Ditch Witch ht25 User manual

HT25 - SERVICE 1

SERIAL NUMBER RECORD

HT25 - SERVICE 1

SERIAL NUMBER RECORD

SERVICE

SERIAL NUMBER RECORD

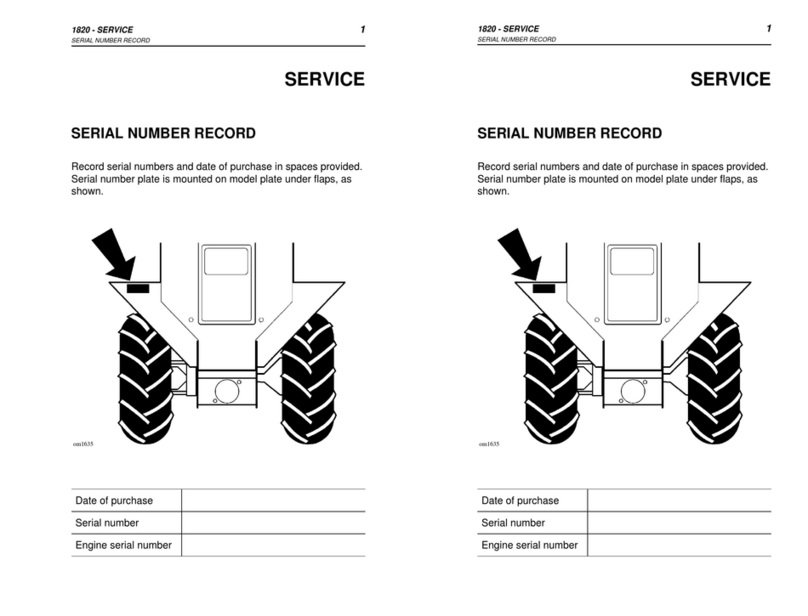

Record serial number and date of purchase in spaces provided.

Tractor serial number is located as shown.

Date of Manufacture:

Date of Purchase:

Tractor Serial Number:

Front Attachment Serial Number:

Engine Serial Number:

Trailer Serial Number:

SERVICE

SERIAL NUMBER RECORD

Record serial number and date of purchase in spaces provided.

Tractor serial number is located as shown.

Date of Manufacture:

Date of Purchase:

Tractor Serial Number:

Front Attachment Serial Number:

Engine Serial Number:

Trailer Serial Number:

2HT25 - SERVICE

SUPPORT PROCEDURE 2HT25 - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of

equipment purchase. This information should be recorded and

placed on file by owner at time of purchase.

Return damaged parts to dealer for inspection and Warranty

consideration.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications covering

operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact your

Ditch Witch dealer.

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of

equipment purchase. This information should be recorded and

placed on file by owner at time of purchase.

Return damaged parts to dealer for inspection and Warranty

consideration.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications covering

operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact your

Ditch Witch dealer.

HT25 - FOREWORD 3

HT25 - FOREWORD 3

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have taken

place after this manual was published. For the latest information

on Ditch Witch equipment, see your Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have taken

place after this manual was published. For the latest information

on Ditch Witch equipment, see your Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

4HT25 - FOREWORD 4HT25 - FOREWORD

Operator's Manual

Issue Number 1.0/OP-4/00

Part Number 054-062

Copyright 2000

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, Jet Trac, Pro Tech, Fluid Miser, Perma-Soil,

Modularmatic, Roto Witch, AutoCrowd, and Subsite are

registered trademarks of The Charles Machine Works, Inc.

CMW is a trademark of The Charles Machine Works, Inc.

Pierce Airrow is a registered trademark of Oklahoma Airrow, Inc.

Operator's Manual

Issue Number 1.0/OP-4/00

Part Number 054-062

Copyright 2000

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, Jet Trac, Pro Tech, Fluid Miser, Perma-Soil,

Modularmatic, Roto Witch, AutoCrowd, and Subsite are

registered trademarks of The Charles Machine Works, Inc.

CMW is a trademark of The Charles Machine Works, Inc.

Pierce Airrow is a registered trademark of Oklahoma Airrow, Inc.

HT25 - CONTENTS 5

HT25 - CONTENTS 5

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number Record. . . . . . . . . . . . . . . . . . . . . . . . . .1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Underground Hazards. . . . . . . . . . . . . . . . . . . . . . . . .20

Emergency Procedures. . . . . . . . . . . . . . . . . . . . . . . .21

Jobsite Classification. . . . . . . . . . . . . . . . . . . . . . . . . .24

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . .28

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Serial Number Record . . . . . . . . . . . . . . . . . . . . . . . . . 1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Underground Hazards . . . . . . . . . . . . . . . . . . . . . . . . 20

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . . 21

Jobsite Classification . . . . . . . . . . . . . . . . . . . . . . . . . 24

Safety Alert Classifications. . . . . . . . . . . . . . . . . . . . . 28

Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6HT25 - CONTENTS 6HT25 - CONTENTS

TRACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tiedown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TRENCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 51

BACKHOE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

TRACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tiedown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TRENCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 46

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 51

BACKHOE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Control Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

HT25 - CONTENTS 7

HT25 - CONTENTS 7

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Ground Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Trencher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Backfill Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Ground Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Trencher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

HT25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

A225 Backhoe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Ground Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Trencher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Backfill Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Ground Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Trencher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

HT25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A225 Backhoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8HT25 - CONTENTS 8HT25 - CONTENTS

HT25 - OVERVIEW 9

HT25 - OVERVIEW 9

OVERVIEW

The HT25 is a 25 hp (18.6 kW) riding tractor that can be fitted

with a centerline, wide centerline, or offset digging boom.

Optional cab, backfill blade, backhoe, drilling attachment, and

mechanical trench cleaner are available. The HT25 is designed to

cut trenches up to 36 in (91 cm) deep and 16 in (40 cm) wide.

1. Digging boom

2. Lift/tiedown point

3. Engine compartment

4. Rollover Protective Structure

5. Operator’s position

6. Control console

7. Lift/tiedown point

8. Backfill blade*

*optional

OVERVIEW

The HT25 is a 25 hp (18.6 kW) riding tractor that can be fitted

with a centerline, wide centerline, or offset digging boom.

Optional cab, backfill blade, backhoe, drilling attachment, and

mechanical trench cleaner are available. The HT25 is designed to

cut trenches up to 36 in (91 cm) deep and 16 in (40 cm) wide.

1. Digging boom

2. Lift/tiedown point

3. Engine compartment

4. Rollover Protective Structure

5. Operator’s position

6. Control console

7. Lift/tiedown point

8. Backfill blade*

*optional

10 HT25 - OVERVIEW 10 HT25 - OVERVIEW

HT25 - CONTROLS 11

OVERVIEW

HT25 - CONTROLS 11

OVERVIEW

CONTROLS

OVERVIEW

1. Throttle

2. Accessory socket*

3. Backfill blade control*

4. Dome light switch*

5. Windshield wiper switch*

6. Work light switch*

7. Track controls

8. Horn button

9. Digging chain control**

10. Glow plug control

11. Ignition switch

12. Fuel gauge

13. Start interlock indicators

14. Engine water temperature

indicator

15. Engine oil pressure indicator

16. Heater fan control*

17. Heater temperature control*

18. Boom lift control**

19. Battery disconnect*

20. Hourmeter

* Optional

**See TRENCHING for a description of

this control.

CONTROLS

OVERVIEW

1. Throttle

2. Accessory socket*

3. Backfill blade control*

4. Dome light switch*

5. Windshield wiper switch*

6. Work light switch*

7. Track controls

8. Horn button

9. Digging chain control**

10. Glow plug control

11. Ignition switch

12. Fuel gauge

13. Start interlock indicators

14. Engine water temperature

indicator

15. Engine oil pressure indicator

16. Heater fan control*

17. Heater temperature control*

18. Boom lift control**

19. Battery disconnect*

20. Hourmeter

* Optional

**See TRENCHING for a description of

this control.

12 HT25 - CONTROLS

DESCRIPTIONS 12 HT25 - CONTROLS

DESCRIPTIONS

DESCRIPTIONS

Throttle

This lever controls engine speed.

•Push to increase speed.

•Pull to reduce speed.

Accessory Socket

This optional outlet can be used to

provide power for work lights or other

equipment.

ic0128h.eps

DESCRIPTIONS

Throttle

This lever controls engine speed.

•Push to increase speed.

•Pull to reduce speed.

Accessory Socket

This optional outlet can be used to

provide power for work lights or other

equipment.

ic0128h.eps

HT25 - CONTROLS 13

DESCRIPTIONS

HT25 - CONTROLS 13

DESCRIPTIONS

Backfill Blade Control

This optional lever raises, lowers,

and swings backfill blade.

•Push to lower blade.

•Pull to raise blade.

•Move right to swing blade

right.

•Move left to swing blade left.

Work Light Switch

This optional switch controls front

and rear work lights.

•Press right to turn on.

•Press left to turn off.

Dome Light Switch

This optional button controls interior dome light.

•Press top to turn on.

•Press bottom to turn off.

Backfill Blade Control

This optional lever raises, lowers,

and swings backfill blade.

•Push to lower blade.

•Pull to raise blade.

•Move right to swing blade

right.

•Move left to swing blade left.

Work Light Switch

This optional switch controls front

and rear work lights.

•Press right to turn on.

•Press left to turn off.

Dome Light Switch

This optional button controls interior dome light.

•Press top to turn on.

•Press bottom to turn off.

14 HT25 - CONTROLS

DESCRIPTIONS 14 HT25 - CONTROLS

DESCRIPTIONS

Windshield Wiper Switch

This optional switch controls

windshield wipers.

•Press right to turn on.

•Press left to turn off.

Track Controls

These levers, used together,

control left and right track speed

and direction.

•Push to go forward.

•Pull to go backward.

•Return to neutral to stop.

•Use together to steer.

Engine Oil Pressure Indicator

This indicator lights when oil

pressure is low. Light will come on

briefly when engine is started.

If light remains on:

•Turn off engine.

•Check oil level.

•Check for leaks before starting

engine.

Ic0225h.eps

Ic0227h.eps

ic1294.eps

Windshield Wiper Switch

This optional switch controls

windshield wipers.

•Press right to turn on.

•Press left to turn off.

Track Controls

These levers, used together,

control left and right track speed

and direction.

•Push to go forward.

•Pull to go backward.

•Return to neutral to stop.

•Use together to steer.

Engine Oil Pressure Indicator

This indicator lights when oil

pressure is low. Light will come on

briefly when engine is started.

If light remains on:

•Turn off engine.

•Check oil level.

•Check for leaks before starting

engine.

Ic0225h.eps

Ic0227h.eps

ic1294.eps

HT25 - CONTROLS 15

DESCRIPTIONS

HT25 - CONTROLS 15

DESCRIPTIONS

Start Interlock Indicators

To start machine, these must be lit,

indicating the following conditions

have been met:

•Operator is in seat.

•Track controls are in neutral.

•Digging chain clutch is not

engaged.

Horn Button

Press button to sound horn.

ic0138x.eps

Start Interlock Indicators

To start machine, these must be lit,

indicating the following conditions

have been met:

•Operator is in seat.

•Track controls are in neutral.

•Digging chain clutch is not

engaged.

Horn Button

Press button to sound horn.

ic0138x.eps

16 HT25 - CONTROLS

DESCRIPTIONS 16 HT25 - CONTROLS

DESCRIPTIONS

Glow Plug Button

This button helps start cold engine.

To operate, first turn ignition switch to

first position.

•If ambient temperature is below

40°F (4°C), press and hold

button for 15 seconds.

•If ambient temperature is below

20°F (-7°C), press and hold

button for 30 seconds.

Release button, then turn ignition switch all the way clockwise.

Ignition Switch

This three-position switch starts or

stops engine.

•Insertkeyandturnclockwiseto

first position.

•Press glow plugbutton towarm

cold engine if necessary. See

instructions for glow plug

button.

•Turn switch all the way

clockwise.

•Release when engine starts. Key will return to first position.

•Turn counterclockwise to stop engine.

If engine does not start on first attempt, check that all interlock

requirements have been met, return switch to STOP position, and

try again.

ic0219h.eps

Glow Plug Button

This button helps start cold engine.

To operate, first turn ignition switch to

first position.

•If ambient temperature is below

40°F (4°C), press and hold

button for 15 seconds.

•If ambient temperature is below

20°F (-7°C), press and hold

button for 30 seconds.

Release button, then turn ignition switch all the way clockwise.

Ignition Switch

This three-position switch starts or

stops engine.

•Insertkeyandturnclockwiseto

first position.

•Press glowplugbuttontowarm

cold engine if necessary. See

instructions for glow plug

button.

•Turn switch all the way

clockwise.

•Release when engine starts. Key will return to first position.

•Turn counterclockwise to stop engine.

If engine does not start on first attempt, check that all interlock

requirements have been met, return switch to STOP position, and

try again.

ic0219h.eps

HT25 - CONTROLS 17

DESCRIPTIONS

HT25 - CONTROLS 17

DESCRIPTIONS

Fuel Gauge

This gauge indicates fuel level in

tank. Use only #2 diesel fuel.

Engine Temperature Indicator

This indicator lights if cooling

system water overheats.

•Turn off engine and let cool.

•Check cooling system fluid

level.

Heater Fan Control

This optional knob adjusts heater

fan speed.

•Turn clockwise for faster.

•Turn counterclockwise for

slower.

ic1274.eps

Fuel Gauge

This gauge indicates fuel level in

tank. Use only #2 diesel fuel.

Engine Temperature Indicator

This indicator lights if cooling

system water overheats.

•Turn off engine and let cool.

•Check cooling system fluid

level.

Heater Fan Control

This optional knob adjusts heater

fan speed.

•Turn clockwise for faster.

•Turn counterclockwise for

slower.

ic1274.eps

18 HT25 - CONTROLS

DESCRIPTIONS 18 HT25 - CONTROLS

DESCRIPTIONS

Heater Temperature Control

This optional knob adjusts heater

temperature.

•Turn clockwise for warmer.

•Turn counterclockwise for

cooler.

Hourmeter

This gauge, located under seat,

records engine operating time.

Use these times to schedule

lubrication and maintenance.

Battery Disconnect

Use this optional knob, located

under seat, to disconnect battery

when servicing unit or during long-

term storage.

•Turn clockwise to connect

battery power.

•Turn counterclockwise to

disconnect battery power.

Heater Temperature Control

This optional knob adjusts heater

temperature.

•Turn clockwise for warmer.

•Turn counterclockwise for

cooler.

Hourmeter

This gauge, located under seat,

records engine operating time.

Use these times to schedule

lubrication and maintenance.

Battery Disconnect

Use this optional knob, located

under seat, to disconnect battery

when servicing unit or during long-

term storage.

•Turn clockwise to connect

battery power.

•Turn counterclockwise to

disconnect battery power.

HT25 - SAFETY 19

HT25 - SAFETY 19

SAFETY

Follow these guidelines before operating any jobsite equipment:

•Complete proper training and read operator’s manual before

using equipment.

•Contact One-Call (888-258-0808) and any utility companies

which do not subscribe to One-Call. Have all underground

pipes and cables located and marked before operating

equipment. If you damage a utility, contact utility company.

•Classify jobsite based on its hazards and use correct tools

and machinery, safety equipment, and work methods for

jobsite.

•Mark jobsite clearly and keep spectators away.

•Wear personal protective equipment.

•Review jobsite hazards, safety and emergency procedures,

and individual responsibilities with all personnel before work

begins. Safety videos are available from your Ditch Witch

dealer.

•Replace missing or damaged safety shields and safety signs.

•Use equipment carefully. Stop operation and investigate

anything that does not look or feel right.

•Do not operate unit where flammable gas is present.

•Contact your Ditch Witch dealer if you have any question

about operation, maintenance, or equipment use.

SAFETY

Follow these guidelines before operating any jobsite equipment:

•Complete proper training and read operator’s manual before

using equipment.

•Contact One-Call (888-258-0808) and any utility companies

which do not subscribe to One-Call. Have all underground

pipes and cables located and marked before operating

equipment. If you damage a utility, contact utility company.

•Classify jobsite based on its hazards and use correct tools

and machinery, safety equipment, and work methods for

jobsite.

•Mark jobsite clearly and keep spectators away.

•Wear personal protective equipment.

•Review jobsite hazards, safety and emergency procedures,

and individual responsibilities with all personnel before work

begins. Safety videos are available from your Ditch Witch

dealer.

•Replace missing or damaged safety shields and safety signs.

•Use equipment carefully. Stop operation and investigate

anything that does not look or feel right.

•Do not operate unit where flammable gas is present.

•Contact your Ditch Witch dealer if you have any question

about operation, maintenance, or equipment use.

20 HT25 - SAFETY

ACCESSORIES 20 HT25 - SAFETY

ACCESSORIES

ACCESSORIES

Fire Extinguisher

If required, a fire extinguisher should be mounted near the power

unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric

fires. It should meet legal and regulatory requirements.

Lighting Kit

If you need additional light, plug lighting kit into provided outlet.

Contact your Ditch Witch dealer for further information.

UNDERGROUND HAZARDS

Striking underground hazards can cause explosion, electrocution,

fire, and exposure to hazardous materials.

Hazards include:

•Electric lines

•Natural gas lines

•Fiber optic cables

•Water lines

•Sewer lines

•Pipes carrying other chemicals, liquids, or gases

•Storage tanks

ACCESSORIES

Fire Extinguisher

If required, a fire extinguisher should be mounted near the power

unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric

fires. It should meet legal and regulatory requirements.

Lighting Kit

If you need additional light, plug lighting kit into provided outlet.

Contact your Ditch Witch dealer for further information.

UNDERGROUND HAZARDS

Striking underground hazards can cause explosion, electrocution,

fire, and exposure to hazardous materials.

Hazards include:

•Electric lines

•Natural gas lines

•Fiber optic cables

•Water lines

•Sewer lines

•Pipes carrying other chemicals, liquids, or gases

•Storage tanks

Table of contents

Other Ditch Witch Tractor manuals