Digistar Moisture Tracker User manual

D3998-US Page 1 Rev A 4/10/2015

Getting Started With Moisture Tracker

1. Retrieve the USB from the Moisture Tracker USB port.

2. Insert USB into the computer and double click "Setup.exe"

3. Install the PC Utility.

4. Setup farm(s) by selecting the Farms icon.

5. Setup ingredients per farm by selecting the Ingredients icon.

a. Use the “Feed Description” field to view all available forages.

NOTE: A chart to assist in setting up ingredients is on the Digi-Star website at:

https://digi-star.com/library_v2/solutions/documents/MTingredientsetuptabs.jpg

b. Or use the 4 fields to narrow the ingredient options

6. Transfer the ingredient and farm information to the USB by selecting the Send/Retrieve Data icon.

a. Select individual ingredients, or click the "Select All" button to choose all ingredients.

b. Once the desired ingredients are chosen, click the "Send Ingredients" button.

7. Insert the USB into the Moisture Tracker USB drive, the farms and ingredients will auto-install into the Moisture

Tracker unit during power up.

D3998-US Page 2 Rev A 4/10/2015

Activating the 1 year license

A temporary license comes with the unit. The full 1 year license must be downloaded from

www.digi-star.com/store/mt_activate.php

How to Activate

1. On your Moisture Tracker select "About this Device" from the main menu.

2. Write the 16 digit Device ID code from your Moisture Tracker below:

__ __ : __ __ : __ __ : __ __ : __ __ : __ __ : __ __ : __ __

3. Power off the Moisture Tracker and remove the USB memory stick.

4. Insert the USB memory stick into a USB port on your PC.

5. On your PC go to the Digi-Star website: https://digi-star.com

6. Select Moisture Tracker and Activate Software License.

7. Enter your device ID into the area shown.

8. Save the MoistureCompute.License file to the "Moisture Tracker" USB memory device.

NOTE: Do not place MoistureCompute.License in a folder.

9. Insert the USB memory stick into the Moisture Tracker hand held unit. The license file will upload automatically

when the unit is powered on.

10. Verify the license in the "About this Device" screen. The expiration should be 1 year from the current date.

D3998-US Page 3 Rev A 4/10/2015

“Best Practices” for Moisture Tracker

General Use and Care

Keep the glass lens clean and free of debris or moisture. Clean with monofilament cloth and solution designed for

use with eyeglasses or LED type screens. Do not use any cleaning solution that may leave a residue which could

interfere with readings. Any dust, debris, etc., WILL effect calibration and results!

Clean the screen/grate on the end of the probe between samples or during scans as needed. A stiff bristle brush

works well for this.

Check regularly for potential updates to software or feed calibrations.

Calibration

Check calibration daily, or more often if doing continuous-type testing, such as during forage harvest. Best if re-

calibrated any time the result is < 99.50%

Keep Calibration disk/probe stable during calibration or checking calibration. Place the calibration disk on a table or

other stable, flat surface. Hold probe firmly against the disk during the procedure; avoid movement of the probe.

Keep calibration target disk CLEAN and DRY. Always be sure to clean the Moisture Tracker screen/grate prior to

placing it against the calibration target disk to avoid contamination. Always replace the cover on the calibration

target disk and store it in the carrying case. Do not leave it exposed to direct sunlight.

If the unit is stored in a place that differs more than a few degrees from the place where it will be used, allow the

unit to acclimate to the ambient temperature of the test area. Turn on the MT for 10 minutes or more where it will

be used prior to calibrating or taking a measurement. Change the power-down settings if needed.

Measurements

Hold the probe squarely on the material being sampled, eliminating external light error, but not to the point where

material pushes up through the screen. This is extremely critical when testing finely ground materials. The weight of

the unit on the sample material is generally enough.

Do not move lift or move the unit until you hear the audible beep confirming the scan has completed. An

inadvertent trigger pull or premature move that results in the unit beeping while in the air can be eliminated from

the sample by pressing the back arrow button.

If sampling multiple materials, it is advised to start with the driest material first and end with the wettest or stickiest

material last. This will minimize the need to do a major cleaning between materials.

In extreme cold environments near or below freezing, bring a sample to a more moderate environment to perform

the testing. Frozen material WILL NOT give accurate results. Completely thaw frozen material prior to sampling.

Increase the minimum number of scans from 20 up to 30 (or more) to increase accuracy for materials of these types:

fresh/green chop, material with a coarse chop length, material with lower moisture, material that is a mixture of

grass and legumes.

Take readings on a freshly exposed layer of the material. Get beneath the surface that may have already dried out.

Variations in moisture can quickly change on surface material exposed to sunlight and air. Piles of material that get

rained on should be mixed thoroughly prior to sampling to get a more representative reading.

D3998-US Page 4 Rev A 4/10/2015

Moisture Tracker Adjustment Procedure

The Dry Matter results (DM) of a MT (MT) can be aligned with a known reference DM (from Lab, Dehydrator,

Koster, etc.). Individual feedstuff DM readings may not all align the same due to natural variations in feeds,

but should be within acceptable ranges (+/- 2%). If you have questions please contact:

Dick Bonner - Technical Sales Representative

Office: 920-568-6210

Mobile: 608-359-5930

W5527 Hwy 106, Fort Atkinson, WI 53538

Toll Free: 1-800-225-7695, Ext 6210 (USA only)

1. Gather samples of 2 –3 common feedstuffs (corn silage, alfalfa haylage, high moisture

ground shell corn, etc.) that have Calibrations available for the MT. Gather enough material

that you can send some to the lab and save back enough to do future scans with the MT.

2. Divide the total sample of each feedstuff into one portion for testing per your preferred

reference method, a second portion for original measurement with MT, and a third portion

(packaged in an air-tight container (zip-lock bag) and stored in a refrigerator or freezer) for

later MT readings to verify the results after adjustment.

3. Take 2-3 DM readings on each of the feedstuffs using the MT.

4. Compare DM readings with reference DM reading. Compare the reference DM results to

your original MT DM readings.

If the MT DM is within 1-2% of the reference DM: do nothing.

If the MT DM is more than 2% higher than the reference DM: decrease the Calibration

Code.

If the MT DM is more than 2% lower than the reference DM: increase the Calibration

Code.

5. Adjust the Calibration Code:

On the MT, Select Main Menu > Calibrate Sensor > Enter New Calibration Code (3)

Change the Calibration Code by 5. (Ex: changing a code of 545493 to 545488 –a

reduction of 5 counts.) Use the right or left arrow buttons to get to the desired digit

and the up or down arrows to scroll the digit to the desired number. Press the “Enter”

button to save the adjusted code.

6. Recalibrate the MT.Hold the probe on the Calibration Disk and press “2”.

7. Take 2-3 new DM readings on each of the stored feedstuff samples using the MT. Be sure

that the samples are completely thawed out if they had been frozen. If you decreased the

code number, you should see a reduced DM reading for each of the feeds.

8. Compare with reference DM reading.

If the MT DM is within 1-2% of the reference DM, no more adjustment is needed.

If the MT DM is still more than 2% higher or more than 2% lower than the reference

DM, make additional adjustments to the calibration code as in step 5.

9. Record the adjusted Calibration Code. Write down the adjusted 6 digit calibration code and

save it with the disk. Use the adjusted code for future calibrations.

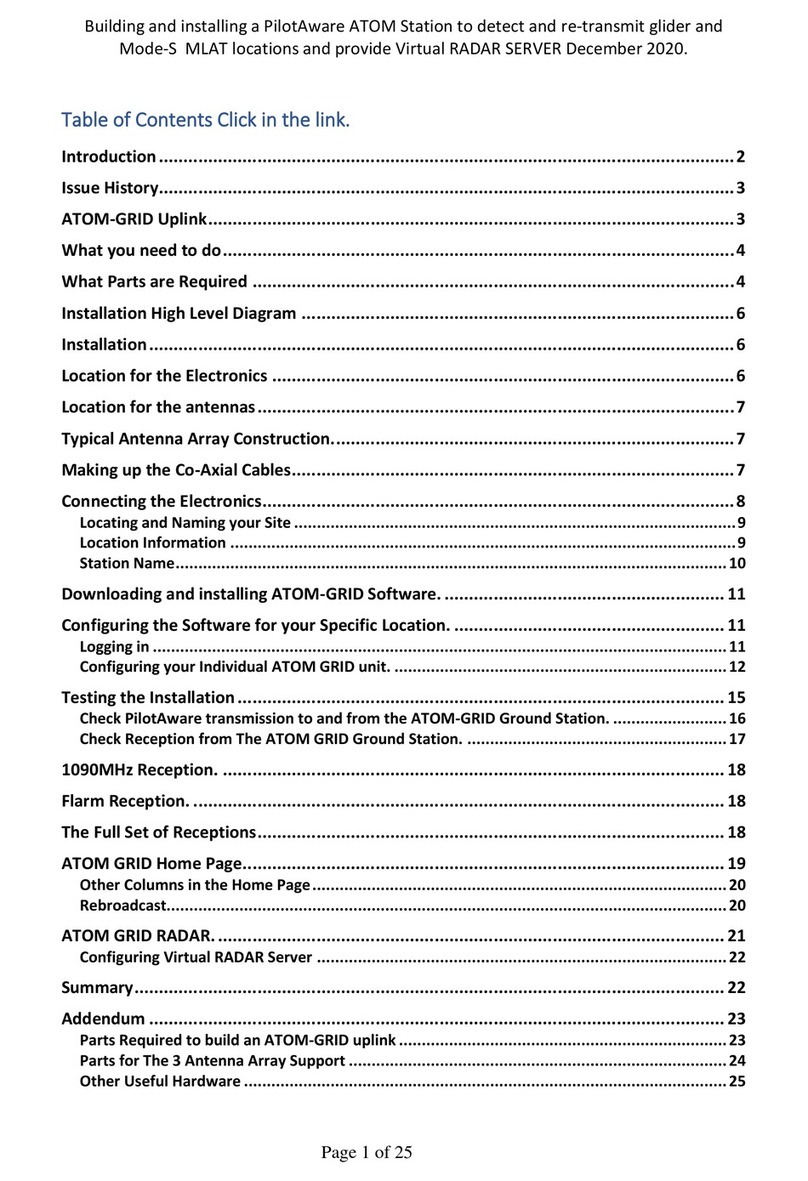

Table of contents