice

to dial the number with the question “Transponder schreiben? Bitte auflegen”

appears. Now the transponder must be held parallel on the surface on the marking of

the ID Manager. This number is written by pressing the rotary encoder again. You

can also stop the process by turning the knob counterclockwise. The display asks

you: “xxxx zurück?” xxxx stands for the selected number. By pressing the rotary

knob, you can start entering the number from the beginning without having written

this number, or by turning it clockwise you can return to the write query.

You can check whether the transponder has been correctly written by turning the

rotary encoder counterclockwise and display shows “Transponder lesen?” Hold the

transponder parallel to the surface above the marking. When the transponder has

3

been read out, the display changes to “Transponder gelesen:xxxx” for three seconds,

where xxxx stands for the number read out.

You can read out a transponder again or return to the menu for describing a

transponder by turning the rotary knob clockwise.

The transponders can be rewritten as often as required. Empty, still blank

transponders show 0000 when they are read out, can of course also be written in this

way again.

The ID Manager is powered by a USB mini cable from a standard USB charger that

can be plugged into the side of the unit. Bothe is included in the scope of delivery.

The device can be updated via this USB connection and is therefore prepared for

future innovations or expansions.

The appropriate transponders can be obtained from us. The mounting on or in the

vehicles is unproblematic with two exceptions:

1. They must not be glued directly onto or behind metallic substrates. Metal of

such magnitudes interferes with radio signals and makes there use

impossible. Tests have shown that the distance between a transponder and a

metal surface must be at least 10 mm.

2. The transponder must be placed as close as possible to the reader. So

underside of a vehicle or inside on the underside if the reader is mounted

under the track. Normal rails of a track limit the function only insignificantly.

Depending on the size of the transponder, distance of 15----35 mm are

possible.

The reader module 4010 consists of the actual module (blue) and the associated

electronics. A coded 8-pole cable (enclosed) connects these two elements. The

reading unit can easily be mounted under the desired track, and the function is also

available under the track substructure. Therefore, retrofitting existing plants is

relatively easy. Also here no metallic layers or foils should be present between

vehicle transponder and reader.

The transponder technology can be used independently of the many different current

systems and track gauges, whether analogue or digital. The mounting of

transponders on model vehicle as well as the installation of readers under a track is

relatively easy. The biggest advantage of this technology is that the existing electrical

systems do not have to be interfered with. Track separations or track contacts are

also not necessary! In addition, no special knowledge is required to use this

technology.

Legal information:

This device is exclusively approved for the intended use in dry rooms. The power

supply may only be providing from specially designed, approved and marked sources

for model railways applications.

Not technical changes may be made to the power supply or to our device be

unauthorized persons. Any liability for improper use or unauthorized modification is

rejected.

Reading this operating instruction is part of the intended use and is therefore

necessary before using our device.

Not suitable for children under the age of 14.

4

Stand 08/2019

Änderungen im Sinne des technischen Fortschrittes

vorbehalten.

Elektroaltgeräte gehören nicht in den Hausmüll! Bitte

entsorgen Sie diese kostenfrei bei Ihrem örtlichen

Entsorgungsunternehmen.

Digimoba Elektronic

Sudetenstraße 10

D-96253 Untersiemau

Tel.: 09565 488423

Fax.: 09565 488432

Ust-Id.Nr: DE814201353

WEEE-Nr : DE58841512

www.digimoba.de

Table of contents