Dings DS-OLBS6-FSC User manual

page│1

Technical Manual

DS-OLBS6-FSC

DS-OLBS6-FSC Manual

VER 1.0

page│2

Table of Contents

1. Specification and Description…..……..…………………………...…………3

2. Product Characteristic..………..…………………..………….….…………..3

3. Terminal Connection…………………………..………………….…………..4

3.1Power Input……………………………………...……………………....4

3.2 Motor Input….…………………………………...………………………4

4. Connection Diagram ofMotor and Driver……………..……………………..4

5. Dimension……………….…….……….………………..……………………...5

6. Functions and Usage...…….……….………………..………………………..5

6.1 Speed Adjustment Method..………………...………………………....5

6.2 Motor Operate / Stop Control (EN)…..………………………………...6

6.3 Motor Rotation Direction Control (F/R).……………………………....6

6.4 Brake the Motor to Stop (BK)………...……...……………………........6

6.5 Speed Signal Output (PG)……………..…………………………….....6

6.6 Alarm Output (ALM)……..……………..…………………………….....6

6.7 Drive Failure……………..……………..…………………………….....7

7. Using……….…….……………………………..………...……………………..7

Click to return to table of contents

Contents

page│3

Summary

This closed-loop speed controller is de

signed with the latest type IGBT and MOS

power devices. It takes advantage of DC brushless motor’

s Hall signal to double

frequency for closed-loop speed control. PID control links with the speed controller.

The control system is stable and reliable, especially at low speed, it always can reach

the maximum torque, The speed control range is from 150 to 10000rpm.

1. Specification and Description

PID speed and current double loop regulator

High performance, low price

20KHZ Chopper frequency

Electrical stop toensure the quickly action of motor

Over load ratio larger then 2, torque always can achieve the max in low speed

Provide OVP, LVP, OCP, OTP, illegal horal signal and other fault alarm.

2. Product Characteristic

Drive model DS-OLBS6-FSC

Input voltage 24 VDC – 48 VDC

Min. Input voltage 12 VDC

Max input voltage 60 VDC

Maximum continuous output current 15 A

Accelerate time constant, default 2sec others can be customized

Warning

*Do not measuring or touch any components without housing while operating.

* Should check soleplate or change fuse 1minter later after power off.

* Operating without housing is forbidden.

* Make sure to connect the ground terminal, otherwise the brushless motor will

working unsteadily

* Sudden damage while drives working, our company only affords the service

and replace in guarantee. Personal injury and motor damage caused by the

accident will invalidate the guarantee.

Specification and Description / Product Characteristic

page│4

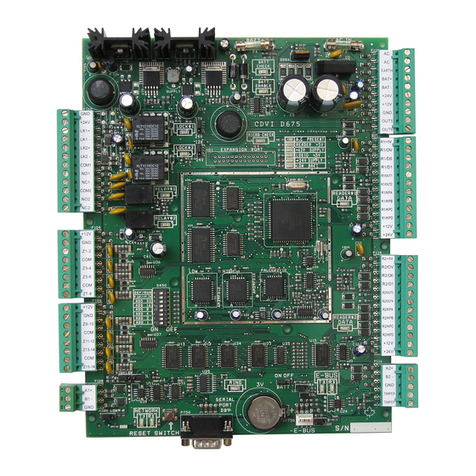

3. Terminal Connection

3.1 Power Input

1 V+ 24VDC - 48VDC input

2 GND GND

3.2 Motor Input

1 MA A phase

2 MB B phase

3 MC C phase

4 GND Hall signal power negative

5 HA Hall signal A input

6 HB Hall signal B input

7 HC Hall signal C input

8 +5V Hall signal power positive

4. Connection Diagram of Motor and Driver

Terminal Connection / Connectino Diagram of Motor and Driver

page│5

5. Dimension : 150×97×48mm

6. Functions and Usage

6.1 Speed Adjustment Method

This drive provide below two adjust methods for the user to choose:

Inner potentiometer speed adjustment : rotate the potentiometer on the driver panel

counterclockwise, the rotate speed of the motor will decrease, rotate the potentiometer on

the driver panel clockwise, The rotate speed become higher. If you use external input to

adjust speed, make sure the potentiometer is set in the min. state.

External speed adjustment : Connect on the GND and +5V of the drives, speed can be

adjusted on external potentiometer ((5K~100K) when connect SV terminal. Input simulate

voltage through other control command (e.x. PLC, SCM etc.) to SV terminal to achieve the

speed adjust as well (relative GND). The range of the SV terminal is DC OV~+5V, the

relevant motor speed is 0~rated speed.

External digital signal speed regulation : Add 5V between SV and GND, speed can be

adjusted by PWM control between the 1KHz~2KHz, motor speed is influenced by duty. At

this time, by adjusting the R-SV potentiometer, SV digital signal amplitude can be 0~1.0 ratio

Dimension / Functions and Usage

96.5

151

142

48

P/A

R-SV

5

page│6

attenuation processing. Generally, adjust R-SV to 1.0, SV input digital signal without

attenuation processing.

6.2 Motor Operate / Stop Control (EN)

You can control the brushless motor to run or stop by controlling the terminal “EN” and “GND”

connecting. The motor will running when we connect the terminal “EN” to “GND”; when shut

down, the motor will stop naturally, and the stopping time will decided by the motor inertia

and load add on the motor.

6.3 Motor Rotation Direction Control (F/R)

You can control the motor rotation direction by controlling the terminal “F/R” and “GND”

connection. When connect terminal “F/R” to terminal “GND”, the motor will run at CCW (view

from motor output side), and when shut down, the motor will run at another direction.

Attention

If you need to change the motor rotation direction, please stop the motor at

first, otherwise the driver shall be damaged.

6.4 Brake the Motor to Stop (BK)

You can break the motor to stop if need. The motor will run when the terminal “BK” not

connects to “GND”, but if you connect these two terminals, the motor will stop quickly. And

the motor stopping time will be decided by inertia and load adding on the motor.

Attention

If you are not necessary to stop the motor quickly, please don’t use with this

function since it has some electrical and mechanical impact on the motor and

controller.

6.5 Speed Signal Output (PG)

The speed pulse output is 0C, output 30V/10mA max. You can connect with a resistance

(3K ohm ~10K ohm) between the signal and the input power to get the speed pulse signal.

3xN Output Pulse per revolution, N is pole of motor, Example: 2 pairs of pole motor,12

pulses per revolution, when the motor speed is 500 rev/min, the pulses from PG output

pulses are 6000.

6.6 Alarm Output (ALM)

The alarm output port is 0C, output 30V/10mA max. You can connect with a resistance (3K

ohm ~10K ohm) between the signal and the input power to get the alarm signal. When

Functions and Usage

page│7

alarm, this port and the GND connecting (Low voltage), and the controller will stop working

and keep in alarm status.

6.7 Drive Failure

Over voltage or over current can lead the driver to a protected status, the drive will

automatically stop working, the motor stop and blue light is flashing. As long as you enable

terminal re-reset (EN and GND disconnected) or power Off, the driver will disarm the alarm.

When this failure occurs, please check the motor wire connection.

7. Using

Insure that motor line, hall line and power line connect correct, Motor and driver will be

damaged if lines connected wrong.

When using inner potentiometer speed adjust, connect “EN” with “GND” terminal,

connect SV terminal with 5V terminal, adjust speed by inner potentiometer.

When using external potentiometer to adjust speed: adjust R-SV to 1.0 position,

meanwhile connect EN to GND terminal, connect external potentiometer (middle

connection ) to SV terminal, the other two connect GND and +5V terminal.

Motor will running with highest speed under closed loop, adjust attenuation

potentiometer to get speed commanded.

Functions and Usage / Using

page│8

International

Customer

Person in Charge :

Daniel Jang

daniel@dingsmotion.com

Building 1#, 355 Longjin Road,

Changzhou Economic Development

Zone, Jiangsu, China

+86-519-85177826, 85177827

North America

Customer

Person in Charge :

Nicolas Ha

sales@dingsmotionusa.com

335 Cochrane Circle Morgan Hill,

CA 95037

+1-408-612-4970

China

Customer

Person in Charge :

Sweet Shi

info@dingsmotion.com

Building 1#, 355 Longjin Road,

Changzhou Economic Development

Zone, Jiangsu, China

+86-519-85177826, 85177827

It is prohibited to copyright or replication of the part or whole of user manual without permission.

+86-0519-8517 7825

+86-0519-8517 7807

Building 1#,355 Longjin

Road, Changzhou

Economic Development Zone, Jiangsu, China

www.dingsmotion.com

Table of contents

Other Dings Controllers manuals

Popular Controllers manuals by other brands

Cleco

Cleco DGD mPro400GC Programming manual

TYROLIT Hydrostress

TYROLIT Hydrostress PPH40RR Series operating instructions

Texas Instruments

Texas Instruments TUSB5052 user guide

Vaillant

Vaillant VRT 350 installation instructions

Power Jacks

Power Jacks EMA I Maintenance manual

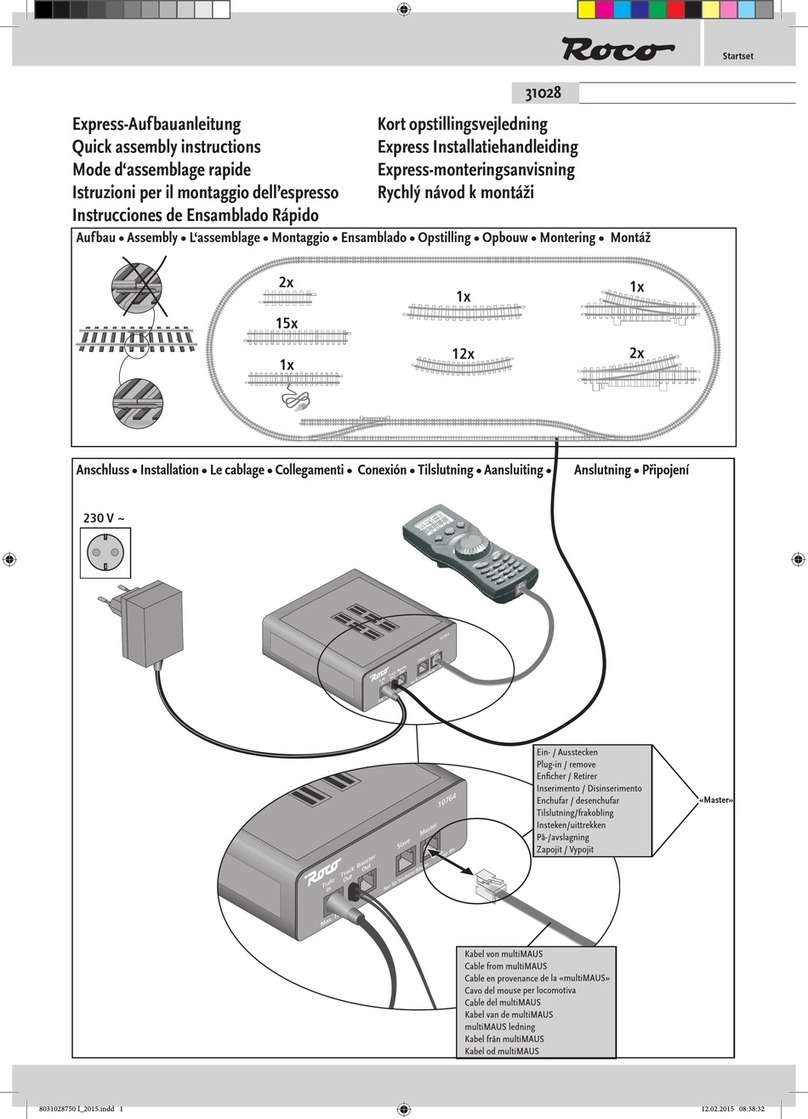

roco

roco 31028 Quick assembly instructions