1.1 KOS1401 LOOP POWERED TRIP

INPUT

Type Two wire 4-20mA, 50mA Max.

Protection Reverse connection protected.

Loop Drop 5V Max.

OUTPUT

Alarm HIGH or LOW level switch selected, side entry.

Contact Single Relay Changeover with NO/NC contacts available.

Rating Resistive Load 2ª@250V AC/125V DC

Max. Power 150W (Inductive Loads).

Indication Alarm LED on module front face

Setpoint 0-100% multi turn potentiometer, access on module front

face(Repeatibility ±0.2%)

Hysteresis 0.1-5% Single turn trim pot on module front face

Delay 0.5 second fixed delay

Failuremode On loss of signal: HIGH level No alarm condition

LOW level Alarm condition

(i.e. Alarm operates as if signalhas fallen to –25% or 0mA)

Min.Current 3.5mA

1.2 GENERAL SPECIFICATIONS

Isolation 3000V AC rms between contacts and inputs

1000V AC rms between contacts

Ambient 0-50ºC ; 10-95% RH non condensing

Connection Captiveclampscrews

Cable Size 4mm2solid/2.5mm2 stranded

Case Material Grey Poliamide

Case Flammability To UL94-V0 VDE 0304 pt3 Level IIIA

Dimensions 60 x 60 x 21 (67.5mm above rail)

Mounting Snap on top hat (DIN EN 50022-35)

Max Vibration 12G 10 to 55 Hz at double amplitude 2mm

Shock Res 12G

Compliant with EN50081-1, EN50082-1

Weight 100grams

2.0 INSTALLATION

WARNING - Hazardous voltages may be present on the terminals – the

equipment must be installed by suitability qualified personnel and

mounted in an enclosure providing protection to at least IP20.

WARNING –If

not installed and used in accordance with these

instructions, protection against hazards may be impaired.

(IMPORTANT NOTE it may be preferred to set the user adjustment on

the bench prior to installation).

2.1 MECHANICAL

This trip must be housed within a suitable enclosure that will provide

protection from the external environment, to ensure that the stated

temperature and humidity operating ranges are mantained. As KOS1401

contains a high quality relay, care must be taken to ensure the trip is not

subjected to strong shock or vibration, as this may result in momentary

opening of the relay contacts. The KOS1401 must not be located near a

strong magnetic field, such as a transformer, solenoid or electric motor.

The KOS1401 case is designed to snap fit onto a standard ”TOP HAT”

DIN rail. To remove from DIN rail, apply pressure at the bottom face of the

back upwards towards the rail to release the spring clip and tip away from

the top. The trip may be mounted in any orientation and stacked side by

side along the rail.

2.2 ELECTRICAL

Connections to the trip are made via screw terminals, with wire protector

plates provided inside each terminal. To maintain CE compliance twisted

pair (screened) cables are recommended for signal connections. It is also

good practice to ensure that all 4-20mA loops are grounded at a single

point. Before installation ensure the 4-20mA loop has enough voltage

available to drive the trip. Refer to the above specification for the loop

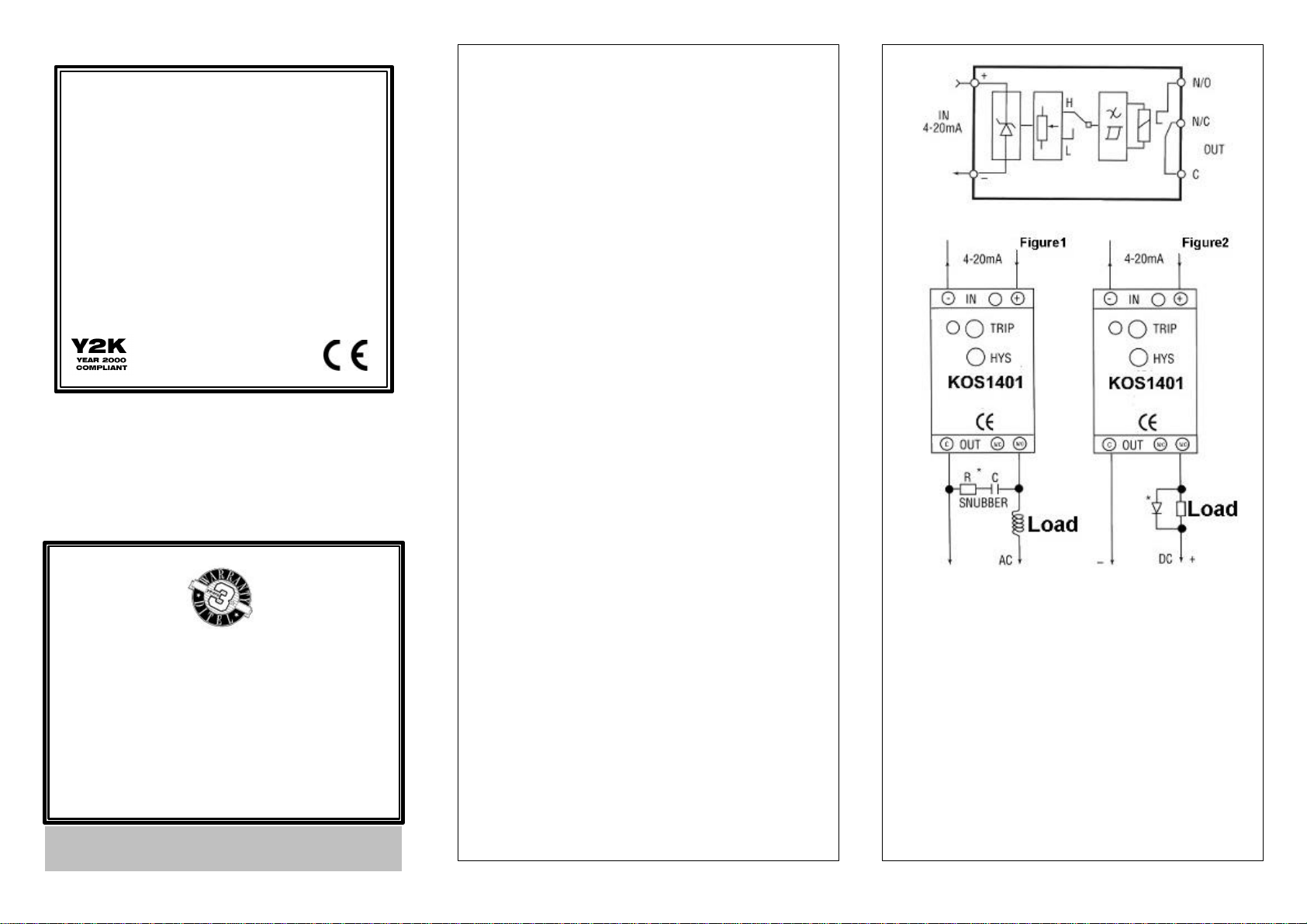

voltage drop. The change over contacts provided by the KOS1401 are

capable of switching 250V AC 125V DC @ 2 A resistive load, 150 Watts

inductive load. Internal Varistors are connected across the contacts to

protect against over voltage. It is advised that a external RC snubber

network is used when switching inductive AC loads (see fig 1).When

switching DC inductive loads, a diode connected in parallel with the

inductor must be used to protect the contact from the energy stored in the

inductor (see fig 2).

KOS1401

LOOP POWERED

TRIP AMPLIFIER

1 RELAY

The instruments are warranted against defective materials and

workmanship for a period of three years from date of delivery.

If a product appears to have a defect or fails during the normal use

within the warranty period, please contact the distributor from which

you purchased the product.

This warranty does not apply to defects resulting from action of the

buyer such as mishandling or improper interfacing.

The liability under this warranty shall extend only to the repair of the

instrument. No responsability is assumed by the manufacturer for

any damage which may result from its use.