Ditchburn Music Maker 200 Quick start guide

Music Maker 200

T200 Service Engineers Manual

Also Suitable for

Tonomat Telematic 200 and MM200

This Manual is an English Translation of the Tonomat Telematic 200 Manual, many

thanks to Stuart and Sue Saunders for undertaking the translation and for the

assistance from Hildegard Stamann for the additional amendments, information and

use of diagrams within the manual.

Various parts and complete printed and bound original manuals for Ditchburn and

Tonomat Jukeboxes can be purchased from

www.jukebox-world.de/en/Onlineshop/

More information on Ditchburn Jukeboxes can be found at

www.ditchburn.co.uk

2

CONTENT

1. Important data of the "telematic 200"………………………………………………… 3

2. Installation and operation ……………………………………………………….. 4

3. Description of the electrical functions when dialing……………………………… 5

Coin…………………………………………………………………………………............ 5

Selection of the first digit……………………………………………………………………..5

Dial the second digit………………………………………………………………………. 5

Dial the third digit………………………………………………………………………….. 5

Raising the selector pin…………………………………………………………………… 5

Reset the rotary selector………………………………………………………….............. 6

4. Description of credit……..………………………………………………………….. 6

50 Pfg insert……………………………………………………………………………… 6

1 DM insert……………………………………………………………………………… 6

5. Change in the credit settings…………………………………………………………….. 7

6. Equipped with long-playing records………………………………………………….. 7

7. Electrical functions when selecting an LP…………………………………………… 8

Coin………………………………………………………………………………………….. 8

pay more appears……………………………………………………………………………. 8

The error button……………………………………………………………………………… 8

8. Description of the electrical functions when changing records…………………….9

Lifting a record………………………………………………………………………………… 9

Return the played disc……………………………………………………………………… 9

9. Adjustment regulation................................................................................................ 12

Lift and lower the records……………………………………………………………………..12

Center the record…………………………………………………………………................ 12

Adjustment of the switching cams………………………………………………................ 12/13

Raise and reset the selection pins…………………………………………………….. 14

Clean the sapphire………………………………………………………………………….. 14

10. Description of the mechanical functions when changing plates………………… 15

How the Record lifters work……………………………………………………………….. 15

Center the record…………………………………………………………………………… 15

Clutch pinion and turntable drive………………………………………………………….. 15

returns……………………………………………………………………………………….. 15

11. Diagnostic sources of interference......................................................................... 16

Troubles before dialing……………………………………………………………………. 16

after dialing………………………………………………………….............. 16

when changing……………………………………………………………… 17

while playing………………………………………………………………… 17

12. General electrical switching faults…………………………………………………….. 17

13. Maintenance and care……………………………………………………………………. 18

14. Guarantee……………………………………………………………………...................... 18

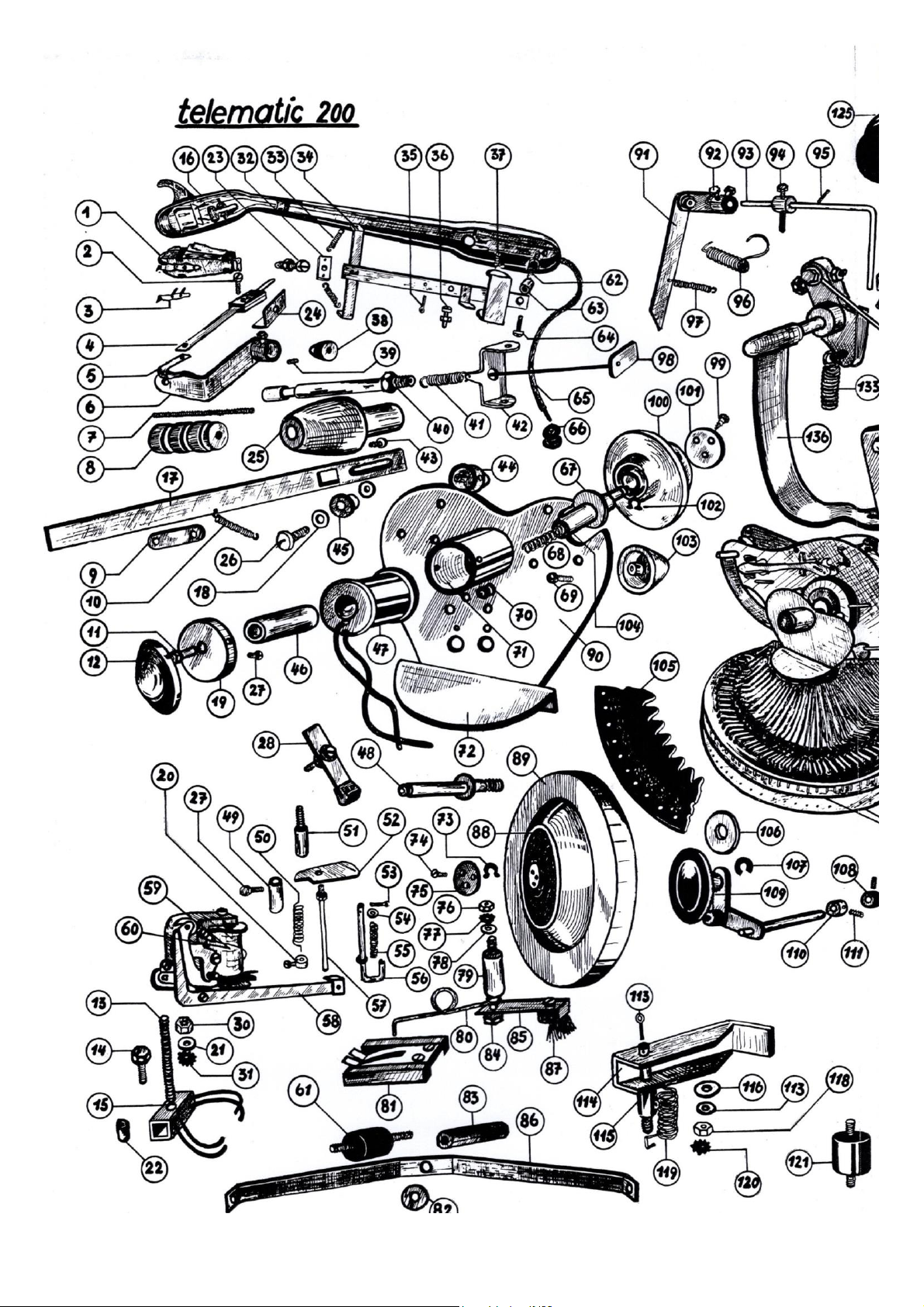

15. Individual parts of the mechanics……………………………………………………… 18 to 21

16. Individual parts - housing rear view…………………………………………………… 19

17. Single parts - housing front view………………………………………………………. 20

3

Important data

The "telematic 200"

Dimensions:

Height: 145 cm

Width: 94 cm

Depth: approx. 73 cm

Voltage values:

220 volt amplifier

Power Supply:

Input: 220 volts

Output: = 60 volts

Command Device

Control voltage of the relays: = 60 volts

Control voltage for motors 220 volts

Operating voltage for the player engine: 110 volts

(Half of the incoming voltage is destroyed by

the upstream resistor)

Service:

The records are selected using the dial disc

known from the telephone.

The request to choose and the '' wait '' sign

appears as a green or red illuminated

transparency to the right and left of the dial.

Another indicator lamp prompts you to “pay

extra '' when a long-playing record is selected.

The telephone system, which has been tried

and tested a million times, offers the choice of

up to 40 long-playing records with more than

200 options. An error button gives you the

option to undo an already initiated dialing.

Pickups:

Crystal system made by '' ELAC '' KST 11 with

Micro-sapphire SM11.

We advise you to replace the sapphire needle

after 2000 to 2500 games. On request, we can

also supply diamond needles with 30 times the

lifespan.

Amplifier:

30 Watt high-performance Hi-Fi amplifier with

connection option for additional speakers.

Tubes: 1 x EZ 81, 4 X EL 84, 2 X ECC 81.

A potentiometer serves as the volume control.

50 K-ohm layer resistance.

For more detailed information about the

amplifier, please refer to the separate

operating and service instructions enclosed

with the guarantee cards for the amplifier tubes.

Speaker:

Two permanently dynamic loudspeakers with a

voice coil design of 5 OHM.

The tweeter has an output of 8 watts, while the

low-frequency speaker, whose diaphragm is

300 mm in diameter, delivers 12 watts of

power.

When connecting external speakers, please

note that their voice coil design is also 5 OHM.

Fuses:

The power supply is fused with 0.5 Amp. Slow-

blow, while a 0.8 Amp slow-blow fuse must be

used for the amplifier at 200 volt mink voltage.

Coin validator:

The well-known National Coin Rejector with

central coin slot for 0.10, 0.50 and 1. - DM is

also used in our device. You can find the

special details of this in the description

enclosed with these operating instructions.

Lighting:

Two 16 watt HNW70 fluorescent lamps with

matching chokes and starters are installed to

illuminate the program board and rotating far

roller.

Three telephone lamps 60 volt 0.4 Amp.

Illuminate the signs: "dial", "wait" and "pay

later".

4

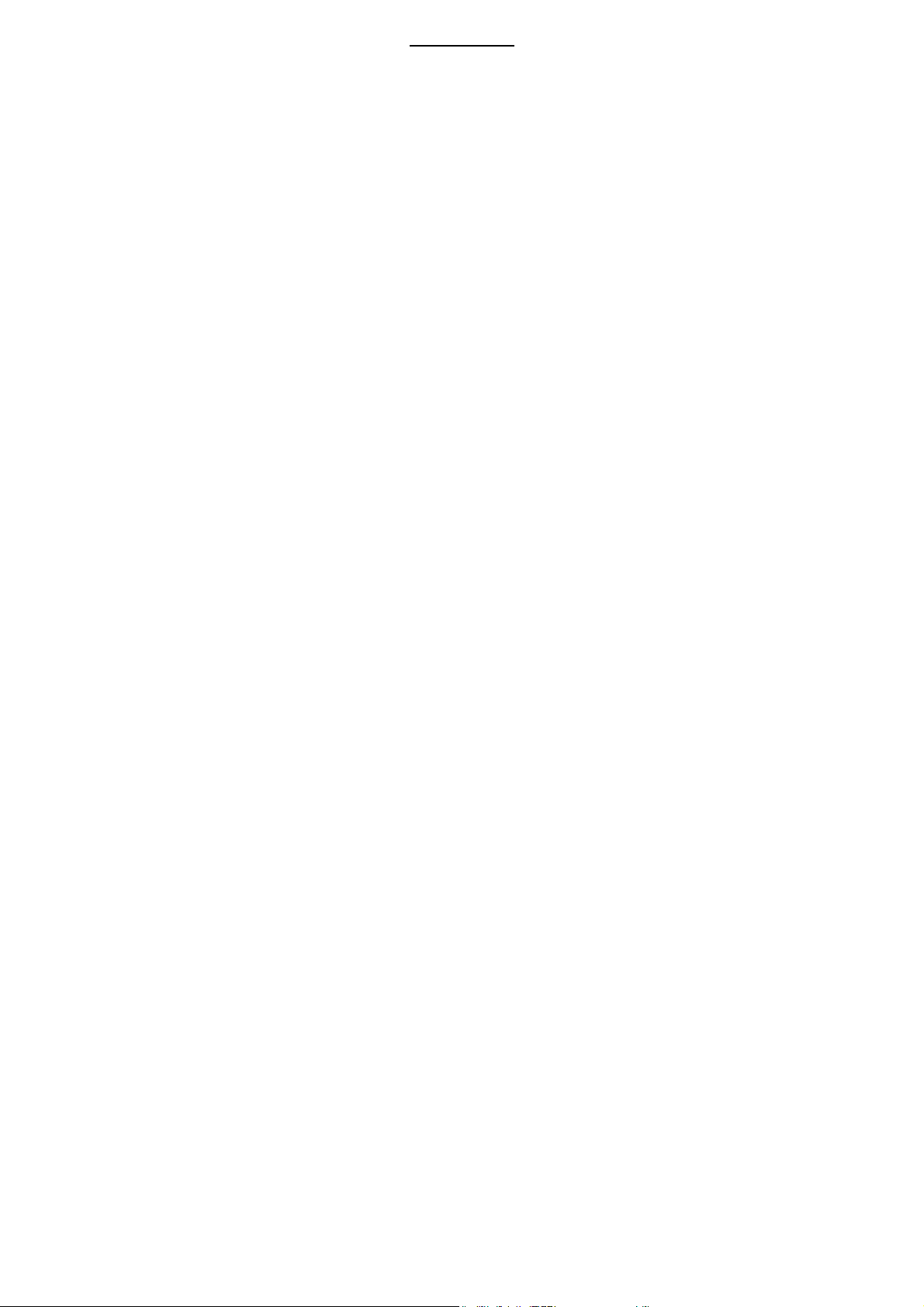

Installation and operation

The delivered music automat "telematic 200" has to be

checked for possible damage during commissioning.

Any defects found must be reported immediately to your

dealer or to us, the manufacturer. the defect notice must

be received by registered letter within 14 days of receipt

of the machine. Before you proceed to populate the unit

with records, it is necessary to remove the fuses used

for transport. We therefore ask you to use the illustration

above:

A) Remove the rubber band from the sapphire treasure

to be released in the direction of the arrow and remove

the rubber grommet of the tonearm support

B) The counterweight of the tonearm is secured to the

rear head plate with a wire clip, which must also be

removed.

C) The shafts of the two drive motors for the dial and the

magazine are protected by a rubber hose and attached.

This fuse must also be removed.

D) To prevent the mechanics from spinning, it is secured

against the intermediate floor by means of the two

designated screws. Loosen the two wing nuts and take

out the scrapers together with the wooden blocks

underneath.

E) The position of the sapphire is crucial for the correct

play of your records. Therefore, note that the swivelling

marking points to "N".

Note: We advise you to keep all removed transport

locks in a safe place. If you ever intend to change your

TELEMATIC, then protect these things from transport

disruptions. The rubber tubes pulled off the axles of the

two motors are also ideal for replacing the 60 volt bulbs

"choose", "wait" and "pay later"

The keys for the control panel and rear panel of an

automatic machine, you will find it attached to the side

handle of the rear panel.

The cash box keys are attached to the strut that

supports the mechanics in the housing.

The title paper as well as the coloured information

leaflets for "new appearances" and "hit song of the

month" are kept safe in the cash register bag during

transport.

The installation site if possible, it should not be in

front of a heater or next to an oven. In any case, care

must be taken that the sun cannot shine on the records

at any time of the day. The back of the device should be

a hand's width from the wall.

All selector pins those that may have worked their

way up during transport must be pushed down again

with the hand.

The operating voltage for the machine is 220 volts

alternating current. For other AC voltages, a 300 watt

series transformer must be used. Also make sure that

the device is connected using a Schuko socket, which

must be earthed.

Before inserting the vinyl records it is essential to

ensure that any burr residues in the centering lock of the

panels, which are caused by improper punching out of

the centering hole or protruding paint marks, must be

removed. In any case, it is advisable to use a scraper,

knife, file or the like to clean the centering lock of each

plate before use in order to avoid faults in which the

records may get stuck on the centering cone of the

centering plate after being removed.

The coin rejector only works one hundred percent if

you set up your TELEMATIC horizontally and vertically.

Do not scrub this little effort, the national rejector coin

acceptor pays off with its exact way of working

5

Description

The electrical functions

When dialing

Relay switched on

I

II

J

V

(DZ)

A

J

(DZ)

U

V

(DE)

M

H

(DZ)

(DE)

Coin engagement (normal plate)

The coin validator gives a pulse each time a 10 Pfennig piece is inserted.

The coin stacking works on the principle of the flip-flap circuit and means

that the choice is only released after the second 10 pfennig coin has

been inserted .

When the 10 pfennig coin contact MK10 is closed, the I relay picks up. If

the MK10 opens again, the short circuit of the II relay (winding I) is

released and this also picks up. If the second coin falls now, the MK10

wears again, the I relay is short-circuited and falls off. In this position: II

relay on, I relay off, the J relay is activated via the 212 - 1II and vIII

contact. This is maintained via the iI2 contact and the nsi contact on the

number plate. At the same time, the lamp "select" is switched on via the

iII2 and the 1III2 contact .

The V relay then pulls in via the iIII1 contact and the selector arm dzII

and the uI1 contact.

Dial the first digit (select group 100 or 200)

When a 1 is selected, the circuit of the J relay is interrupted, this drops

out and controls the selector DZ via the iII1 contact. If a 2 is selected as

the first number, the group contact and the short-circuit contact close.

The nsk contact short-circuits one of the two given impulses, so that the

dialler DZ stands for step 1 in both cases after the first digit. The nsg

contact allows the A relay to respond via the iII2 contact and the selector

arm dzl. This stays over the al-contact and turns on the magnet for the

second group of hundreds through the all-contact.

Dial the second digit (tens digit)

Pressing the number plate interrupts the number plate impulse contact

nsi, causing the J relay to pulse. This pulse series is transferred from the

iII1 contact to the DZ selector.

Choice of the third digit (one digit)

After the second number is selected, the V relay drops out.

Corresponding bridges in the distributor (e.g.: r, s, t, with u, o, p) connect

via the vII1 contact and use the selector arm dzII U-Relay to pull in,

which is via the uI2 contact itself holds. The uII1 contacts, so that the

next series of pulses goes from the number plate via the iII1 contact to

the DE dialler, the V relay holds over the pulses and then drops out. After

both diallers are set, the "wait" lamp lights up.

The M and H relays are now switched on via the uII contact, and the

selector and magazine motor sum is started with the mI1 and mI2

contact.

Pushing up the selection pin (storage)

The position of the two contact arms de1 and dz1 of the rotary selector,

which give the previously selected number, is directly connected to the

dial of the mechanics via the cable routing of the "A" connector. The

selector motor previously started via the ml1 contact now brings the

rotating one

6

M

H

S

S

(DZ)

(DE)

J

A

(Lp)

U

Z

(DK)

Z

J

(DZ)

S

J

Z

K

(DK)

J

Sliding contact over the attacks of the contact disc and thus short-circuits

the selector outputs del and dzl, whereby the S relay is attracted via its

winding l. Depending on the position of the all contact, the sl1 contact

energizes the selection magnet 1 or selection magnet 2. These flip the

corresponding selection pin upwards.

Reset the rotary selector

With the slll2 contact or sl2 contact, the home run of the voters is

controlled via their own SU contact (sudz or sude) and their own electoral

roll (dzll or dell). Furthermore, the sll1 contact separates the minus line to

the relays J, A, Lp, U and Z and thus they drop out. Due to the drop in

the U relay, the pulse to the selector magnet is interrupted with the ulll2

contact. The S relay will hold until both diallers are set to step 0 again.

When the S-Relay drops, the storage process ends and the device is

free for a new choice.

Description of credit storage for 50 pfennigs and 1 DM

The credit memory section built into the command device makes it

possible to play 3 to 5 records for a 50 pfennig piece and 5 to 10 records

for 1 DM. The number of plays can be changed by re-soldering bridges.

(See paragraph: change in the credit requirement)

50-pfennig Insertion

When a 50-pfennig piece is inserted, the MK 50 closes. The DK selector

takes a step and uses the dk1 contact to pull in the Z relay, which holds

itself via the zlll2 contact. The J-relay is activated by the zl2 contact and

thus the choice is released. The further selection process for the records

corresponds to that of 2 x 10 pfennig insertion.

Counting Down the established frequency of selection

After the end of the selection, the S relay picks up and switches off the Z

relay via sll2 contact. After the Z relay has dropped out, the DK selector

takes a step via the dkll selector arm and the zlll1 contact. The credit

requirement is thus reduced by one choice. The previous switching

process of the DK selector can now again pull the Z relay via the dkl

contact and issue a new credit.

This process is repeated until the selector DK, with his selector arm dkl,

for example (depending on the credit setting set) comes to the third step.

From this position, the voter returns to the zero position via the dkl train,

the kl1 contact and the sudk contact.

DM1. - Insertion

when inserting a DM1 coin, the K relay picks up first, and the DK selector

takes the first step via the Klll2 contact and switches on the J relay via

the ZIII1 contact. This means that the first record can be selected. The

further selection process corresponds to that of 2 times 10 Pfennig insert.

Counting Down the established frequency of selection

The reduction in the selection option corresponds to the same

procedures as with the 50 Pfennig insertion. The voter now only runs

after the sixth step, for example, due to the now open kl1 contact on the

eleventh step. This short-circuits the K relay and drops out. The DK

selector only returns to its zero position after the K relay has dropped out.

7

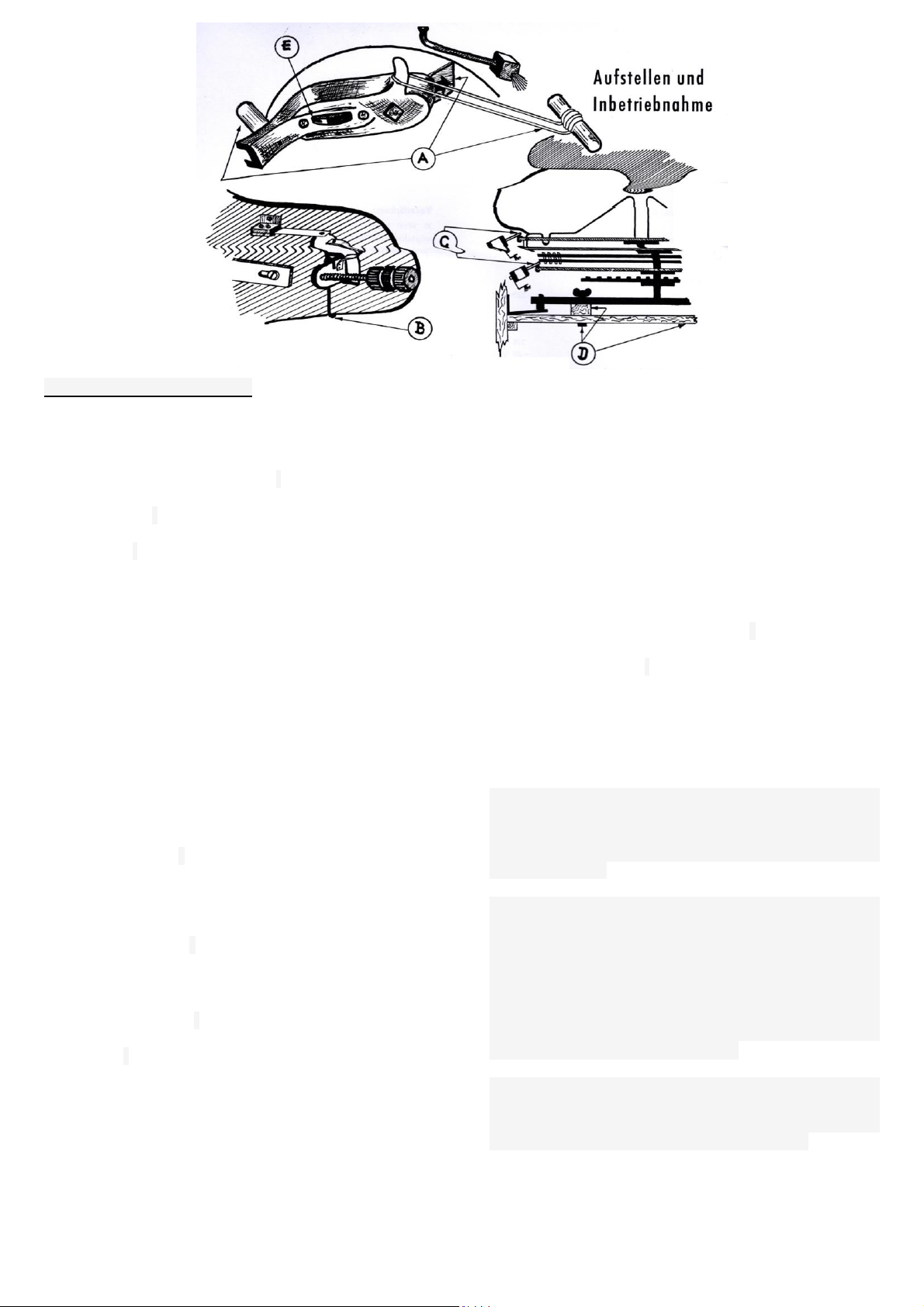

Change in Credit Settings .

Possible credit change

a) 2 x 10 Pfg. 1 PLAY –50 Pfg. 3 PLAY –DM 1 –6 PLAY

b) 2 x 10 Pfg. 1 PLAY –50 Pfg. 3 PLAY –DM 1 –7 PLAY

c) 2 x 10 Pfg. 1 PLAY –50 Pfg. 4 PLAY –DM 1 –8 PLAY

d) 2 x 10 Pfg. 1 PLAY –50 Pfg. 5 PLAY –DM 1 –10 PLAY

With 1 play for 1 x 10 Pfg. regardless of which credit is required for 50 Pfg. or DM 1 - is selected to connect A & B of the terminal block.

In addition, the two red and pink wires from the coin switch on the terminal block must be exchanged.

Necessary bridge connections on the terminal block

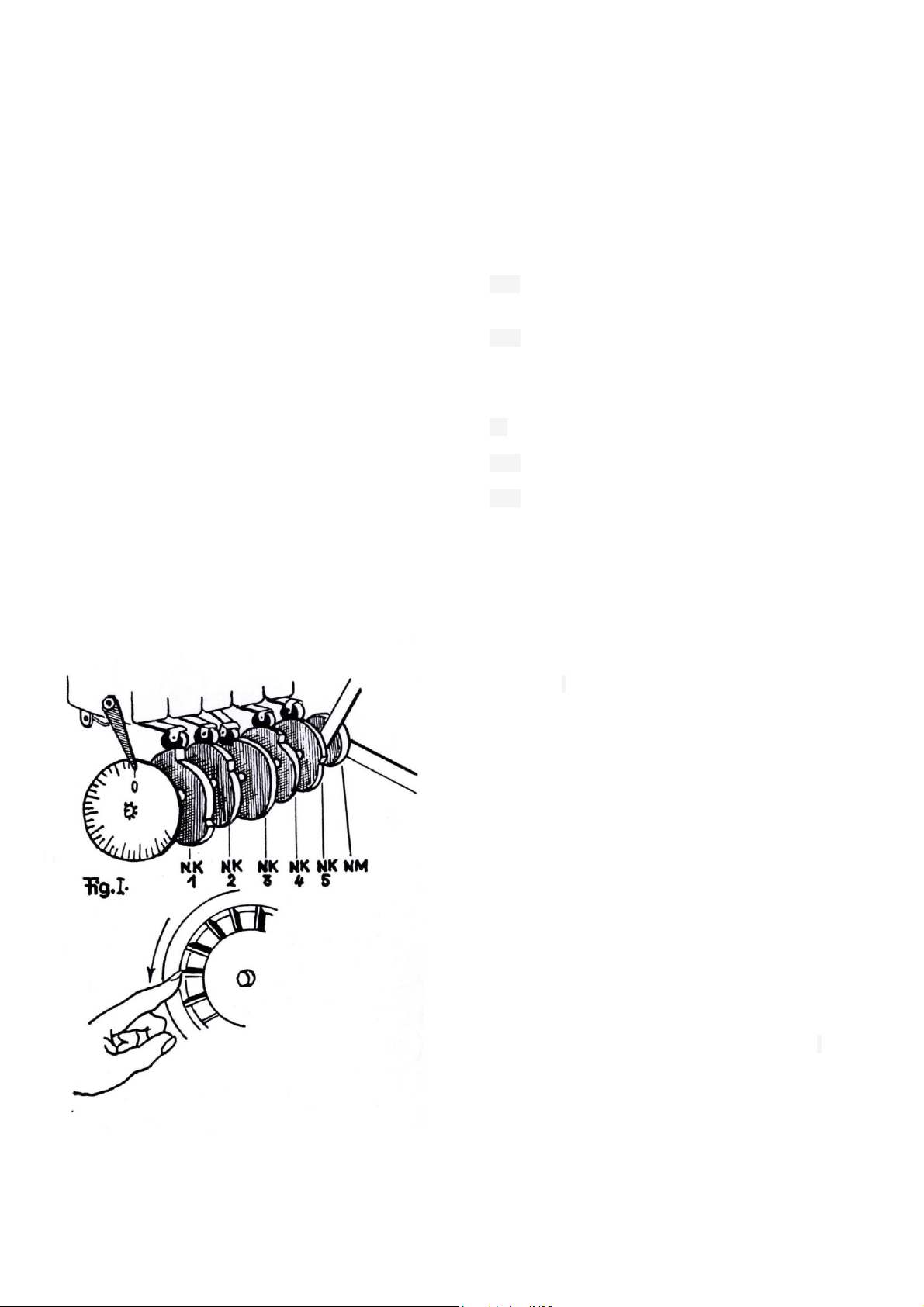

The desired change in the frequency of

failure for 50 Pfg. and DM 1. - is carried out

on the floor-facing terminal strip of the

command device. (See Fig 1)

The change provided can be carried out on

the two lower rows of solder pins, which are

labelled A - F in our diagrams

Example a)

Example b)

Example c)

Example d)

Equipping with LPs

Setting the command device

On the upper terminal block of the command

device (see fig I) lie solder pins connected in

pairs on the right and left. When viewed

horizontally, they represent tap number 7, 8, 9

and 10 of the DZ selector. This precaution

makes it possible to equip the machine with

either, 10, 20, 30 or 40 long boards.

8

If you would like to expand your vinyl record

equipment in this way, you only need to change the

bridge connections on the connection strip as

shown in the illustration.

As an example:

If the music machine is to be equipped with 10 LPs,

the bridges between d and h and qu and u must be

removed. Then qu is connected to the soldering lug

on the left. With an expansion to 20, 30 and 40 LPs,

the connections above can also be changed.

Description of the electrical function

When choosing a long-playing record

RELAY

I

LP

Coin insertion

If a coin insert of 3 times 10 Pfennigs is inserted before the choice of a long-playing

record, the electrical switching operations up to the second 10 Pfennig piece are the

same as those described under "coin insert normal record". In the order of the

switching sequence, the: I, II, J, and V relays have already been actuated.

If the MK 10 opens again after the second 10 Pfennig piece, the II relay drops out and

the stacking relays are prepared for receiving the third coin pulse. When the third coin

is inserted, the I relay picks up again and, via the IL1 and 1III and 1III2 contacts, brings

the LP relay to the suit. The LP relay maintains contact via its own LpII2 and connects

the outputs of the DZ selectors. At the same time, the connection to the lamp “pay

more”is interrupted via the LpIII1 contact. The selection of the record is possible.

Pay More appears

If you already select a long-playing record from an existing credit due to the previous

insertion of 50 Pfennigs or 1, - DM, the lamp "pay more" lights up. This process is

explained by the fact that the Lp relay (depending on the number of bridges on the

connecting strip for long-playing records, with the IpI1, IpI2, IpIII1 or IpIII2 contact)

interrupts the connection from the tap of the DZ selector to the dial of the mechanics.

The lamp "Pay More" is switched on via the dialer dzII and the IpII1 contact. If a 10

Pfennig piece is thrown, the Lp relay responds, the IpII1 contact interrupts "Pay More"

and, depending on the number of the selected plate, the IpI1, the IpI2, the IpIII1 or

IpIII2 contact connects the selector output with the mechanical dial. The desired record

is selected.

The error button

The error button returns the memory to the starting position in the event of a wrong

choice or an operating error, but without erasing the loan. by pressing the error button,

the L-relay speaks and lasts until the home run of the selector ends, S relay has

dropped out and the sII1 contact is opened. The LII2 contact holds the J, V, I and II

relays over the time the S relay is energized so that the credit is not lost.

Disc Nr. 160-269

Disc Nr. 170-279

Disc Nr. 180-289

Disc Nr. 190-299

9

Description of the electrical

functions when changing records

Record Lift

When the selection of the desired record

(raised selector pin) is complete, the magazine

motor, controlled via the MI2 contact, moves

the record magazine with the MSK contact

against the selector pin raised up.

At the moment of contact between the

insulated brass bracket (MSK contact) on the

record magazine and the selector pin, the

resulting earth connection (plus) switches on

the W relay, which holds itself via the wIII2

contact. At the same time, the wIII1 contact

causes the M relay to drop out.

By switching the wI1 contact to the wI2 contact,

the magazine motor is switched off and the

player motor is switched on. The brake

connected in line with the player motor also

applies. By releasing the brake, the lift spring

acts, which takes over the gear transmission to

transport the record into the play position.

The following electrical switching functions are

carried out by the cam contacts NK1 to NK5 on

the changeover gear during lifting.

1) By switching the NK1:

a) the magazine motor is interrupted again

and

b) prepared the return of the player engine

2) The NK2 closes and prepares the switching

on of the M relay for the later return.

3) By switching NK4, the centering magnet

picks up.

4) The NK5 closes and prepares to switch on

the reset magnet.

5) By switching back the NK4:

a) the centering magnet is switched off so

that the record can be pressed against the

turntable by the centering plate using spring

pressure.

b) The reset magnet is switched on.

6) The NK5 opens and brings the reset magnet

to waste.

7) The NK3 controls the muting of the amplifier

when the plate is changed, so that the

placement of the tonearm and the brushing of

the sapphire are not transferred. As a last

function, when a plate is placed on the NK3, a

relay in the amplifier is interrupted, which drops

out after a delay and switches on the anode

voltage.

Return the played record

The tonearm switch-off contact is located on

the back of the pickup. When the record is

played, i.e. when leaving the lead out groove,

the switch-off spring touches the TA contact

and causes the W relay to drop out due to the

resulting mass connection by short-circuiting it

via a resistor. The M relay receives voltage via

the wIII1 contact and picks up. At the same

time, the player motor is repositioned via the

wI1 contact, which in turn actuates the cams

NK1 to NK5 and the cams NM via the gearbox.

In that the returning lifter returns the records to

the record magazine, the switching sequence

of the cam contacts is in the reverse order to

when the records were placed. when the

player motor runs out, the NK1 switches over

and starts up via the mI2 contact cdn

magazine motor, and also moves the selector

motor via the mI1 contact. When the record

magazine rotates, the NK7 cam contact is

opened briefly, causing the M relay to drop out

(selector motor switched off).

After a further full turn, the shut-off cam of the

record magazine actuates the NK6, opens it

briefly, and also stops the magazine motor via

the deactivated relay.

If several records have been selected, the

same procedure as described will be repeated

after the return of the first record has ended.

The magazine motor moves the MSK contact

against the high-positioned selector pin, the W

relay picks up again, etc.

10

11

12

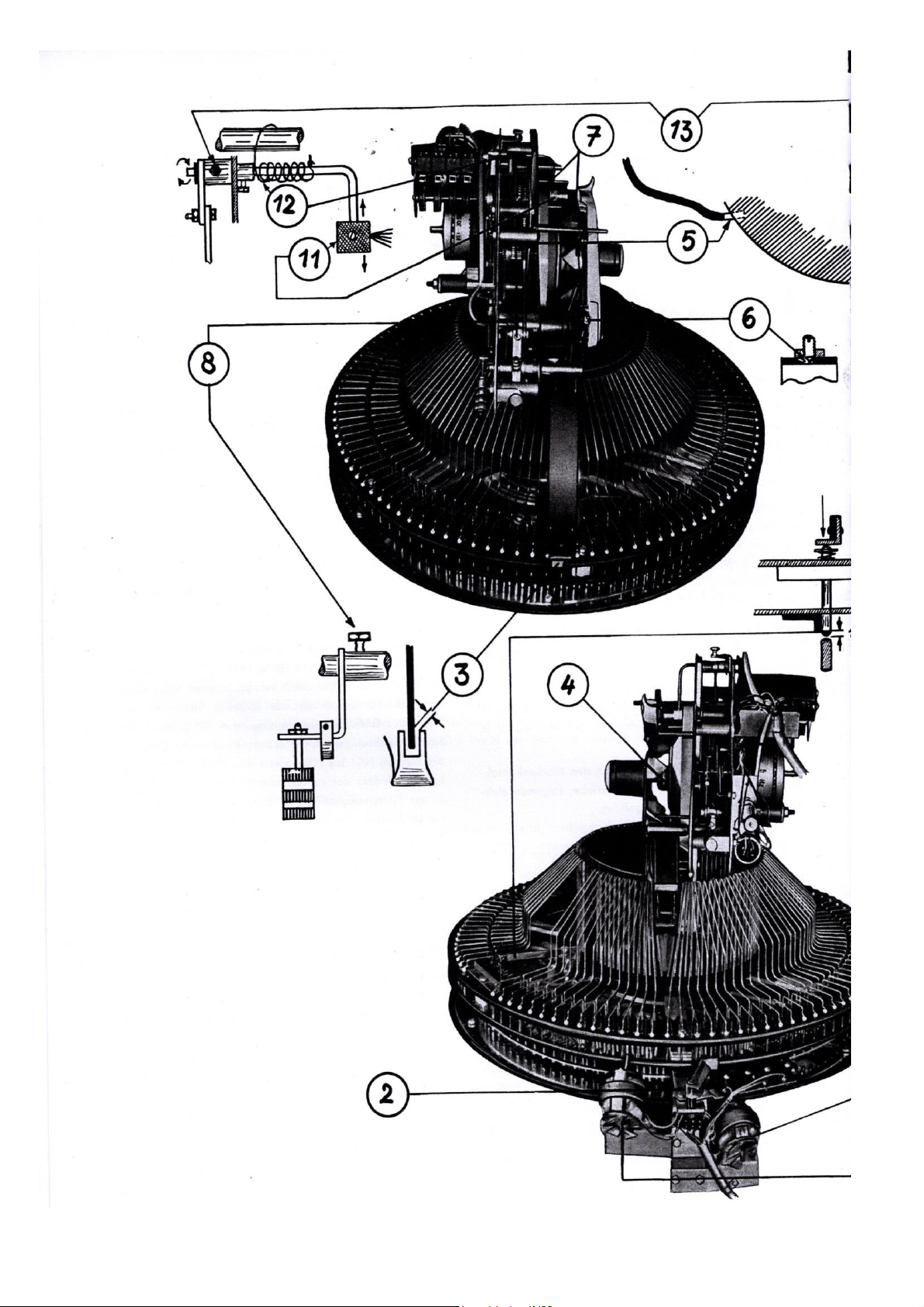

Adjustment regulation for the "telematik 200"

(The numbers of the individual positions refer to the

picture on page 10/11)

RAISING AND LOWERING THE RECORD

(Adjustments 1 - 5 are follow-up adjustments and must

be done in the specified order)

1. The record bracket:

the record brackets should stand vertically on the

record magazine while the front part of it should lie

horizontally to the magazine.

Adjustment: Align to the side or to the front with

adjusting pliers.

2. Setting the drum:

While the record magazine is hitting a selection

pin the record should be parallel to the chassis.

Adjustment: Adjust the anchor bracket of the

selection drum in the slot.

3. Lateral position of the lifters:

The turntable rotating with the record should be in

the middle the lift fork run. When entering the record

compartment should do not touch the lifting fork on the

side of the plate bracket.

adjustment: lift axis within the lift drive lever move

axially or bend the lifter accordingly

to adjust.

Note: To make this adjustment easier, too

adjustment no. 2 should be corrected

4. Press on the record:

When the plate is in the play position, the magnetic

core of the centering plate should have a lot of tolerance

on all sides, up and down.

Adjustment: Loosen the two fastening screws of the

heart disk and adjust the heart letter with the centering

magnet.

5. Centering the record:

In the play position, the distance between the edge of

the plate and the lifter or tipper should be 2-3 mm.

Adjustment: adjust the lift stop screw and the

eccentric tipper stop accordingly.

Note: This adjustment is for the front and back of

the make playing plate.

ADJUSTMENT OF THE SWITCHING CAMS

The control of important electrical switching sequences

when playing and changing the records is done by the

cam contacts NK1 - NK7 (microswitches) attached to the

rear of the playing chassis and to the side of the record

magazine. The mechanical cam for actuating the

tonearm and the sapphire brush, which is called NM in

our explanations, is also attached behind the switch NK5.

The switching functions of the respective cams are:

NK1 switching magazine - player motor

NK2 timer in conjunction with switches NK6 and NK7

(dial and record magazine run out)

NK3 mute (turn on and off the anode voltage of the

amplifier)

NK4 magnet for plate centering

NK5 reset magnet for selector pin

NM Mechanical control of the tonearm movement to the

record and back as well as actuation and the sapphire

brush.

Important NOTE!

The setting instructions below for the cam contacts NK1

to NK5 and for the cam NM are only valid for devices

with a manufacturing number exceeding 11500. In this

version, the tonearm control rail according to Fig. II is

changed at the same time.

In the previous series with the tonearm control rail

according to Fig. III, deviating from the specified

adjustment regulation, the NK4 has to switch to 48 at

rest, while at 25 the cam NM should move the tonearm

control rail so far that the inner one.

13

Cut out the same with the tip of the tonearm control cone

(see Fig IV)

A check of the correct switching torques of the individual

cam contacts and the prescribed triggering of the

tonearm control rail by the cam NM must be carried out

using the setting pointer and the dial.

For this purpose, let a record run in the playback

position and then interrupt the power supply to the

device. If, as in Fig. I, the player changer motor turns in

the direction of the arrow, the following switching torques

must result in the range of 10 –240:

At 10

NK3 work

NK5 rest

At 55

Tonearm control lever aligns with the camshaft and switching pin of the NM. See Fig V

At 68

NK4 rest

At 230

NK2 rest

At 240

NK1 rest

In addition, in this position the lifters should end with the outer edge of the record magazine.

At 250

End of lifting spout

A necessary adjustment of the cam contacts NK1 to

NK5 is done by adjusting and the shutter cams, the two

pressure screws of which must be tightened firmly

against the camshaft after the setting has been

completed.

Is the trigger point of the switch between "rest"

and "work" is not on the middle of the support surface

(see Fig. VI), the shifting tongue of the same must be

adjusted accordingly by bending.

Figure VII shows the rest position of the NK, while its

working position can be seen in Figure VIII.

14

TONE ARM ADJUSTMENTS

(Adjustments 6 - 13 are follow-up adjustments and must

be carried out in the order listed)

6. Tonearm tip bearing:

The tonearm must be slightly stored in the tip bearing

without any play on the side.

Adjustment: After loosening the lock nut, adjust a

bearing screw.

7. Sagging of the tonearm:

When the mechanics are in the playing position, the

tonearm should sag so that there is a 3-5 mm distance

between the record and the needle.

Adjustment: adjust the height adjustment screw of the

tonearm accordingly.

8. Point of attachment of the needle:

The needle should be placed 2 - 3.5 mm from the edge

of the plate.

Adjustment: Loosen the pressure screw of the balance

flange and change the angular position of the balance

weight flange to the tonearm accordingly.

Note: Make sure that the tonearm axis has enough axial

play when making this adjustment.

9.Tonarm-balance weight:

The tonearm should always have a small torque

upwards, just enough to move it back to its original

position when it is lifted off the plate.

Adjustment: shift balance weight accordingly.

Note: It is important to ensure that due to probable.

mechanical inhibitions, the balance weight is not being

adjusted too tight to satisfy this adjustment.

10 switch-off position of the tonearm:

The tonearm should switch off when the needle is 35

mm from the edge of the plate.

Adjustment: Swivel the switch-off contact accordingly.

11. Brush distance:

When the mechanism is at the rest position, the needle

should just pass the brush.

Adjustment:

a) Adjust the brush holder with adjusting pliers

accordingly.

b) Move the brush on the holder accordingly.

12. Brush reset force:

Adjustment: The torsion spring should be pretensioned

about five turns.

13. End position of the brush:

When the mechanism are at rest, the brush should be

pivoted about 3 mm past the needle.

Adjustment: Twist the brush holder within the operating

lever.

14. Contact pressure of the magazine motor:

The magazine motor should press so hard on the

rubbing edge of the magazine that it is driven safely. The

contact pressure must not be so strong that the motor

can no longer start when the magazine is locked.

Adjustment: Adjust the fastening screw of the pressure

leaf spring accordingly.

15. Selector magnet working position:

When the selection magnet is actuated, the selector

plunger should be raised about 6 - 7 mm above the

selector disc.

Adjustment: After loosening its fastening screw, adjust

the push lever in the hole.

16. Selector magnet rest position:

a) When in position, the tappet should rest about 0.5 mm

above the dial, so that the tappet can pivot without

touching the dial.

b) There should be a tolerance of approx. 5 mm

between the tappet and the push lever.

Adjustment:

a) Move the bearing bush of the selector plunger axially

after loosening the pressure screw.

b) After loosening its fastening screw, adjust the back

stop on the selector magnet accordingly.

17. Reset force and torque of the tappet:

After actuation, the selector plunger should safely return

to its initial position. If it is influenced laterally, it should

also swivel back safely.

Adjustment: Turn and move the adjusting ring of the

plunger spring on the selector plunger accordingly.

18. Contact pressure of the selector motor:

The selector motor should press so hard on the rim of

the dial that it is driven safely. The contact pressure

must not be so strong that the motor can no longer start

when the selector is locked.

Adjustment: Adjust the fixing screw of the pressure leaf

spring accordingly.

19. Selection contact loop:

The two sliding contacts should sag about 1 mm. The

contact pressure of the grinding wheel must be slightly

stronger than the contact pressure of the sliding contacts.

20. Contact disc:

The plunger should shoot up the selection pin cleanly

without touching the previous or subsequent selection

pin.

Adjustment: Move the fastening bolt of the sliding

contact in the slot accordingly.

21. Return magnet stroke:

When the reset magnet is actuated, the reset plunger

should bump up to about 1 mm below the magazine stop.

Adjustment: When the reset magnet is actuated, adjust

the push lever in its slot accordingly.

22. Return magnet rest position:

In the rest position, there should be a tolerance of

around 0.5 mm between the push lever and the return

push rod.

Adjustment: After loosening its fastening screw, adjust

the back stop of the reset magnet

15

Description of the mechanical functions when changing records

Centre

the upward movement of the lifter is limited

by the lifter stop screw which, in

conjunction with the setting of the eccentric

tipper stop, enables the centering of the

record. The centering hole of the record

should be slightly below the centering cone

of the centering plate so that the plate is

lifted off the lifting fork and the tipper when

it is mounted on the plate.

Clutch pinion and turntable drive

After the lifter is pivoted into the play

position, the further drive on the gear is

taken over by the tension spring which is

hooked onto the stop angle of the

gearwheel shown in FIG. 1.

The stop of the large gear is limited by the

stop pin B. The coupling sleeve C (FIG. 1)

is now screwed out of the engagement of

the large gearwheel like a screw by the

constantly acting friction of the felt strip D.

The player motor now has the task of

driving the turntable via the axis F and the

rubber intermediate wheel G (Fig. 2). The

drive surface of this friction wheel is inside

the platter.

The idler gear is pulled against the drive

shaft of the motor and the running edge of

the platter via the spring shown under J

(Fig. 2). If the player motor is reversed

after the record has been played, the

brake H (Fig. 2) mounted inside the

turntable prevents it from rotating in the

normal direction.

Returns

With the polarity reversal of the player motor and due to the brake loop D, the clutch pinion moves back into the

engagement of the large drive gear. the motor now acts via the gearwheel gear winds the lift pull chains onto the roller of

the large gearwheel and thereby returns the plate lifter to the starting position. Due to the return of the lifters, the played

record is placed in the plate magazine and the lifter tension spring is preloaded again. The magnetic brake, which has

now fallen off, prevents the spring-loaded mechanism from moving the plate lifter inwards again thanks to the brake

rubber placed on the jacket of the player's motor.

How the plate lifters work

The drive of the plate lifter,

which takes over the transport

of the record into the play

position, is taken over by the

tension spring connected to the

two lifter drive levers. In the

rest position of this spring is

tensioned on train. When the

plate magazine with the MSK

contact that rotates after the

selection touches the shifted

stylus, relays switch on the

player motor and apply the

magnetic brake. the axis of the

player motor moves the two

gearwheels from the

transmission via the clutch

sprocket C (see Fig. 1) and

allows the wound-up pull

chains A (see Fig. 1) of the

lifters to run off. At the same

time, the lifter tension spring

starts to operate and,

depending on the traction chain

that is running, pulls the lifter

inwards.

While one lifter now runs against

a plate bracket and thus locks

the plate magazine, the other

lifter lifts a plate out of the

magazine and pushes it upwards

on the tipper. If necessary, the

tipper is swivelled from the plate

to the corresponding

side .

16

Interference sources –Diagnosis

Before dialling

Lights up after inserting money

"Select" lamp not on.

Bulb broken or no contact.

Power supply fuse defective.

Coin contact does not work because it

is defective or jammed.

change

change

replace or readjust if necessary

"Select" lamp burns constantly

and you can play without money.

Coin hangs on the coin switch.

Coin switch always switched on

because it is jammed.

Remove

readjust or replace

The record lifter runs upwards

without a selection being made.

Ground connection of the MSK contact

(yellow connecting wire)

check with measuring instrument

Selector magnet attracts

continuously.

Defect at the condenser C4 in the

command device.

change

Reset magnet is attracted

Defective cam switch NK5.

Switch burnt due to missing spark

suppressor capacitor.

Reset button stuck on the cabinet is

stuck

Install spark suppressor if

necessary

change

The fuse of the power supply

blows continuously

The two sliding contacts under the

tipper bracket are connected (plus with

minus).

Centring solenoid or reset solenoid

defective.

readjust

change

Both record lifters swing against

the plate magazine and back.

The magnetic brake on the player

motor is too low.

Brake pad damaged or loose

readjust

change

After dialing

Both selection magnets fire at the

same time.

The contact fingers of the lower double

sliding contact have a connection.

Possibly. jumped out of the track

during transport.

readjust

Dial magnet No. 100 or No. 200

shoots without pushing up a dial

pin.

The locking spring of the switching pin

has broken off or slipped out of the

guide bush.

The plunger flag is therefore

transverse.

replace or readjust

The dial disc or record magazine

does not start

Broken rubber buffer to fasten the

selector or magazine motor.

Drive rubber on the dial or magazine

disc defective. Leaf spring, the motor

presses, too little tension.

change

readjust

The centred plate does not pick

up the record.

Adjustment 4 and 5 is not correct, lift

stop screw and tipper stop adjusted.

The centre hole of the record was not

cleaned of any burrs or varnish

residues before using -

Check adjustment no. 4 and 5

Clean the centre hole of the plate

Centering magnet does not

respond

Coil defective (fuse of the power pack

blows).

Cam contact NK 4 does not switch.

Readjust or replace

Selection pin does not raise

Contact disc dirty.

Sliding contact on one side no support

Clean and readjust with switch

cleaner spray

Tonearm jumps when it touches

the record.

The clutch pinion is too quickly

removed from the engagement of the

large gear due to the felt of the brake

rod, which is too tight.

Mechanical jamming in the gearbox,

for example, tooth engagement of the

clutch pinion too deep

relax the brake rod

Move the player engine sideways

accordingly

Tonearm sets down too early or

too late or switches off too early

or too late

Tonearm-balance-flange misadjusted.

Tonearm switch-off contact

misadjusted

readjust

readjust

17

When changing

The record returns to the wrong

compartment.

Two records clamp on to the

centering plate

When lowering, the plate remains on

the centering plate, the centre hole of

the plate is too tight.

scrape out

Tonearm switches off, record

does not go back with the lifter

Brake rod has too little tension, the

clutch sprocket is not deflected and

does not bring the lifters back via the

gear ratio.

tighten slightly

Lifts don’t move out of the record

magazine all the way back and

the selection disc runs

The clutch gear is not sufficiently firmly

gripped by the compression spring on

the clutch sleeve

Tension the spring or replace it

Sapphire is not cleaned from the

brush.

Thrust shackle pin of cam NM slipped,

torsion spring broken.

Mount

change

While playing

Sound fluctuates, even though

the record plays correctly centred.

Rubber idler gear oiled or stiff on

bearing axle. Running rim in the

turntable dirty or oiled. Greased axis of

the player motor, tension spring for

friction wheel too little tension

Remove

clean with tetra

change

tighten

Strong humming while playing

Transport security of the mechanism

not loose.

Bass adjustment too strong in relation

to the volume.

Remove or adjust

Played disc runs backwards.

Return stop in turntable defective

replace

Disc does not switch off.

Tonearm switch-off contact dirty

clean with tetra

Dialler is not deleted.

Reset magnet coil defective.

Cam contact NK 5 does not work.

Switch pin worn

change

adjust if necessary

lightly grease

General electrical switching problems

We recommend a routine check in the following order:

1. Check the defective switching element, such as the motor or solenoid, for mechanical jamming.

2. Check the faulty switching element for electrical interruption or short to ground.

3. Check the relevant lines, especially the clamp connections, sliding contacts and plug connections

for loose contacts, wire breaks and short to ground.

4. Using the description of the "electrical functions" when selecting or changing, check whether the

designated relays pick up in the corresponding changeover position.

5. Check whether the normally open contacts of the relays close properly and sufficiently interrupt the

normally closed contacts.

6. Check whether the working contacts of the relays that have not been energized interrupt

sufficiently and the rest contacts of the relays close properly.

18

Individual parts of the mechanics "telematic

200"

1 KST 11 crystal system

2 Screw M2 x 12 DIN 85A

3 Micro sapphire SM11

- Diamond needle for KST 11 crystal system

4 Contact spring

5 Contact sheet

6 Compensation lever

7 Threaded rod M4 x 60

8 Counterbalance

9 Sliding plate

10 Tension spring (valid until serial number 11 499)

11 Guide bolts

12 Coil cover

13 M4 x 55 threaded rod

14 S.K. Screw M4 x 20 Din 933

15 Contact holder cpl. with contact finger

16 Tonearm

17 Tonearm rail (valid up to serial number 11 499)

- Tonearm rail (valid up to serial number 11 500)

18 U-washer 6

19 Coil cap

20 Collar with screw

21 U-washer 4

22 D socket

23 Screw M3 x 15 DIN 85 A

24 Angle

25 Tonearm bearing

26 Screw M4 x 12 DIN 85 A

27 Screw M3 x 3 DIN 86

28 Brake

29 S.K. Screw M3 x 8 DIN 933

30 Nut M4 DIN 934

31 Toothed washer F.Z.A. 4 DIN 6797

32 Holding Brackets

33 Tension spring

34 Tonearm carrier

35 Spin 1 x 5 DIN 94

36 M 3 x 10 DIN 85 A screw

37 Tonearm centering screw

38 Tonearm cones (valid up to serial number 11 499)

- The tonearm cone 4 - 17 is omitted for devices

from serial number 11 500

39 Setscrew M2 x 4

40 Threaded tube (valid up to serial number 11 499)

- Threaded tube (valid from serial number 11 500)

41 Tension spring

42 Tonearm holder

43 Screw M3 x 6 DIN 85 A

44 Plate guide with lateral Hole for the cable

passage d. centering magnets

45 D sleeve

46 Core sleeve

47 T 200 centering coil

48 Axis for turntables

49 Guide sleeves for lower switching pin

50 Compression spring (W magnet No. 100)

-Compression spring (W magnet Nr 200)

51 Stop bolt

52 Pestle flag

53 Split pin 1 x 8 DIN 94

54 U disc 3

55 Compression spring

56 Upper switching pin

57 Lower switching pin

58 Shift lever assy.

59 Coil for reset magnet 60 Ohm

60 Coil for optional magnet 90 Ohm

61 Conti buffer 21 239

62 Mega buffers

63 Threaded tube

64 M 3 x 4 DIN 85 A screw

65 Tonearm braided flex

66 Rubber grommet

67 Felt ring

68 Coil spring

69 Phillips screw 4.2 x 13

70 Rubber grommet

71 Coil sheath cpl

72 Cover plate

73 Seeger ring 6 x 0.7 DIN 471

74 Countersunk screw M3 x 5 DIN 63

75 Turntable disc

76 Mother M4

77 Tooth lock washer F.Z.A. 4 DIN 6797

78 Washer 4

79 D - sleeve

80 Spring hooks

81 Contact rotor cpl

-Contact spring

82 Washer 25 x 6 x 1

83 Intermediate piece

84 S.K. M4 x 40 screw

85 + 87 brush holder cpl. with brush

-Brush

86 Strut

88 Rubber ring

89 Turntables

90 Front cover plate

91 Bracket compl.

92 S.K. Screw M3 x 8

93 Brush rod

94 Collar with screw

95 S - dowel pin 1 8 DIN 1481

96 Torsion spring

97 Tension spring

98 Pressure piece cpl. (valid until serial number 11

499)

- Push pin (valid from serial number 11 500)

99 Self-tapping screw 4 x 6.5 DIN 7975

100 Plate centering

101 Disc

102 Seeger ring 6 x 0.7 DIN 471

103 Plate guide (metal coating)

19

104 Coil core

105 Upper plate holder segment

(Specify number range)

106 Felt disc

107 Seeger ring 4.5

108 Collar

109 Intermediate wheel cpl.

110 Collar

111 Setscrew M3 x 5

112 Tension spring

113 Split pin 1 x 15 DIN 94

114 Locking lever

115 Bearing bolts

116 U disk 16 x 5.2 x 1

117 Washer 5

118 Nut M5 DIN 934

119 Torsion spring

120 Tooth washers F.Z.A. 5 DIN 6797

121 Conti buffer 20 292 FJ 95

122 T 200 magazine motor (shaft offset at the front)

122a T 200 selector motor (cylindrical shaft)

123 Mega buffer 781 002

124 Leaf spring

125 Clamp

126 Quenching capacitor 2 x 0.5 MF

127 Bracket for wiring harness

128 Brushes

129 Grub screw M3 x 5

130 Knurled screw M3 x 5 DIN 464

131 Angle bracket

132 Chain holder

133 Tension spring

134 D sleeve

135 Pull chain

136 Lifter (left) cpl.

137 Bearing bush

138 S.K. Screw M5 x 50 DIN 931

139 Circlip D8 (seeger)

140 Gear plate

141 Gear

142 Condenser CO - MP 35 - 4.5 C - 220 V.

(BOSCH)

143 Angles

144 Sliding resistance 1000 ohms 12 watts

145 Holders

146 M4 x 10 DIN 85 A screw

147 Microswitch 925 R

148 Tippers

149 Small spacer sleeve

150 Tipper axle

151 Cover plate

152 Microswitch 925 R

153 Threaded bolts M 3.5

154 U washer 3.7 DIN 433

155 Nut M 3.5 DIN 934

156 Adjusting washer

157 Tooth lock washer F.Z A. 3.7 DIN 6797

158 Cams

159 Hands

160 Tension spring

161 Gear w. chain roller

162 Gear plate

163 Setscrew M4 x 10 DIN 553

164 Control disc

165 Square screw

166 Cams

167 Papal motor without clutch

168 Adjusting screw

169 Pull rod

170 Brake ring

171 Clutch with pinion

172 Coil for magnetic brake 5 - 55

173 Turnbuckle nut

174 Lever (valid for serial number 11 499)

174a Lever (valid for serial number 11 500)

175 Grub screw M6 x 15 DIN 913

176 Magnetic brake

177 S.K. Screw M4 x 20 DIN 933

178 Tension spring

179 Felt

180 Cap for lift

181 Lifter (right) cpl.

182 Screw M3 x 6 DIN 85 A

183 Mounting bracket

184 Insulating washer 16 x 1

185 Brake rod cpl.

186 U disc 1 x 6 x 20

187 Threaded rod M4 x 100

188 Mother M4

189 Eccentrics

190 2-pole push button switch

191 Push button

192 Brake rod

193 Large spacer sleeve

194 Toggle switch (Marquard) No. 100 NT

195 Plate baffle

196 Plate bracket

197 Holding tube

198 Pearl

199 Drive rubber f. Record magazine u. dial

20

This manual suits for next models

3

Table of contents

Popular Jukebox manuals by other brands

Philips

Philips HDD6330 GoGear quick start guide

Grace Digital

Grace Digital Victoria Jukebox GDI-JBP100 user guide

Crosley

Crosley CR11 instruction manual

Wurlitzer

Wurlitzer One More Time CD operating instructions

Philips

Philips HDD120 Specifications

Innovative Technology

Innovative Technology VJB-125 instruction manual