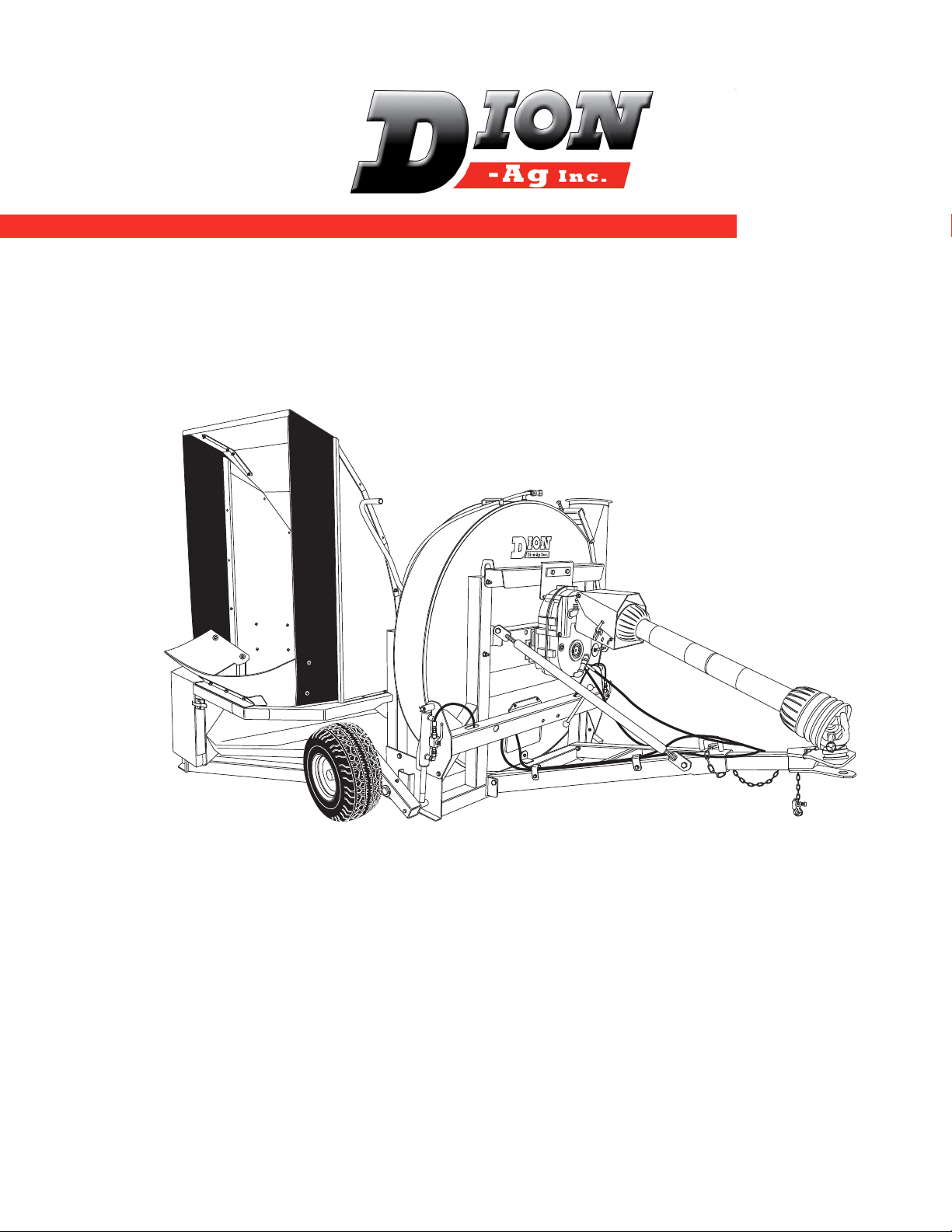

Dion-Ag 860 User manual

Forage Blower

Operator’s Manual

Manual no. S5522E032

860

860HO

2MANUAL / MANUEL NO. S5522E032 V1.0

DION-AG INC. LIMITED WARRANTY TERMS AND CONDITIONS

Covered by Warranty – Under the warranty, Dion-Ag guarantees its new machinery and/or equipment to be free of

defects, both in workmanship and material, for a period of one (1) year from the time of delivery by the dealer. Dion-

Ag Inc. will repair or replace, at its discretion and without charge for service parts or labour, any defective part of the

equipment on condition that the machinery and/or equipment has been operated in accordance with the instructions

contained in the Dion-Ag Inc. Operator’s Manual.

Not covered by Warranty – This warranty does not cover: (1) service parts and labour needed to maintain the

unit; and (2) the replacement of parts due to normal wear and tear. The owner is responsible for these items. Some

examples of maintenance and normal wear parts are: oil, lubricants & other uids, belts, knives, clutch and clutch

discs, roller chain, paddles, etc. Dion-Ag Inc. is not responsible for depreciation or damage caused by normal

wear, lack of reasonable and proper maintenance, failure to follow operating instructions, misuse, lack of proper

protection during storage, vandalism, the elements, collision or accident.

Securing Warranty Service – To secure warranty service, the purchaser must report the machinery and/or

equipment defect to an authorized dealer and request warranty service within the applicable warranty terms.

Owner’s Obligation – It is the responsibility of the Owner to transport the equipment to the service shop of an

authorized Dion-Ag Dealer or to reimburse the dealer for any travel or transportation expense involved in fullling

this warranty. This warranty does NOT cover rental of replacement equipment during the repair period, loss of

prots, or other commercial loss, and any or all incidental or consequential damages, overtime labour charges and/

or freight charges for replacement parts.

Limitations of This Warranty – No agent, employee or representative of Dion-Ag Inc. has the authority to

amend, or modify, in any manner whatsoever, the terms of the present warranty. The express warranties herein

contained exclude all other express, implied or statutory warranties. THIS WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES INCLUDING THE WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR ANY

PARTICULAR PURPOSE.

Right to Inspect – Dion-Ag and its authorized agents reserve the right to inspect the purchaser’s Dion-Ag product

to determine if a defect in material or workmanship exists prior the commencement of any covered repairs. It is

the purchaser’s responsibility to ensure availability and/or delivery of the product to Dion-Ag for the purpose of

inspection.

Right to Make Design Changes – Dion-ag reserves the right to make changes in the design and other changes in

its products at any time and from time to time without notice and without incurring any obligation of its part to modify,

improve or add to products previously ordered from Dion-Ag and sold or shipped by Dion-Ag.

Liability – Dion-Ag Inc. shall not be liable, if, during the use of the machinery and/or attachment, the security guards

have been removed, modied, or have not been properly maintained.

The Warranty shall not apply if the instructions mentioned in this manual have not been followed completely and

correctly. Nor will the warranty apply if the owner or any third party modies the machine without Dion-AG’s knowledge

and/or authorization. Every purchaser, when buying a Dion-Ag machine, agrees and undertakes to use and operate

the machinery and its component parts safely, and in accordance with all applicable laws, and in accordance with

the Operator’s Manual. Furthermore, the purchaser agrees and accepts to indemnify and hold harmless Dion-Ag for

all losses and damages to any person or property resulting from the purchaser’s non-compliance with the terms and

conditions of this warranty. Each purchaser further agrees to bring the warranty to the attention of any subsequent

purchaser, and to obtain agreement therein as a condition of resale or transfer.

3

MANUAL / MANUEL NO. S5522E032 V1.0

FORAGE BLOWER

860 - 860HO

TO OUR CUSTOMER

We appreciate your condence in Dion Farm Equipment and thank you for your trust. In preparing this manual, we

hope we have furnished you with a valuable tool for operating and maintaining this ne machine. Use this manual as

your guide. Practicing the instructions given here will result in many years of dependable service from your machine.

Your Dealer can give you assistance with parts and specially trained personnel to assist you in repair and

maintenance.

Call your Dealer if you need any assistance or information.

TABLE OF CONTENTS

4MANUAL / MANUEL NO. S5522E032 V1.0

SPECIFICATIONS........................................................................5

SERIAL NUMBER LOCATION ..............................................................6

CHECK LIST............................................................................7

FOREWORD ............................................................................8

SAFETY RULES .........................................................................9

SAFETY ALERT SYMBOL.........................................................................9

FOLLOW A SAFETY PROGRAM ...................................................................9

A WORD TO THE OPERATOR .....................................................................9

PTO OPERATION ...............................................................................10

RECOMMENDED WORKING AREA.................................................................11

PROCEDURES FOR STOPPING THE FORAGE BLOWER...............................................12

GUARDS AND SHIELDS..........................................................................12

SAFETY SIGNS.................................................................................13

SAFETY SIGN APPLICATION PROCEDURE ..........................................................14

ASSEMBLY INSTRUCTIONS...............................................................16

DRIVELINE ASSEMBLY INSTRUCTIONS ............................................................16

1000 RPM GEARBOX INSTALLATION PROCEDURE ...................................................18

HYDRAULIC WHEEL INSTALLATION INSTRUCTIONS..................................................22

OPERATING INSTRUCTIONS ..............................................................26

DRIVELINE SHAFT ALIGNMENT ..................................................................26

RUNNING SPEED ..............................................................................26

WHEEL LIFT SYSTEM...........................................................................27

TRANSPORTING INSTRUCTIONS ................................................................27

FORAGE BLOWER LIFTING HOOKS...............................................................29

MAINTENANCE DOOR ..........................................................................29

WATER SYSTEM...............................................................................29

SPEED REDUCER .............................................................................30

HYDRAULIC WHEEL SYSTEM (OPTION)...........................................................31

LUBRICATION ..........................................................................32

DRIVELINE .....................................................................................32

SPEED REDUCER ...............................................................................32

LUBRICATION CHART ............................................................................32

ADJUSTMENTS & MAINTENANCE .........................................................35

ROTATING OUTLET ..............................................................................35

FAN ADJUSTMENT...............................................................................35

SPOUT KNIFE ADJUSTMENT ......................................................................36

FAN BLADE REPLACEMENT .......................................................................38

INSTRUCTIONS FOR REASSEMBLING THE FAN SHAFT................................................39

DRIVELINE SHEAR BOLTS ........................................................................41

AUGER ADJUSTMENT ............................................................................41

REVERSIBLE CONTOUR REPLACEMENT ............................................................42

AUGER INTERMEDIATE BELT TENSION .............................................................43

AUGER DRIVE BELT TENSION .....................................................................43

AUGER BELT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

AUGER BRAKE..................................................................................44

AIR INTAKE CONTROL............................................................................44

SUGGESTED INITIAL AIR INTAKE ADJUSTMENTS .....................................................45

DISMANTLING AND REASSEMBLY OF DRIVELINE ROTATING GUARDS ...................................45

ECCENTRIC LOCKING COLLAR INSTALLATION .......................................................45

SPEED REDUCER ...............................................................................46

CHAIN TENSION CHECK ..........................................................................46

CHAIN TENSION ADJUSTMENT ....................................................................46

ALIGNMENT AND ADJUSTMENT OF THE SPEED REDUCER.............................................47

ASSEMBLING THE WHEEL HUBS...................................................................48

STORAGE..............................................................................49

TROUBLESHOOTING ....................................................................50

SPECIFICATIONS

5

MANUAL / MANUEL NO. S5522E032 V1.0

Specications and design are subject to change without notice and without liability from the

manufacturer therefore.

MAIN FAN

Main fan ............................................................................ 59” (150cm)

Blades................................................................................ 8

RPM................................................................................... 540

RPM (with reducer)............................................................ 650

Speed at blade tip:

540 RPM............................................................................ 8340 ft/min. (ft/min) (2542m/m)

650 RPM............................................................................ 10038 ft/min. (ft/min) (3060m/m)

MAIN AUGER

Length................................................................................ 55” (140cm)

Diameter............................................................................ 14” (36cm)

Pitch.............................................. 14” (35.5cm)

RPM................................................................................... 500

RPM (with reducer)............................................................ 601

Overall length with pole ..................................................... 129” (378cm)

Overall width...................................................................... 84” (213cm)

Overall height when operating (wheels lowered)............... 72.5” (184cm)

DRUM OUTLET HEIGHT

Transport position.............................................................. 70” (178cm)

Operating position (wheels lowered) ................................. 61” (155cm)

HOPPER

Height (operating position) ................................................ 21” (53cm)

Inlet width .......................................................................... 42” (107cm)

Inlet depth.......................................................................... 30” (76cm)

Tires................................................................................... 18.5 X 8.5-8

Weight ............................................................................... 1350 lbs (610Kg)

RECOMMENDED TRACTOR POWER

540 RPM - 14” dia. auger ................................................. 60 to 160 HP

1000 RPM - 14” dia. auger ............................................... 130 to 200 HP

RECOMMENDED DRIVELINE

540 RPM: Tractor under 160 HP, use a T80 driveline

Tractor over 160 HP, use a T90 driveline

1000 RPM: Tractor under 210 HP, use a T80 driveline

Tractor over 210 HP, use a T90 driveline

SERIAL NUMBER LOCATION

6MANUAL / MANUEL NO. S5522E032 V1.0

For your convenience, write down in full in this manual both the model and serial numbers of your machine, as

shown on the name plate illustrated below. Always mention both the model and the serial numbers when ordering

parts or regarding any other correspondence referring to your machine.

Write down your number here:

MODEL NO. SERIAL NUMBER

R.H.

REAR

L.H

FRONT

WARNING

MAXIMUM SPEED LIMIT 15

M.P.H

VITESSE MAXIMALE 25

K.P.H

ATTENTION

MADE IN CANADA

DION-AG INC.

BOISBRIAND QUE.

MODEL NO.

SERIAL NO.

- Ag Inc.

MADE IN CANADA

DION-AG INC.

BOISBRIAND QUE.

MODEL NO.

SERIAL NO.

- Ag Inc.

CHECK LIST

7

MANUAL / MANUEL NO. S5522E032 V1.0

PRESEASON CHECKS

❑Check auger brake.

❑Check tension of belts. Check all sheaves for correct alignment.

❑Check all adjustable components for correct setting (blower and auger).

❑Check tire pressure. See specications.

❑Check wheel bolts. They should be tighten to a recommended torque of 85 to 95 lbs/ft.

❑Perform complete lubrication and servicing of the machine according to Servicing. Make sure all grease

ttings are in place and taking grease properly. Check transmission uid levels if you have the option.

❑Check transmission chain tension

❑Look for loose or missing bolts and parts.

❑Run the machine in a stationary position at half-speed for a short period of time. Shut off tractor engine.

Make sure all moving parts have stopped, then inspect bearings for over-heating, excessive wear, or

loose anges and lock collars.

❑Make sure the proper operating adjustments have been made, taking into account the harvest conditions.

❑Make sure all shields are installed. Review Safety Precautions.

❑Make sure all safety decals are readable and in good condition.

❑Check for wear on parts (paddles, blower and auger bottoms, etc.).

❑Make sure holes for the injection of water in the fan and the feed table are not obstructed.

DAILY CHECKS

❑Check auger brake

❑Remove all crop residue and wipe off oil and dirt.

❑Lubricate and service the machine according to the Servicing section.

❑Check chain and belt tension. Check all sheaves for correct alignment.

❑Check tire pressure. See Specications.

❑Make sure Blower is hooked to tractor correctly, and that the safety chain is installed

securely. Make sure all controls are operable.

❑Make sure that all shields are in good condition on the blower (with special attention to the driveline

shields).

FOREWORD

8MANUAL / MANUEL NO. S5522E032 V1.0

TO OUR CUSTOMER

The following pages and illustrations are printed to help

supply you with the knowledge to better operate and

service your Dion Forage Blower.

Any piece of equipment needs, and must have a certain

amount of service and maintenance to keep it in top

running condition. We have attempted to cover all the

adjustments required to t most conditions; however,

there may be times when special care must be taken to

t a condition.

Study this operator’s manual carefully and become

acquainted with all the adjustments and operating

procedures before attempting to operate your new

equipment. Remember, it is a machine and it has been

designed and tested to do an efcient job in most

operating conditions and will perform in relation to the

service it receives.

If special attention is required for some conditions, ask

your Dion Dealer; his parts and Service Organization will

be glad to help and answer any questions on operation

and service of your new machine.

THIS MANUAL SHOULD REMAIN WITH

THE MACHINE WHEN SOLD

This manual was prepared from the latest product

information available at publication time. The Company

reserves the right to make changes at any time without

notice.

The safety section of your Operator’s manual is intended

to point out some of the basic safety situations which

may be encountered during the normal operation and

maintenance of your Forage Blower, and to suggest

possible ways of dealing with these situations. This

section is NOT a replacement for other safety practices

featured in other sections of this book.

WARRANTY INFORMATION

Your Dion Warranty for this machine appears on your

copy of the Retail Purchase Order and Warranty Terms

and Conditions Statement which you received from your

dealer when you purchased the Blower.

As indicated on the Retail Purchase Order signed by

you and your dealer, you, the equipment purchaser,

shall assume charges for service calls or transportation

of equipment to and from the location of servicing Dion

dealer.

SAFETY

The safety of the operator is one of the main concerns

in designing and developing a new Forage Blower.

Designers build in as many safety features as possible.

However, accidents still occur, which can be avoided by

proper thinking and a more careful approach to handling

farm machinery and implements.

Read and implement the safety instructions detailed in

the safety section of this manual.

SAFETY RULES

9

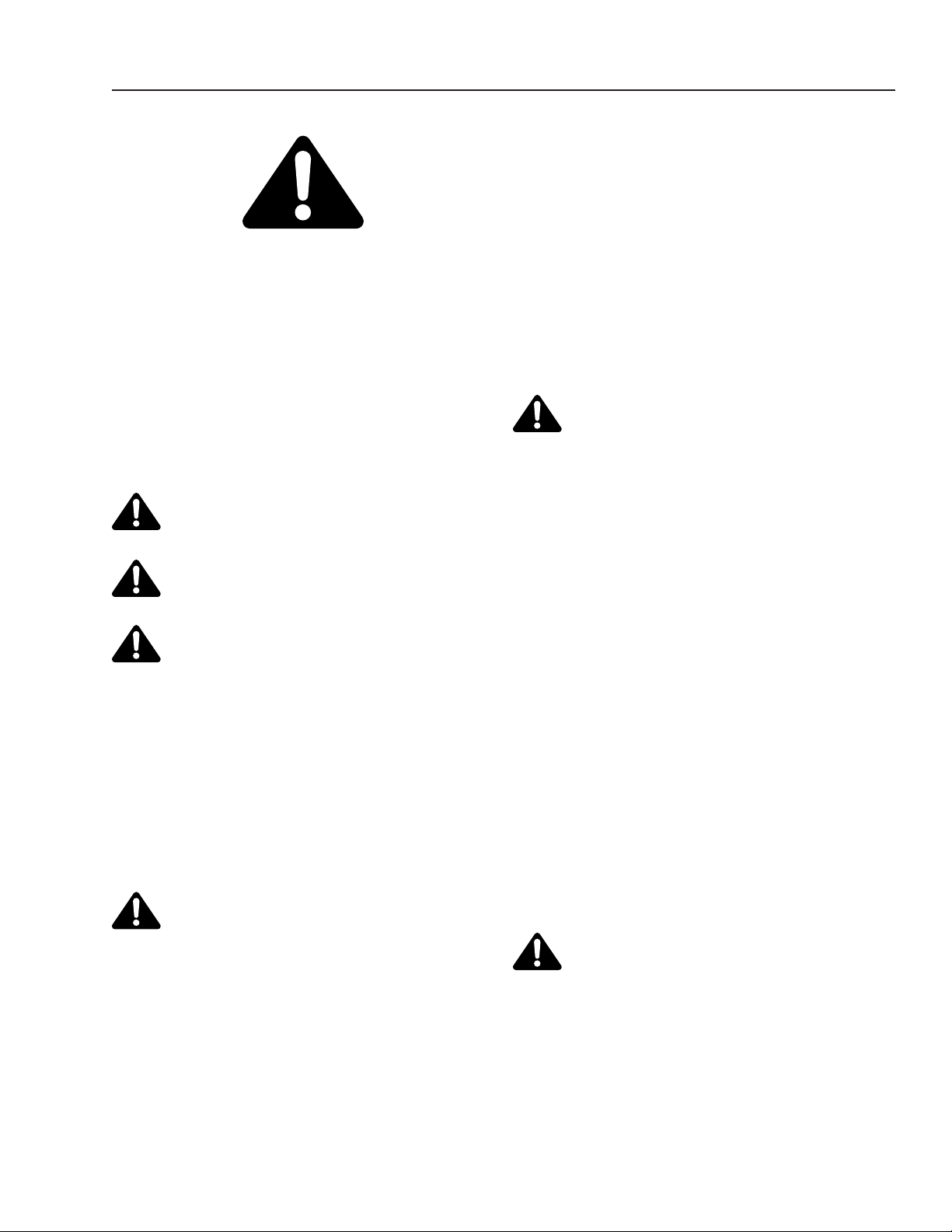

SAFETY ALERT SYMBOL

The symbol above calls your attention to instructions

concerning your personal safety. It is found throughout

the manual as well as on the machine to point out

specic hazards and ways to avoid them. Always follow

the instructions to minimize the risk of personal injury or

death.

DANGER, WARNING AND CAUTION

Whenever you see the words and symbols shown below,

used in this manual and on decals, you MUST take note

of their instructions as they relate to personal safety.

DANGER: Indicates an imminently hazardous

situation that, if not avoided, will result in DEATH

OR VERY SERIOUS INJURY.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in

DEATH OR SERIOUS INJURY.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in MINOR

INJURY.

IMPORTANT: The word IMPORTANT is used to identify

special instructions or procedure which, if not strictly

observed, could result in damage to, or destruction of

the machine, process or its surroundings.

NOTE: The word NOTE is used to indicate points of

interest for more efcient and convenient repair

or operation

SIGNS

WARNING: DO NOT remove or obscure Danger,

Warning, Caution safety signs or Instruction

signs that are not readable or are missing.

Replacement signs are available from your

Dealer in the event of loss or damage. The actual

location of these Safety signs is illustrated on

page 14.

FOLLOW A SAFETY PROGRAM

For proper operation of a Forage Blower, you must be

a qualied and authorized operator. To be qualied,

you must read and understand the written instructions

supplied in this Operator’s Manual, have training, and

know the safety rules and regulations for the job.

Some local regulations specify that no one under the

age of 16 years old, for example, may operate power

machinery. This includes tractors. It is your responsibility

to know what these regulations are, and obey them, in

the operating area or situation. These will include, but

are not limited to, the following instructions for proper

operation

WARNING: An operator should not use alcohol

or drugs which can change their alertness or co-

ordination. An operator on prescription or “over

the counter” drugs needs medical advice on

whether he or she can properly operate machines.

A WORD TO THE OPERATOR

It is YOUR responsibility to read and understand the

safety section in this manual before operating your

machine. You must follow these safety instructions that

take you step by step through your working day.

In reading this section, you will note that illustrations

have been used to highlight certain situations. Each

illustration is numbered and the same number appears

in the text in parenthesis. This number is placed at the

end of the written text that refers to the illustration.

Remember that YOU are the key to proper operation of

the machinery. Good safety practices not only protect

you, but also the people around you. Study the features

in this manual and make them a working part of your

safety program. Keep in mind that this safety section is

written only for this type of machine. Practice all other

usual and customary working precautions, and above all.

REMEMBER - SAFETY IS YOUR RESPONSIBILITY.

YOU CAN PREVENT SERIOUS INJURY OR DEATH.

WARNING: In some of the illustrations used in this

Operator Instruction Book, panels or guards may

have been removed for clarity. Never operate the

machine without these components in position.

If the removal of panels or guards is necessary

to make a repair, they MUST be replaced before

operation.

SAFETY RULES

10

• Wear appropriate clothing, safety boots or shoes.

Do not operate the machine when visibility is bad, or

during night, in poor lighting.

• Keep children away from the machine at all times.

• Carefully read all safety signs applied on the machine.

If they are damaged, replace them immediately.

• Keep hands and clothes away from all moving parts.

• Never lubricate or clean any part while the machine

or tractor engine is running.

• If a feeding or throwing mechanism should become

jammed, never attempt to unblock it or remove any

material when the machine is in motion or the tractor

engine running.

• Never remove guards or make adjustments while the

machine or tractor engine is running.

• Before starting the tractor engine, make sure all

guards, shields, and doors are in place and properly

secured and check the machine thoroughly for

possible loose parts or bolts and tighten them.

• Be very careful when adjusting the fan blades and

hopper auger.

• Before operating make sure that all projection pipes

are properly fastened..

• Keep hands and feet out of hopper when the driveline

is coupled to the tractor and the tractor engine is

running.

• Do not climb over or around the hopper when the

forage blower is in operation.

• If it is necessary to enter a silo, make sure it is well

ventilated.

• Always keep the forage blower hitch pinned to tractor

draw bar when operating.

• Make sure all rotating parts are stopped and the tractor

engine is turned off before cleaning or servicing fan

and conduct.

• After having performed any adjustments, be sure that

there are no tools in or on the machine.

• When proceeding onto a public road, always use a

safety chain with a minimum load of 6400 lbs (2910

kg) equipped with a identication plate and a hook

with safety lock.

• When proceeding onto a public road with a Blower

equipped with an hydraulic lift system, always close

the two safety valves (see Figure 40 on page 31).

• Always make sure wheel bolts are well tighten before

proceeding onto a public road. The recommended

torque is 85 to 95 lbs/ft.

• Always install the manual jack (item 7 in Figure 33

on page 28), before uncoupling the Blower with a

1000 RPM transmission.

PTO OPERATION

• POWER-TAKE-OFF DRIVE - Before starting the

tractor engine make sure that the PTO driveline

locking device is properly engaged onto both the

tractor and equipment drive shafts.

• Never wear loose clothing and keep people,

especially children away from the driveline.

• Do not connect a tractor with a PTO speed of 540

RPM on a machine equipped with a 1000 RPM drive.

Do not connect a tractor with a PTO speed of 1000

RPM on a machine equipped with a 540 RPM drive.

• Never proceed to the starting of the machine before

making sure all PTO, machine and tractor shields are

well installed in place.

• The PTO driveline shields should turn freely, be well

connected and kept in good condition.

• Never step across any PTO driveline.

• Never use the PTO driveline as a step.

• Keep at least your height away from a rotating

driveline.

SAFETY RULES

11

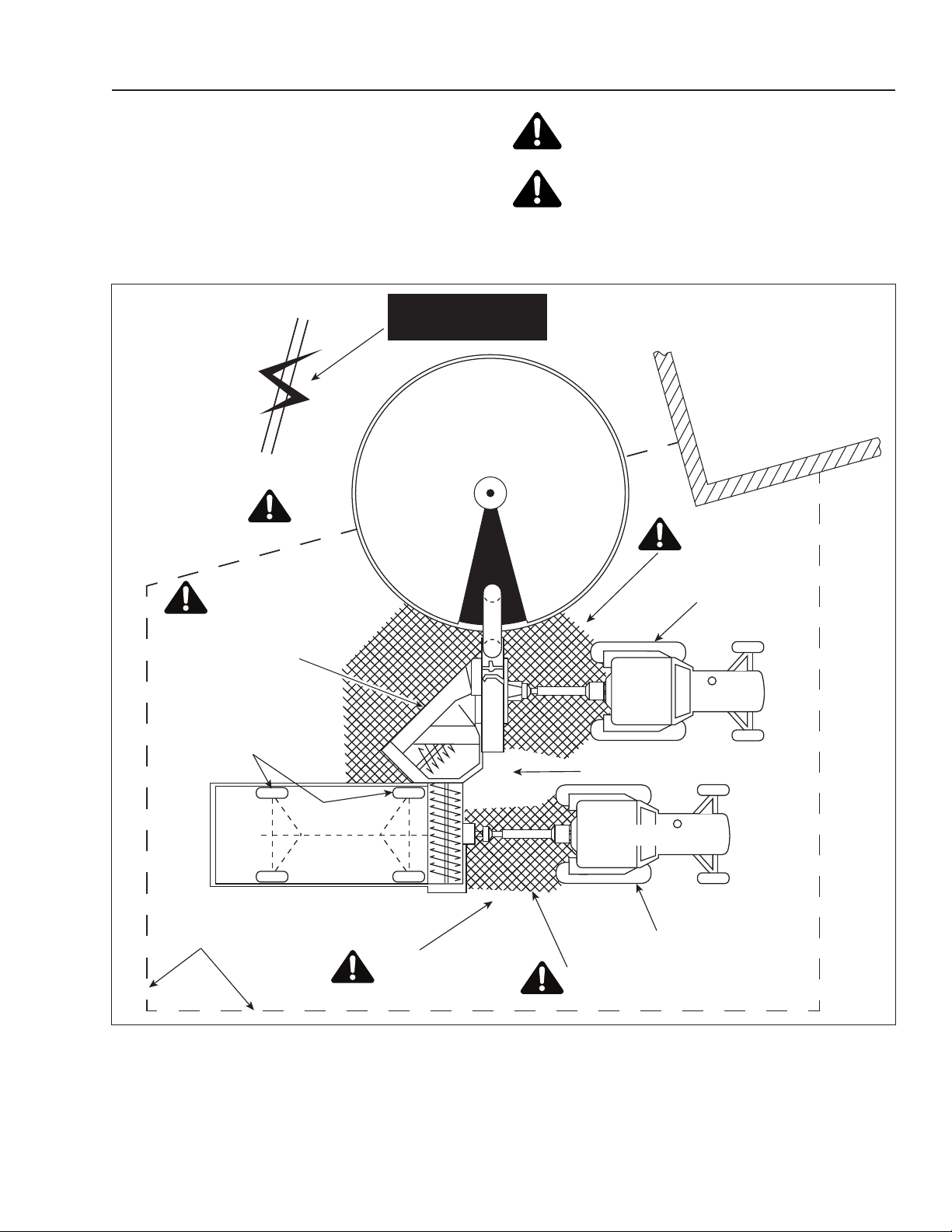

RECOMMENDED WORKING AREA

FIGURE 1

The diagram in Figure 1 shows the recommended

working area. It should be marked off with colored nylon

or plastic ropes as portable barriers to dene exactly the

designated working areas.

WARNING: To prevent personal injury, keep

all persons out of the working area.

WARNING: To prevent personal injury, the

work area must be smooth, clean and free of

debris and tools.

WORK ZONE

AUGER INTAKE AREA

PTO DRIVE AREA

PTO DRIVE AREA

BARN

OPERATOR AREA

BLOCKED WHEELS

BLOCKED

WHEELS

BLOCKED WHEELS

OPERATING AREA

KEEP CLEAN

TRACTOR

BEATER

BLOWER LOWERED

TO THE GROUND

AND STABILIZED

OVERHEAD WIRES

KEEP AWAY

Figure 1 Typical working area diagram

SAFETY RULES

12

PROCEDURES FOR STOPPING THE

FORAGE BLOWER

WARNING: To prevent personal injuries, do not

perform any kind of maintenance work while the

machine is running.

Before cleaning, adjusting, or greasing, the following

procedures should be followed to stop the Forage

Blower:

1. Disengage the tractor PTO.

2. Stop the tractor engine.

3. Set parking brake and remove the key.

4. Wait until all rotating movements have come to a

complete stop.

5. Remove the PTO chain.

6. Remove the driveline from the tractor output shaft

and attach it on its special support.

WARNING: Secure the PTO driveline to the

support to prevent rotation of the fan or auger.

7. Block all equipment wheels.

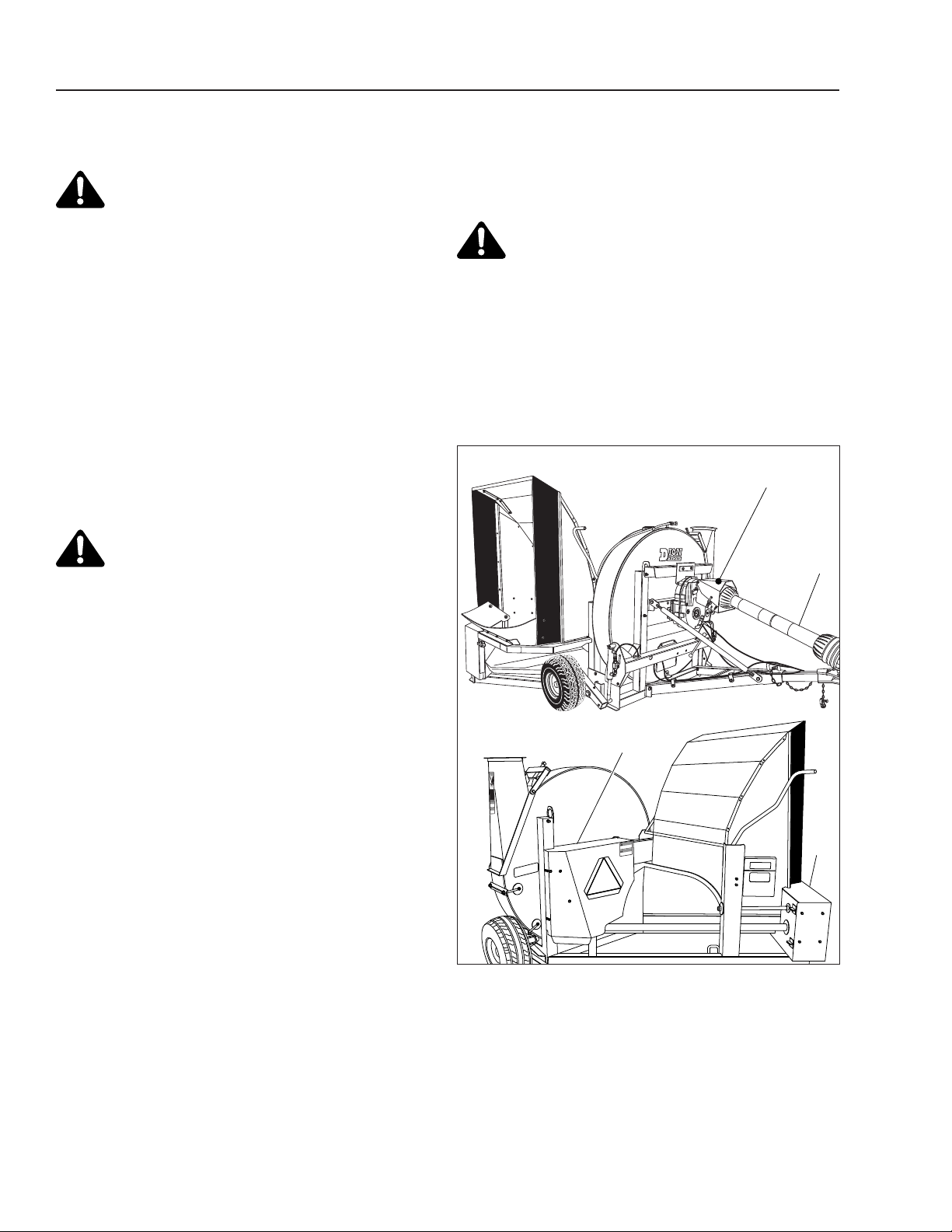

GUARDS AND SHIELDS - FIGURE 2

The Forage Blower is equipped with guards and shields

at various locations. Observe the safety signs and follow

their instructions.

All guards and shields factory installed should be

in place and maintained in good condition.

1. The telescopic driveline which couples to the tractor

is covered with a rotating shield (item 1).

2. A hinged guard covers the driveline (item 2).

3. A hinged guard covers the belt mechanism, driving

the hopper auger (item 3).

4. A hinged guard covers the main fan rear mechanism

(item 4).

1

3

2

4

WARNING

ATTENTION

DONOTOPENWHILE

MACHINEISINOPERATION

ARRÊTERLEMÉCANISME

AVANTD’OUVRIR

B58-24830

WARNING

ATTENTION

DONOTOPENWHILE

MACHINEISINOPERATION

ARRÊTERLEMÉCANISME

AVANTD’OUVRIR

B58-24830

DANGER

ILYA DES PIÈCE ROTATIVESÀ

L’INTÉRIEURDECETTE OUVERTURE.

ARRÊTERLEMO TEUR DU TRACTEUR

ETDÉSENGAGERLA PRISE DE FORCE.

ATTENDREQUETOUT MOUVEMENT

SOITARRÊTÉAVANTD’AJUSTER OU

DENETTOYER

ROTATINGPARTSINSIDE THIS

OPENING.SHUTOFF TRACTOR ENGINE

ANDDISENGAGEPOWER TAKE OFF

ANDWAITFOR ALL THE MO TIONS TO

STOPBEFORECLEANINFG OR

SERVICING

Figure 2

Guards and shields

SAFETY DECALS

13

MANUAL / MANUEL NO. S5522E032 V1.0

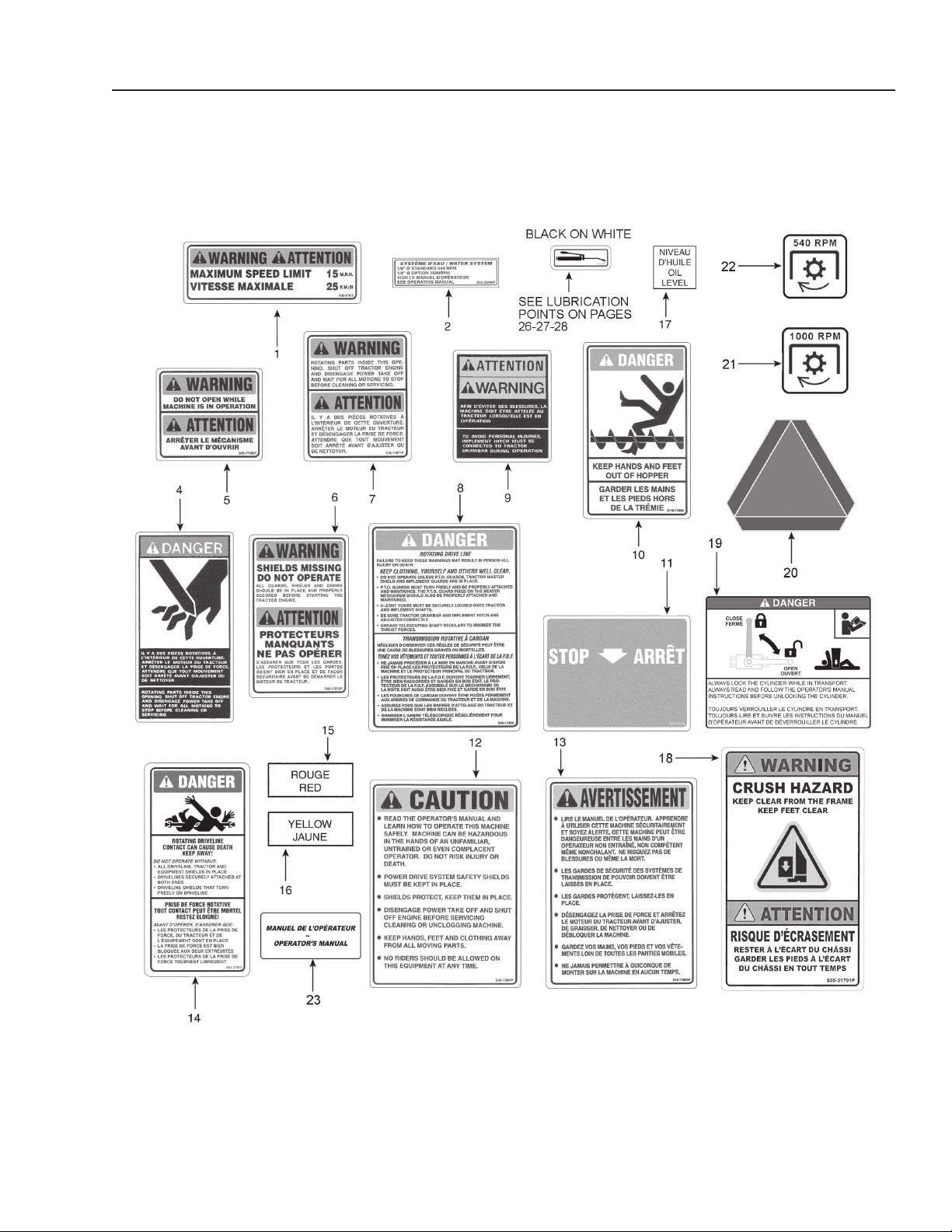

SAFETY SIGNS - FIGURE 3

NOTE: All safety signs should be kept as clean and free

of dust as possible.

NOTE: When safety signs are worn or if machine is

repainted, order a complete kit of safety signs.

Figure 3 Safety decals

SAFETY DECALS

14 MANUAL / MANUEL NO. S5522E032 V1.0

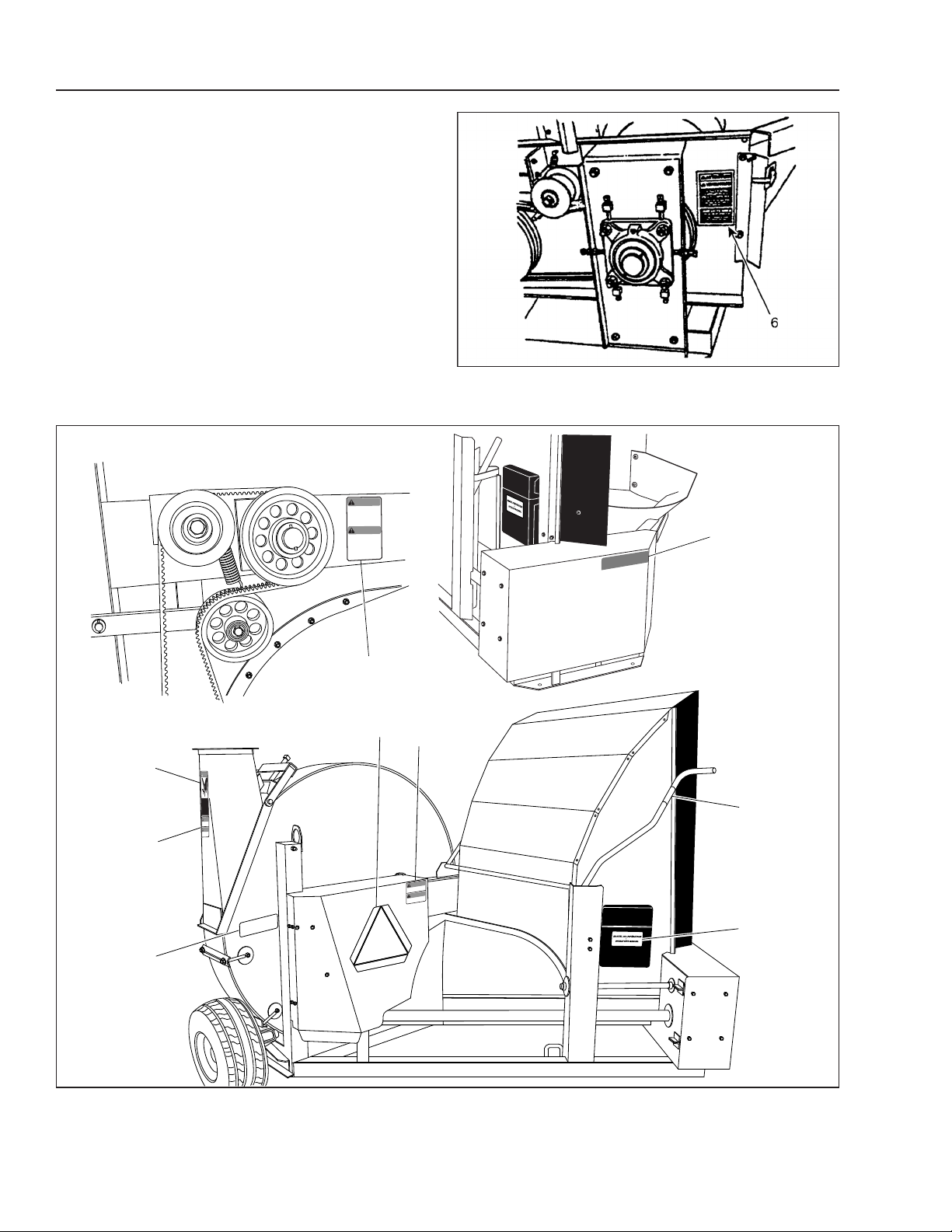

SAFETY SIGN APPLICATION PROCEDURE

FIGURE 4, FIGURE 5 AND FIGURE 6

1. The surface should be free from dirt, grease, earth,

or any other foreign material.

2. When the surface is dry, remove a portion of the

backing paper and apply the decal in part and align

its position as per the surrounding parts. Slowly peel

off the remaining backing paper and apply hand

pressure.

3. Press slightly on the surface of the safety sign to

remove all air bubbles.

Figure 4 Safety sign locations

6

4

7

15

5

20

15

23

11

WARNING

ATTENTION

ALLGUARDS, SHILEDSANDDOORS

SHOUILDBE IN PLACEANSPROPERLY

SECURTEDBEDORESTARTINGTHE

TRACTORENGINE

SHIELDS MISSING

DO NOT OPERATE

S’ASSURERQUETOUSLES GARDES,

LESPROTECTEURSETLES PORTES

SOIENT BIENENPLACEET DE FAÇON

SÉCURITAIREAVANTDEDÉMARRERLE

MOTEUR DUTRACTEUR

PROTECTEURS

MANQUANTS

NE PAS OPÉRER

WARNING

ATTENTION

DONOTOPEN WHILE

MACHINE IS INOPERATION

ARRÊTER LE MÉCANISME

AVANT D’OUVRIR

B58-24830

WARNING

ATTENTION

DONOTOPEN WHILE

MACHINE IS INOPERATION

ARRÊTERLEMÉCANISME

AVANT D’OUVRIR

B58-24830

DANGER

ILY ADES PIÈCE ROTATIVES À

L’INTÉRIEURDE CETTE OUVERTURE.

ARRÊTERLE MOTEUR DU TRACTEUR

ETDÉSENGAGER LA PRISE DE FORCE.

ATTENDREQUE TOUT MOUVEMENT

SOITARRÊTÉ AVANTD’AJUSTER OU

DENETTOYER

ROTATINGPARTSINSIDE THIS

OPENING.SHUT OFF TRACTOR ENGINE

ANDDISENGAGE POWER TAKE OFF

ANDWAIT FOR ALL THE MOTIONS TO

STOPBEFORE CLEANINFG OR

SERVICING

Figure 5 Safety sign locations

SAFETY DECALS

15

MANUAL / MANUEL NO. S5522E032 V1.0

10

16

2

8

13

17

19

21-22

9

4

1

7

18

19

18

18-19

19

5

12

5

14

11

7

Figure 6 Safety sign locations

ASSEMBLY INSTRUCTIONS

16 MANUAL / MANUEL NO. S5522E032 V1.0

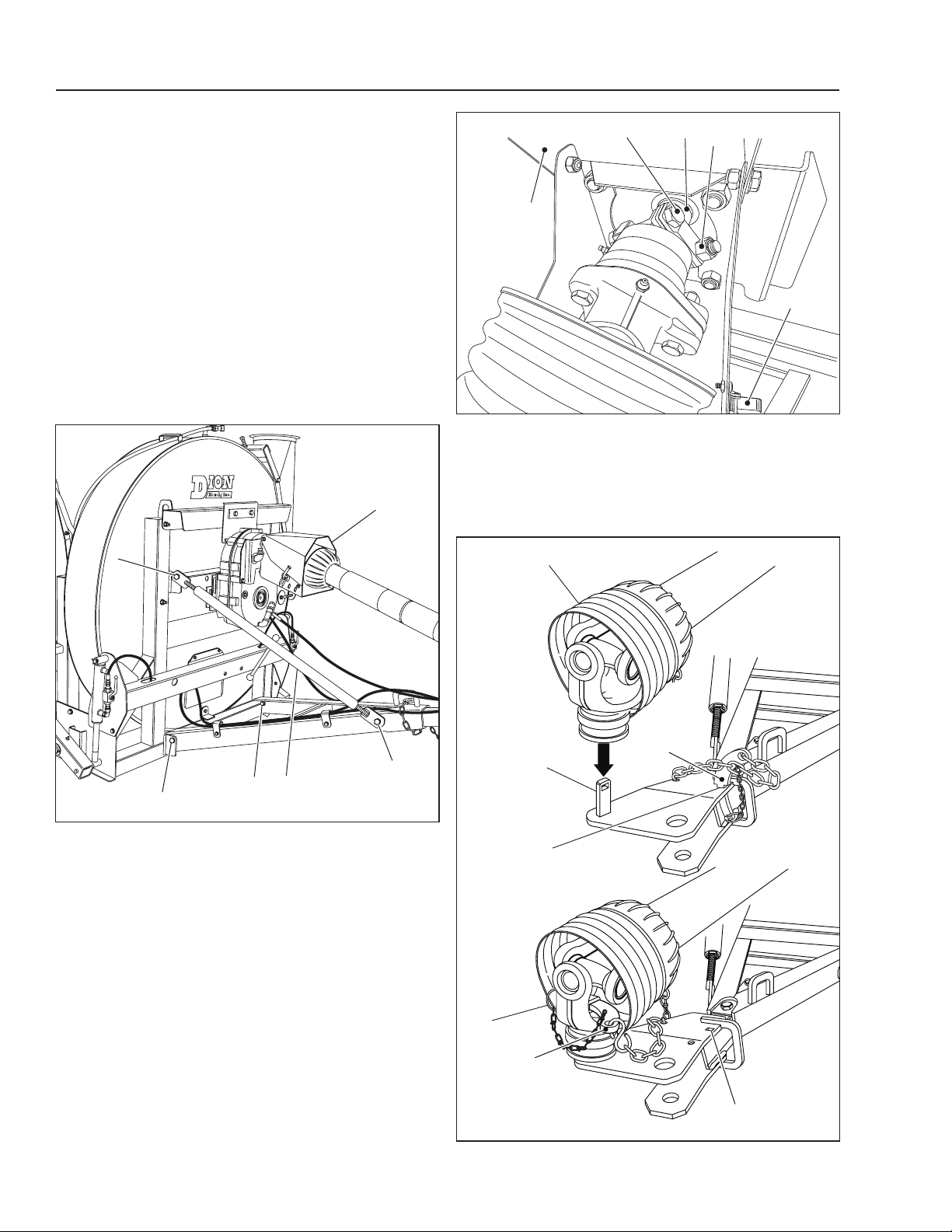

DRIVELINE ASSEMBLY INSTRUCTIONS

FIGURE 7 TO FIGURE 12

Remove all cables and/or wires used for transportation.

Attach the draw bar to the Forage Blower main frame

using bolts (item 4) already installed. Do not tighten

these bolts.

Attach the turnbuckle (item 5) to the Forage Blower

using the bolts (item 6) already in place. Adjust the draw

bar height in relation to the tractor.

Carry out this adjustment making sure both the Forage

Blower and the tractor are on a level terrain (see Figure

30 on page 26).

Tighten the draw bar lock nuts (item 4) and the turnbuckle

lock nuts (item 6) by applying a light pressure.

7

6

4

45

6

Figure 7

Open the driveline guard (item 7) then slide and bolt the

driveline to the fan shaft (item 9). Secure using the locks

(item 10). Tighten bolts (item 8) to

103 N-m then

close

the guard.

7

88

9

10

Figure 8 Assembling the driveline

Place the end of the 540-1000 RPM driveline (item 1) that

connects to the tractor in its support (item 2), then secure

with the special lock (item 3) which is itself secured with a

safety spring pin (item 4)

.

1

2

5

5

3

3

4

Figure 9 Assembling the driveline

ASSEMBLY INSTRUCTIONS

17

MANUAL / MANUEL NO. S5522E032 V1.0

Figure 10 Driveline

Lubricate the Forage Blower (refer to the lubrication

Instructions) and make sure that all rotating parts move

freely.

When the PTO is hitched to the tractor, insert the special

lock in the hole (item 5 in Figure 9) provided for that

purpose.

WARNING: Always install the manual jack (item

12) when the 1000 RPM Blower is not hitched to

the tractor.

12

Figure 11 Manual jack in place

CAUTION: The driveline should never extend

beyond 63” (1,6 m) that is when measured from

both of its ends.

Adjust the Blower draw bar according to the RPM, either

540 or 1000 RPM, as shown below. Refer to Figure 33

on page 28. Use the two bolts already in place (item 1

in Figure 12) with lock nuts. Tighten well.

1000 540

1000 540

540 RPM

1000 RPM

(CHOICE BETWEEN 2 POSITIONS)

POSITION 1 POSITION 2

1

1

Figure 12 Draw bar adjustment

To Blower

To tractor

ASSEMBLY INSTRUCTIONS

18 MANUAL / MANUEL NO. S5522E032 V1.0

NOTE: Must be installed on a blower with main shaft

specially designed for a 1000 rpm transmission

(without grooves, for driveline anchor bolt)

1. Remove driveline and guard (item 1).

2. Remove the two nuts (item 2), insert the two 1/2”

dia. lock washers (item 18) then install the U-shaped

support bracket (item 8).

NOTE: On the model with hydraulic lift, the U-shaped

support bracket (item 8) is already in place.

3. Fasten the top plate (item 3) to the gearbox using

the four 1/2” X 1 1/4” lg bolts and the four 1/2” lock

washers.

4. Fasten the lower plate (item 4) to the gearbox using

the three 5/16” X 5 1/2” lg bolts (item 20), twelve

5/16” washers (item 6) (the number of washers can

vary according the nal adjustment), three 5/16” lock

nuts (item 21) and three spacers (item 14).

NOTE: The 12 washers (item 6) must be inserted

between the plate (item 4) and the gearbox as

needed. These washers will set the gearbox

parallel to the machine frame and thus avoiding

any pressure on the drive shaft.

5. Slide the gearbox onto the shaft (item 5).

6. Align the gearbox as shown on page 47.

7. Re-adjust the lower plate (item 4) with the at

washers (item 6).

8. Fasten the plate (item 7) to the lower plate (item 4)

and to the U-shaped support bracket (item 8) with

two 5/8” X 1 1/2” lg hex head bolt (item 15), two lock

washers and two 5/8” nuts.

9. Install the upper elbow (item 9) in the appropriate

hole of the housing. Use Teon tape.

10. Screw the four 5/8” X 1 1/2” lg bolts (item 15) with

four 5/8” nuts to the plate (item 11).

11. Install the plate (item 11) to the gearbox using the

two 1/2” X 1 1/4” bolts and two lock washers.

12. Install the lower elbow (item 12) and the coupling

(item 10). Use teon tape.

13. Fill up the gearbox with oil. Pour oil into the upper

elbow (item 9) until the oil comes out of the lower

elbow (item 12). Follow recommendations on page

34.

14. Screw the cap (item 17) to the elbow.

15. Install the breather (item 13).

16. Install the guard (item 1) with four 5/8” nuts.

17. Install the driveline.

18. Install the guard (item 16).

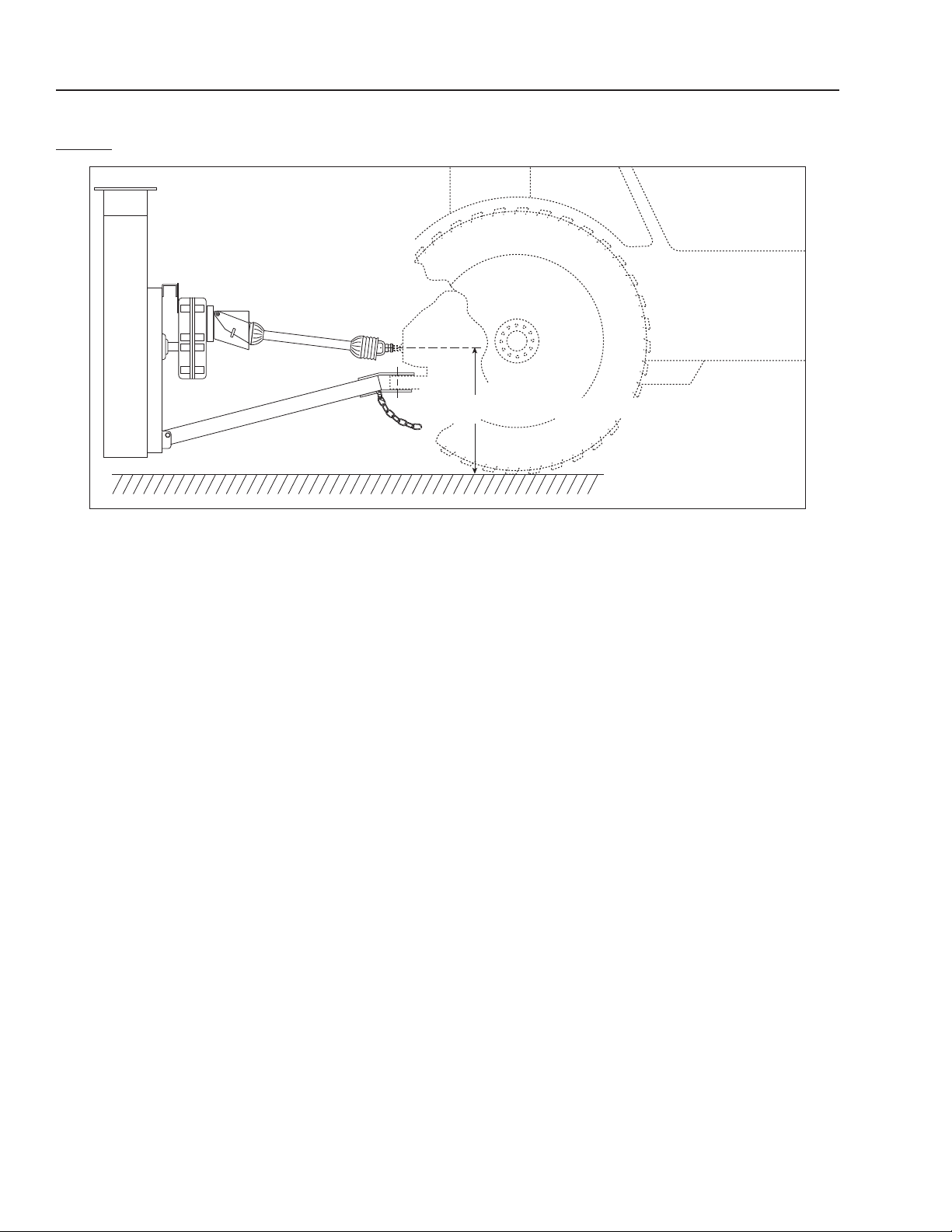

1000 RPM GEARBOX INSTALLATION PROCEDURE WHEN TRACTOR’S PTO SHAFT IS

LESS THAN 30” (76 CM) FROM THE GROUND - FIGURE 13 AND FIGURE 14

< 30” (76 cm) from the ground

Figure 13 Tractor PTO shaft at less than 30” from the ground

ASSEMBLY INSTRUCTIONS

19

MANUAL / MANUEL NO. S5522E032 V1.0

1

1

12

17

10

9

13

16

18

18

14

5

6

3

24

4

8

15

15

11

7

8

20

Figure 14 Assembling the 1000 RPM gearbox

ASSEMBLY INSTRUCTIONS

20 MANUAL / MANUEL NO. S5522E032 V1.0

1000 RPM GEARBOX INSTALLATION PROCEDURE WHEN TRACTOR’S PTO SHAFT IS

MORE THAN 30” (76 CM) FROM THE GROUND - FIGURE 15 AND FIGURE 16

> 30” (76 cm) from the ground

Figure 15 Tractor PTO shaft at more than 30” from the ground

NOTE: Must be installed on a blower with main shaft

specially designed for a 1000 rpm transmission

(without grooves, for driveline anchor bolt)

1. Remove driveline and guard (item 1).

2. Remove the two nuts (item 2), insert the two 1/2”

dia. lock washers (item 18) then install the U-shaped

support bracket (item 8).

3. Fasten the lower plate (item 4) to the gearbox using

the four 1/2” X 1 1/4” lg bolts and the four 1/2” lock

washers.

4. Fasten the upper plate (item 4) to the gearbox using

the three 5/16” X 5 1/2” lg bolts (item 20), twelve

5/16” washers (item 6) (the number of washers can

vary according the nal adjustment), three 5/16” lock

nuts (item 21) and three spacers (item 14).

NOTE: The 12 washers (item 6) must be inserted

between the plate (item 4) and the gearbox as

needed. These washers will set the gearbox

parallel to the machine frame and thus avoiding

any pressure on the drive shaft.

5. Slide the gearbox onto the shaft (item 5).

6. Align the gearbox as shown on page 47.

7. Re-adjust the upper plate (item 3) with the at

washers (item 6).

8. Fasten the plate (item 7) to the plate (item 3) and to

the U-shaped support bracket (item 8) with two 5/8”

X 1 1/2” lg hex head bolt (item 15), two lock washers

and two 5/8” nuts.

9. Install the lower elbow (item 9) and coupling (item

10) in the appropriate hole of the housing. Use teon

tape.

10. Screw the adapter (item 19).

11. Screw the four 5/8” X 1 1/2” lg bolts (item 15) with

four 5/8” nuts to the plate (item 11).

12. Install the plate (item 11) to the gearbox using the

two 1/2” X 1 1/4” bolts and two lock washers.

13. Install the upper elbow (item 12) and the coupling

(item 10). Use teon tape.

14. Fill up the gearbox with oil. Pour oil into the upper

elbow (item 12) until the oil comes out of the lower

elbow (item 9). Follow recommendations on page

34.

15. Screw cap (item 17) to the adapter (item 10).

16. Install the breather (item 13).

17. Install the guard (item 1) with four 5/8” nuts.

18. Install the driveline.

This manual suits for next models

1

Table of contents

Other Dion-Ag Blower manuals

Popular Blower manuals by other brands

Stihl

Stihl BR 450 instruction manual

Echo

Echo PB-251E - PARTS CATALOG SN P06113001001-P06113999999 REV... parts catalog

Lavorwash

Lavorwash SWL R 950 owner's guide

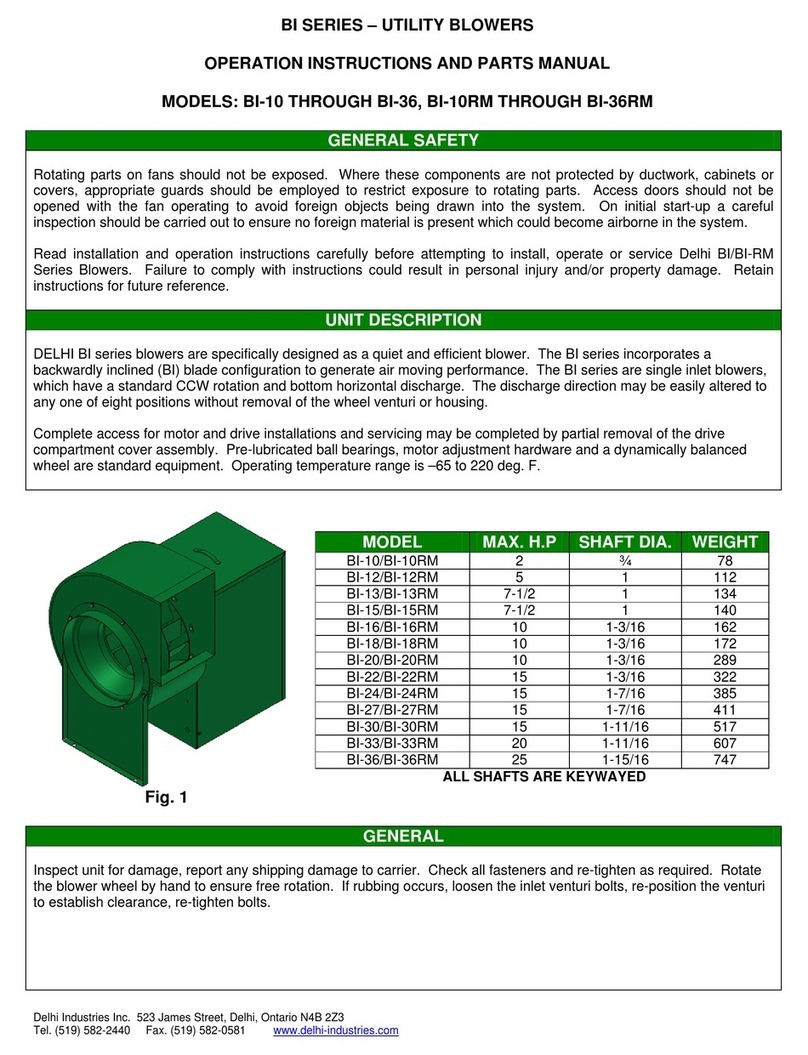

Delhi Industries

Delhi Industries BI Series Operation instructions and parts manual

Mantis

Mantis BBLOW40-25 Series Operator's & parts manual

Central Machinery

Central Machinery 99989 Assembly, operating, and maintenance instructions