DINGO 950 User manual

DINGO™ 950

OPERATION AND

MAINTENANCE

MANUAL

IMPORTANT: Become familiar with the

contents of this Manual before operating

the Dingo. It contains Safety Instructions

& Warranty Information. Also become

familiar with the controls & their proper

use before operating the Dingo.

Edited February 2004

Dingo 950 Operation & Maintenance Manual

2

Dingo 950 Operation & Maintenance Manual 3

Introduction

Thank-you for purchasing a Dingo.

We believe that in purchasing a Dingo you have purchased a machine of the highest

quality and we want you to be totally satisfied as our customer. Please feel free to

contact any of our branches for help with service, genuine replacement parts, or other

information you may require.

When contacting us please have your Dingo Chassis and Model numbers handy.

These details enable us to know the specifications of your Dingo.

Best Wishes,

Gary Briggs

And the entire Dingo Pack.

This Manual belongs with Dingo:-

Dingo Chassis Number

Dingo Model Number

Engine Type & Serial Number

Date Purchased

(Please insert your Dingo details)

Attachments

Item Model Number Chassis / Serial Number

(Please insert your attachment details)

Dingo 950 Operation & Maintenance Manual

4

Table of Contents

SAFETY________________________________________________ 5

General Operation___________________________________________________5

Operating on Slopes _________________________________________________6

Children __________________________________________________________6

Service ___________________________________________________________7

SAFETY AND INSTRUCTION DECALS____________________ 8

SPECIFICATIONS ___________________________________ 8

SPECIFICATIONS_______________________________________ 9

OPERATING INSTRUCTIONS – Pre Start-up ______________ 11

Pre start-up (daily) _________________________________________________11

Adding Fuel ______________________________________________________11

Checking the Oil Level. _____________________________________________12

Remove debris from the machine ______________________________________12

Check hydraulic fluid _______________________________________________12

Tyres and Traction _________________________________________________13

OPERATING INSTRUCTIONS___________________________ 14

Controls__________________________________________________________14

Control levers/ Control panel _________________________________________15

Control panel diagram_______________________________________________16

Flow divider control ________________________________________________17

Starting and stopping the Engine ______________________________________17

Driving forward or backward _________________________________________17

Stopping the machine _______________________________________________18

Moving a Non functioning machine ____________________________________18

Using Cylinder Locks _______________________________________________18

Attachments - Connecting & Disconnecting______________________________19

Transporting and securing____________________________________________20

Maintenance ___________________________________________ 21

Dingo Service Pack_________________________________________________23

Air Cleaner _______________________________________________________23

Bushes & Pins_____________________________________________________23

Engine Oil________________________________________________________24

Spark Plugs _______________________________________________________24

Fuel Filter ________________________________________________________24

Fuel Tank ________________________________________________________25

Hydraulic System __________________________________________________26

Replacing the Hydraulic Filter ______________________________________26

Changing the Hydraulic Fluid_______________________________________26

Check hydraulic lines _____________________________________________26

Adjusting Drive Chains______________________________________________27

Battery___________________________________________________________27

Cleaning and long term storage _______________________________________28

Troubleshooting ________________________________________ 29

Dingo 950 Operation & Maintenance Manual 5

SAFETY

General Operation

1. Read, understand, and follow the instructions in the operators manual before

using the Dingo.

2. Keep hands, feet and clothing away from all moving parts and hydraulic

cylinders.

3. Allow only responsible adults who are familiar with the Dingo and its operation

to use the Dingo.

4. Do not allow any passengers on any part of the Dingo, including buckets and the

operating platform.

5. Do not re-fuel with engine running, or while you or someone near is smoking.

6. Do not operate any of the control levers (including auxiliary lever) unless you are

standing with both feet on the platform and firmly holding the grip handles.

7. Always wear long pants and substantial shoes (no sandals, thongs, tennis shoes,

sneakers, shorts or skirts). Clothing should not be loose fitting.

8. Do not place feet under the platform.

9. Watch where you are driving. Always look down and behind, before and while

reversing.

10. Warning

Engine exhaust contains Carbon Monoxide, which is an odourless, deadly poison.

Carbon Monoxide can kill you. Do not run engine indoors or in a confined space.

11. Always lower loader arms and/or place attachment on the ground when parking or

leaving the Dingo unattended. Always stop the engine if leaving the operators

platform.

12. Important

Do not carry a load or heavy attachment with the loader arms in a raised position. Do

not step off the platform with a load raised.

13. Never jerk the control levers. Use a steady motion. Slow down before turning.

Sharp turns may cause loss of control.

14. Stop the engine before making any adjustments to the attachments or the machine.

15. Warning – never weld on or near the fuel tank whether it is empty or full.

16. Do not operate on or near embankments. Look out for ditches, holes, etc and

beware of traffic when near roads.

17. Do not allow any person or animal close to the Dingo or its attachments while in

operation. Stop the machine if any person or animal comes close.

18. Operate only in daylight or good artificial lighting.

19. Do not operate the machine whilst under the influence of alcohol or drugs.

20. Use extra care while loading or unloading the Dingo onto a trailer or truck.

21. Do not touch equipment or attachment parts that may be hot from operation.

Allow to cool before attempting to maintain, adjust or service.

22. The Dingo is not a toy – Do not allow children to play on it.

Remember – Safety is your responsibility.

Dingo 950 Operation & Maintenance Manual

6

Operating on Slopes

All slopes require extra caution.

1. Do not operate on slopes exceeding 15º. If a slope is greater than 5°, only go up

and down (not across).

2. Always have the heavy end of the machine uphill. Weight distribution will

change. An empty bucket will make the rear of the machine heaviest, a loaded

bucket will make the front of the machine heaviest. Various attachments will

change which end is heaviest. If you are unsure, phone us and ask. These same

rules apply when loading and unloading the Dingo onto a trailer or truck.

3. Avoid turning on slopes. If you must turn, turn slowly keeping the heavy end of

the machine uphill.

4. Do not operate near ditches or embankments, the machine could turn over if a

wheel goes over the edge of a cliff or ditch or the edge caves in.

5. Do not operate on wet grass, reduced traction could cause wheel slip.

6. Remove obstacles such as rocks, tree limbs, etc from the work area. Watch for

ruts or bumps as uneven terrain could overturn the machine. Tall grass can hide

obstacles.

7. Operate in slow speed. Put pump selector valve in slow (turtle) position so that

you will not have to stop or shift while on the slope.

8. If parking on slopes or hillsides always lower the loader arms and attachment to

the ground and chock the wheels.

9. If machine becomes unstable, jump clear. Never try to stabilise the machine by

putting your foot on the ground.

Children

Be wary of the presence of children when operating a Dingo. Children are often

attracted to the Dingo and the work activity.

Keep children out of the work site and under the watchful care of a

responsible adult.

Be alert and turn the machine off if children enter the area.

Never carry children (or anyone) on the Dingo or any of its

attachments.

Do not allow children to play on the Dingo or within the Dingo

work site (aside from the danger of working machinery there may

be holes into which a child could fall or various other dangers).

Do not allow children to use the machine.

Before reversing look behind and down for small children. Be

aware of blind corners, shrubs, trees, or ends of fences that may

obscure vision.

Dingo 950 Operation & Maintenance Manual 7

Service

1. Before performing any service, repairs, maintenance or adjustment, stop the

engine and remove the key.

2. Never run the machine in an enclosed area.

3. Perform all maintenance with the loader arms fully lowered. If loader arms need

to be raised to perform tasks, secure them in the raised position by using cylinder

locks or a safety stand. (Contact a Dingo representative if you are unsure)

4. Look after the Dingo. Keep nuts and bolts tight.

5. Do not tamper with safety devices. Before each use check safety systems

properly.

6. Keep the machine free of grass, leaves, or other debris build-up. Clean up oil or

fuel spillage. Allow machine to cool before storing.

7. Use extra care when handling petroleum and other fuels. They are flammable and

vapours are explosive.

A. Use only an approved container.

B. Never remove the fuel cap or add fuel while the engine is running. Allow

engine to cool before refuelling. Do not smoke.

C. Never refuel the machine indoors.

D. Never store the machine or fuel container inside where there is an open

flame, such as near a water heater or furnace.

E. Never fill a container while it is inside a vehicle, car boot, utility tray or

any surface other than the ground.

F. Keep container nozzle in contact with the tank during filling.

8. Stop and inspect equipment if you strike anything or hear any strange noise

coming from the machine. If necessary repair machine before starting again.

9. Use only genuine replacement parts to ensure that original standards are

maintained.

10. Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes, and

clothing. Your face, eyes, and clothing should be protected when working with a

battery.

11. Battery gases can explode. Keep cigarettes, sparks and flames away from battery.

12. Warning!

Hydraulic pressure escaping under pressure can penetrate the skin and cause

injury.

Keep hands and body away from pin hole leaks or nozzles that eject high pressure

hydraulic fluid. A small leak can be dangerous. To find hydraulic leaks use cardboard

or paper.

If fluid is accidentally injected into the skin a doctor familiar with this type of injury

must surgically remove it within a few hours.

SAFETY AND INSTRUCTION DECALS

Pump Selector Valve.

Hare – forward

↓Turtle - rearward↓

↓On front Control Panel↓

←

On front

Control

P

ane

l

↑On front

Control Panel

↑

On Control

P

ane

l

↑On front Control Panel↑

(Part No. 2DDECPNL)

↑

On front Control Panel↑

←

On loader Cross Member

(Part No. 2DDECCTN)

←

On outside right edge of fuel

tank. (Diesel Only)

(Part No.2DDECDIESEL)

←On outside right edge of fuel tank

(Petrol Only)

(Part No. 2DDECUNLEAD)

←

On front of fuel tank. With line

approx. 60mm below top of tank.

(

Part No. 2DDECLINE

)

Dingo 950 Operation & Maintenance Manual

8

Dingo 950 Operation & Maintenance Manual 9

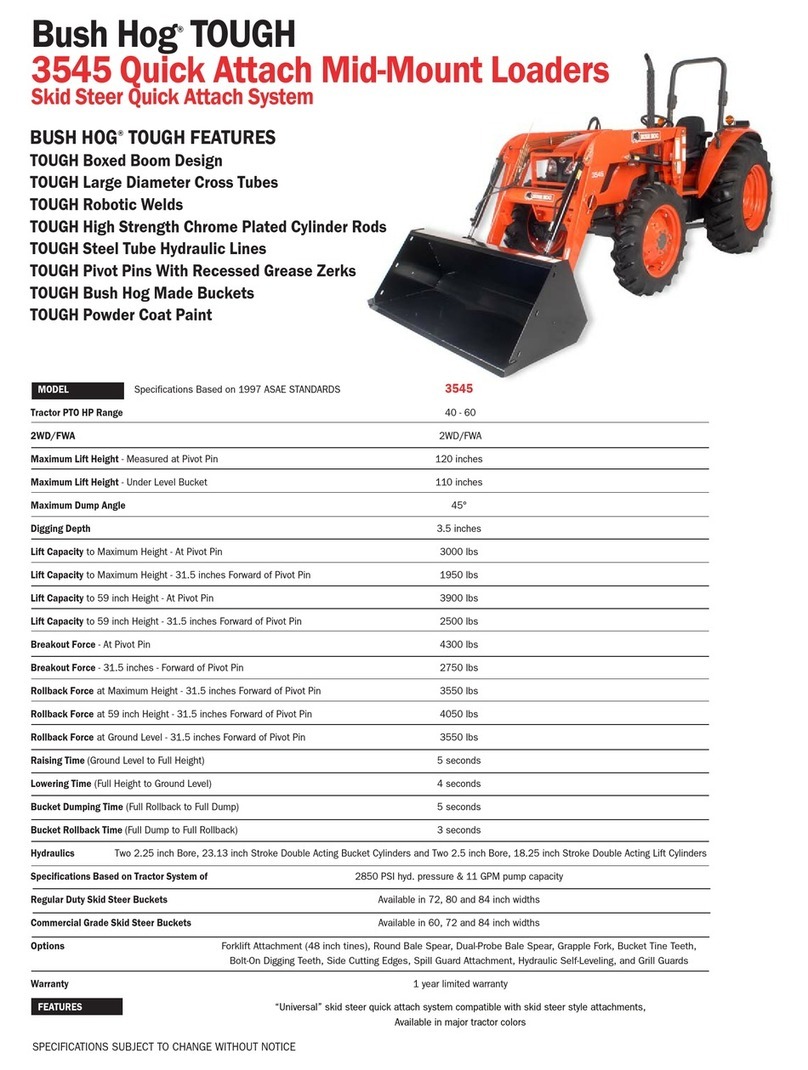

SPECIFICATIONS

General Specifications

(without operator and without attachments)

All Dingo 950 models have the same outside dimensions/Chassis.

(Approximate Only)

Overall width 840mm-1050mm

Overall length (without attachment) 1565mm

Overall height 1200mm

Maximum Operating Height (with standard bucket) 2080mm

Operating Weight 700-800kg

Turning radius with standard bucket 1300mm

Rated lift capacity - bucket (with 90kg operator) 250kg

(lifting capacity up to 500 kg with certain attachments)

Speed 0→6 km/hr

Angle of departure 20°

Engine HP 20-22 HP

Wheel motor sizes 29 cu in

Wheel base 710-800mm

Drive Chain ASA 60H (Heavy Link ¾”)

Ground clearance 135mm

Tyre size 18 x 8.50 x 8 (4 ply) std

Hydraulics 2 pump

Pump sizes 9 & 3 cc

System relief pressure (hydraulic) 3000psi (206 Bar)

Hydraulic Reservoir capacity 60 litres

Hydraulic Output 43 litres per minute

Filtration 25 micron

Standard bucket capacity 0.11 cu m

Standard bucket dump height 1240mm

Reach fully raised standard bucket 600 mm

4 in 1 bucket capacity 0.11 cu m

4 in 1 bucket dump height 1750mm

Reach fully raised 4 in 1 bucket 600 mm

Chipbark bucket capacity 0.18 cu m

Height to hinge pin (std bkt in highest position) 1680mm

Specifications and design subject to change without notice.

Dingo 950 Operation & Maintenance Manual

10

Dingo 950 Operation & Maintenance Manual 11

OPERATING INSTRUCTIONS – Pre Start-up

Pre start-up (daily)

Read this manual and the Engine manual and become familiar with the contents of

both.

Always check the following before operation:

Fuel level – fill if necessary

Ensure breather on top of the fuel cap is open (where applicable)

Engine oil level (refer to engine manual)

Remove all refuse from the machine.

Check air filter

Check bushes

Tyre pressure

Drive chain condition and tightness

Be sure that the work area is free from other people and children

Clear work area of any debris.

Know and mark the location of any utility lines

For first 6 days of operation of new machine, and first 6 days of operation after

changing wheels, tighten wheel nuts daily.

Adding Fuel

Labelling on the fuel tank tells whether a machine requires petroleum or diesel fuel.

For fuel types and information on suitable additives refer to Engine Manual as

supplied. (NB if labelling becomes lost or damaged or you do not have either Manual,

order replacements from your nearest Dingo representative or head office).

Filling the fuel tank

Position machine on level surface, lower the loader arms and turn off the engine (turn

ignition key to off). Remove the key.

Clean around the fuel tank cap and remove the cap. Use a funnel to add fuel as

specified above to the fuel tank, filling until the fuel reaches 60-70mm below the top

of the tank. This space is needed to allow the fuel to expand. Do not fill the fuel tank

completely full.

Replace the fuel cap securely. Clean away any fuel that may have spilt.

Danger!

Petroleum can be extremely flammable and highly explosive. To avoid a fire or

explosion that may burn yourself, others, or cause property damage: -

Use a funnel and fill the fuel tank outdoors, in an open area, when the engine is cold.

Clean up any petrol spills.

Do not completely fill the fuel tank. Follow guidelines above.

Never smoke while handling fuels, and stay away from an open flame or any place

that a spark may ignite petroleum fumes.

Store fuels in an approved container, out of reach from children. Never buy more

than a 30-day supply of fuel.

Dingo 950 Operation & Maintenance Manual

12

Checking the Oil Level.

Refer to your engine manual.

Remove debris from the machine

IMPORTANT: Overheating will result if the engine is operated with a blocked grass

screen, dirty or plugged cooling fins, and/or cooling shrouds removed.

Park the machine on a flat surface, lower the loader arms and turn off the engine (turn

ignition key to off). Remove the key.

Check the air filter pre-cleaner for debris. If required, wipe away debris before and

during each use.

Debris can build up in the engine area. Clean any debris build-up with a brush or

blower before each use.

IMPORTANT: It is preferable to blow out dirt than to wash it out. If water is used,

keep it away from electrical appliances.

IMPORTANT: Do not high-pressure wash. High-pressure washing can damage the

electrical system.

Check hydraulic fluid

Check the hydraulic fluid level before engine is first started and after every 25 hours

of operation.

Fluid type: H68 or equivalent

Hydraulic tank capacity: 60 litres

Position machine on level surface, lower the loader arms and stop the engine

Clean area around filler neck of hydraulic tank.

Remove cap from filler neck and check fluid level. Fluid level should be to approx.

75-100mm below the top of the tank.

If level is low, add enough fluid to raise to proper level.

Install cap on filler neck.

Dingo 950 Operation & Maintenance Manual 13

Tyres and Traction

Warning! Dingo tyres should be filled with water or solid fill. Failure to do so will

result in poor weight distribution, which will drastically reduce the stability and

carrying capacity of the machine.

Use of incorrect tyre pressure will also reduce the stability and carrying capacity of the

Dingo. The correct tyre pressure is usually between 140 and 155kpa (20-22psi).

Various types of equipment are available for adding water to tyres. Filling equipment

can also be purchased from Dingo Mini Diggers.

You should also be aware that the tyres fitted to your machine may not be the most

suitable for all work environments and there is a range of traction equipment to suit

every application.

This range includes:

• 8” Turf tyres [machine width – 1050mm] (general purpose - suitable for

grassy areas, dry soil and paved surfaces – minimum ground disturbance).

• 8” Lug tyres [machine width – 1050mm] (tractor type, for building sites,

muddy situations and trenching).

• 5” Forklift type tyres [machine width – 890mm] (narrower tyres, suitable for

heavy loads, restricted access, inside buildings and foundries – great on all

hard surfaces).

• 3” Narrow solid tyres [machine width – 840mm] (only for very restricted

access – will fit through a standard doorway).

• Tracks [machine width – 1200mm] (excellent floatation and traction –

suitable for mud, sand or slush).

• Solid fill (all of the tyres mentioned above (excluding the 3” solids) can be

supplied by Dingo Mini Diggers, filled with a puncture-proof, solid foam).

For more information on our range of traction products, please speak to your nearest

Dingo representative.

Dingo 950 Operation & Maintenance Manual

14

OPERATING INSTRUCTIONS

Read all the safety instructions and the pre start up section of this manual and the

engine manual before operating the Dingo.

Caution – Do not operate any of the control levers (including auxiliary lever) unless

you are standing with both feet on the platform and firmly holding the grip handles.

Important!

Ensure the Auxiliary hydraulic lever is in centre position before attempting to start

engine. The most common cause of ‘hard to start / engine will not turn over fast

enough / battery does not have enough power’ type starting problems is that the

auxiliary lever has been left on or knocked into gear and the engine is trying to start

under load. Ensure auxiliary lever is in centre position before starting engine.

Controls

Become familiar with the controls before starting the engine or operating the machine.

Key Switch

The Key Switch, used to start the engine, varies on Petrol and Diesel models. Check

engine manufacturers manual for starting instructions.

To shut engine off, rotate key to OFF position (counter clockwise direction).

Throttle

Move control forward/upward to increase engine speed and rearward/downward to

decrease engine speed.

Choke

For instructions regarding use of the choke (petrol models) refer to the engine

manufacturers manual.

Dingo 950 Operation & Maintenance Manual 15

Control levers/ Control panel

(refer to ‘Control panel diagram’)

Drive control levers

To go forward, slowly push the right and left drive control levers forward.

To go backward, slowly pull the right and left drive control levers backward.

To go straight, apply equal pressure to both drive control levers.

To turn, decrease pressure on the drive control lever closest to the direction you want

to turn.

The farther you move the drive control levers in either direction, the faster the

machine will move in that direction.

To slow or stop, move or release the drive control levers into neutral. (If released the

control levers should automatically return to neutral).

The Dingo is capable of turning in it’s own length by applying equal power to each

drive lever in opposite directions.

Attachment tilt lever

To tilt attachment forward, slowly push the tilt lever forward.

To tilt attachment backward, slowly pull the tilt lever backward.

Loader arms lever

To lower loader arms, slowly push arm lever forward.

To raise loader arms, slowly pull arm lever backward.

Control panel diagram

1. Drive control levers

2. Attachment tilt lever

3. Loader arms lever

4. Auxiliary hydraulic lever

5. Pump selector valve

6. Kohler engine Dingoes – Choke

Robin engine Dingoes – Throttle

Kubota engine Dingoes – position empty

7. Kohler and Kubota engine Dingoes – Throttle

Robin engine Dingoes – position empty

8. Ignition.

Auxiliary hydraulic lever

The auxiliary hydraulics lever is to allow you to alter the direction of rotation of

hydraulically driven attachments or stop them completely.

Attention

Ensure auxiliary hydraulic lever is in neutral position before starting engine. Aside

from starting difficulties the attachment may move during starting.

To operate attachment in forward direction, slowly pull auxiliary lever rearward.

To operate attachment in reverse direction, slowly push auxiliary lever forward.

Pump selector valve

When faster ground speed and lifting speed is required more than attachment speed

and power, push the pump selector lever to the full forward position (hare).

When faster attachment speed and power is required more than ground speed and

lifting speed, pull pump selector lever to the full rearward position (turtle).

Dingo 950 Operation & Maintenance Manual

16

Flow divider control

Move flow divider control to twelve-o’clock

position (normal operating position, as pictured) for

no flow division. When moving control to nine-

o’clock position, flow is diverted to the attachments

and less is available to the wheels and loader arms.

This allows for greater concentration of power

where it’s needed most.

9 O’clock position

12 O’clock position

Starting and stopping the Engine

Starting

Stand on the platform.

Move the auxiliary hydraulics lever to neutral.

Attention

Ensure auxiliary hydraulic lever is in neutral position before starting engine. Aside

from starting difficulties it may cause the attachment may move during starting.

1. Follow instructions on starting engine as detailed in the engine manufacturers

manual.

Stopping

Move the throttle lever to “slow”.

Lower loader arms to the ground.

Turn the ignition key to off.

Note: If the engine has been working hard or is hot, let it idle for a minute before

turning the ignition key “OFF”. This helps cool the engine before it is stopped. In an

emergency, turning the ignition key to “OFF” will stop the engine.

Driving forward or backward

The throttle control regulates the engine speed as measured in rpm (revolutions per

minute). Place the throttle control in the “fast” position for best performance.

Note: Throttle position can be utilised to operate at slower speeds.

Forward

To go forward, slowly push the drive control levers forward.

To go straight, apply equal pressure to both drive control levers.

To turn, decrease pressure on the drive control lever closest to the direction you want

to turn.

The farther you move the drive control levers in either direction, the faster the

machine will move in that direction.

To slow or stop, move or release the drive control levers into neutral. (If released the

control levers should automatically return to neutral).

Dingo 950 Operation & Maintenance Manual 17

Dingo 950 Operation & Maintenance Manual

18

Backward

To go backward, slowly pull the drive control levers rearward.

To go straight, apply equal pressure to both drive control levers.

To turn, decrease pressure on the drive control lever closest to the direction you want

to turn.

To slow or stop, move or release the drive control levers into neutral. (If released the

control levers should automatically return to neutral).

Stopping the machine

To stop the machine, move the drive control levers to neutral, lower loader arms to the

ground, and turn the ignition key to “OFF” to stop the engine. Remember to remove

the key from the key switch.

Caution!

If children or bystanders attempt to operate the machine, someone could be injured.

To avoid attempted use by children or bystanders while machine is unattended,

remove the key from the ignition, even if just for a few minutes.

Moving a Non functioning machine

IMPORTANT: Never tow the machine because hydraulic damage may occur.

To Move the Machine

Turn the ignition key to “OFF” to stop the engine.

Lift the entire machine off the ground and move the machine.

Using Cylinder Locks

IMPORTANT: Normal maintenance should be completed with the loader arms

lowered. If maintenance or repairs requires the loader arms raised, use cylinder locks.

Warning!

Loader arms may lower when in the raised position. Anyone under the loader arms

could be injured or crushed. To avoid this hazard always install cylinder locks or a

safety stand. (Contact a Dingo representative if you are unsure).

Dingo 950 Operation & Maintenance Manual 19

Attachments

Connecting

IMPORTANT: Use only Dingo approved attachments. Attachments can change

stability and operating characteristics of the machine. The warranty of the machine

may by voided if used with unapproved attachments.

IMPORTANT: Before connecting any attachments to the machine, make sure mount

plates are free of any dirt and debris.

1. Move pump control lever to slow (turtle) position.

2. Slowly push the attachment tilt lever forward to tilt the attachment mount

plate forward.

3. Position mount plate into the upper lip of the attachment’s receiver plate.

4. Raise the loader arms while tilting back the mount plate at the same time.

5. IMPORTANT: The attachment should be raised enough to clear the ground

and the mount plate tilted all the way back.

6. Turn the ignition key to “OFF” to stop the engine.

7. Engage the attachment lock pins (the lock pins should go down 15mm as

they turn).

Note: Lock pins are located on the operator side of the mount plate and

should be turned toward the inside to engage.

8. Note: Proceed to next step if auxiliary hydraulics are required with

attachment.

9. IMPORTANT: Make sure all foreign matter is cleaned from hydraulic

connections before making connections.

10. Move the auxiliary hydraulics lever to the forward, backward, and back to

neutral position to relieve hydraulic pressure at the hydraulic couplers.

11. Remove protective covers from the hydraulic couplers on machine. Connect

covers together to prevent contamination during operation.

12. Slide collar back on hydraulic coupler and connect attachment couplers to

machine couplers. There will be two connections to make.

13. Confirm that connection is secure by pulling on the hoses.

Disconnecting

1. Lower attachment to the ground or onto a trailer.

2. Turn the ignition key “OFF” to stop the engine.

3. Move the auxiliary hydraulics lever forward, backward and back to neutral

position to relieve hydraulic pressure at the hydraulic couplers.

4. Slide collar back on the hydraulic coupler and disconnect attachment

couplers from machine couplers. (Note: if this is difficult return to step 3 and

repeat.)

5. IMPORTANT: Connect attachment hoses together to prevent contamination

during storage.

6. Install protective covers onto machines hydraulic couplers.

7. Disengage the attachment lock pins by turning them to the outside.

Dingo 950 Operation & Maintenance Manual

20

8. Start engine, tilt the mount plate forward and back machine away from

attachment.

Transporting and securing

IMPORTANT: Do not operate or drive machine on roadways.

IMPORTANT: When transporting machine on a trailer, always use the following

procedure.

Lower the loader arms.

Turn the ignition key to “OFF” to stop the engine.

Secure the machine to the trailer with chains or straps using the rear platform support

openings to secure rear of machine and loader arms/mount plate to secure front of

machine.

Table of contents

Other DINGO Compact Loader manuals